Содержание

- 2. DC motor: Introduction Design Physical way a DC motor works and equations Characteristics of a DC

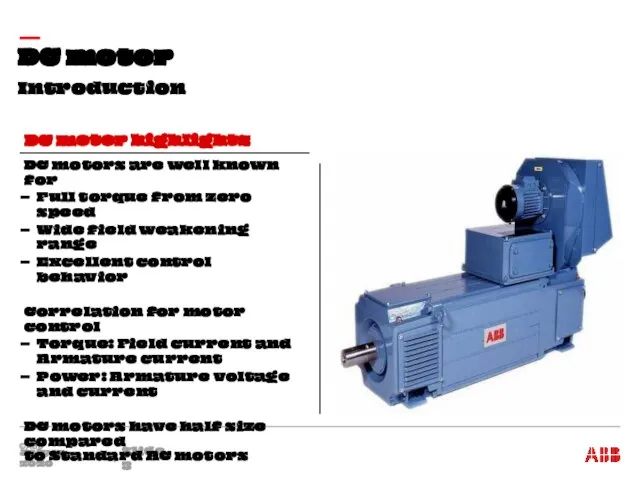

- 3. Introduction DC motor July 15, 2020 Slide DC motors are well known for Full torque from

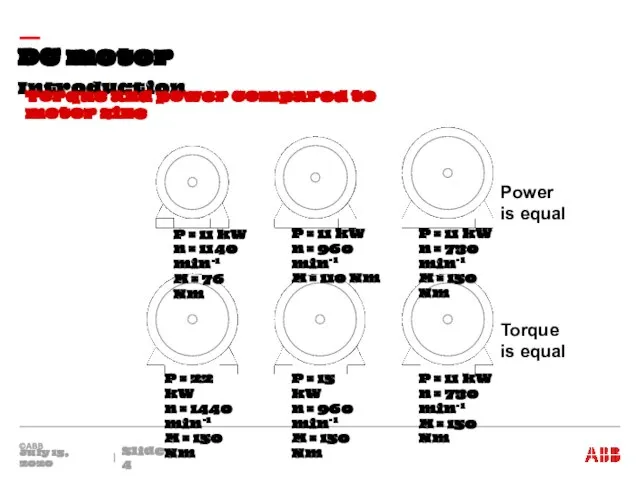

- 4. Introduction DC motor July 15, 2020 Slide Torque and power compared to motor size Power is

- 5. Design - Stator of a DC machine DC motor July 15, 2020 Slide Stator is the

- 6. Physical way a DC motor works DC motor July 15, 2020 Slide Stator of a 2

- 7. Physical way a DC motor works DC motor July 15, 2020 Slide Conductors have to be

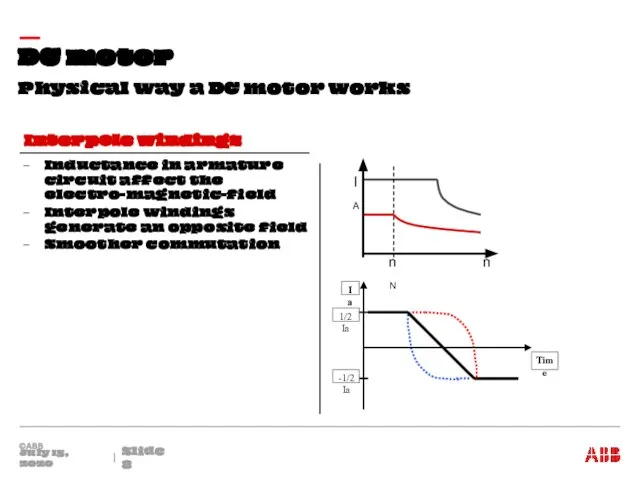

- 8. Physical way a DC motor works DC motor July 15, 2020 Slide Inductance in armature circuit

