Содержание

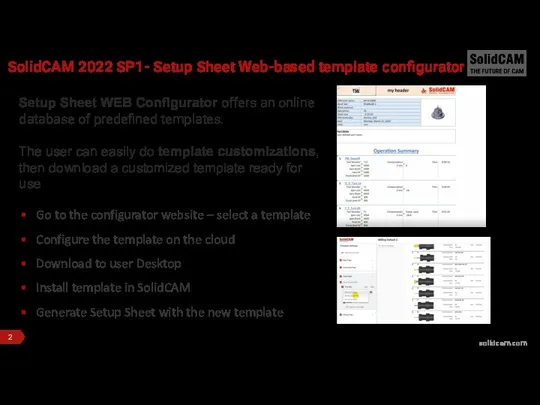

- 2. SolidCAM 2022 SP1- Setup Sheet Web-based template configurator Setup Sheet WEB Configurator offers an online database

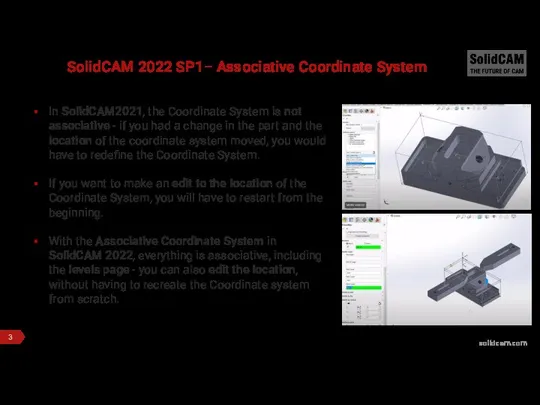

- 3. SolidCAM 2022 SP1– Associative Coordinate System In SolidCAM2021, the Coordinate System is not associative - if

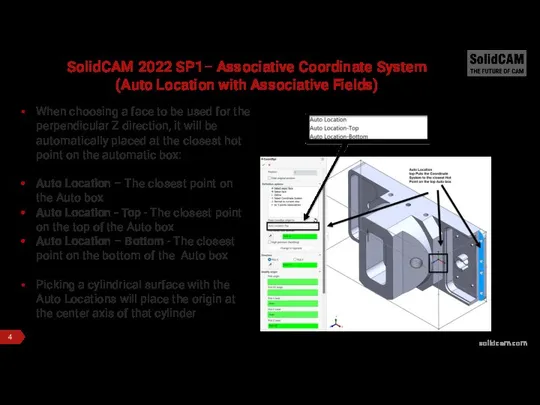

- 4. SolidCAM 2022 SP1– Associative Coordinate System (Auto Location with Associative Fields) When choosing a face to

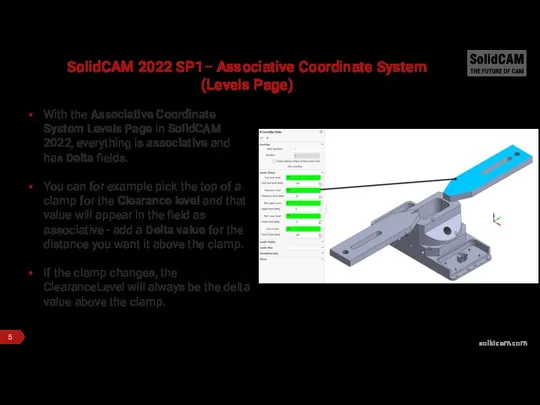

- 5. SolidCAM 2022 SP1– Associative Coordinate System (Levels Page) With the Associative Coordinate System Levels Page in

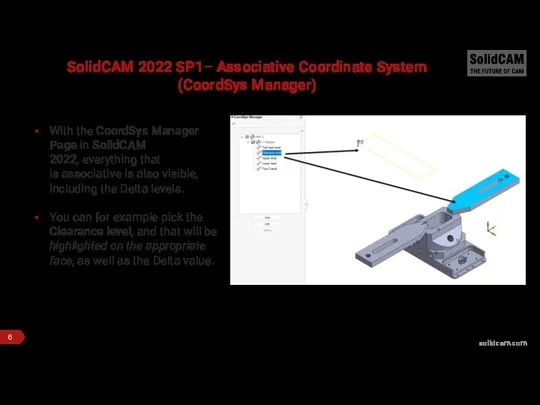

- 6. SolidCAM 2022 SP1– Associative Coordinate System (CoordSys Manager) With the CoordSys Manager Page in SolidCAM 2022,

