Содержание

- 2. Contents 1. PRECAUTIONS (SAFETY WARNINGS).............3 2. PRODUCT SPECIFICATIONS ...................7 3. DISASSEMBLY & REASSEMBLY.................14 4. TROUBLE SHOOTING........................

- 3. 1. PRECAUTIONS (SAFETY WARNINGS) - Unplug the power supply when repairing/replacing electronic control system. Beware of

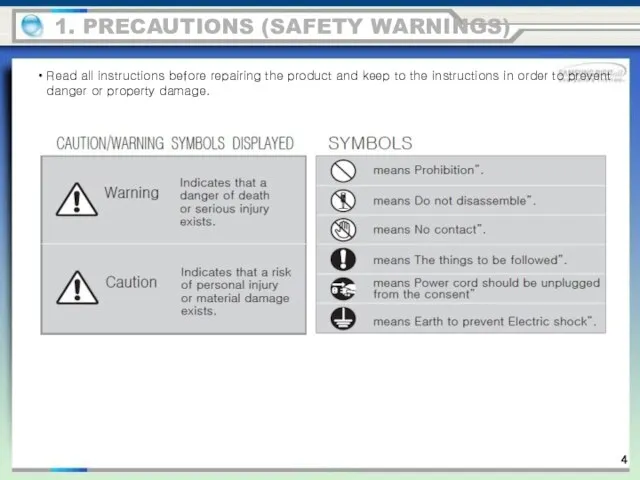

- 4. Read all instructions before repairing the product and keep to the instructions in order to prevent

- 5. 1. PRECAUTIONS (SAFETY WARNINGS)

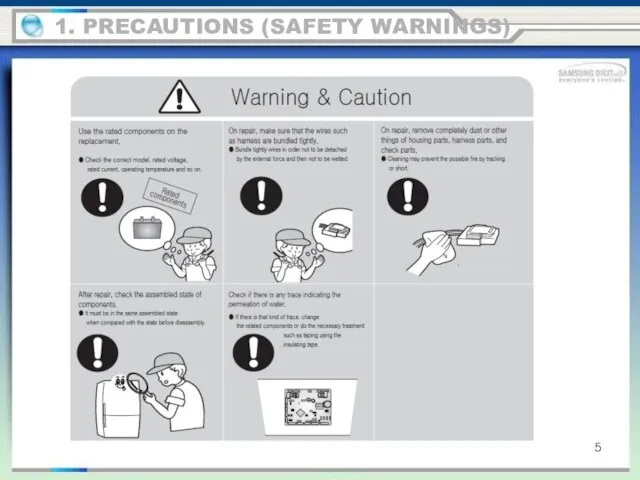

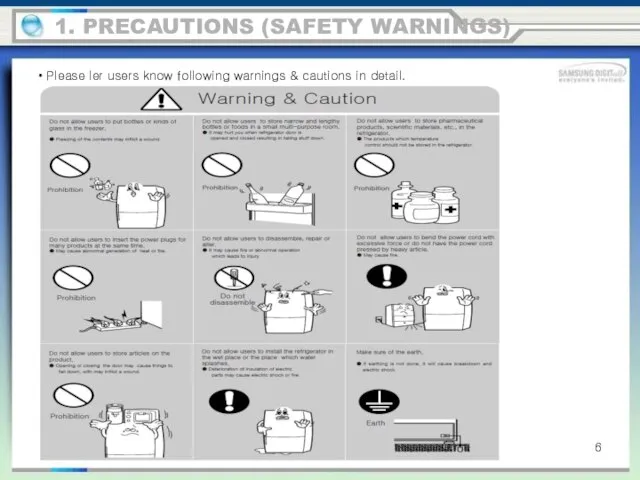

- 6. Please ler users know following warnings & cautions in detail. 1. PRECAUTIONS (SAFETY WARNINGS)

- 7. product feature 2. PRODUCT SPECIFICATIONS NO FROST INVERTER COMP INTERNAL LED DISPLAY MULTI FLOW

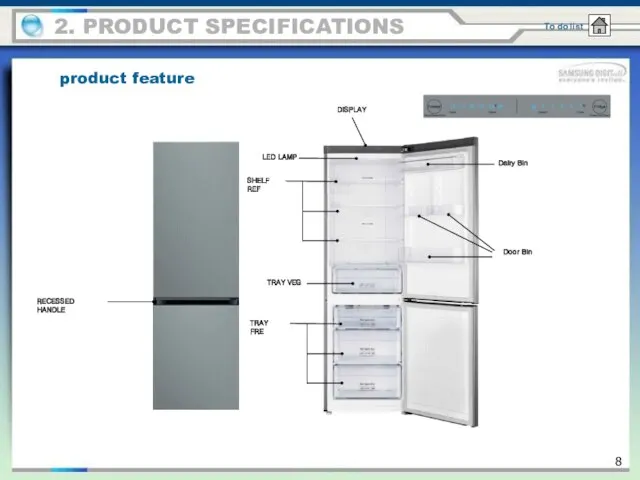

- 8. DISPLAY SHELF REF Dairy Bin Door Bin TRAY VEG TRAY FRE LED LAMP RECESSED HANDLE product

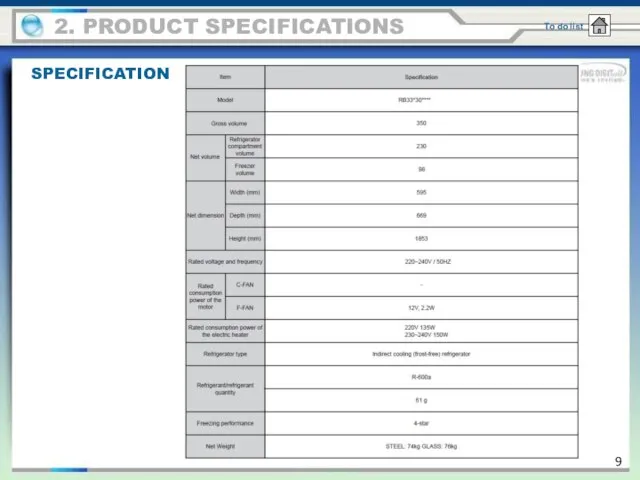

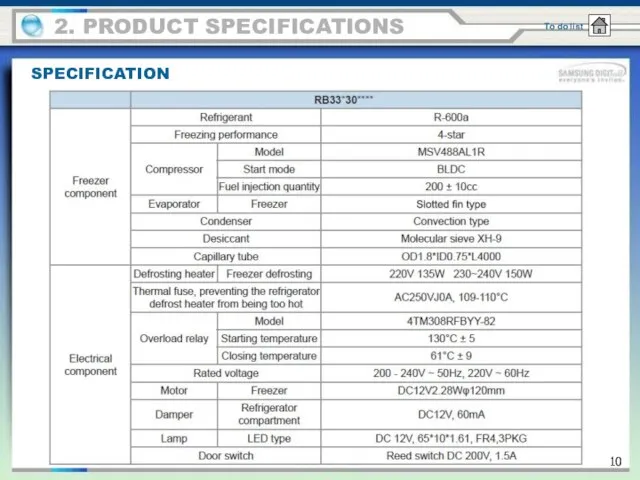

- 9. 2. PRODUCT SPECIFICATIONS SPECIFICATION

- 10. 2. PRODUCT SPECIFICATIONS SPECIFICATION

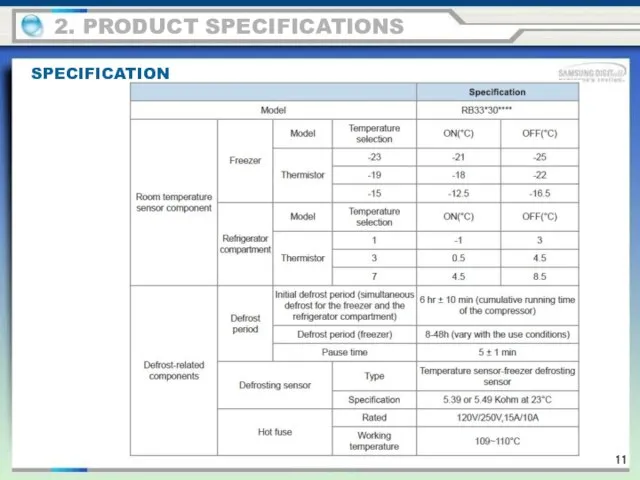

- 11. 2. PRODUCT SPECIFICATIONS SPECIFICATION

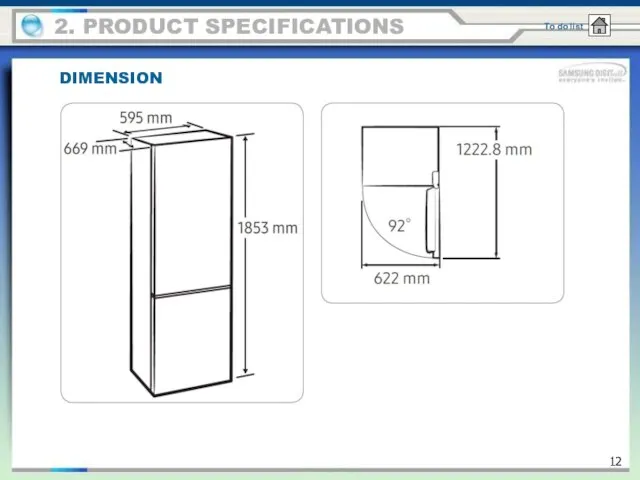

- 12. DIMENSION 2. PRODUCT SPECIFICATIONS

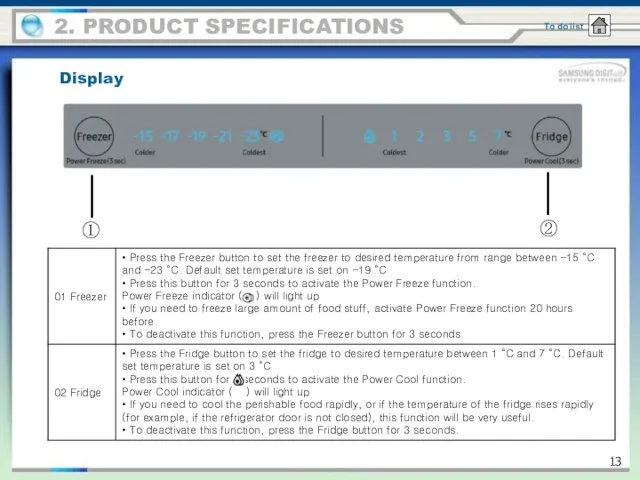

- 13. 2. PRODUCT SPECIFICATIONS Display ① ②

- 14. PRECAUTIONS 3. DISASSEMBLY & REASSEMBLY Unplug the refrigerator before cleaning and making repairs. Do not dissemble

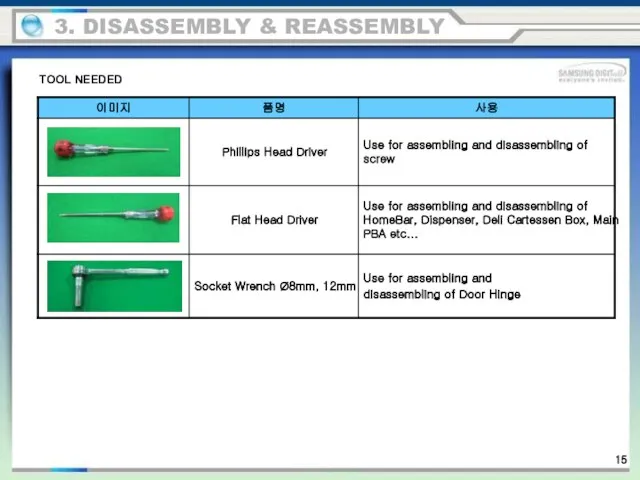

- 15. 3. DISASSEMBLY & REASSEMBLY TOOL NEEDED

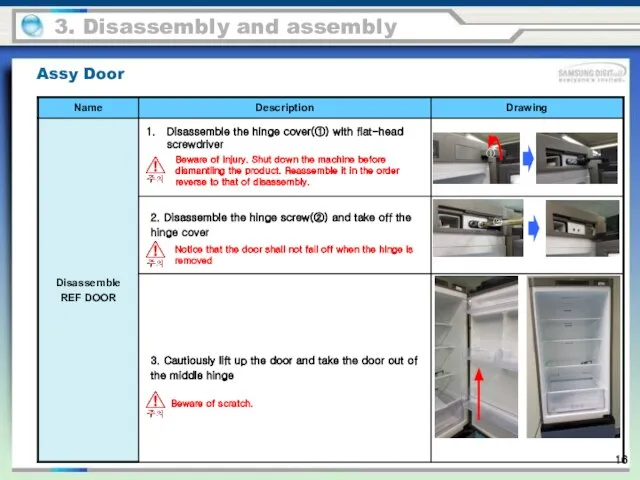

- 16. 3. Disassembly and assembly Beware of injury. Shut down the machine before dismantling the product. Reassemble

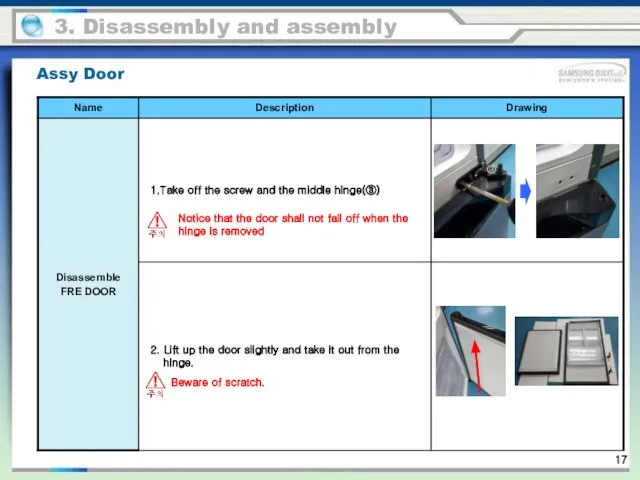

- 17. Notice that the door shall not fall off when the hinge is removed Beware of scratch.