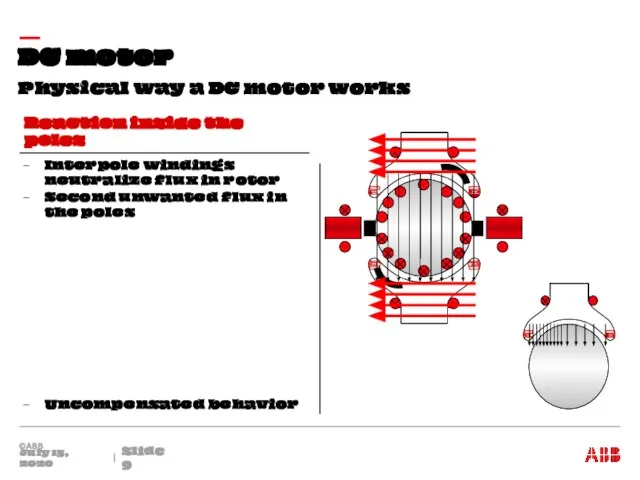

- 9. Physical way a DC motor works DC motor July 15, 2020 Slide Interpole windings neutralize flux

- 10. Physical way a DC motor works DC motor July 15, 2020 Slide Neutralizes effect of unwanted

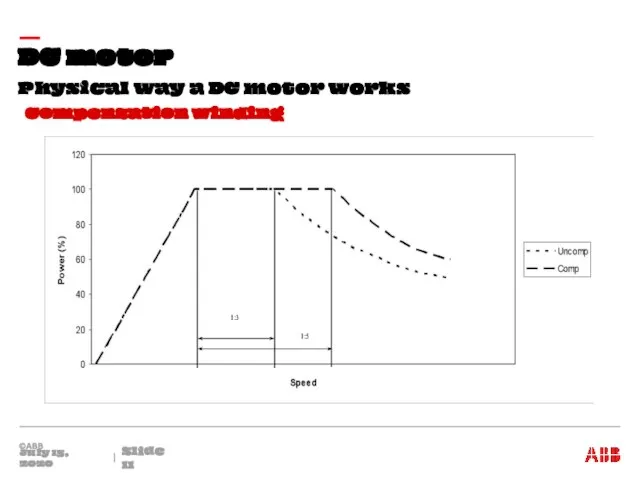

- 11. Physical way a DC motor works DC motor July 15, 2020 Slide Compensation winding

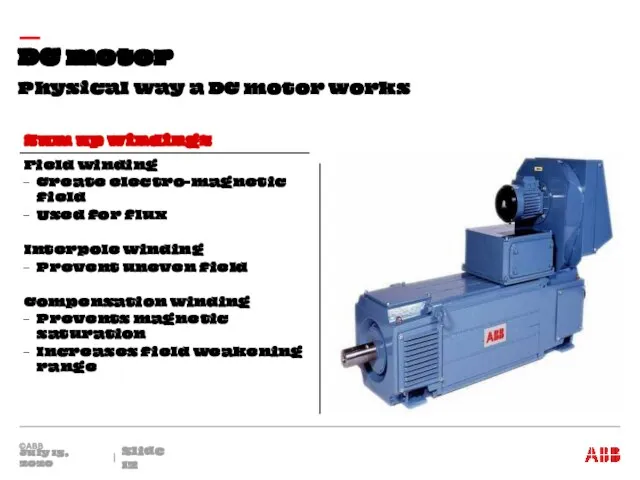

- 12. Physical way a DC motor works DC motor July 15, 2020 Slide Field winding Create electro-magnetic

- 13. Design DC motor July 15, 2020 Slide Shaft as center axis Armature winding Commutator connected with

- 14. Design DC motor July 15, 2020 Slide Commutator is used to transfer energy Fins are connected

- 15. Equations DC motor July 15, 2020 Slide Field circuit Armature circuit Circuit diagram Equations:

- 16. Drive’s characteristics DC motor July 15, 2020 Slide Characteristic of a DC machine Field weakening factor:

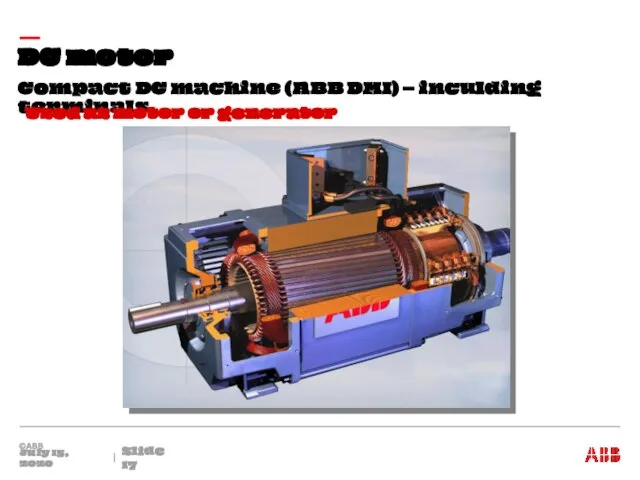

- 17. Compact DC machine (ABB DMI) – inculding terminals DC motor July 15, 2020 Slide Used as

