Содержание

- 2. Centravis Profile My Career at Centravis 09/2011 06/2012 Trainee Operator assistant Operator of the 5th category

- 3. Key Stages of Research Analysis of product range of the mill. Analysis of HPT-55’s equipment and

- 4. Analysis of Product Range of the Mill DT ☓ ST = 25 ☓ 2 mm sized

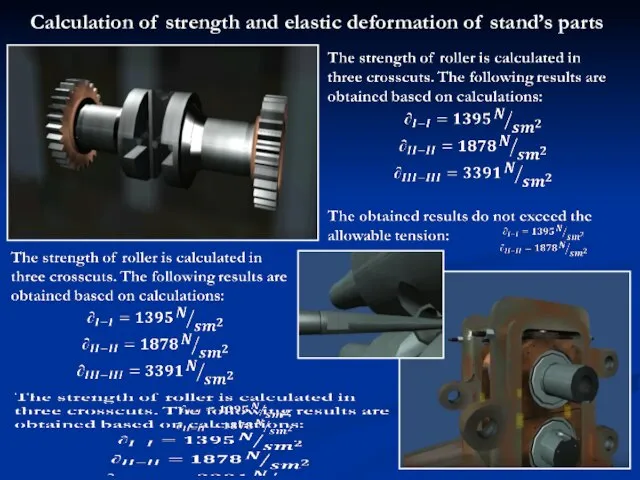

- 6. Calculation of strength and elastic deformation of stand’s parts

- 8. Скачать презентацию

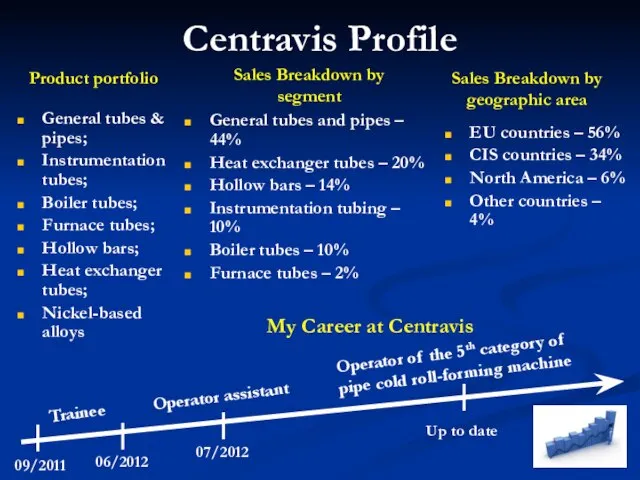

Centravis Profile

My Career at Centravis

09/2011

06/2012

Trainee

Operator assistant

Operator of the 5th category of

Centravis Profile

My Career at Centravis

09/2011

06/2012

Trainee

Operator assistant

Operator of the 5th category of

07/2012

Up to date

General tubes & pipes;

Instrumentation tubes;

Boiler tubes;

Furnace tubes;

Hollow bars;

Heat exchanger tubes;

Nickel-based alloys

Product portfolio

Sales Breakdown by segment

General tubes and pipes – 44%

Heat exchanger tubes – 20%

Hollow bars – 14%

Instrumentation tubing – 10%

Boiler tubes – 10%

Furnace tubes – 2%

Sales Breakdown by geographic area

EU countries – 56%

CIS countries – 34%

North America – 6%

Other countries – 4%

Key Stages of Research

Analysis of product range of the mill.

Analysis of

Key Stages of Research

Analysis of product range of the mill.

Analysis of

Justification of rational technology and facilities in process of product manufacturing.

Calculating the calibration of HPT-55’s working tool.

Calculation of strength and elastic deformation of stand’s parts.

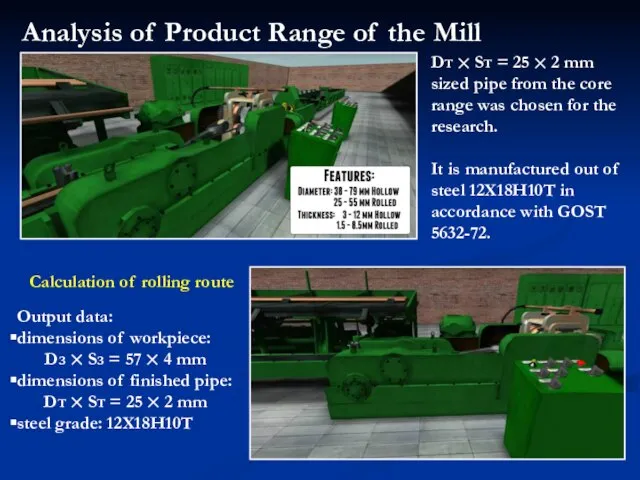

Analysis of Product Range of the Mill

DT ☓ ST = 25

Analysis of Product Range of the Mill

DT ☓ ST = 25

It is manufactured out of steel 12X18H10T in accordance with GOST 5632-72.