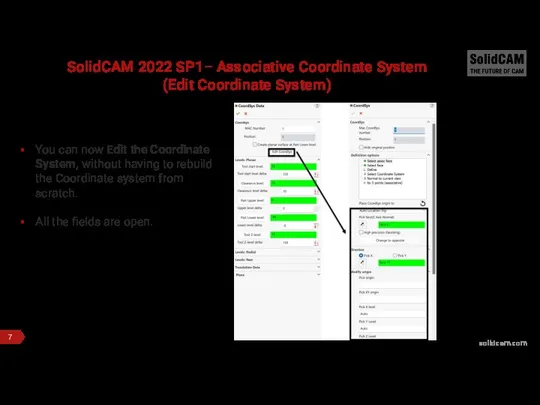

- 7. SolidCAM 2022 SP1– Associative Coordinate System (Edit Coordinate System) You can now Edit the Coordinate System,

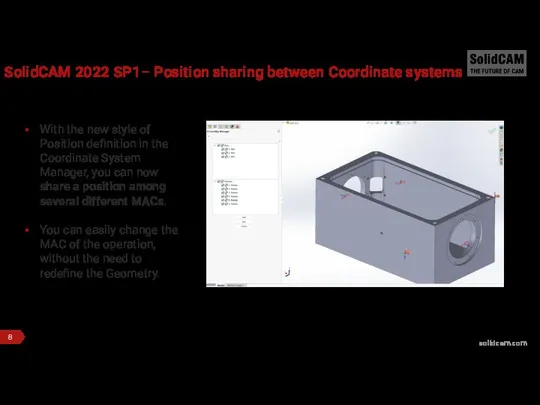

- 8. SolidCAM 2022 SP1– Position sharing between Coordinate systems With the new style of Position definition in

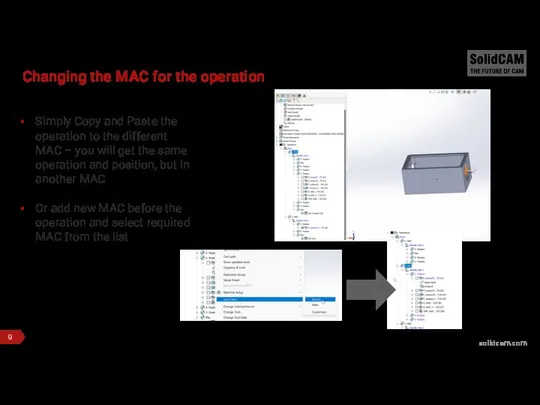

- 9. Changing the MAC for the operation Simply Copy and Paste the operation to the different MAC

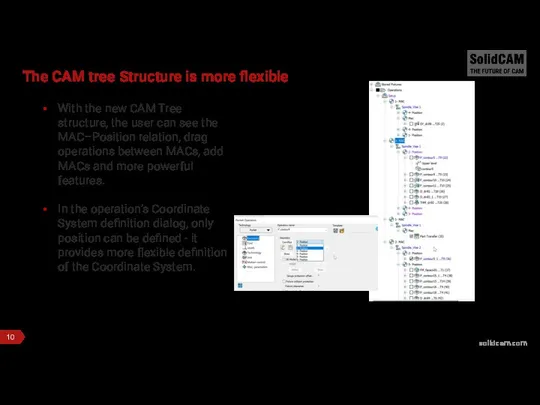

- 10. The CAM tree Structure is more flexible With the new CAM Tree structure, the user can

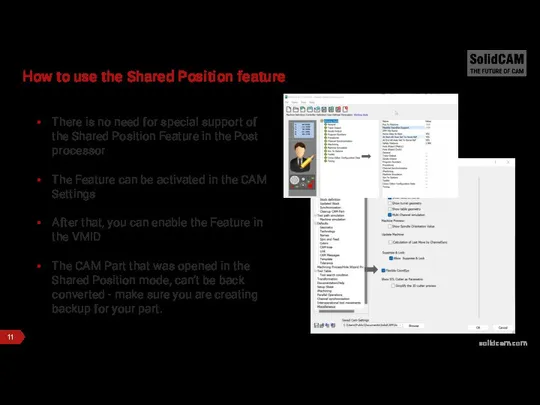

- 11. How to use the Shared Position feature There is no need for special support of the

