Содержание

- 2. Master's major Master's major: CAD/CAE-modeling Coupled calculations performing (gasdynamic, strength, vibration, thermal process, kinematics, tribology) Scientific

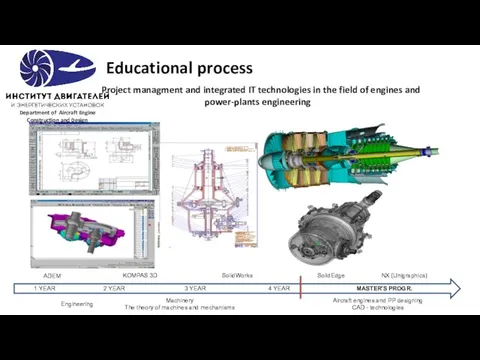

- 3. Educational process ADEM KOMPAS 3D SolidWorks SolidEdge NX (Unigraphics) 1 YEAR 2 YEAR 3 YEAR 4

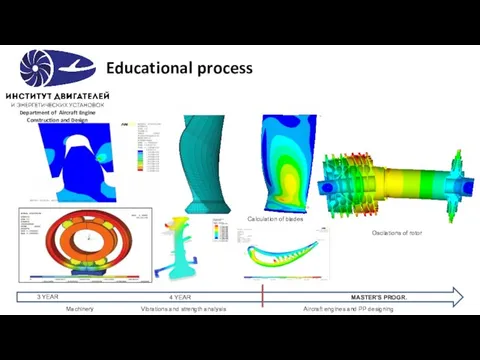

- 4. Educational process 3 YEAR 4 YEAR MASTER'S PROGR. Machinery Vibrations and strength analysis Oscilations of rotor

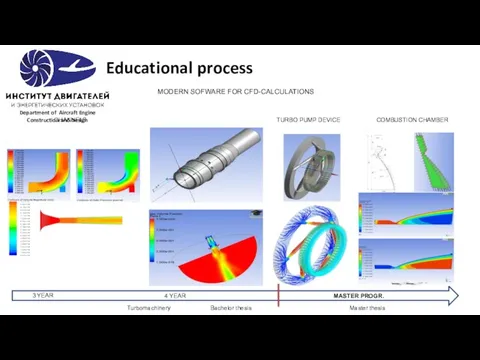

- 5. Educational process MODERN SOFWARE FOR CFD-CALCULATIONS 3 YEAR 4 YEAR Master thesis Turbomachinery CHANNELS TURBO PUMP

- 6. Special aspects of curriculum Special aspects of training: 1. Continuing of professional training of bachelors: Providing

- 7. Special aspects of curriculum 3. Teaching what the specialized departments are strong in: Virtual product development

- 8. Places for R&D: Joint laboratories Research laboratory «SSIL-1" Center of history of aircraft engines PAO «KUZNETSOV»

- 9. 1. Performance of works by the order of factories 2. R&D works of department Creation of

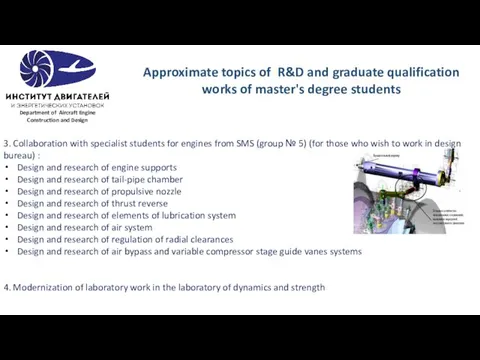

- 10. 3. Collaboration with specialist students for engines from SMS (group № 5) (for those who wish

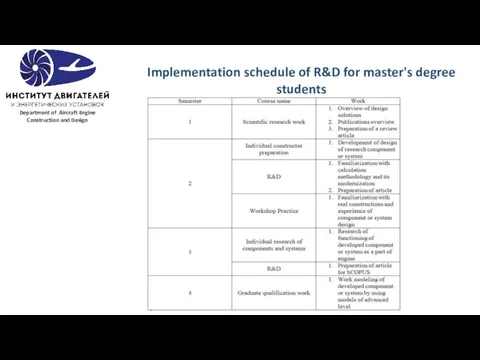

- 11. Implementation schedule of R&D for master's degree students Department of Aircraft Engine Construction and Design

- 12. Students research activities Department of Aircraft Engine Construction and Design

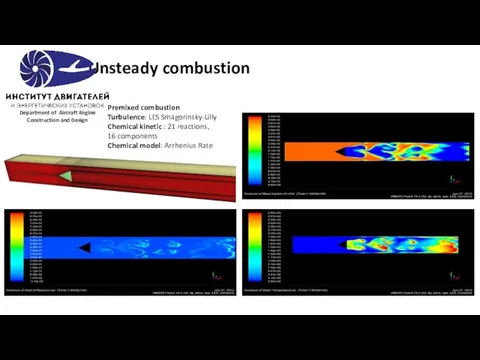

- 13. Unsteady combustion Premixed combustion Turbulence: LES Smagorinsky-Lilly Chemical kinetic : 21 reactions, 16 components Chemical model:

