Содержание

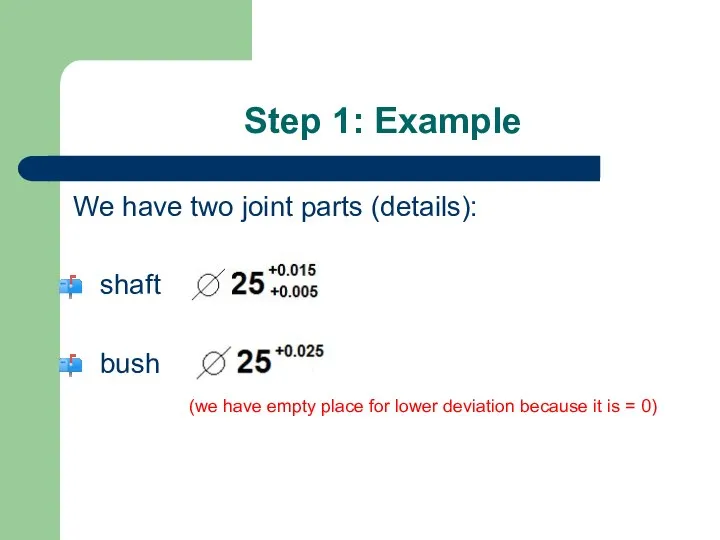

- 2. Step 1: Example We have two joint parts (details): shaft bush (we have empty place for

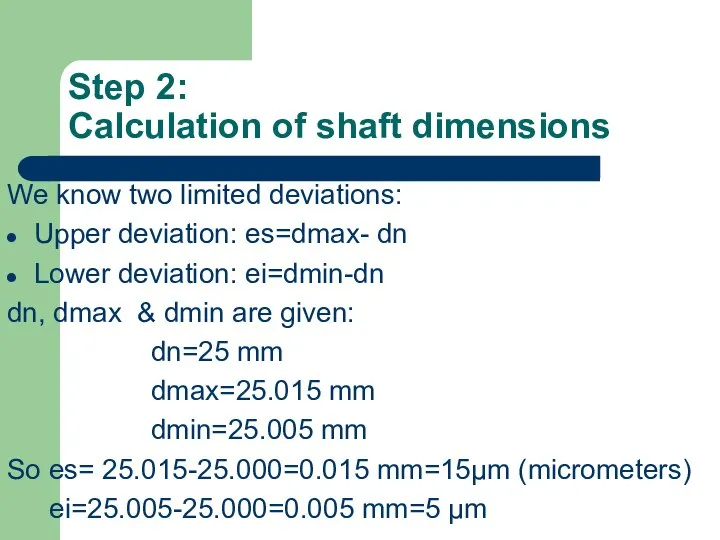

- 3. Step 2: Calculation of shaft dimensions We know two limited deviations: Upper deviation: es=dmax- dn Lower

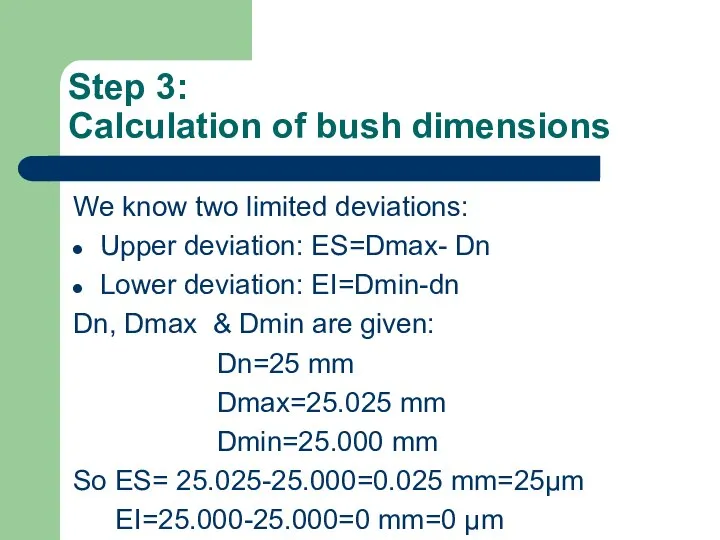

- 4. Step 3: Calculation of bush dimensions We know two limited deviations: Upper deviation: ES=Dmax- Dn Lower