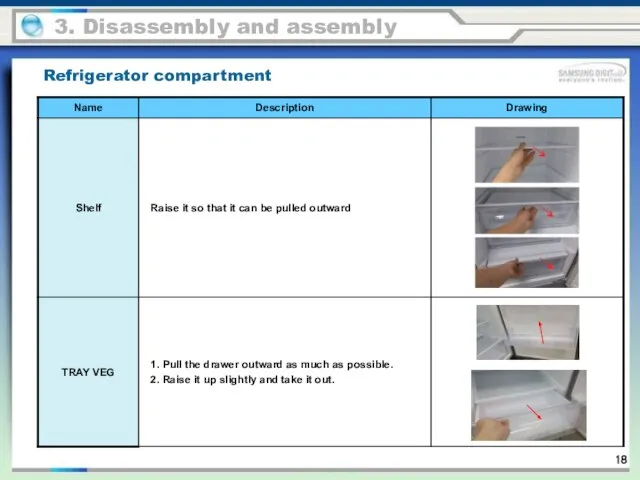

- 18. Refrigerator compartment 3. Disassembly and assembly

- 19. Refrigerator compartment 3. Disassembly and assembly

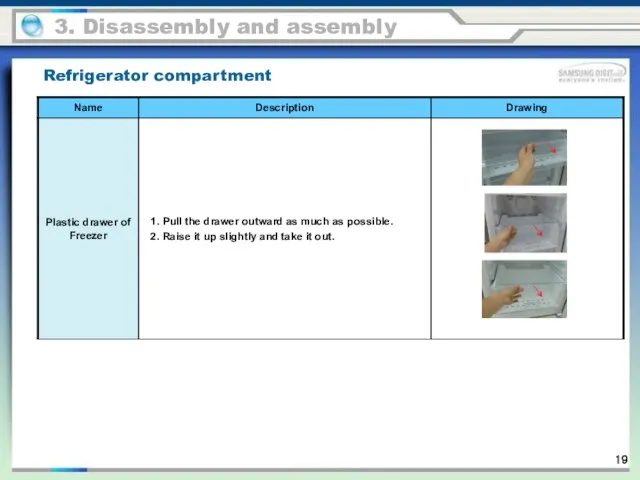

- 20. Refrigerator compartment 3. Disassembly and assembly

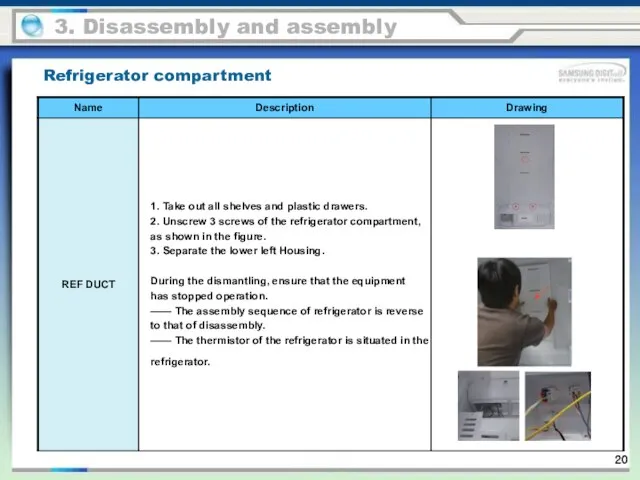

- 21. Refrigerator compartment 3. Disassembly and assembly

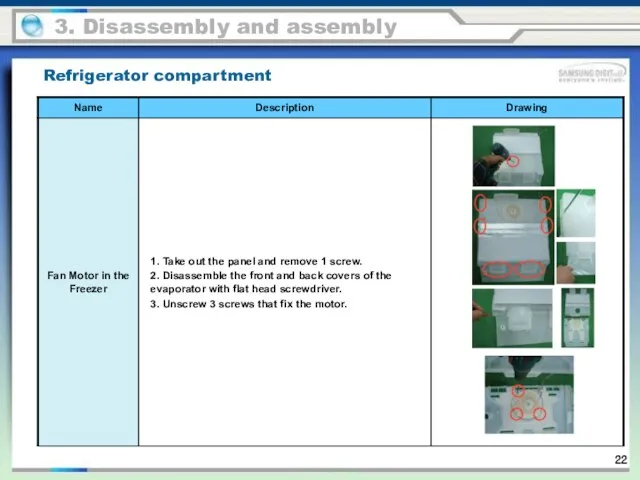

- 22. Refrigerator compartment 3. Disassembly and assembly

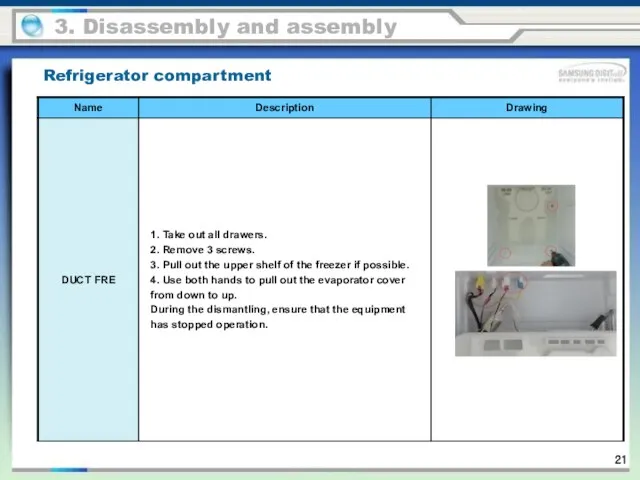

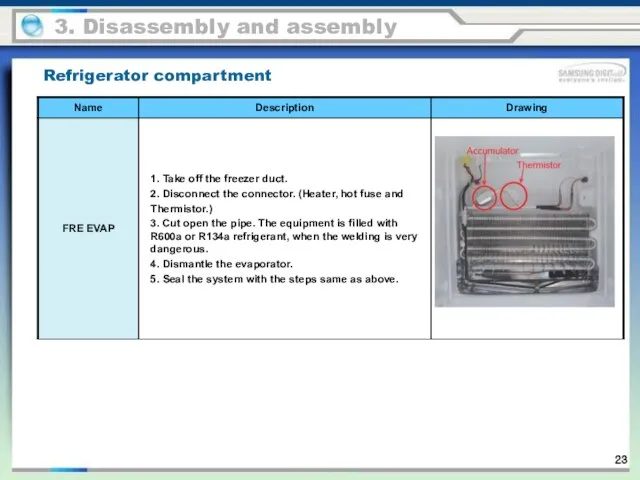

- 23. Refrigerator compartment 3. Disassembly and assembly

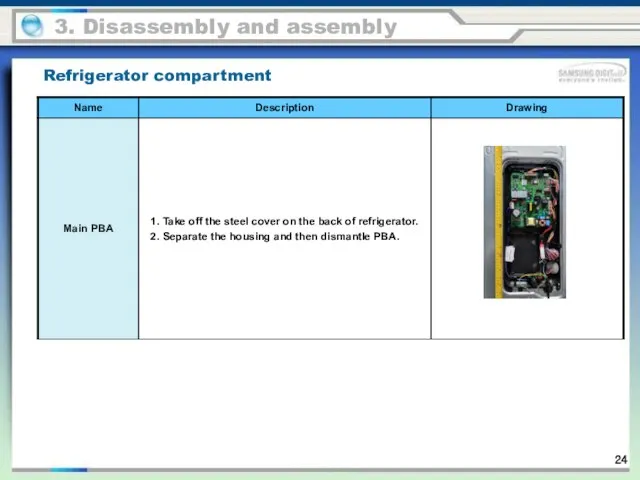

- 24. Refrigerator compartment 3. Disassembly and assembly

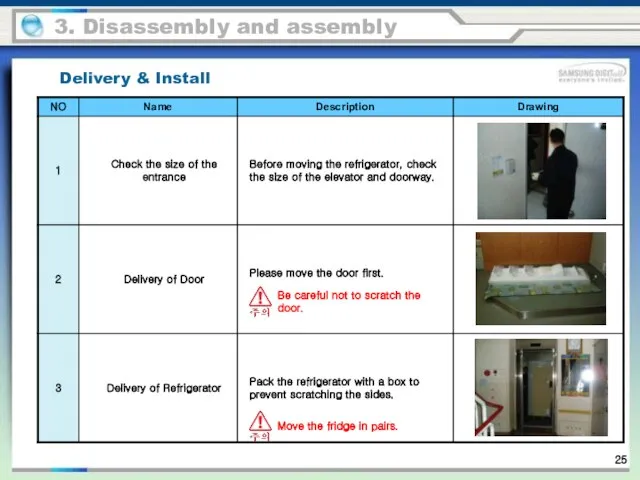

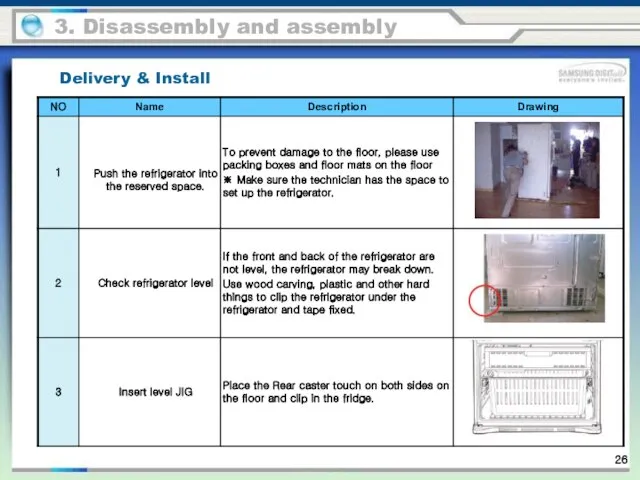

- 25. Delivery & Install Be careful not to scratch the door. Move the fridge in pairs. 3.