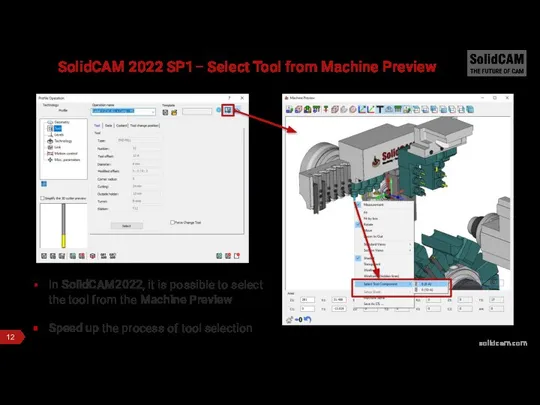

- 12. SolidCAM 2022 SP1– Select Tool from Machine Preview In SolidCAM2022, it is possible to select the

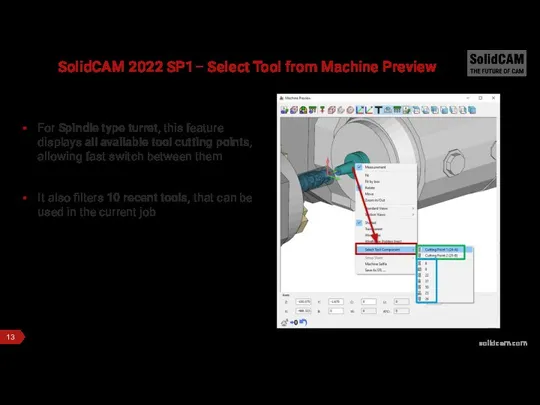

- 13. SolidCAM 2022 SP1– Select Tool from Machine Preview For Spindle type turret, this feature displays all

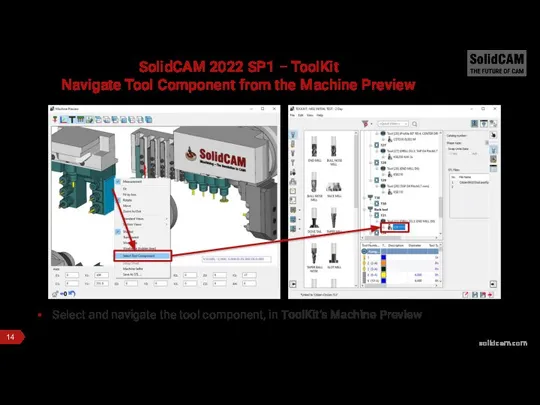

- 14. SolidCAM 2022 SP1 – ToolKit Navigate Tool Component from the Machine Preview Select and navigate the

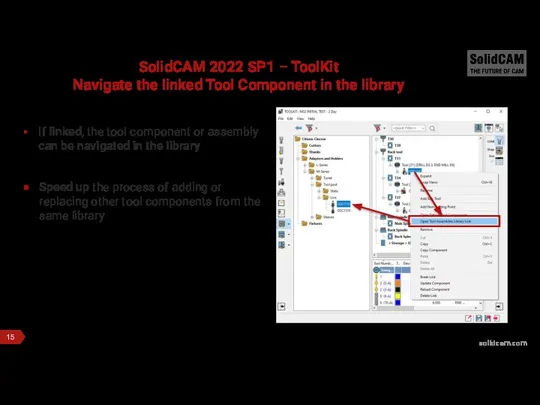

- 15. SolidCAM 2022 SP1 – ToolKit Navigate the linked Tool Component in the library If linked, the

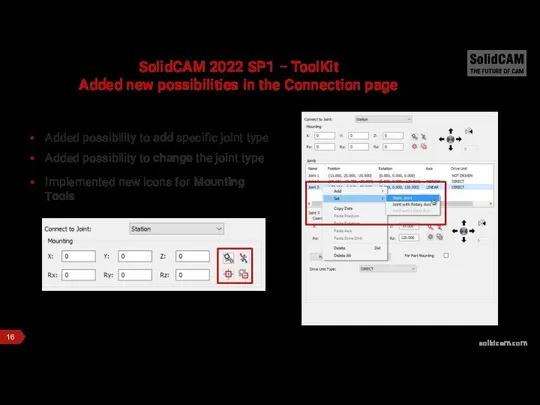

- 16. SolidCAM 2022 SP1 – ToolKit Added new possibilities in the Connection page Added possibility to add

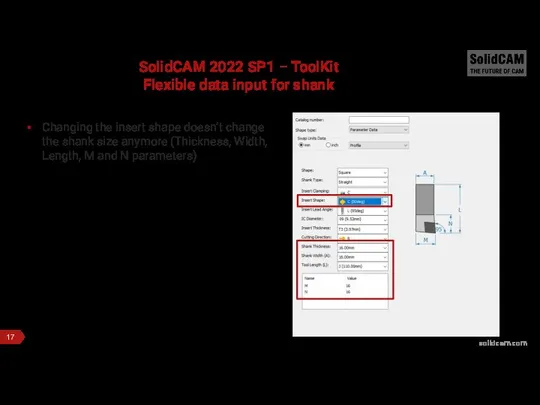

- 17. SolidCAM 2022 SP1 – ToolKit Flexible data input for shank Changing the insert shape doesn’t change