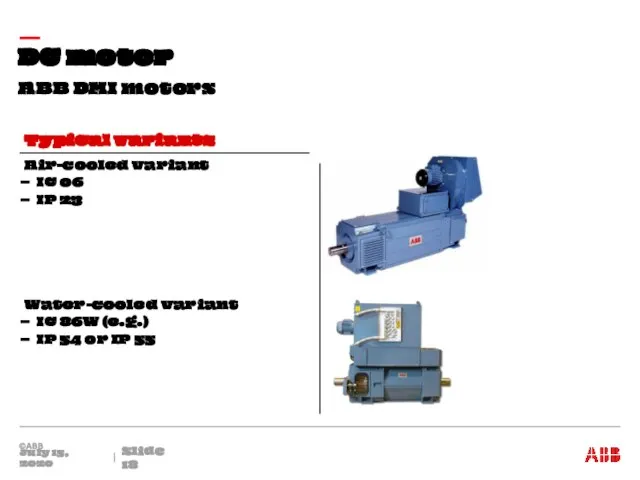

- 18. ABB DMI motors DC motor July 15, 2020 Slide Air-cooled variant IC 06 IP 23 Water-cooled

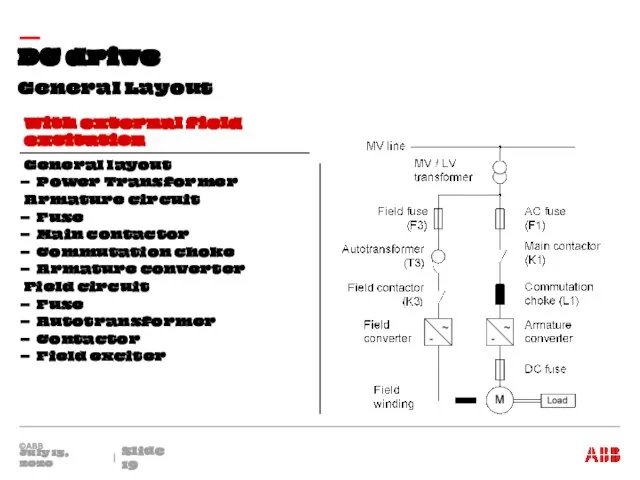

- 19. General Layout DC drive July 15, 2020 Slide General layout Power Transformer Armature circuit Fuse Main

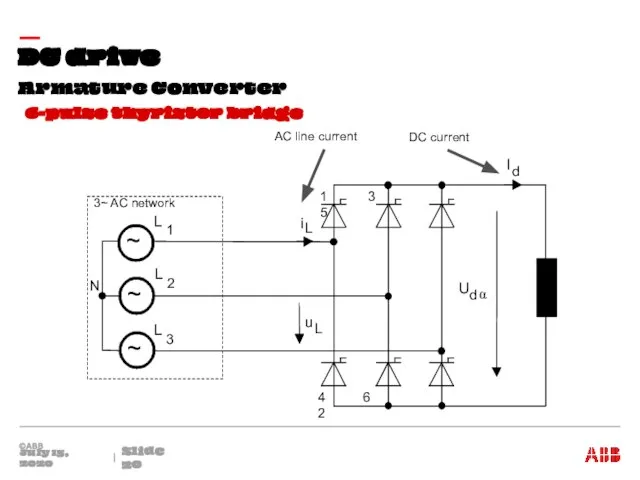

- 20. Armature Converter DC drive July 15, 2020 Slide 6-pulse thyristor bridge DC current AC line current