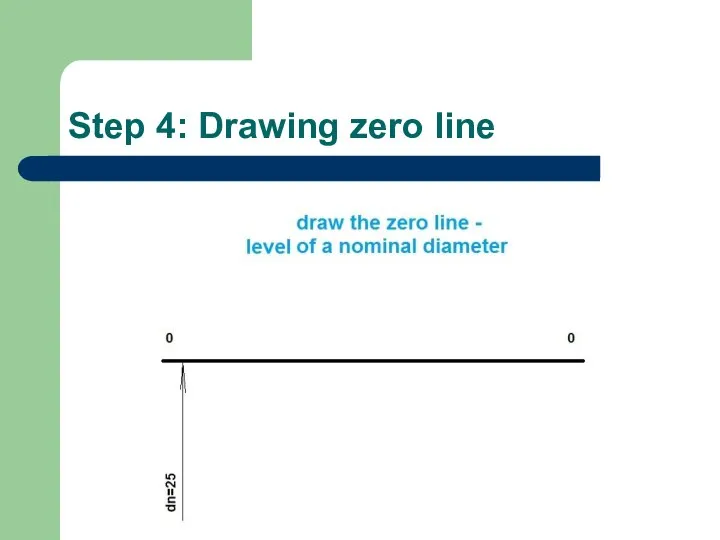

- 5. Step 4: Drawing zero line

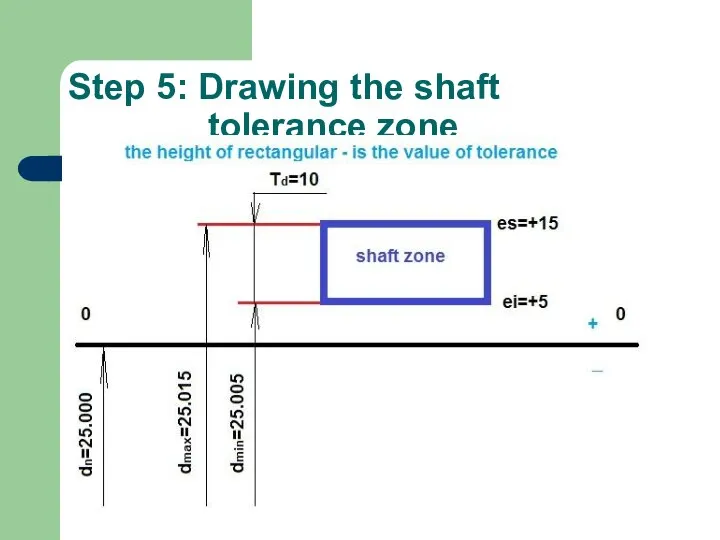

- 6. Step 5: Drawing the shaft tolerance zone

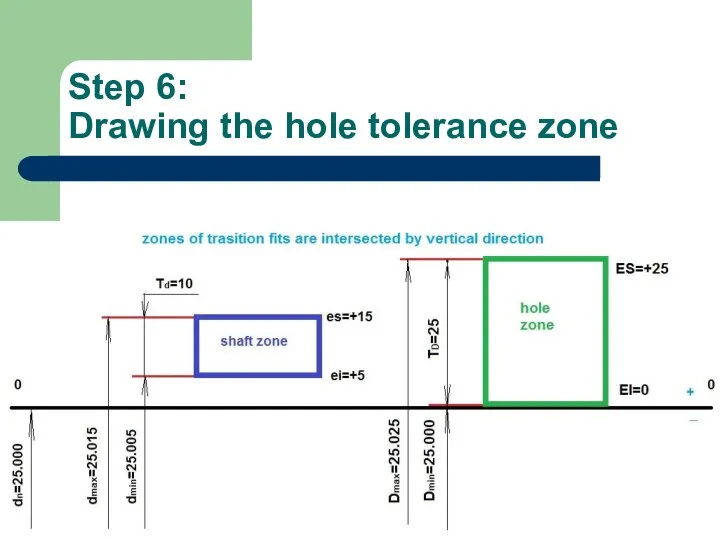

- 7. Step 6: Drawing the hole tolerance zone

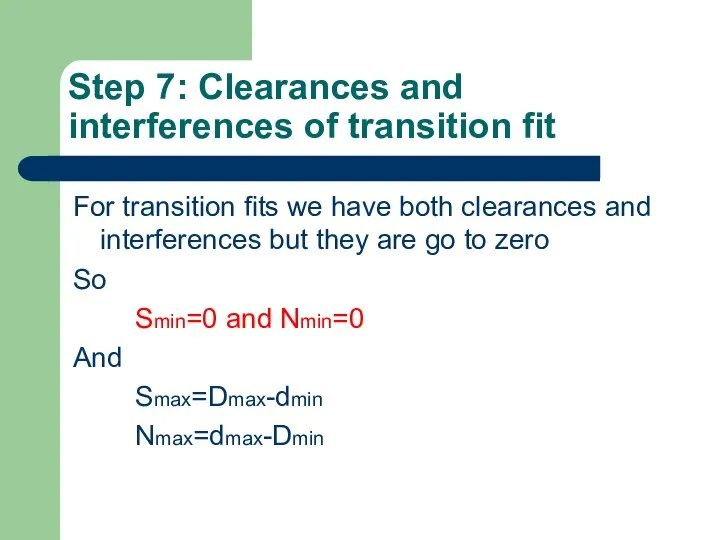

- 8. Step 7: Clearances and interferences of transition fit For transition fits we have both clearances and