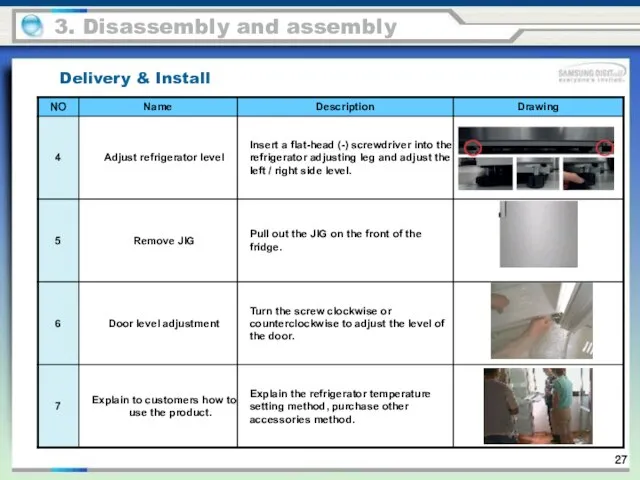

- 26. Delivery & Install 3. Disassembly and assembly

- 27. Delivery & Install 3. Disassembly and assembly

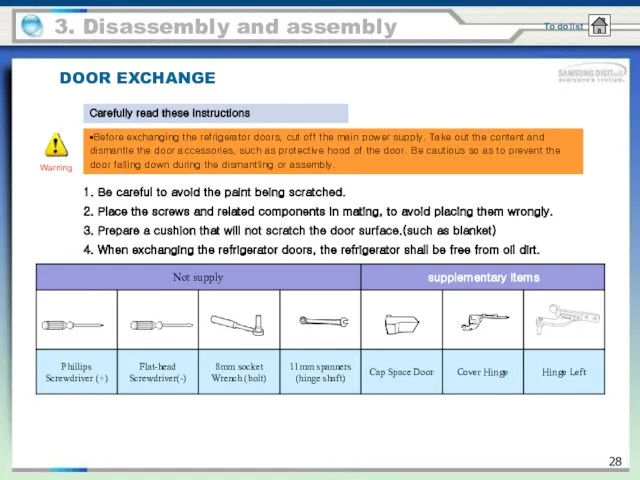

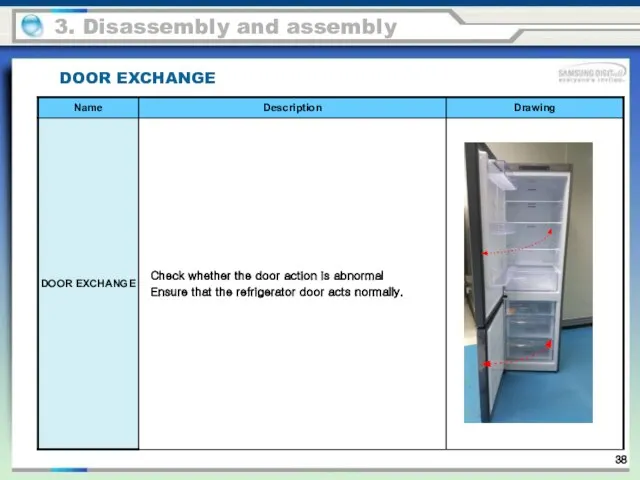

- 28. DOOR EXCHANGE Warning Carefully read these instructions 3. Disassembly and assembly •Before exchanging the refrigerator doors,

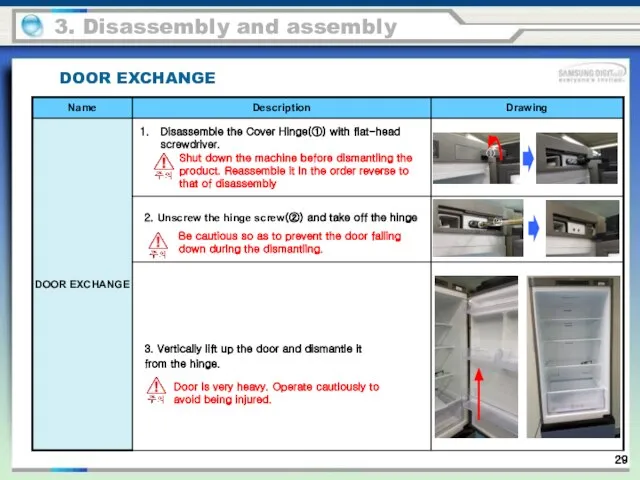

- 29. 3. Disassembly and assembly Shut down the machine before dismantling the product. Reassemble it in the

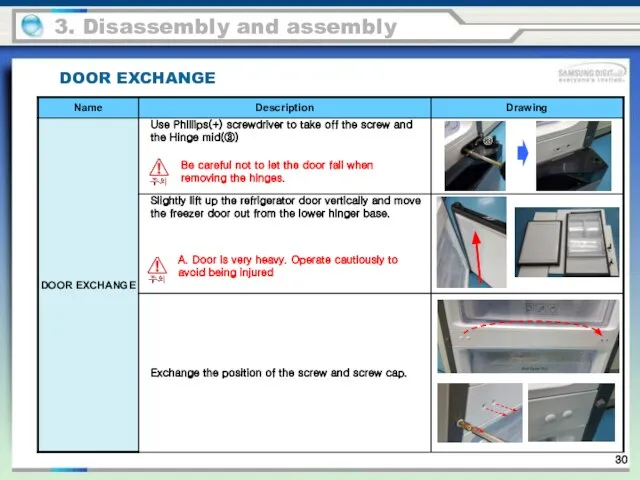

- 30. Be careful not to let the door fall when removing the hinges. A. Door is very

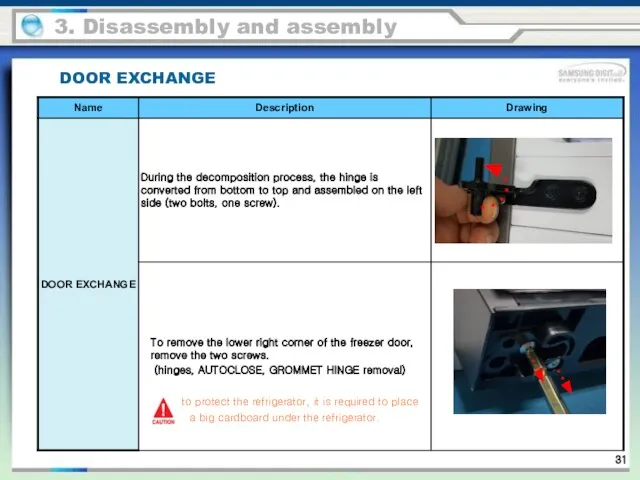

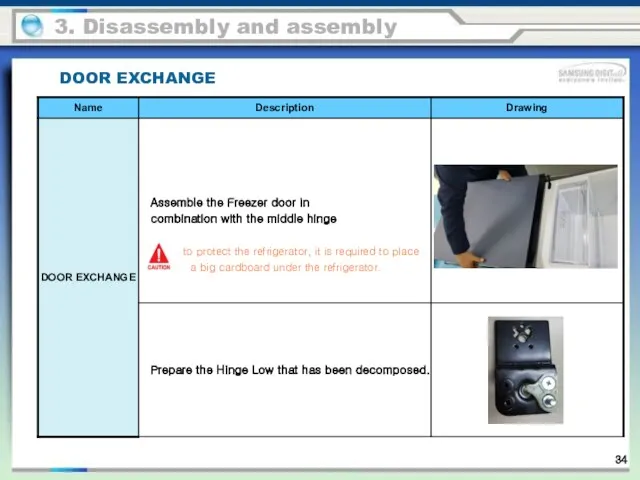

- 31. to protect the refrigerator, it is required to place a big cardboard under the refrigerator. 3.

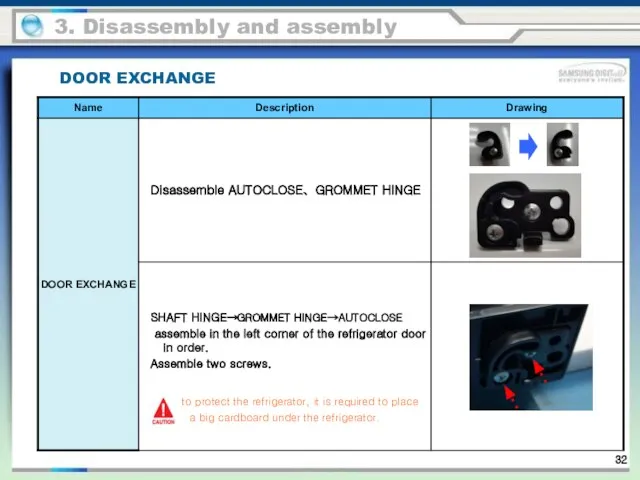

- 32. 3. Disassembly and assembly DOOR EXCHANGE to protect the refrigerator, it is required to place a

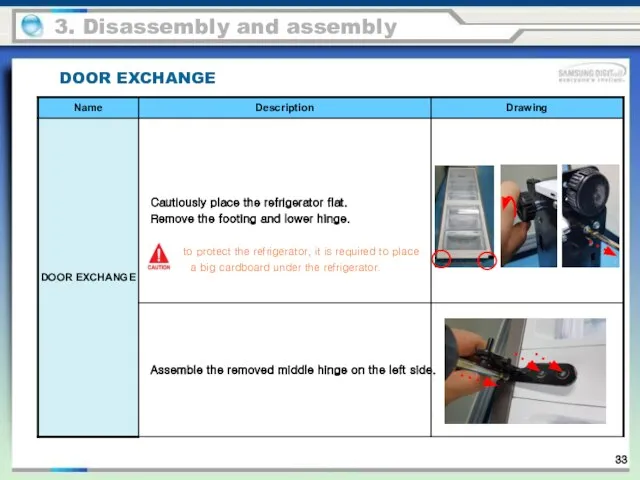

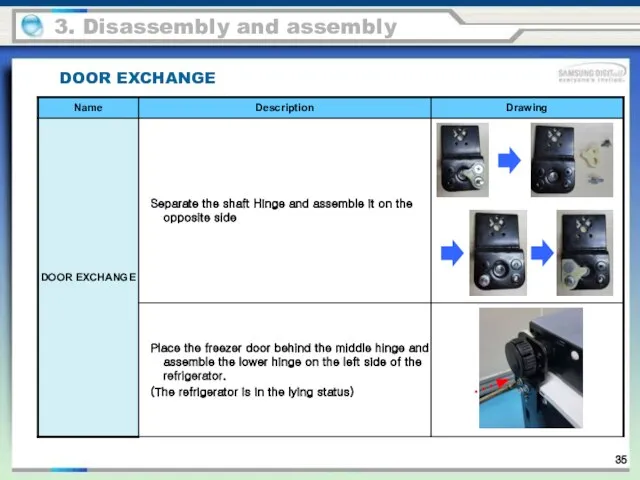

- 33. 3. Disassembly and assembly DOOR EXCHANGE to protect the refrigerator, it is required to place a

- 34. 3. Disassembly and assembly DOOR EXCHANGE to protect the refrigerator, it is required to place a

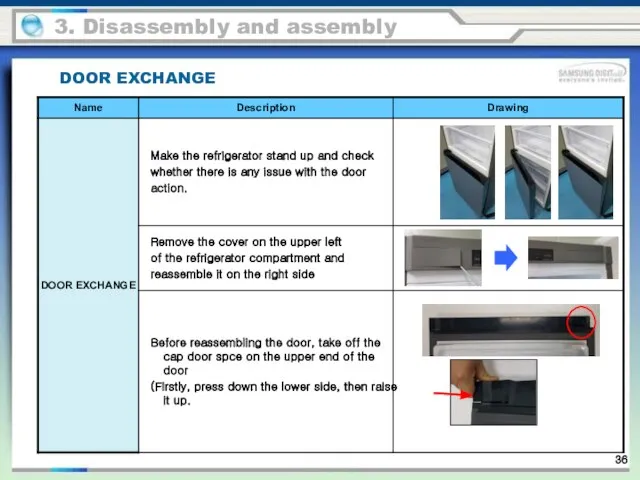

- 35. 3. Disassembly and assembly DOOR EXCHANGE

- 36. 3. Disassembly and assembly DOOR EXCHANGE

- 37. 3. Disassembly and assembly DOOR EXCHANGE

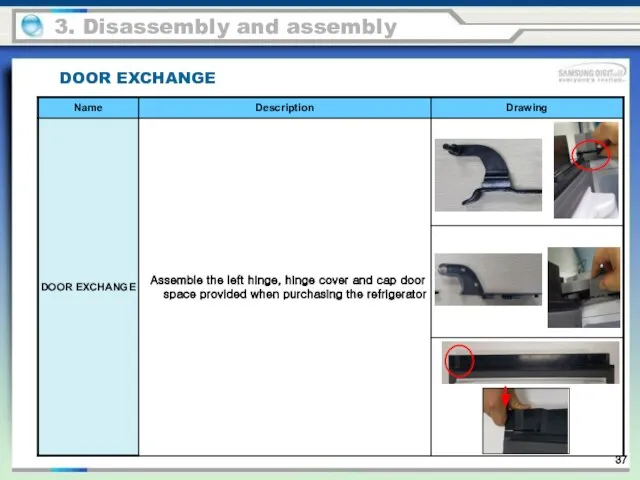

- 38. 3. Disassembly and assembly DOOR EXCHANGE

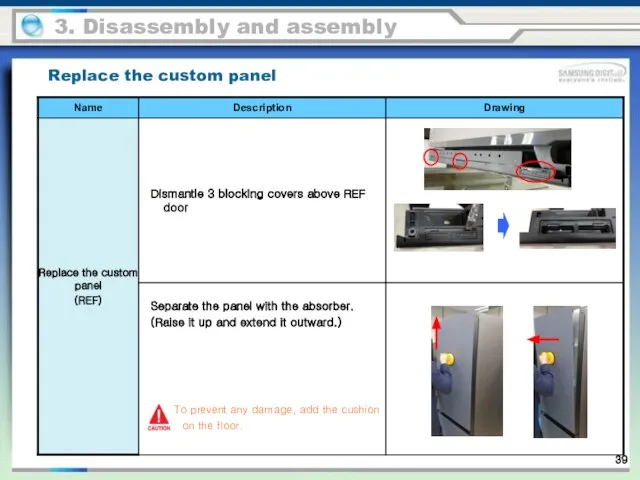

- 39. Replace the custom panel To prevent any damage, add the cushion on the floor. 3. Disassembly

