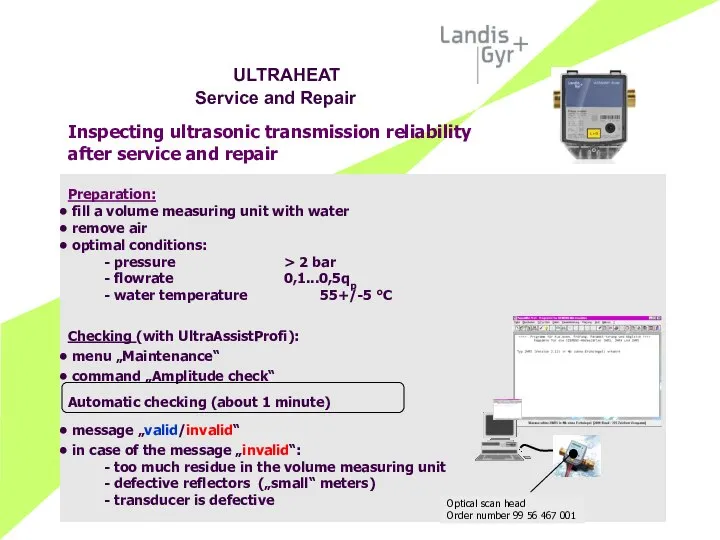

Inspecting ultrasonic transmission reliability

after service and repair

Preparation:

fill a volume

measuring unit with water

remove air

optimal conditions:

- pressure > 2 bar

- flowrate 0,1...0,5qp

- water temperature 55+/-5 °C

Checking (with UltraAssistProfi):

menu „Maintenance“

command „Amplitude check“

Automatic checking (about 1 minute)

message „valid/invalid“

in case of the message „invalid“:

- too much residue in the volume measuring unit

- defective reflectors („small“ meters)

- transducer is defective

ULTRAHEAT

Service and Repair

Optical scan head

Order number 99 56 467 001

Innovation and Change Example

Innovation and Change Example Полевые транзисторы. Часть 2

Полевые транзисторы. Часть 2 Конструкции и тепловая работа печей. Плавильные пламенные печи (Лекция 6)

Конструкции и тепловая работа печей. Плавильные пламенные печи (Лекция 6) Nordon magmatik jinslar

Nordon magmatik jinslar Грачи прилетели А.К.Саврасов

Грачи прилетели А.К.Саврасов Водопровод. Часть 3

Водопровод. Часть 3 10 сынып оқушысы

10 сынып оқушысы График зависимости ресурса сегментов от твердости наполнителя

График зависимости ресурса сегментов от твердости наполнителя Разбор олимпиадных задач

Разбор олимпиадных задач The Holy Spirit & Joy in Luke’s Gospel

The Holy Spirit & Joy in Luke’s Gospel Печатные системы с технологией термопереноса

Печатные системы с технологией термопереноса 20180703_36._algoritm_resheniya_ratsionalnogo_uravneniya

20180703_36._algoritm_resheniya_ratsionalnogo_uravneniya prilozhenie_1_k_zadaniyu_shablon_otcheta_dlya_zapolneniya_3

prilozhenie_1_k_zadaniyu_shablon_otcheta_dlya_zapolneniya_3 Библия и Евангелие. Древнееврейский язык

Библия и Евангелие. Древнееврейский язык Своя игра

Своя игра SOX_Shield_07th_

SOX_Shield_07th_ Религия как одна из форм культуры (обществознание, 8 класс)

Религия как одна из форм культуры (обществознание, 8 класс) 20150313_yakutiya_v_postsovetskiy_period

20150313_yakutiya_v_postsovetskiy_period 20131204_novye_sem_chudes

20131204_novye_sem_chudes 1С_Централизация ФХД 2.0 (1)

1С_Централизация ФХД 2.0 (1) Школа актива 01.04

Школа актива 01.04 19981__24184

19981__24184 Способы гашения дуги в электрических аппаратах

Способы гашения дуги в электрических аппаратах Нетрадиционные техники аппликации

Нетрадиционные техники аппликации Средневековый город

Средневековый город 2022.02.22 Стартовая встреча БСА-Т

2022.02.22 Стартовая встреча БСА-Т Средства организационной техники

Средства организационной техники f-e770038f

f-e770038f