Содержание

- 2. Brief Introduction Application of High Quality Special Steel Process and Equipments Technical Research 1

- 3. 1. Brief Introduction 2 The company is established in April, 2004 in Jiangyou, Sichuan with the

- 4. 3 Brief Introduction

- 5. Brief Introduction National High-Tec. Enterprise Gas Turbine Enterprise Alliance of Sichuan Province in 2014 Research Base

- 6. 5 Vocation Health & Safety Management System: GB/T 28001-2011(OHSAS 18001:2007) Environmental Management System: GB/T 24001-2004(idt ISO

- 7. 2. Application of High Quality Special Steel 6

- 8. Application Blades, strengthening rings applied for supercritical and ultra-supercritical units and nuclear power steam turbines,forgings for

- 9. Main products and application: Thermal power Steam turbines Nuclear power Gas turbines Blades,bolts, stiffening rings for

- 10. Product Photos 9 Application

- 11. Product Photos 10 Application

- 12. Product Photos 11 Application

- 13. Product Photos 12 Application

- 14. Packing Photos 13 Application

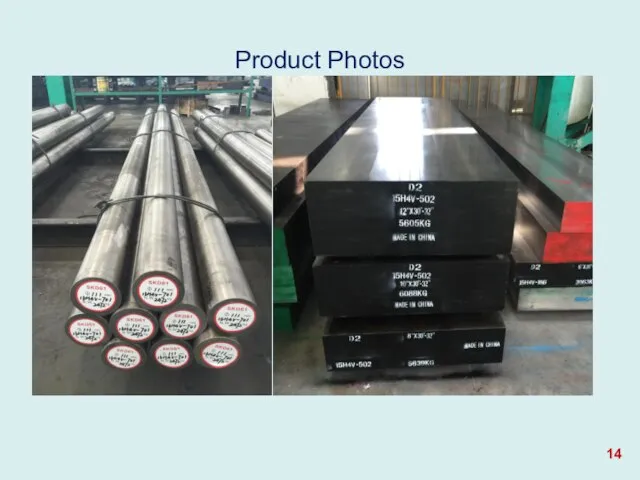

- 15. Product Photos 14

- 16. Product Photos 15 Application

- 17. Product Photos 16 Application

- 18. Product Photos 17 Application

- 19. Product Photos 18 Application

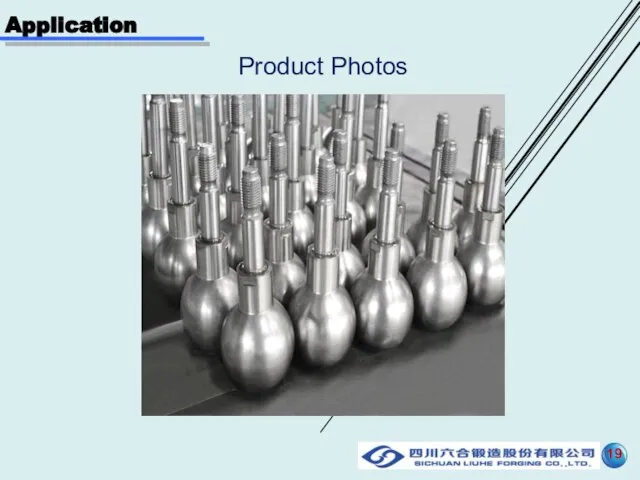

- 20. Product Photos 19 Application

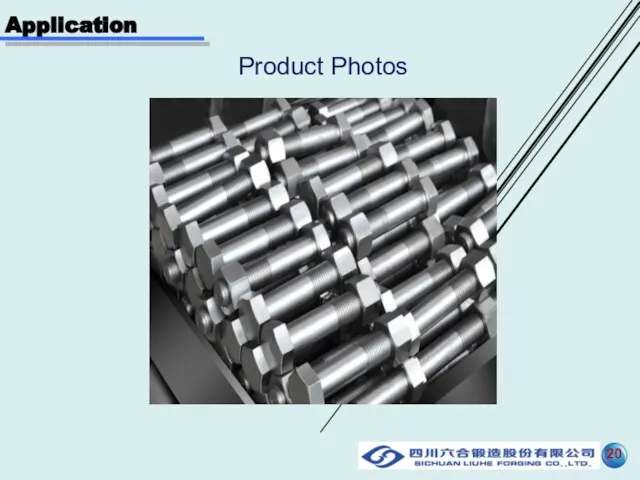

- 21. Product Photos 20 Application

- 22. Application Finished Blades & Machined Parts 21

- 23. Product Photos 22 Application

- 24. Product Photos 23 Application

- 25. Packing Photos 24 Application

- 26. Tangential supporting forgings Middle and small forgings: Small rotors, stiffening rings, fastening rings, tangential supporting plates,