- 40. Replace the custom panel 3. Disassembly and assembly

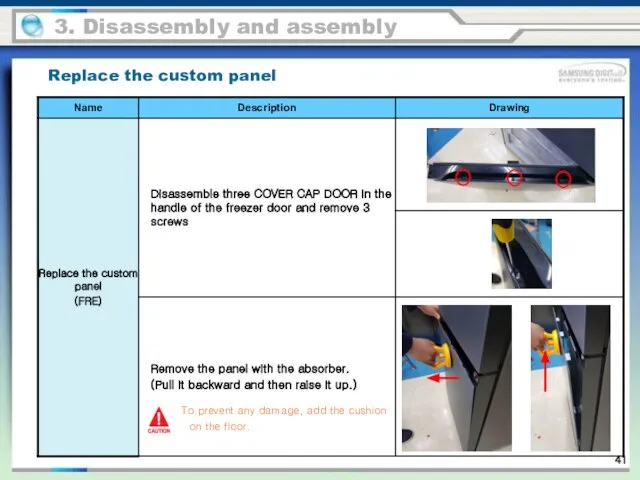

- 41. To prevent any damage, add the cushion on the floor. Replace the custom panel 3. Disassembly

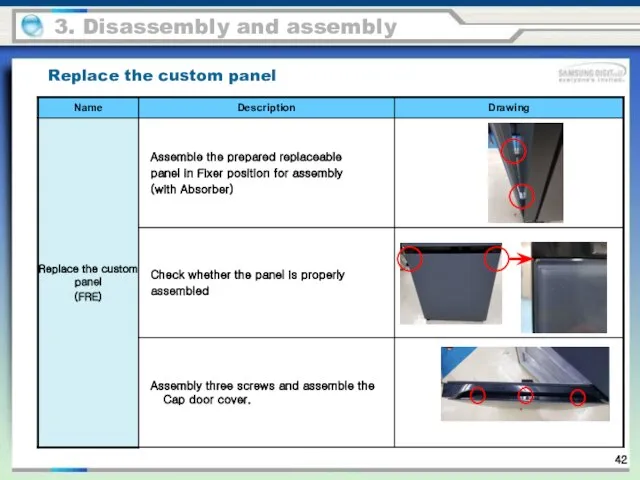

- 42. Replace the custom panel 3. Disassembly and assembly

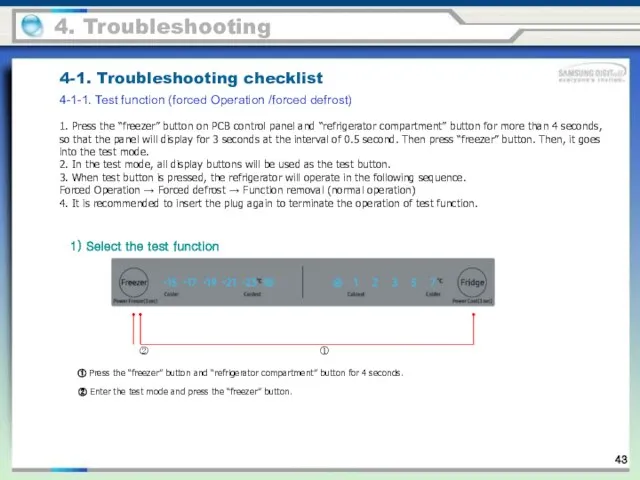

- 43. 1. Press the “freezer” button on PCB control panel and “refrigerator compartment” button for more than

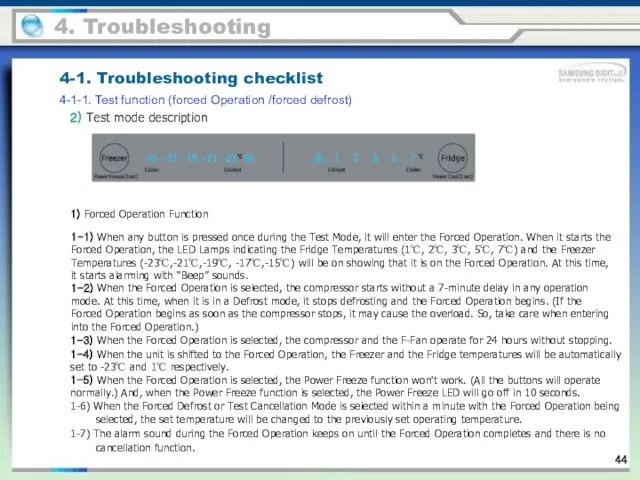

- 44. 2) Test mode description 1) Forced Operation Function 1-3) When the Forced Operation is selected, the

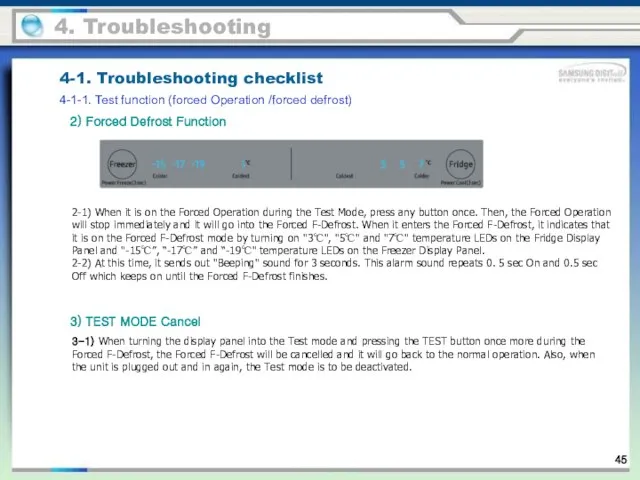

- 45. 2) Forced Defrost Function 2-1) When it is on the Forced Operation during the Test Mode,

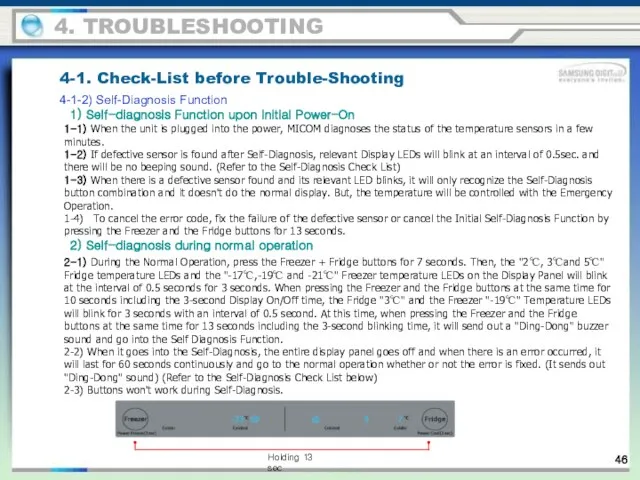

- 46. 1-1) When the unit is plugged into the power, MICOM diagnoses the status of the temperature