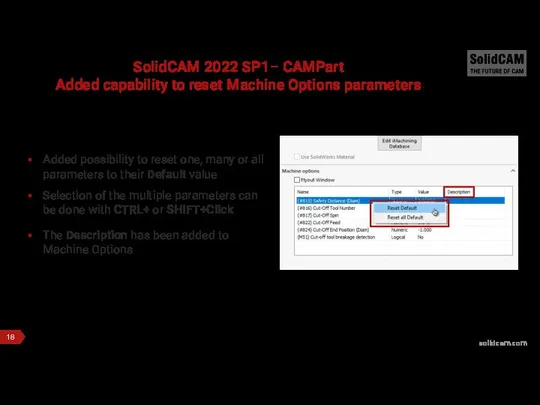

- 18. SolidCAM 2022 SP1– CAMPart Added capability to reset Machine Options parameters Added possibility to reset one,

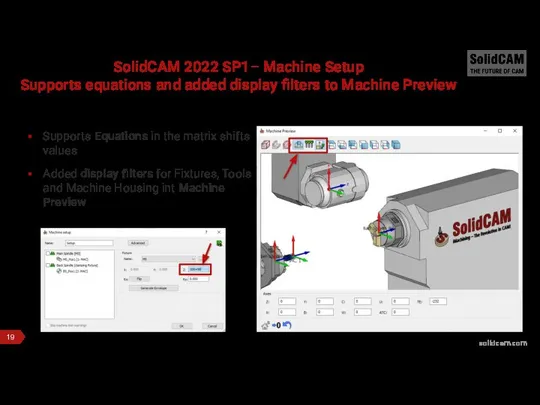

- 19. SolidCAM 2022 SP1– Machine Setup Supports equations and added display filters to Machine Preview Supports Equations

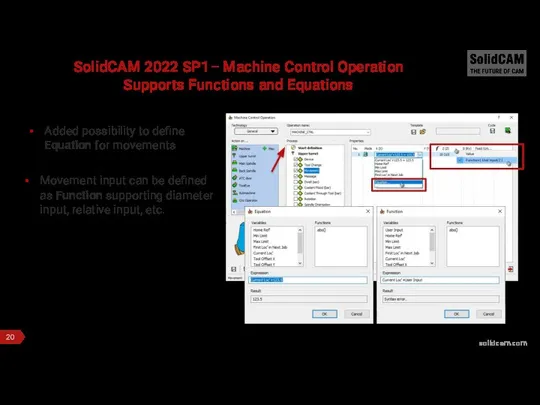

- 20. SolidCAM 2022 SP1– Machine Control Operation Supports Functions and Equations Added possibility to define Equation for

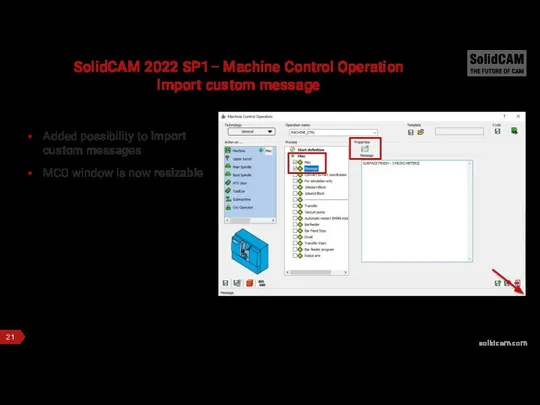

- 21. SolidCAM 2022 SP1– Machine Control Operation Import custom message Added possibility to import custom messages MCO

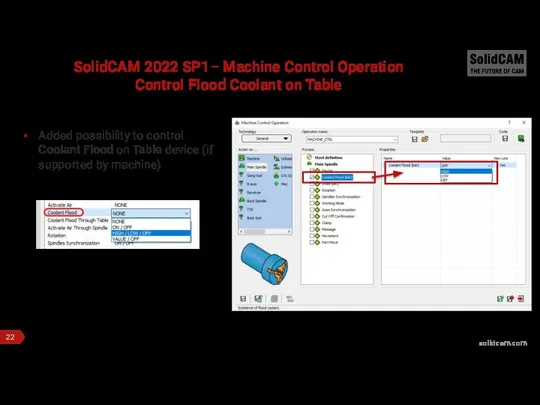

- 22. SolidCAM 2022 SP1– Machine Control Operation Control Flood Coolant on Table Added possibility to control Coolant