Calculation of rolling route

Output data:

dimensions of workpiece:

DЗ ☓ SЗ = 57 ☓ 4 mm

dimensions of finished pipe:

DT ☓ ST = 25 ☓ 2 mm

steel grade: 12Х18Н10Т

Calculation of strength and elastic deformation of stand’s parts

Calculation of strength and elastic deformation of stand’s parts

Студент в среде электронного обучения. Работы для добора баллов

Студент в среде электронного обучения. Работы для добора баллов Система смазки двигателя внутреннего сгорания

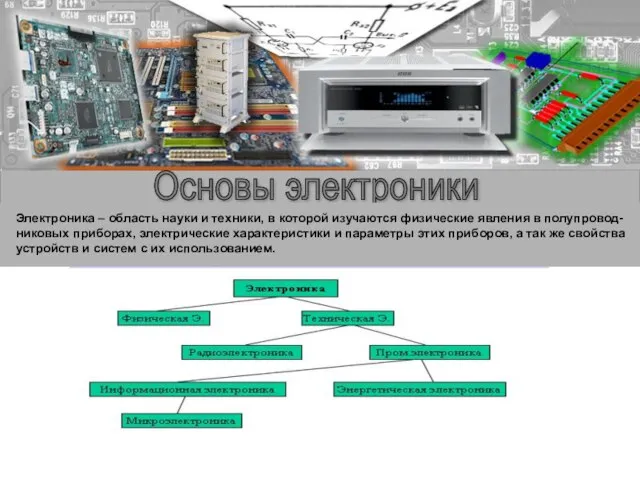

Система смазки двигателя внутреннего сгорания Электроника, как область науки и техники

Электроника, как область науки и техники Бастауышпен қоштасатын кез келді! 2019- 2022 жыл

Бастауышпен қоштасатын кез келді! 2019- 2022 жыл Секреторная функция пищеварительных желёз

Секреторная функция пищеварительных желёз Рэлігія – вера чалавека ў звышнатуральныя сілы

Рэлігія – вера чалавека ў звышнатуральныя сілы грязовецкая

грязовецкая Звукозапись. Носители звукозаписи

Звукозапись. Носители звукозаписи Святые земли русской. Стефан Пермский – просветитель на Коми земле

Святые земли русской. Стефан Пермский – просветитель на Коми земле Osaamiskansio

Osaamiskansio Выбор участка для строительства животноводческого предприятия

Выбор участка для строительства животноводческого предприятия Отчет по Атырауской области

Отчет по Атырауской области Схемотехника аналоговых электронных устройств

Схемотехника аналоговых электронных устройств Школьное научное общество Паллада

Школьное научное общество Паллада 10 правил здорового образа жизни

10 правил здорового образа жизни 1 апреля – международный День Птиц!

1 апреля – международный День Птиц! Правоотношения

Правоотношения Фотографии

Фотографии Повірка засобів вимірювальної техніки електричних та магнітних величин. Калібрування електричних мір

Повірка засобів вимірювальної техніки електричних та магнітних величин. Калібрування електричних мір А. П. Платонов Цветок на земле

А. П. Платонов Цветок на земле Василь Стус. Дорога через терни до зірок…

Василь Стус. Дорога через терни до зірок… Искусственные основания. Геотехника II. Лекция 24-25

Искусственные основания. Геотехника II. Лекция 24-25 лекция 2 - презентация

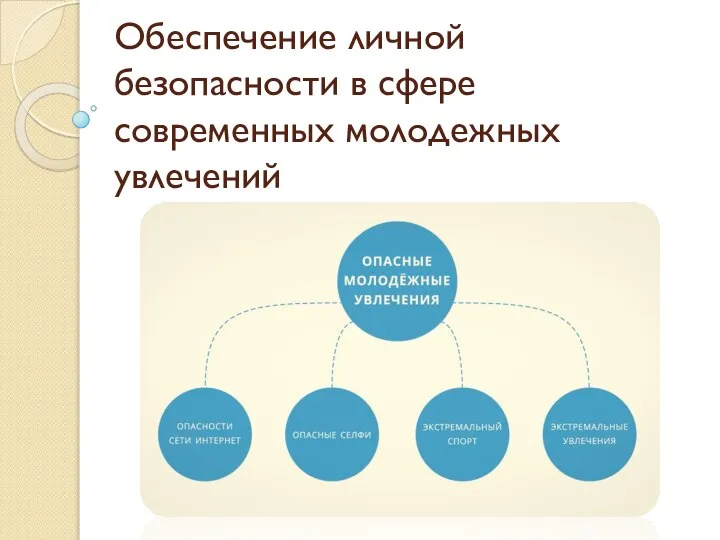

лекция 2 - презентация Обеспечение личной безопасности в сфере современных молодежных увлечений

Обеспечение личной безопасности в сфере современных молодежных увлечений 20120818_kopiya_kak_poyavilis_rycarskie_dospehi

20120818_kopiya_kak_poyavilis_rycarskie_dospehi Электричество. Откуда в наш дом приходит электричество?

Электричество. Откуда в наш дом приходит электричество? То, чем я живу

То, чем я живу Техника художественной обработки ткани и текстильных материалов

Техника художественной обработки ткани и текстильных материалов