- 47. 55 4. TROUBLESHOOTING ※ Self-diagnosis list

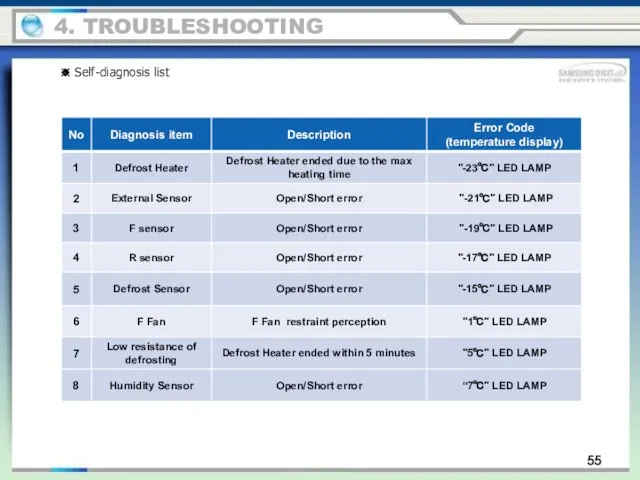

- 48. 56 4. TROUBLESHOOTING ※ Self-diagnosis list

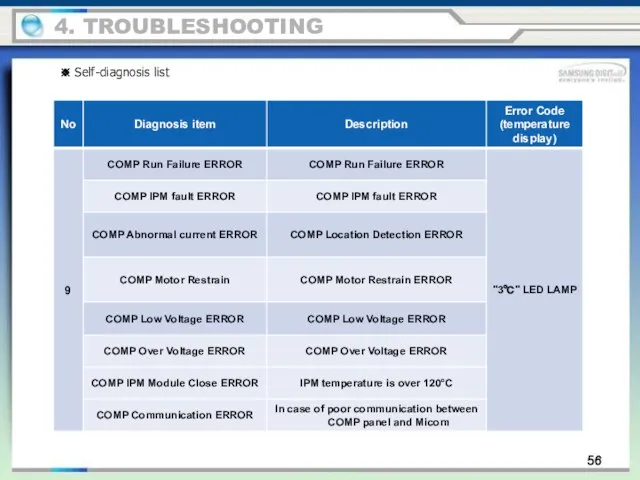

- 49. 57 4. TROUBLESHOOTING ※ Self-diagnosis list

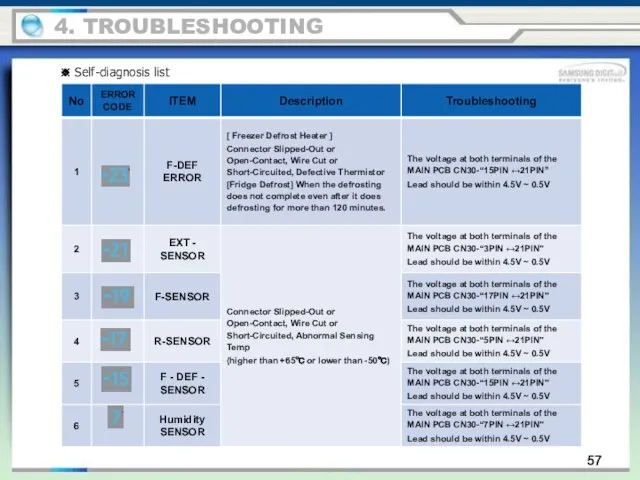

- 50. 58 4. TROUBLESHOOTING ※ Self-diagnosis list

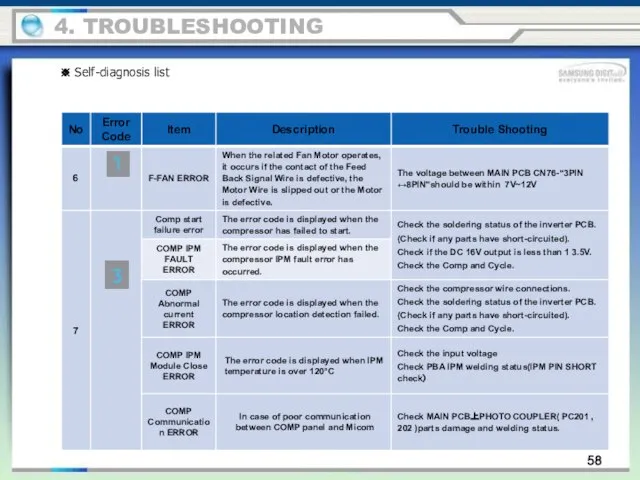

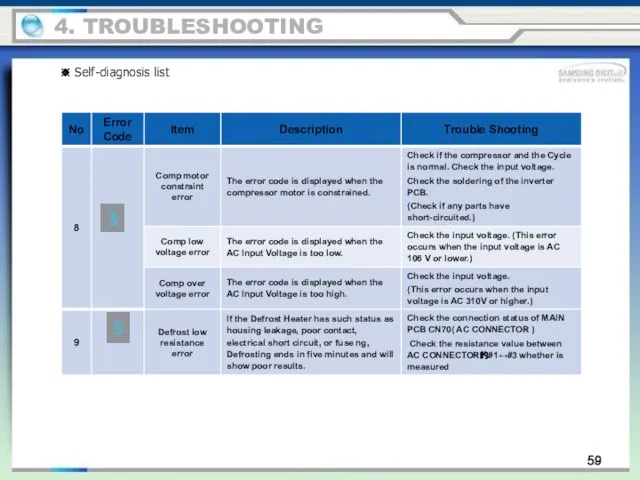

- 51. 59 4. TROUBLESHOOTING ※ Self-diagnosis list

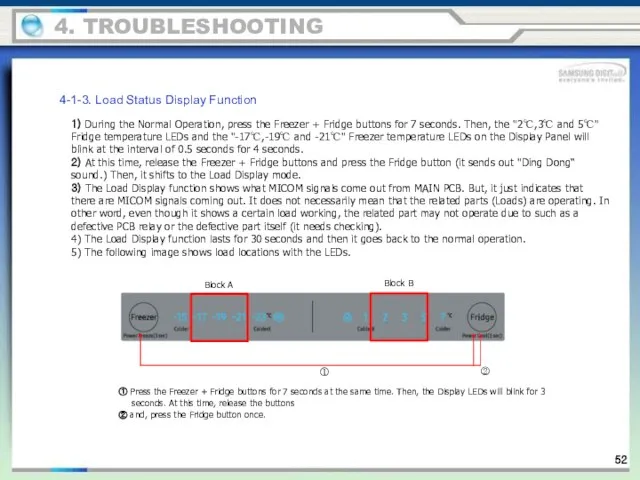

- 52. 4. TROUBLESHOOTING 4-1-3. Load Status Display Function 1) During the Normal Operation, press the Freezer +

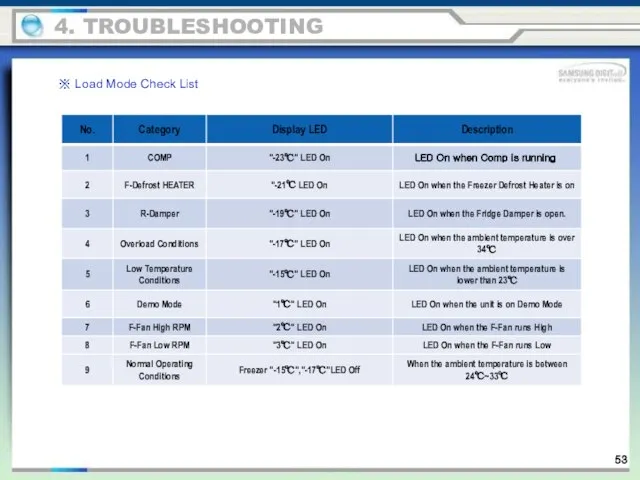

- 53. 4. TROUBLESHOOTING ※ Load Mode Check List

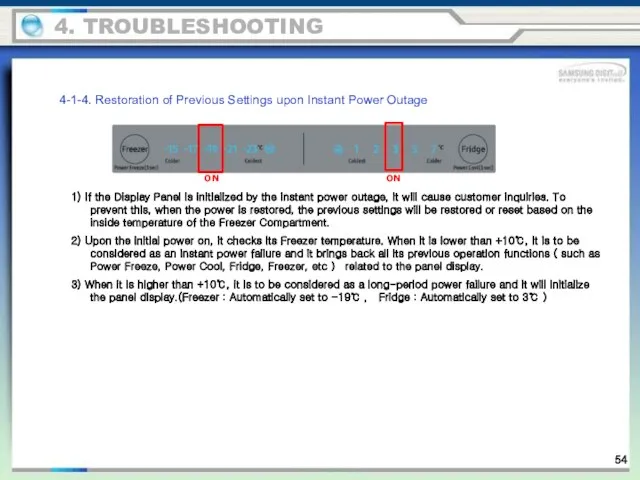

- 54. 4-1-4. Restoration of Previous Settings upon Instant Power Outage 1) If the Display Panel is initialized

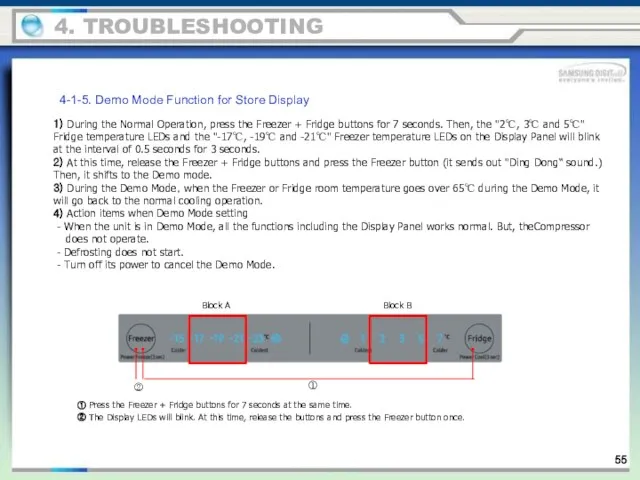

- 55. 4-1-5. Demo Mode Function for Store Display 1) During the Normal Operation, press the Freezer +

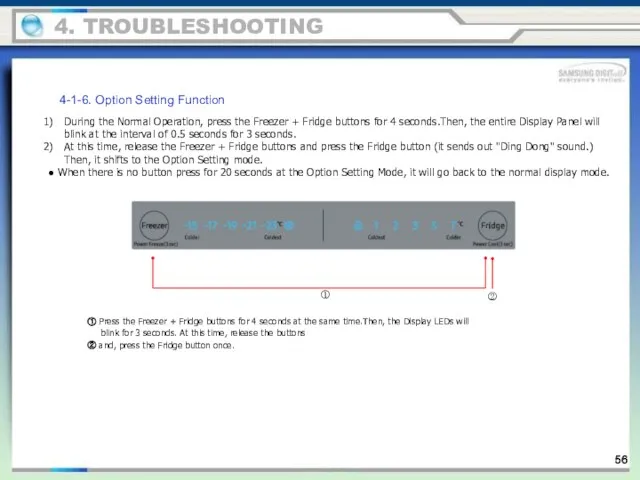

- 56. 4-1-6. Option Setting Function During the Normal Operation, press the Freezer + Fridge buttons for 4

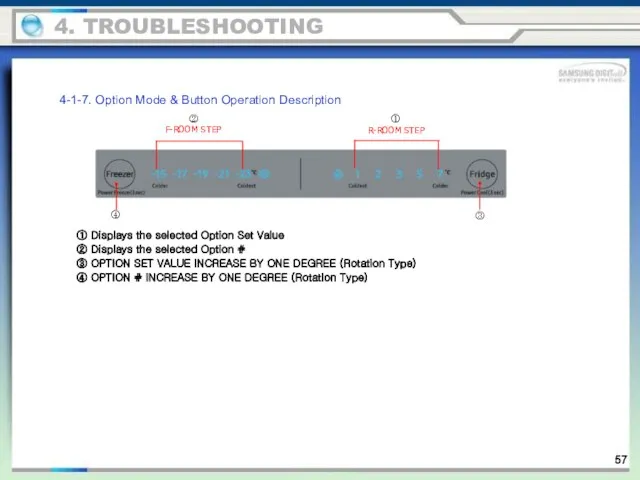

- 57. 4-1-7. Option Mode & Button Operation Description F-ROOM STEP R-ROOM STEP ① ② ③ ④ 4.

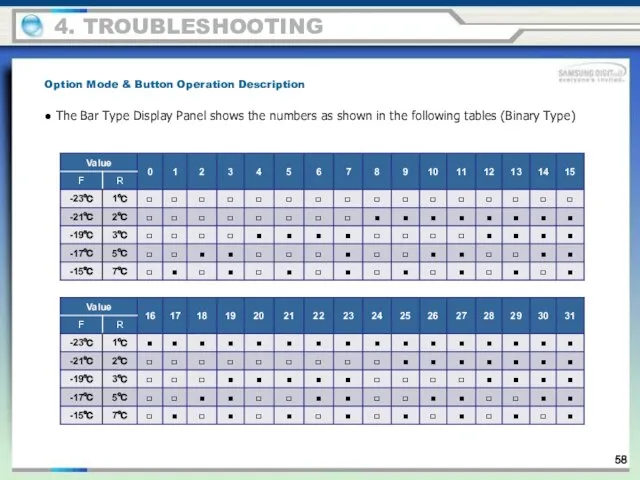

- 58. ● The Bar Type Display Panel shows the numbers as shown in the following tables (Binary

- 59. ● When the Display Panel converts to the Option Setting mode, the entire Display except the

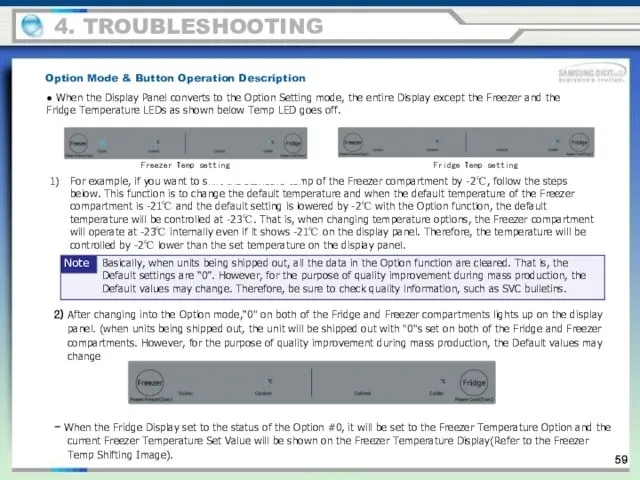

- 60. 3) When "4" is set as shown in the Freezer Option Table below after setting the

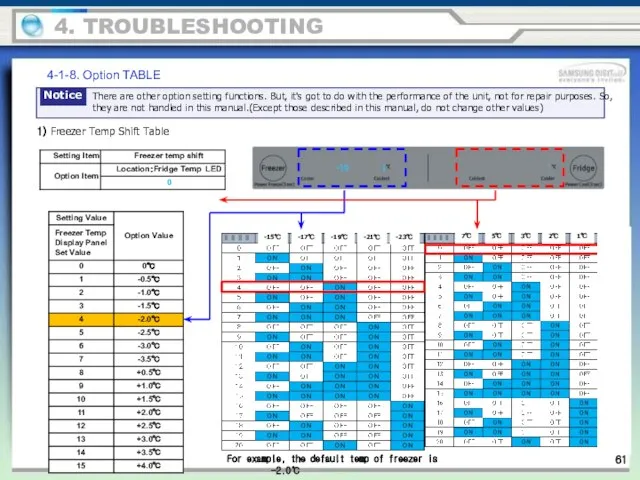

- 61. 4-1-8. Option TABLE 1) Freezer Temp Shift Table For example, the default temp of freezer is