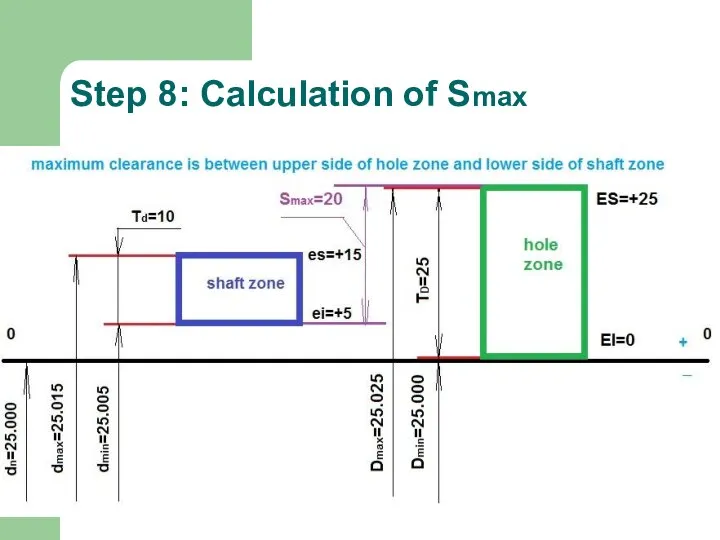

- 9. Step 8: Calculation of Smax

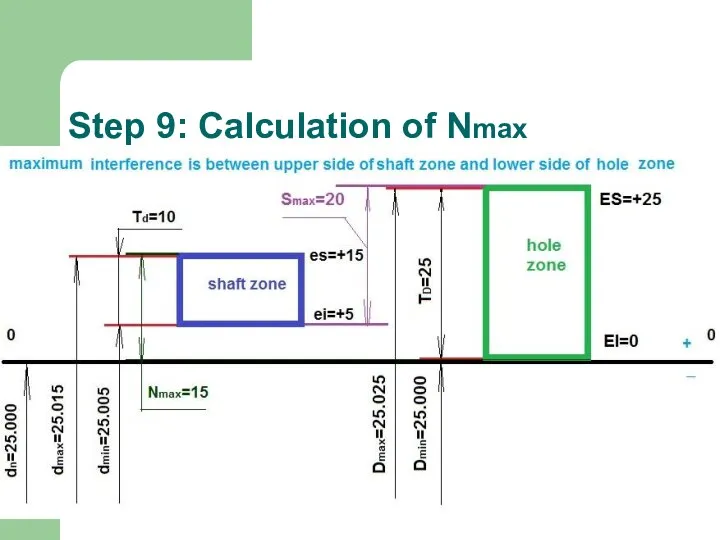

- 10. Step 9: Calculation of Nmax

- 12. Скачать презентацию

Правка тонколистового металла и проволоки

Правка тонколистового металла и проволоки От воспоминаний всем теплей, нам от них нельзя не улыбнуться