- 27. 3. Process and Equipments 26

- 28. Process and Equipments Typical process chart 27

- 29. Process and Equipments Since 2016, the company began to upgrade the present equipments for the aviation,

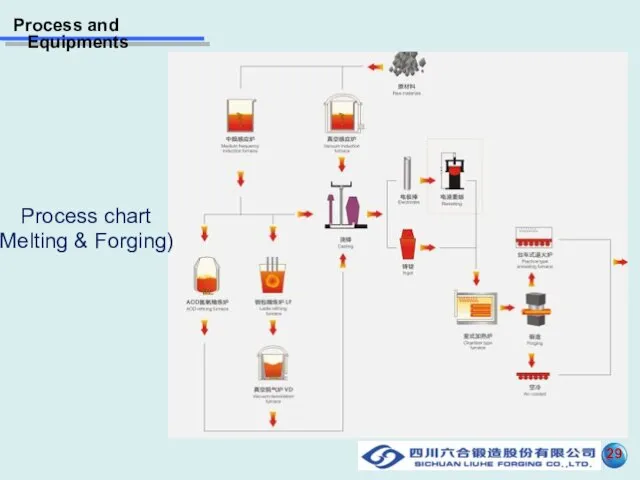

- 30. Process and Equipments 29

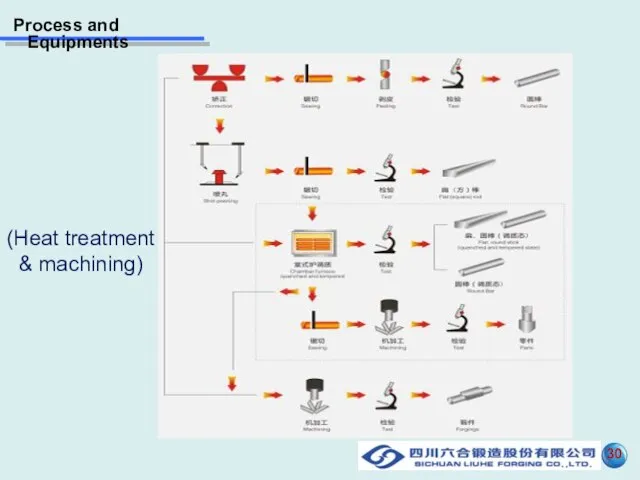

- 31. (Heat treatment & machining) Process and Equipments 30

- 32. Process and Equipments 31

- 33. Process and Equipments Newly installed 6MT VIM 32 Under installation After instalation

- 34. Process and Equipments Secondary remelting Equipments 33 Ordinary ESR furnaces: 5MT Inert gas ESR: 6MT 12MT

- 35. Process and Equipments 2000MT FORGING PRESS 34

- 36. Process and Equipments 6000MT forging press 35

- 37. Process and Equipments Flexible rolling mill(induction heated) 36

- 38. Process and Equipments Heat treatment furnaces 37

- 39. Test Equipements 1 38 Process and Equipments

- 40. Test Equipements 2 39 Process and Equipments

- 41. Process and Equipments Products and size range 40 Delivery condition: Hot working, Annealed, Quenched and tempered;

- 42. Process and Equipments 41 Capability: 1) Melting: 60,000MT (one cycle melting); 30,000MT (ESR) 2) Machining: 50,000MT

- 43. 4. Technical Development 42

- 44. Participated in the drafting and revision of national standards: Second revision unit of ‘Steam Blade Materials’

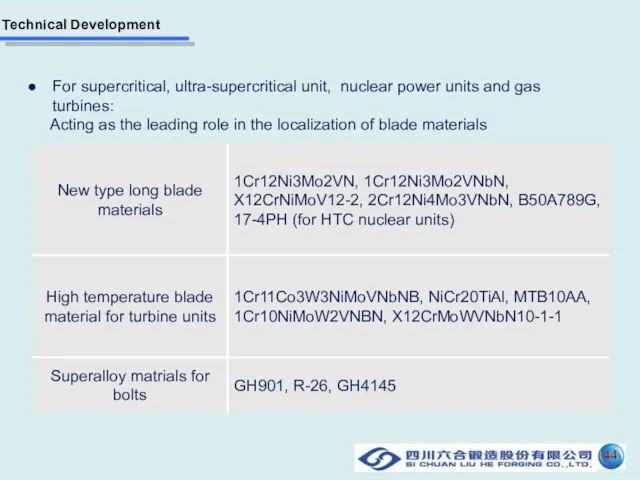

- 45. For supercritical, ultra-supercritical unit, nuclear power units and gas turbines: Acting as the leading role in

- 46. Technical Development 45

- 47. Austenitic stainless steel with higher alloy from ordinary grades to duplex stainless steel Tool steel: Tool

- 48. Superalloy, corrosion-resistant alloy and precision alloy: 47 Technical Development

- 49. Technical Development 48 Orientation of key technical development in the next 5 years

- 51. Скачать презентацию

Trailer Assist

Trailer Assist Презентация Microsoft PowerPoint

Презентация Microsoft PowerPoint О чем говорят девушки?!