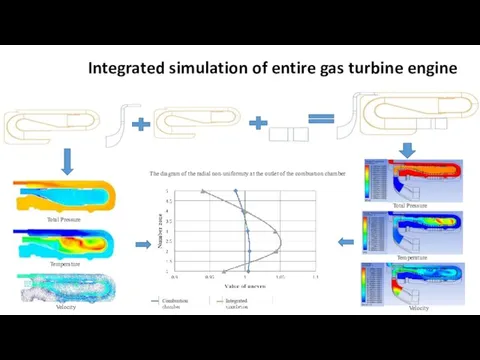

- 14. Integrated simulation of entire gas turbine engine Total Pressure Velocity Temperature The diagram of the radial

- 15. Optimization of mechanical and physico- chemical tough-to-machine material processing Simulation of machining process Simulation of electrochemical

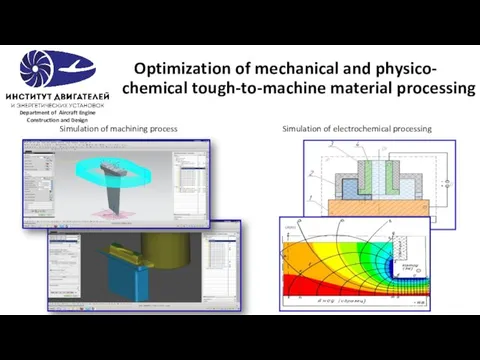

- 16. Variable guide vanes virtual testing bench piston sleeve Lever-crank pneumatic cylinder traction shaft drives Lever pin

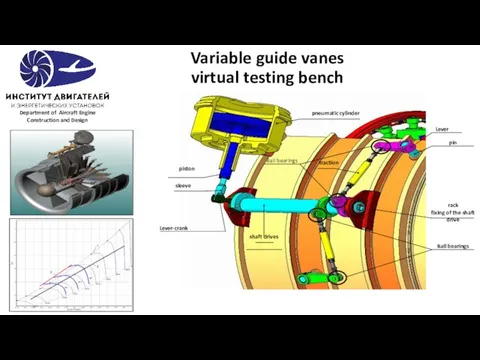

- 17. MODELLING OF SEALS Modeling of seals in a secondary air system Modeling of seals in a

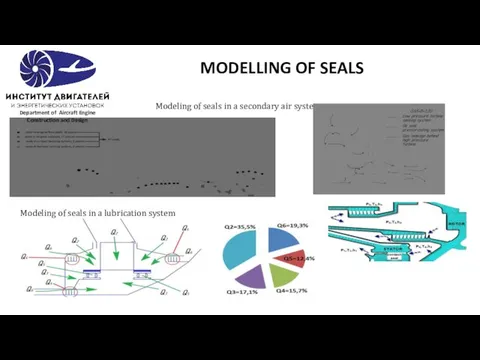

- 18. Creating 3D model of the controlled jet nozzle Three-dimensional models are used in to study dynamics

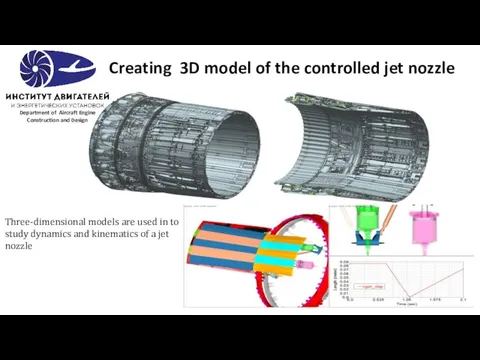

- 19. Master's program “Aircraft Engines and Power-Plants Designing" Example of framework of cooperative educational program Germany Universität

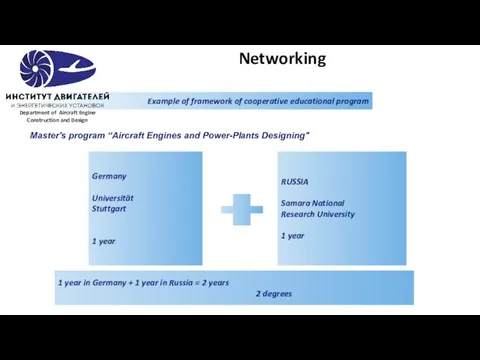

- 20. Master's program “Aircraft Engines and Power-Plants Designing" Example of framework of cooperative educational program China Nanjing

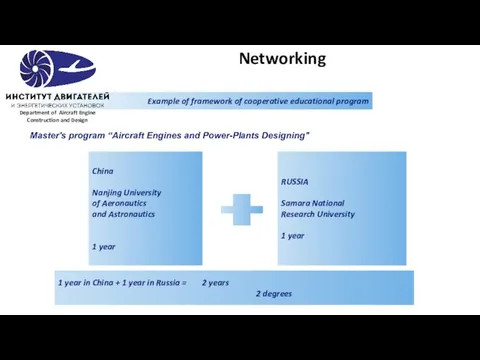

- 22. Скачать презентацию

Улучшение эффективных показателей автомобилей в АО Гордормостстрой при эксплуатации в условиях г. Киров