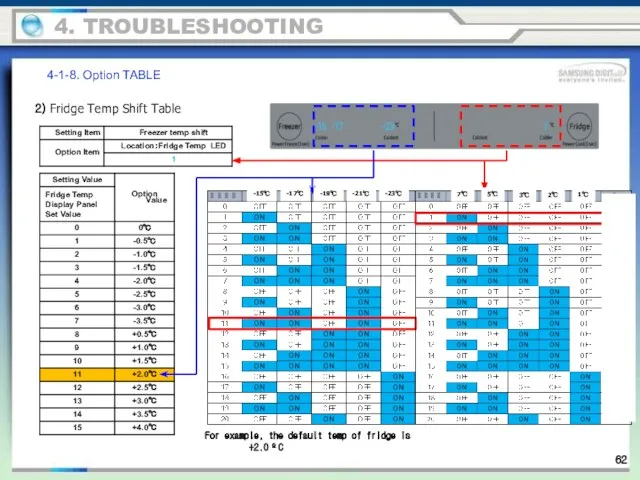

- 62. 2) Fridge Temp Shift Table For example, the default temp of fridge is +2.0ºC -15℃ -17℃

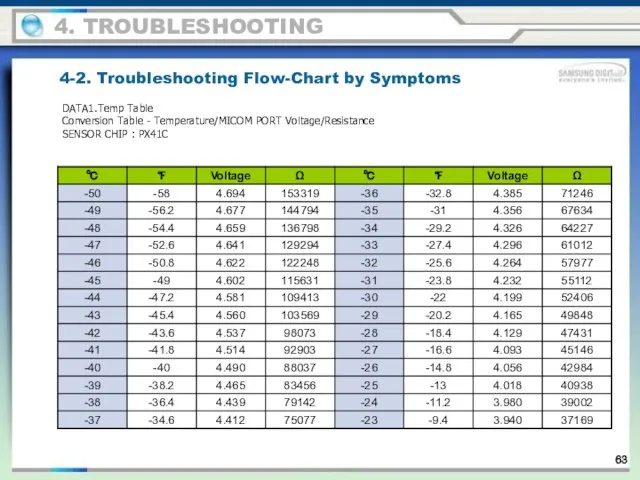

- 63. DATA1.Temp Table Conversion Table - Temperature/MICOM PORT Voltage/Resistance SENSOR CHIP : PX41C 4. TROUBLESHOOTING 4-2. Troubleshooting

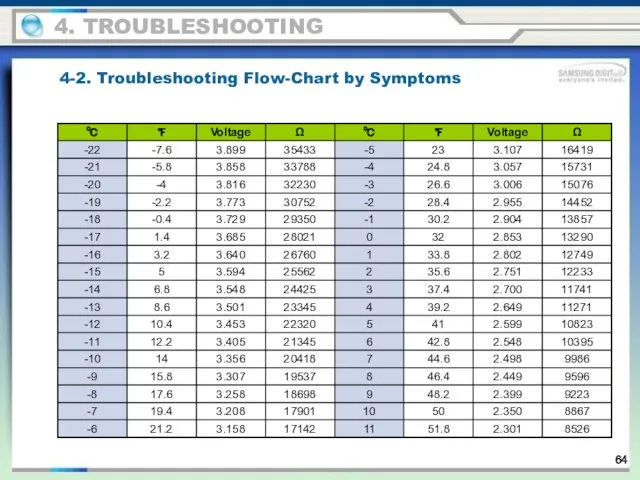

- 64. 4. TROUBLESHOOTING 4-2. Troubleshooting Flow-Chart by Symptoms

- 65. 4. TROUBLESHOOTING 4-2. Troubleshooting Flow-Chart by Symptoms

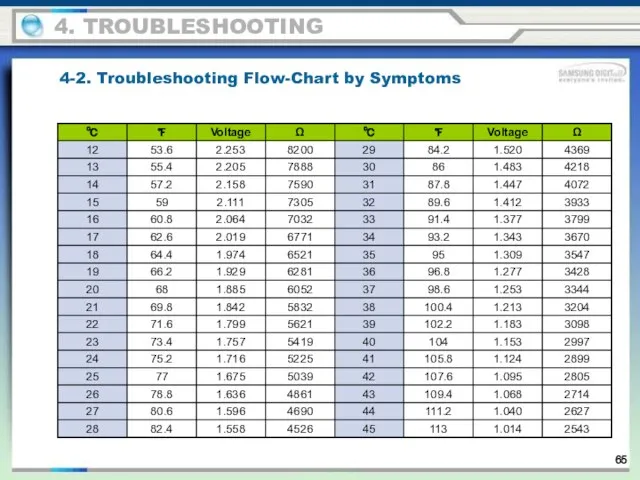

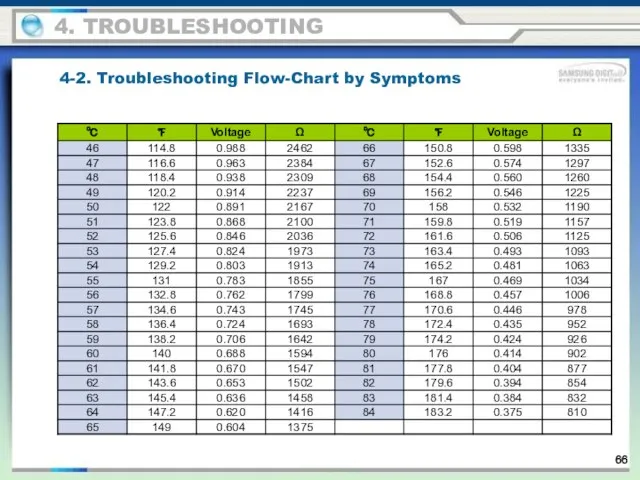

- 66. 4. TROUBLESHOOTING 4-2. Troubleshooting Flow-Chart by Symptoms

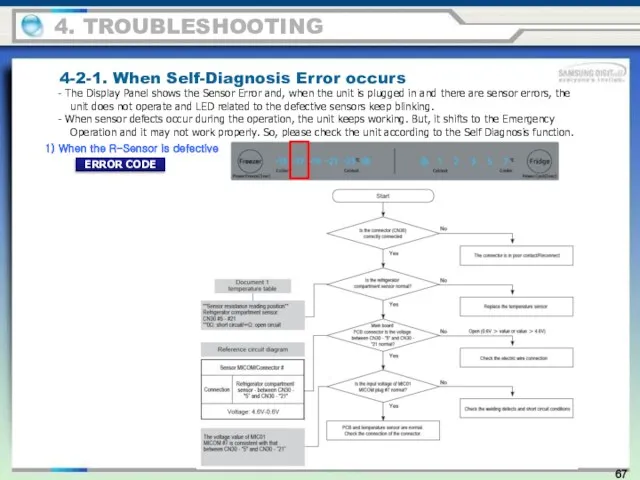

- 67. 4-2-1. When Self-Diagnosis Error occurs - The Display Panel shows the Sensor Error and, when the

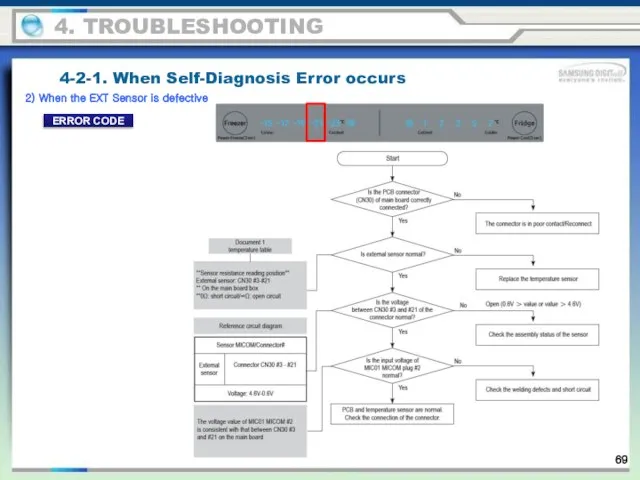

- 68. 2) When the EXT Sensor is defective 4-2-1. When Self-Diagnosis Error occurs 4. TROUBLESHOOTING ERROR CODE

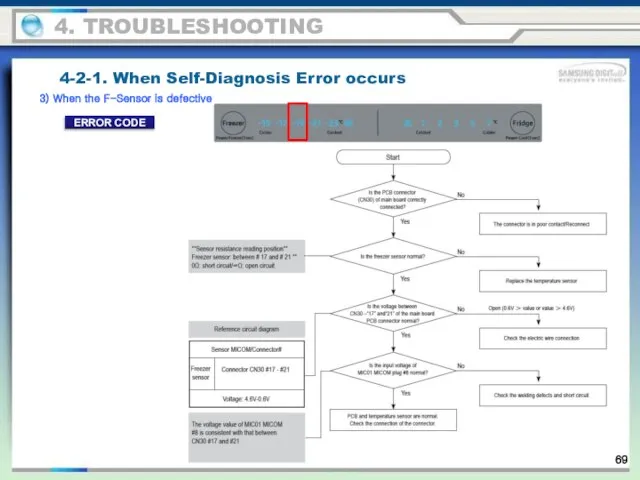

- 69. 3) When the F-Sensor is defective 4-2-1. When Self-Diagnosis Error occurs 4. TROUBLESHOOTING ERROR CODE

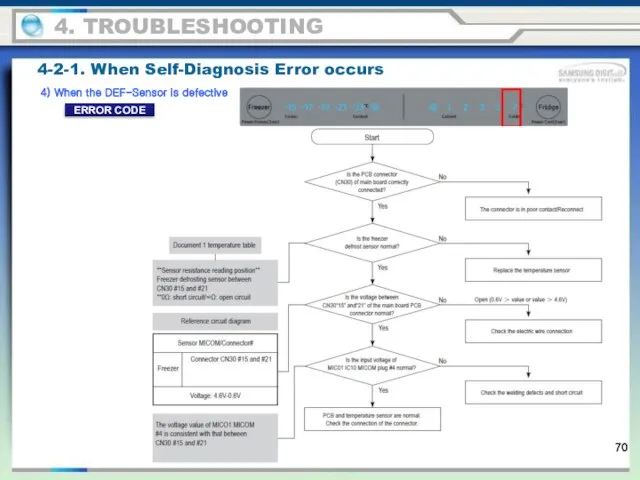

- 70. 4) When the DEF-Sensor is defective 4-2-1. When Self-Diagnosis Error occurs 4. TROUBLESHOOTING ERROR CODE

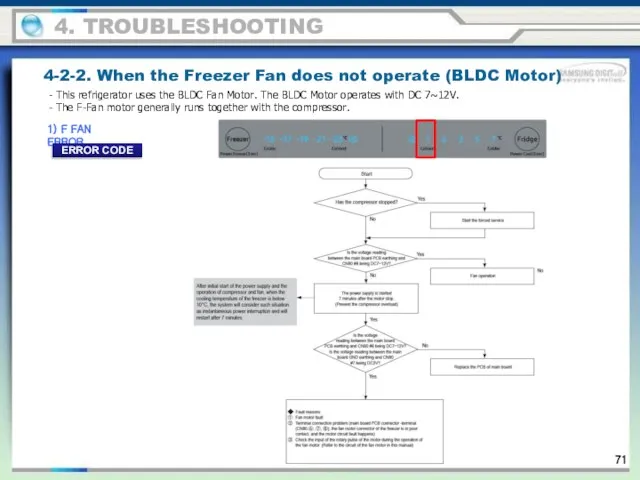

- 71. 4-2-2. When the Freezer Fan does not operate (BLDC Motor) 1) F FAN ERROR 4. TROUBLESHOOTING

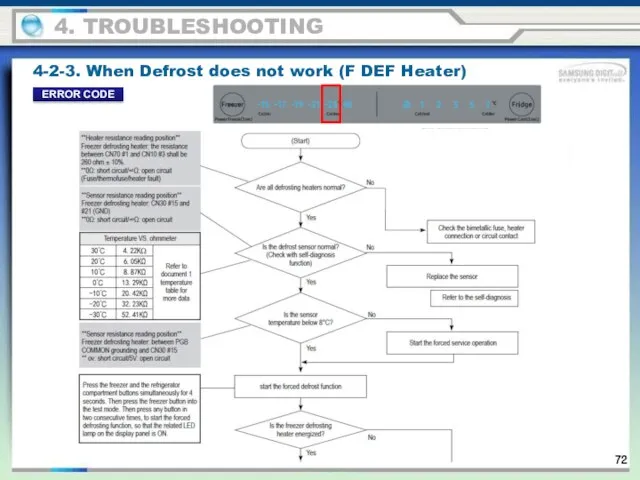

- 72. 4. TROUBLESHOOTING 4-2-3. When Defrost does not work (F DEF Heater) ERROR CODE