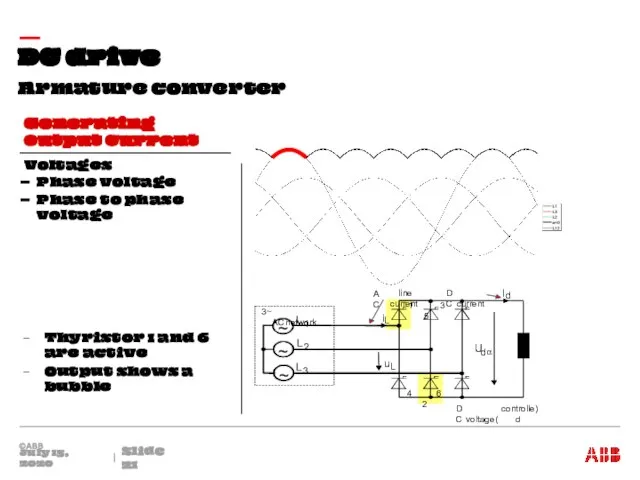

- 21. Armature converter DC drive July 15, 2020 Slide Voltages Phase voltage Phase to phase voltage Thyristor

- 22. Armature converter DC drive July 15, 2020 Slide 6-pulse thyristor bridge with a load Firing sequence:

- 23. Armature converter in “driving mode” DC drive July 15, 2020 Slide Positive voltage Firing angle smaller

- 24. Armature converter in “braking mode” DC drive July 15, 2020 Slide Negative voltage Firing angle greater

- 25. Armature converter in Shoot-through DC drive July 15, 2020 Slide DC drives are compromised by shoot-through

- 26. Line chokes Armature converter DC drive July 15, 2020 Slide Use of commutation chokes Mains Thyristor

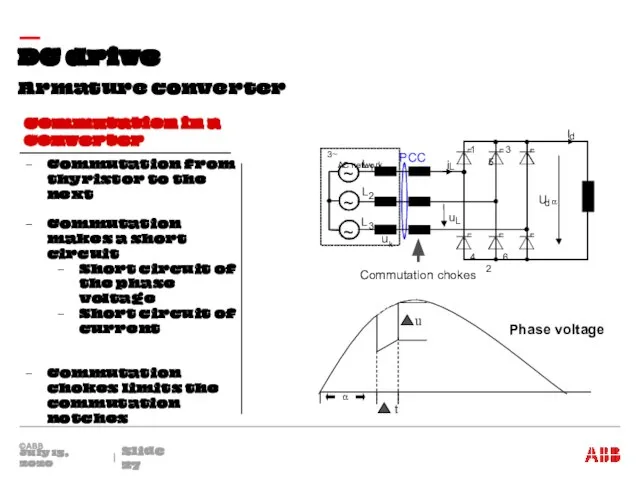

- 27. Armature converter DC drive July 15, 2020 Slide Commutation in a converter Commutation from thyristor to

- 28. Armature converter DC drive July 15, 2020 Slide Commutation chokes limits di / dt during short

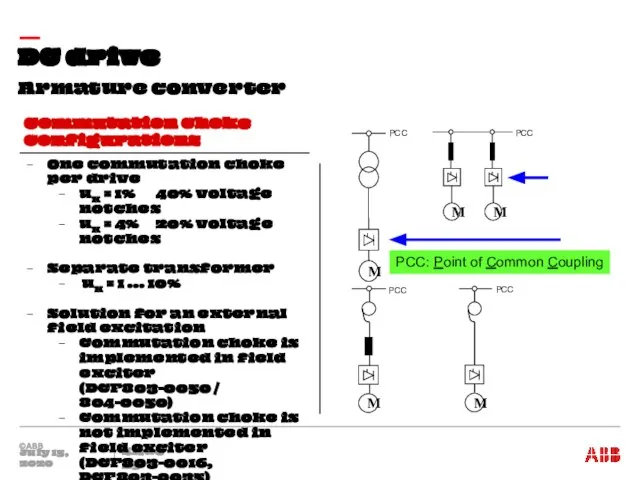

- 29. Armature converter DC drive July 15, 2020 Slide Commutation choke configurations PCC: Point of Common Coupling

- 30. Armature converter DC drive July 15, 2020 Slide Converter current in a DC drive Average current:

