Содержание

- 2. Outline Motivation Problems with characterization of thin films Experimental approach Results X-ray diffraction Raman Spectroscopy Transmission

- 3. Motivation – Phase Equilibrium CZTS is a line compound between Cu2SnS3 and ZnS Theoretically even a

- 4. Motivation – Crystal Structure Crystal structures of secondary phases similar to CZTS All primary peaks overlap

- 5. Experimental Approach Substrate Cu Zn Sn Introduce H2S into chamber during sputter deposition Sulfur is incorporated

- 6. Characterization - XRD Varying Zn/(Cu+Sn) Ratio Zn/(Cu+Sn) ratio is varied while holding Cu/Sn ratio constant Impossible

- 7. Characterization - XRD Varying Cu/(Zn+Sn) Ratio Cu/(Zn+Sn) ratio is varied while holding Zn/Sn ratio constant Need

- 8. Characterization – Raman Varying Zn/(Cu+Sn) Ratio Raman spectra show only minor changes even though composition is

- 9. Device Fabrication Glass Substrate 3000 µm Molybdenum Layer 1 µm 1.75 µm CdS (n-type) 55 nm

- 10. Device Characterization I-V Measurement EQE Measurement First CZTS devices grown by a reactive sputtering process Efficiency

- 11. Characterization - TEM 500nm Detrimental secondary phase interspersed in CZTS matrix Stacking faults in the secondary

- 12. Characterization - Auger Raster beam over sputtered surface of sample and scan for Cu, Zn, Sn

- 13. Characterization - CdZnS Cd penetration into ZnS lowers the cubic-hexagonal transition temperature Stacking faults in TEM

- 14. Characterization - Auger Sn Cd Overlay Sn and Cd signal Cd ion exchanges with Zn during

- 15. Summary CZTS thin films were grown using Reactive Sputtering Films were characterized using X-ray Diffraction and

- 16. Acknowledgements US Department of Energy, Office of Basic Energy Sciences as part of an Energy Frontier

- 18. Скачать презентацию

Годівля овець

Годівля овець National anthem of Іndia

National anthem of Іndia Богословское обоснование трезвенного движения

Богословское обоснование трезвенного движения фразовый глагол make Save the Earth

фразовый глагол make Save the Earth Пространственные концепции

Пространственные концепции Салон красоты Экспресс-макияж

Салон красоты Экспресс-макияж Исследование образцов стали ВКС-10

Исследование образцов стали ВКС-10 Презентация по правосознанию

Презентация по правосознанию Проект: Профессии

Проект: Профессии Машиноведение. История создания швейных машин. Виды приводов

Машиноведение. История создания швейных машин. Виды приводов Регламент формирования сводных годовых и месячных графиков ремонтов устройств РЗА-объектов

Регламент формирования сводных годовых и месячных графиков ремонтов устройств РЗА-объектов Технология обойных работ

Технология обойных работ Педагогика. Психология

Педагогика. Психология 8_задание_Никольская

8_задание_Никольская 20120122_smuta_7_klass

20120122_smuta_7_klass Электроизмерительные приборы. Часть 1.1

Электроизмерительные приборы. Часть 1.1 Технология изготовления валов

Технология изготовления валов презентация по деятельности психологтческой службы 2022-2023

презентация по деятельности психологтческой службы 2022-2023 Лепка из глины Вазы - 3 вида

Лепка из глины Вазы - 3 вида Самоменеджмент_л

Самоменеджмент_л Агентство поздравлений

Агентство поздравлений malenkie_tragedii

malenkie_tragedii Центр гигиены и эпидемиологии по железнодорожному транспорту

Центр гигиены и эпидемиологии по железнодорожному транспорту Корзины

Корзины С Днём Энергетика!!!

С Днём Энергетика!!! По страницам любимых сказок

По страницам любимых сказок Здоровье

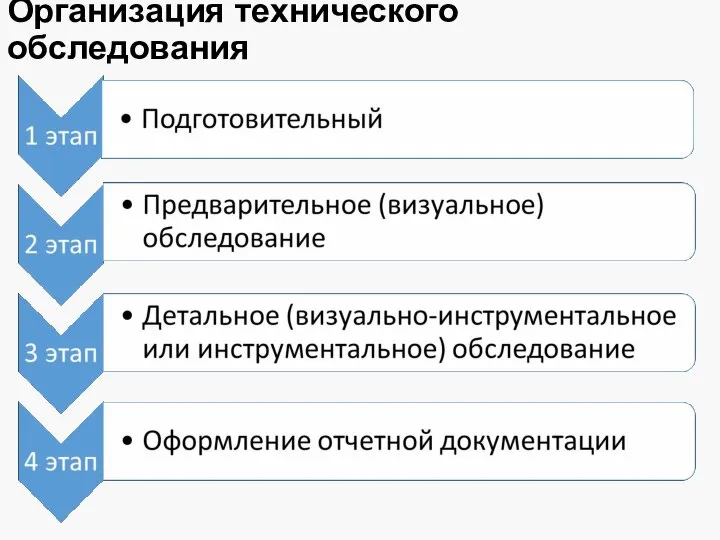

Здоровье Организация технического обследования

Организация технического обследования