О чем говорят девушки?! Православие. Православная Церковь

Православие. Православная Церковь 20180425_psiholog

20180425_psiholog Металлургический комплекс. Чёрная металлургия

Металлургический комплекс. Чёрная металлургия Графический диктант

Графический диктант Учет и анализ имущества в условиях ООО ТМС-Буровой Сервис

Учет и анализ имущества в условиях ООО ТМС-Буровой Сервис 20121217_deti_i_roditeli

20121217_deti_i_roditeli УралВагонЗавод

УралВагонЗавод F-F4

F-F4 Презентация Microsoft PowerPoint (2) (1)

Презентация Microsoft PowerPoint (2) (1) Ход реализации плана организационных мероприятий по созданию области Ұлытау

Ход реализации плана организационных мероприятий по созданию области Ұлытау Фотоальбом. Осень

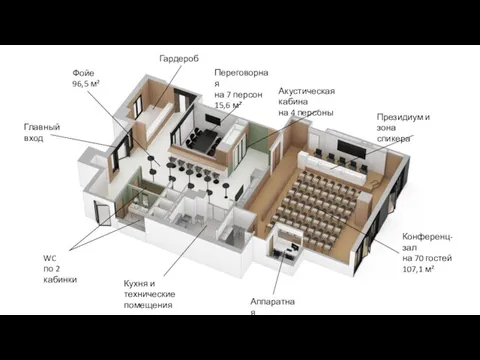

Фотоальбом. Осень прихожая ,обе детские, спальня

прихожая ,обе детские, спальня Научно-исследовательская и проектная деятельность. Энергетика

Научно-исследовательская и проектная деятельность. Энергетика LSP: Liskov Substitution Principle

LSP: Liskov Substitution Principle Организация стока поверхностных вод (Тема 3)

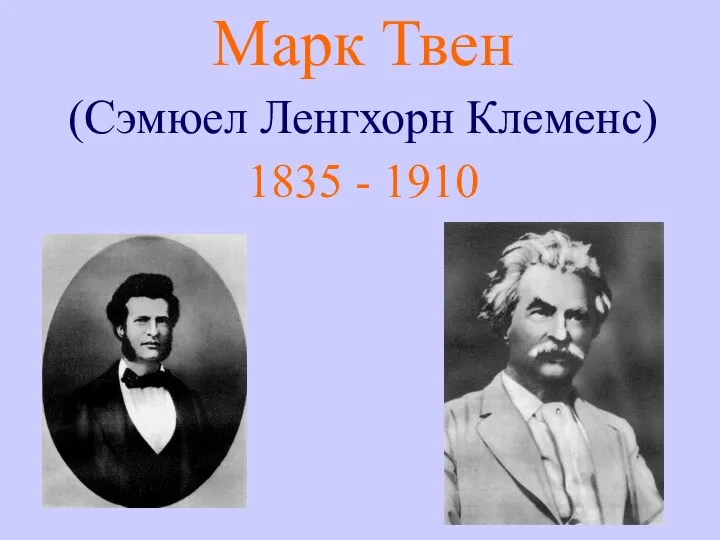

Организация стока поверхностных вод (Тема 3) Марк Твен (Сэмюел Ленгхорн Клеменс) 1835 - 1910

Марк Твен (Сэмюел Ленгхорн Клеменс) 1835 - 1910 Фотомарафон В объективе!

Фотомарафон В объективе! Тепловые насосы

Тепловые насосы Команда Яблочко в карамели

Команда Яблочко в карамели proekt_po_tekhnologii Cамочкова

proekt_po_tekhnologii Cамочкова Школьный робот уборщик

Школьный робот уборщик Теплые и холодные цвета

Теплые и холодные цвета Умники и умницы 2 класс

Умники и умницы 2 класс Стратегия развития линии выходной – лавна

Стратегия развития линии выходной – лавна Группа Светотехника. Отдел категорийного менеджмента

Группа Светотехника. Отдел категорийного менеджмента