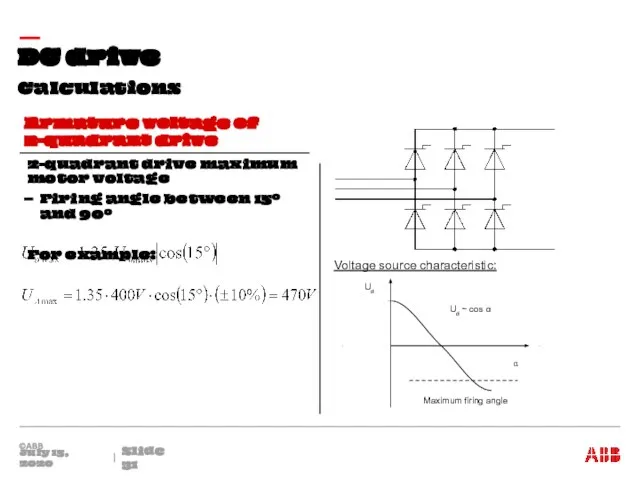

- 31. Calculations DC drive July 15, 2020 Slide Armature voltage of 2-quadrant drive 2-quadrant drive maximum motor

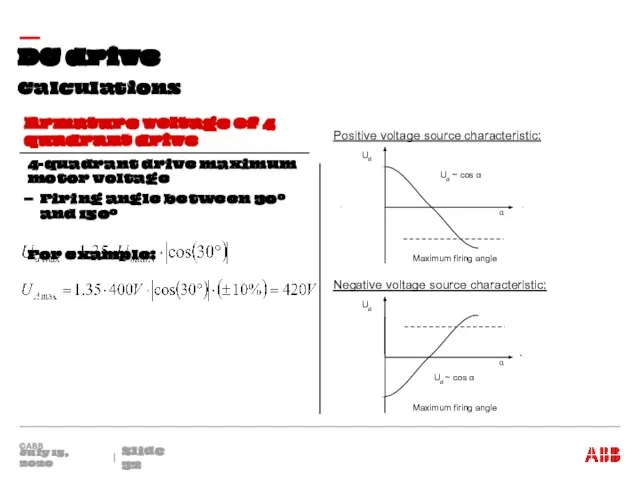

- 32. Calculations DC drive July 15, 2020 Slide Armature voltage of 4 quadrant drive 4-quadrant drive maximum

- 33. DC current and AC current Calculations DC drive July 15, 2020 Slide Calculate AC current with

- 34. Armature converter DC drive July 15, 2020 Slide Continuous and Discontinuous Armature Current Principle circuit diagram:

- 35. Max. regenerative voltage Armature converter DC drive July 15, 2020 Slide Usable working range of a

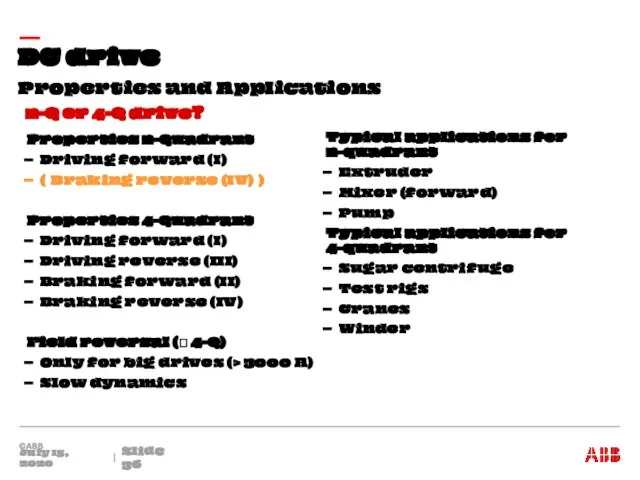

- 36. Properties and Applications DC drive July 15, 2020 Slide 2-Q or 4-Q drive? Properties 2-Quadrant Driving

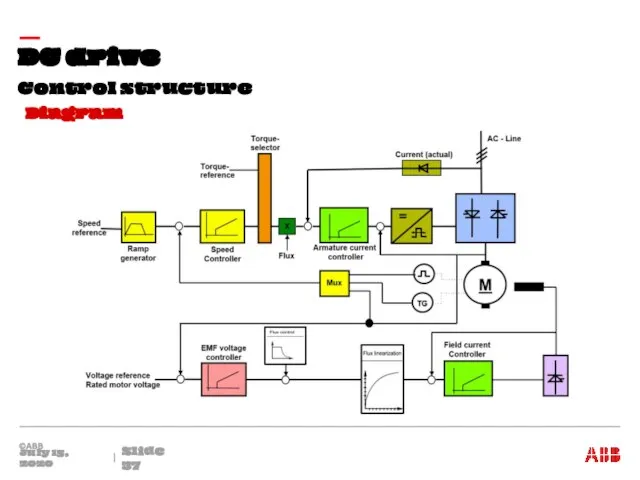

- 37. Control structure DC drive July 15, 2020 Slide Diagram

- 39. Скачать презентацию

Автоматизация производства в легкой промышленности

Автоматизация производства в легкой промышленности Беспроводные и 4-х проводные видеодомофоны, многоабонентские домофонные системы и системы сигнализаций