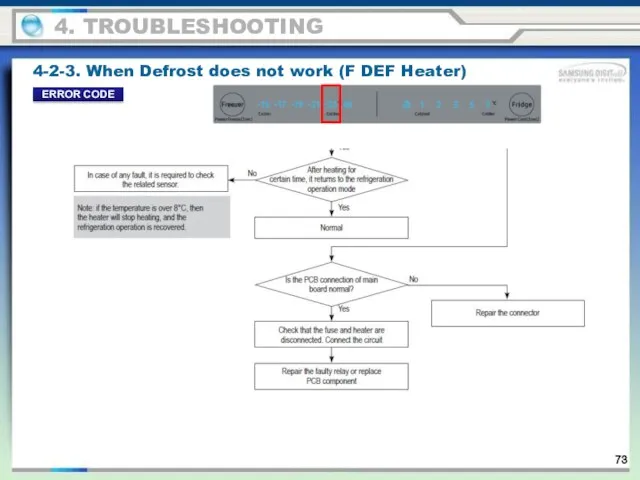

- 73. 4. TROUBLESHOOTING 4-2-3. When Defrost does not work (F DEF Heater) ERROR CODE

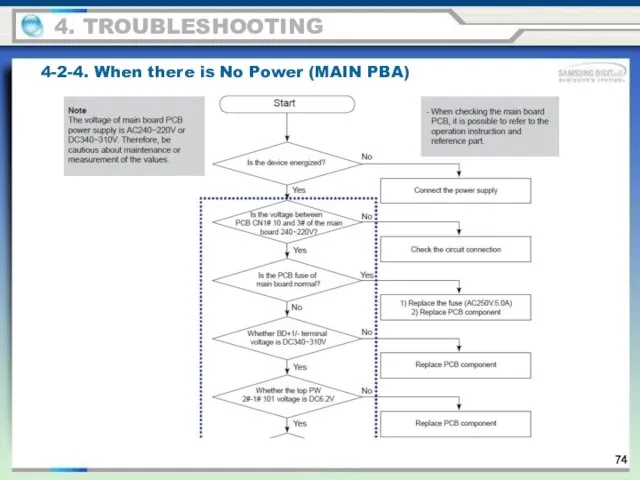

- 74. 4-2-4. When there is No Power (MAIN PBA) 4. TROUBLESHOOTING

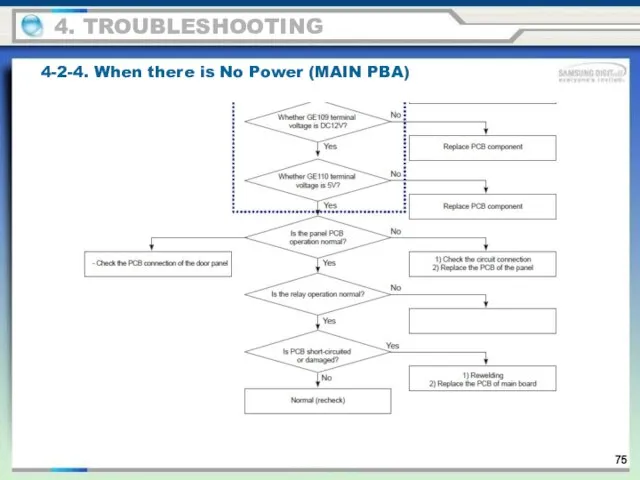

- 75. 4-2-4. When there is No Power (MAIN PBA) 4. TROUBLESHOOTING

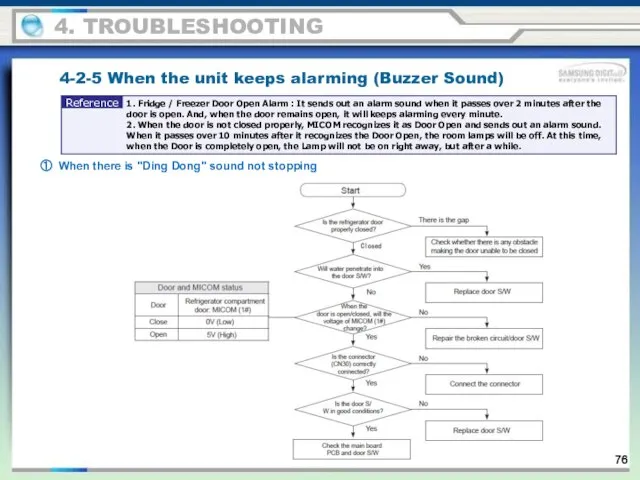

- 76. ① When there is "Ding Dong" sound not stopping 4-2-5 When the unit keeps alarming (Buzzer

- 77. ② When it keeps 'Beeping 4-2-5 When the unit keeps alarming (Buzzer Sound) 4. TROUBLESHOOTING

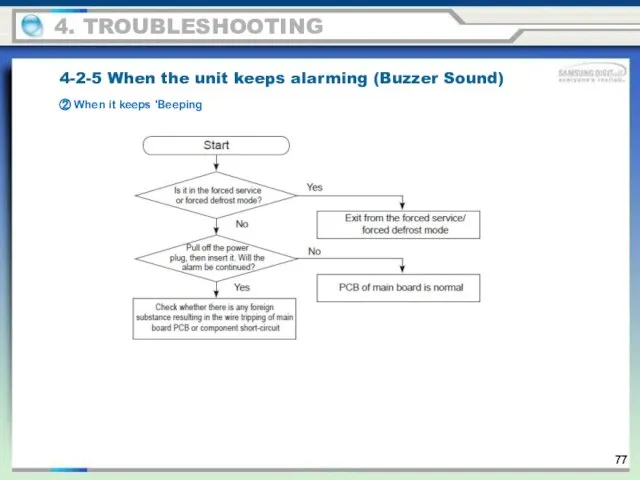

- 78. ③ No Buzzer Sound 4-2-5 When the unit keeps alarming (Buzzer Sound) 4. TROUBLESHOOTING This model

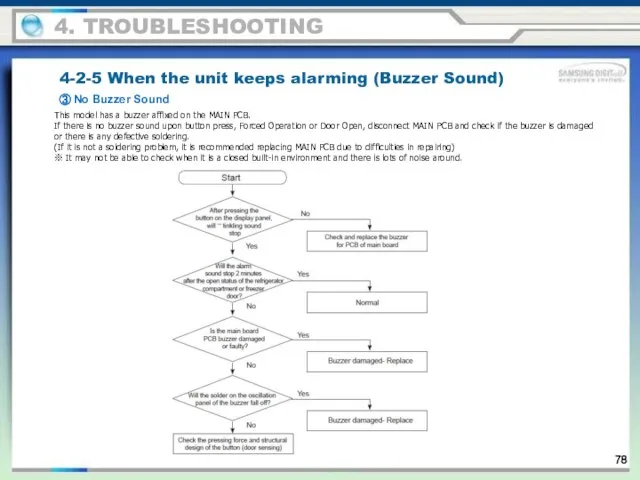

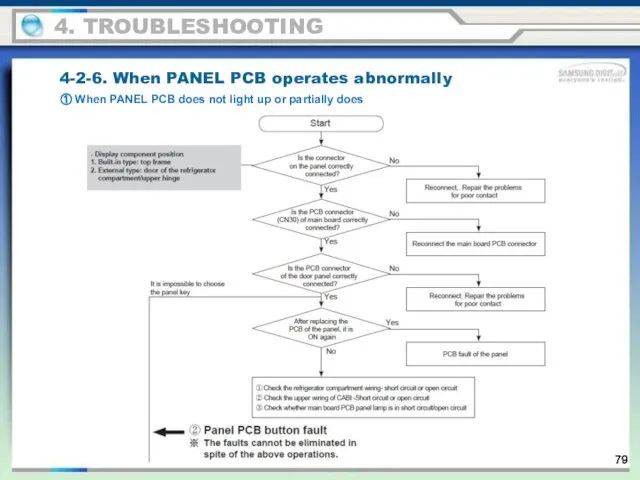

- 79. 4-2-6. When PANEL PCB operates abnormally ① When PANEL PCB does not light up or partially

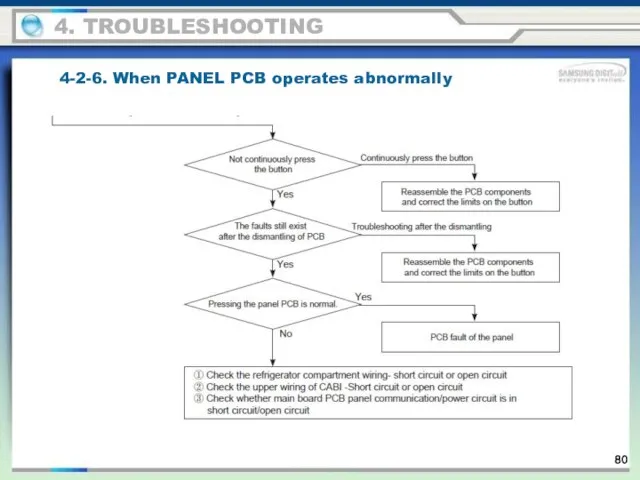

- 80. 4-2-6. When PANEL PCB operates abnormally 4. TROUBLESHOOTING

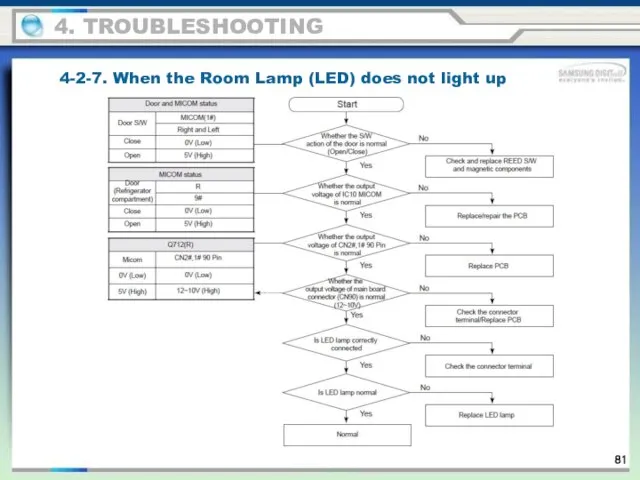

- 81. 4-2-7. When the Room Lamp (LED) does not light up 4. TROUBLESHOOTING

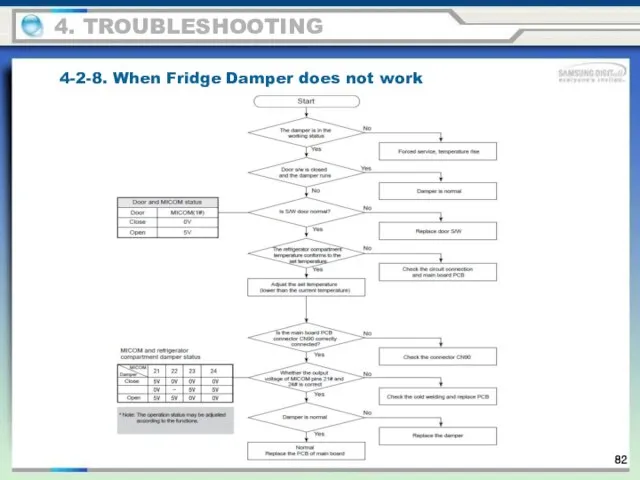

- 82. 4-2-8. When Fridge Damper does not work 4. TROUBLESHOOTING

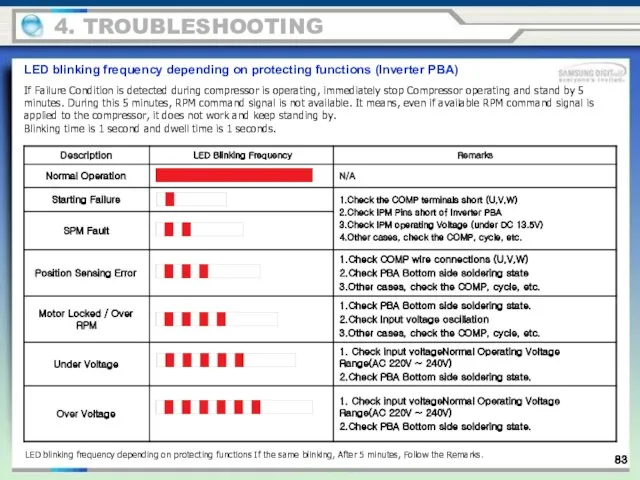

- 83. If Failure Condition is detected during compressor is operating, immediately stop Compressor operating and stand by