От воспоминаний всем теплей, нам от них нельзя не улыбнуться 20150121_logopedicheskoe_zanyatie._analiz_i_redaktirovanie_pismennykh_rabot

20150121_logopedicheskoe_zanyatie._analiz_i_redaktirovanie_pismennykh_rabot Не торопи меня, мой календарь

Не торопи меня, мой календарь Письмо для Вани Жукова

Письмо для Вани Жукова Igra_po_finansam

Igra_po_finansam Курсовая работа

Курсовая работа Керамические стеновые материалы

Керамические стеновые материалы Проект Музейная цифровая лаборатория

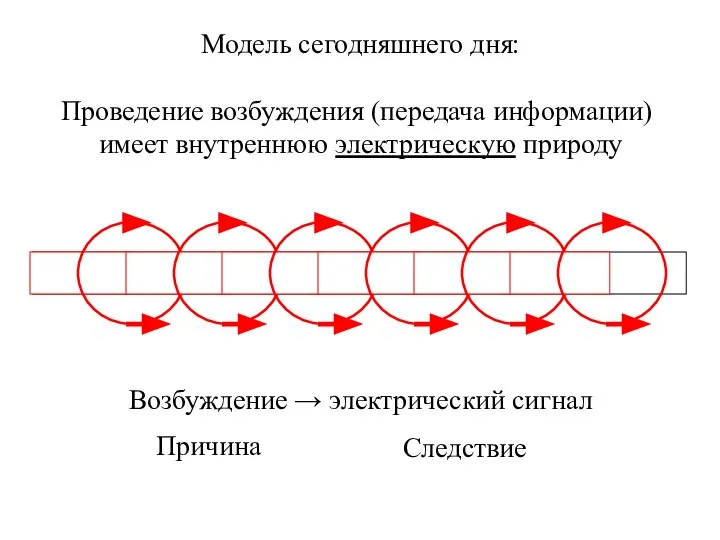

Проект Музейная цифровая лаборатория Импульсный ток

Импульсный ток Епархиальный фестиваль-конкурс фольклорного творчества свет рождествеской звезды

Епархиальный фестиваль-конкурс фольклорного творчества свет рождествеской звезды Зеленый шаблон. Российское общество Знание

Зеленый шаблон. Российское общество Знание продолжение

продолжение Используемые инструменты. Виды клеев

Используемые инструменты. Виды клеев Православные святыни и святые Курской земли

Православные святыни и святые Курской земли Микросхемотехника. Занятие № 34

Микросхемотехника. Занятие № 34 20131219_mezhdunarodnye_otnosheniya_0

20131219_mezhdunarodnye_otnosheniya_0 Современное состояние и перспективы развития глемпинга на территории России

Современное состояние и перспективы развития глемпинга на территории России Заявка на участие в отборе перспективных биотехнологических проектов. Шаблон

Заявка на участие в отборе перспективных биотехнологических проектов. Шаблон презентация 2

презентация 2 презентация

презентация “Базові команди адміністрування ОС.”

“Базові команди адміністрування ОС.” 01-intr

01-intr HollySys PLC Introduction-V1.2-Русский

HollySys PLC Introduction-V1.2-Русский Вязание домика крючком

Вязание домика крючком Фейковые новости: кто привлекается к ответственности за их распространение

Фейковые новости: кто привлекается к ответственности за их распространение 20130321_frebel_0

20130321_frebel_0 Основы технологических процессов в художественном производстве (Практические занятия)

Основы технологических процессов в художественном производстве (Практические занятия)