Беспроводные и 4-х проводные видеодомофоны, многоабонентские домофонные системы и системы сигнализаций Технология сверления заготовок на настольном сверлильном станке

Технология сверления заготовок на настольном сверлильном станке Пищеварение в тонкой и толстой кишке. Всасывание. Моторная функция пищеварительного тракта

Пищеварение в тонкой и толстой кишке. Всасывание. Моторная функция пищеварительного тракта 20171119_kompleknyy_analiz_teksta

20171119_kompleknyy_analiz_teksta Информация о городских новогодних и рождественских мероприятиях

Информация о городских новогодних и рождественских мероприятиях Понятие плитки и ее применение

Понятие плитки и ее применение Техника безопасности на производстве

Техника безопасности на производстве Платы макетно-отладочные

Платы макетно-отладочные Архитектура ПО

Архитектура ПО Казанский зооботсад

Казанский зооботсад Международная премия

Международная премия Ковровые изделия

Ковровые изделия Охранять природу – значит охранять Родину

Охранять природу – значит охранять Родину Жанры ИЗО для учащихся по программе Живопись. Рисунок 3 год обучения

Жанры ИЗО для учащихся по программе Живопись. Рисунок 3 год обучения 20160118_bludnyy_syn

20160118_bludnyy_syn Презентация Новый город финал

Презентация Новый город финал 20130316_dobroe_otnoshenie_k_okruzhayushchim_-_2_chast

20130316_dobroe_otnoshenie_k_okruzhayushchim_-_2_chast Гигиена жилища

Гигиена жилища Цвета флага ДНР

Цвета флага ДНР Экскурсия в Оружейную палату Московского кремля

Экскурсия в Оружейную палату Московского кремля 20120301_longfello111

20120301_longfello111 8 марта 2014

8 марта 2014 20120328_prava_i_polnomochiya_glavy_gosudarstva

20120328_prava_i_polnomochiya_glavy_gosudarstva Эскизная компоновка зубчатого редуктора. Редуктор цилиндрический одноступенчатый горизонтальный

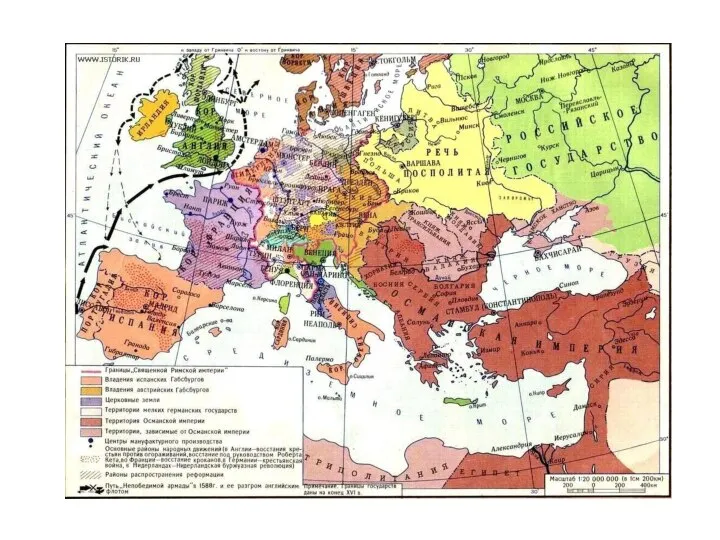

Эскизная компоновка зубчатого редуктора. Редуктор цилиндрический одноступенчатый горизонтальный 20160215_novoe_i_noveyshee_vremya

20160215_novoe_i_noveyshee_vremya 20170125_my_so_zvukom_ch_igraem_

20170125_my_so_zvukom_ch_igraem_ Арматура и арматурные изделия

Арматура и арматурные изделия