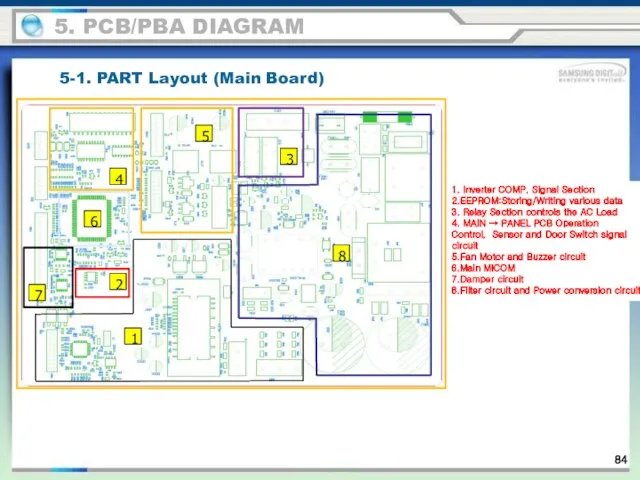

- 84. 5-1. PART Layout (Main Board) 5. PCB/PBA DIAGRAM 1. Inverter COMP. Signal Section 2.EEPROM:Storing/Writing various data

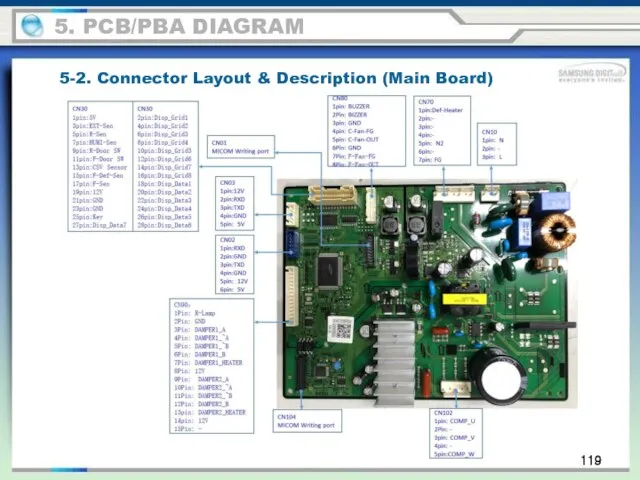

- 85. 119 5-2. Connector Layout & Description (Main Board) 5. PCB/PBA DIAGRAM

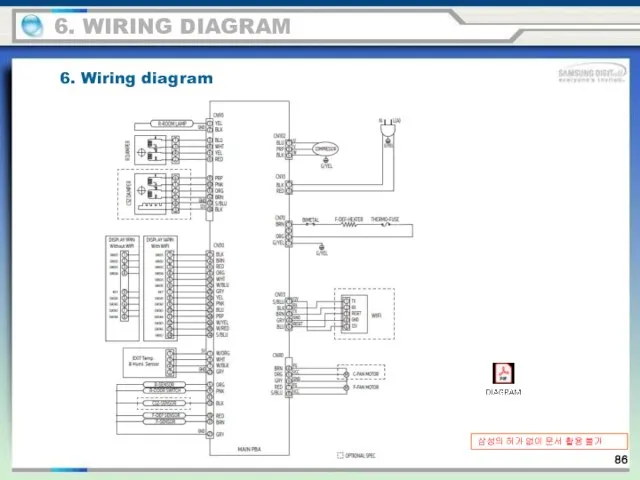

- 86. 6. WIRING DIAGRAM 6. Wiring diagram 삼성의 허가 없이 문서 활용 불가

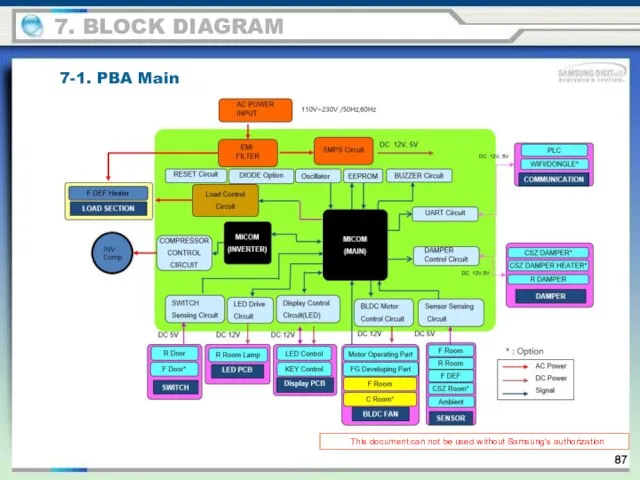

- 87. This document can not be used without Samsung's authorization 7. BLOCK DIAGRAM 7-1. PBA Main

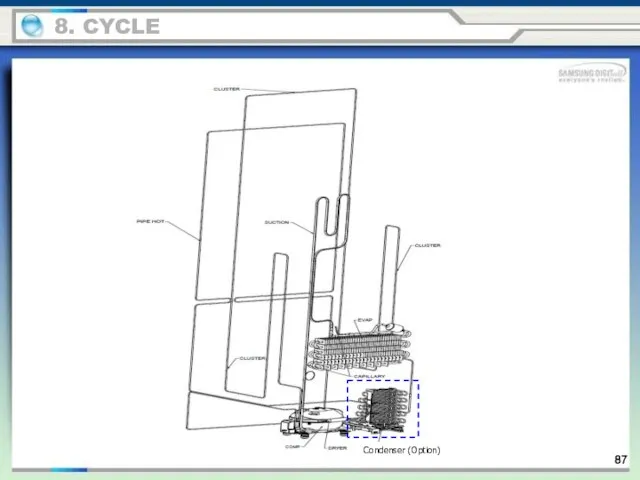

- 88. Condenser (Option) 8. CYCLE 87

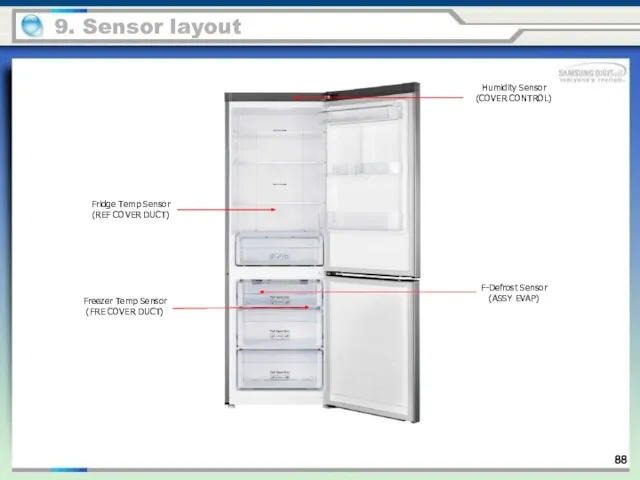

- 89. 9. Sensor layout Fridge Temp Sensor (REF COVER DUCT) Freezer Temp Sensor (FRE COVER DUCT) Humidity

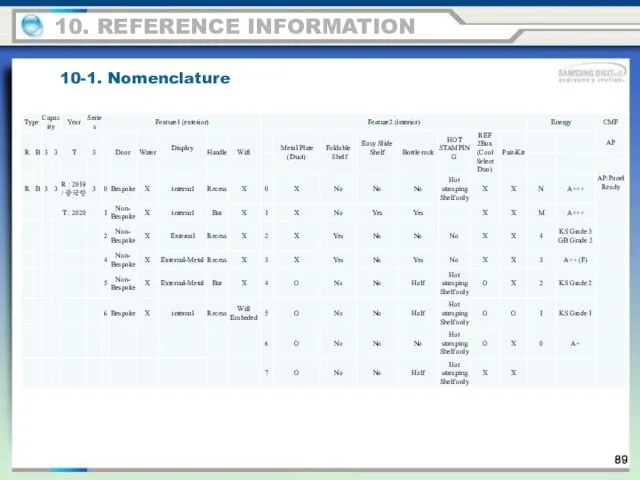

- 90. 10-1. Nomenclature 10. REFERENCE INFORMATION 89

- 92. Скачать презентацию

презентация

презентация Что такое краеведение

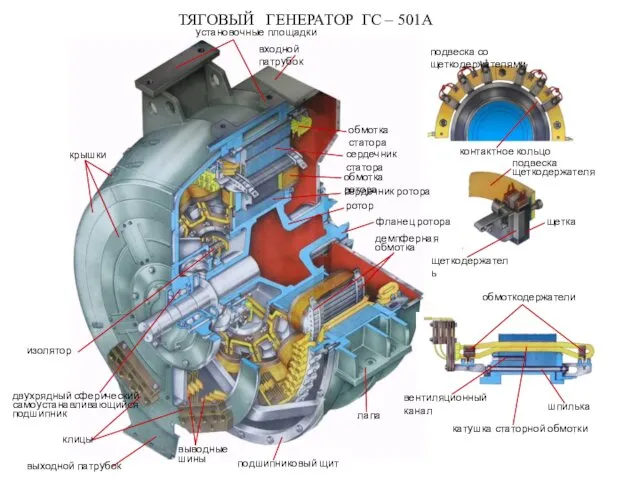

Что такое краеведение Электрическое оборудование тепловозов

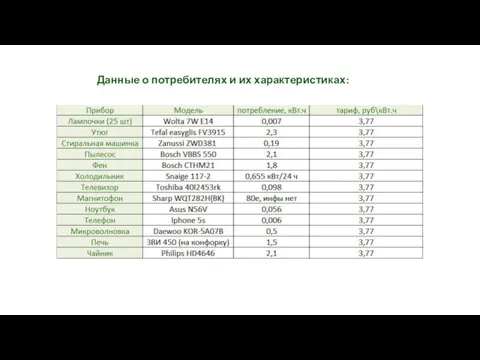

Электрическое оборудование тепловозов Данные о потребителях и их характеристиках

Данные о потребителях и их характеристиках Подготовка и проведение пеших и лыжных походов

Подготовка и проведение пеших и лыжных походов Л М-ды генерир. альтернатив Часть 1

Л М-ды генерир. альтернатив Часть 1 Методи, параметри оцінки та форми контролю якості в системах обробки ілюстративної інформації

Методи, параметри оцінки та форми контролю якості в системах обробки ілюстративної інформації Классификация процессов и объектов автоматизации. Технологические требования к САУ ТП

Классификация процессов и объектов автоматизации. Технологические требования к САУ ТП Overcoming line broadening in real-time pure shift NMR spectroscopy

Overcoming line broadening in real-time pure shift NMR spectroscopy Города России

Города России 20180315_okruglenie_des_drobey

20180315_okruglenie_des_drobey Как росла Церковь

Как росла Церковь new style for ДомашкаГО by Dima Strapolov

new style for ДомашкаГО by Dima Strapolov Устройства СВЧ и антенны

Устройства СВЧ и антенны 20141116_prezentatsiya_microsoft_powerpoint_0

20141116_prezentatsiya_microsoft_powerpoint_0 Воевалко Виктория. Фотоальбом

Воевалко Виктория. Фотоальбом Какие бывают нитки? Как они используются?

Какие бывают нитки? Как они используются? Цифровые системы передачи

Цифровые системы передачи Международный день леса

Международный день леса Сатирические образы человека

Сатирические образы человека Еврейский образ жизни

Еврейский образ жизни Гибка тонколистового металла

Гибка тонколистового металла Robo дім роботів

Robo дім роботів Мозаика из карандашной стружки

Мозаика из карандашной стружки 20170122_poeticheskaya_stranitsa

20170122_poeticheskaya_stranitsa Безпечність та якість відновлених напоїв антистресової дії

Безпечність та якість відновлених напоїв антистресової дії Предложения по развитию транспортно-дорожной сети района Лианозово

Предложения по развитию транспортно-дорожной сети района Лианозово Василий Макарович Шукшин. Село Сростки. Фотографии

Василий Макарович Шукшин. Село Сростки. Фотографии