Улучшение эффективных показателей автомобилей в АО Гордормостстрой при эксплуатации в условиях г. Киров POZnan

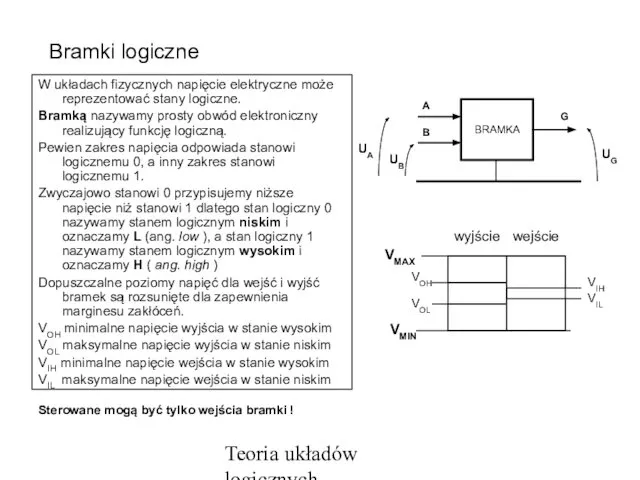

POZnan Bramki logiczne

Bramki logiczne УРОК

УРОК KXN95-50型全伺服折叠型口罩生产线PPT介绍20.02.24-终版

KXN95-50型全伺服折叠型口罩生产线PPT介绍20.02.24-终版 Экологические проблемы органических удобрений

Экологические проблемы органических удобрений Отчет по практике Организация видов работ при эксплуатации и реконструкции строительных объектов

Отчет по практике Организация видов работ при эксплуатации и реконструкции строительных объектов 20150611_nauchnaya_rabota_muzeya

20150611_nauchnaya_rabota_muzeya Материаловедение. Алюминиевые сплавы

Материаловедение. Алюминиевые сплавы Заготовка

Заготовка Двумерные объекты. Строение Раман-спектрометра

Двумерные объекты. Строение Раман-спектрометра Система кондиционирования воздуха

Система кондиционирования воздуха Комплекс учета энергоносителей Эмис-эско 2210

Комплекс учета энергоносителей Эмис-эско 2210 Изобразительное искусство

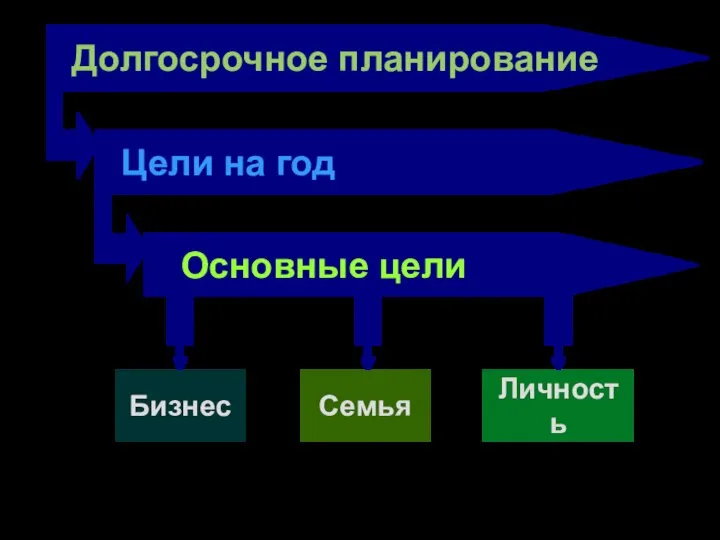

Изобразительное искусство Дневник Планирование

Дневник Планирование 20150405_lermontov

20150405_lermontov История и развитие ВГСЧ

История и развитие ВГСЧ Исследование условий внедрения инновационной технологии изготовления плазменного светильника на ФГУП ПСЗ

Исследование условий внедрения инновационной технологии изготовления плазменного светильника на ФГУП ПСЗ 20120923_prezentaciya_2_-_chast_1

20120923_prezentaciya_2_-_chast_1 Животноводство Тульской области

Животноводство Тульской области Число 10_31.03.2020

Число 10_31.03.2020 Первое Соборное послание святого апостола Петра. Глава 2

Первое Соборное послание святого апостола Петра. Глава 2 В гостях у сказки

В гостях у сказки Опорная электростанция

Опорная электростанция 20130217_griboedov

20130217_griboedov Пластинография. Аппликация - мозаика из шариков пластилина

Пластинография. Аппликация - мозаика из шариков пластилина Принципы управления персоналом

Принципы управления персоналом Оформление интерьеров Центров образования цифрового и гуманитарного профилей Точка роста

Оформление интерьеров Центров образования цифрового и гуманитарного профилей Точка роста