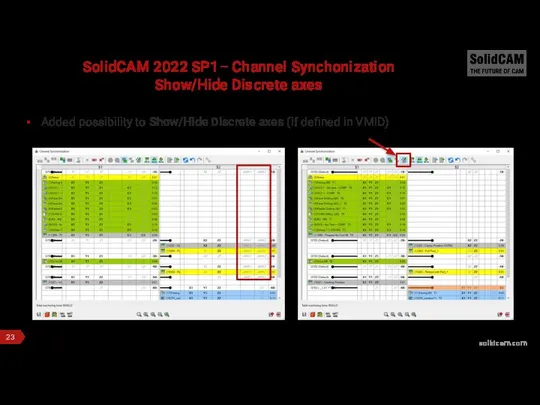

- 23. SolidCAM 2022 SP1– Channel Synchonization Show/Hide Discrete axes Added possibility to Show/Hide Discrete axes (if defined

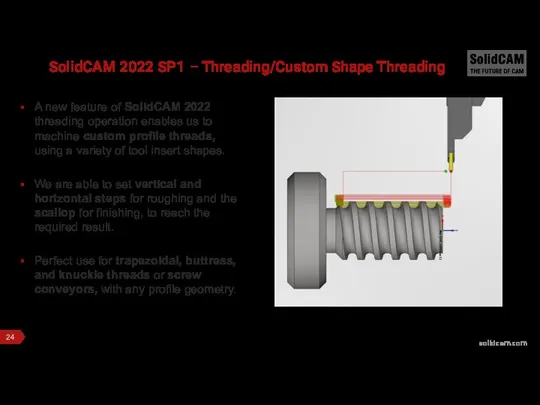

- 24. SolidCAM 2022 SP1 – Threading/Custom Shape Threading A new feature of SolidCAM 2022 threading operation enables

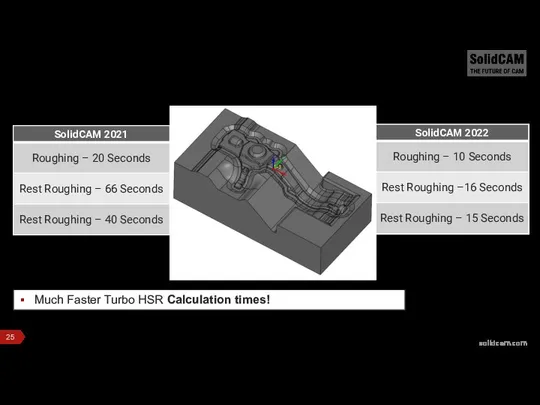

- 25. Much Faster Turbo HSR Calculation times!

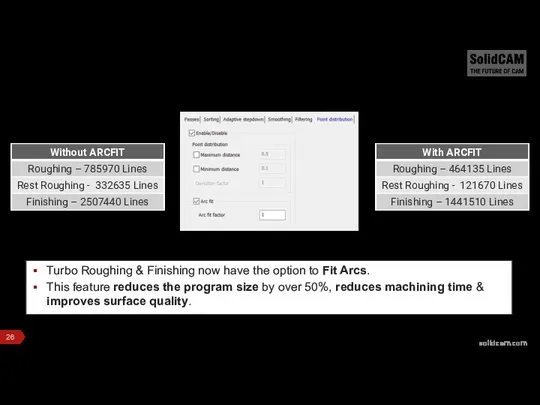

- 26. Turbo Roughing & Finishing now have the option to Fit Arcs. This feature reduces the program

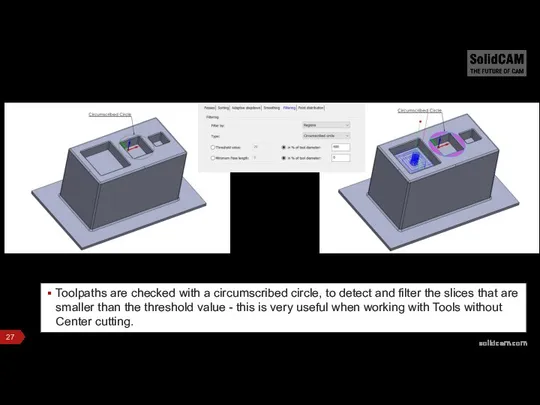

- 27. Toolpaths are checked with a circumscribed circle, to detect and filter the slices that are smaller

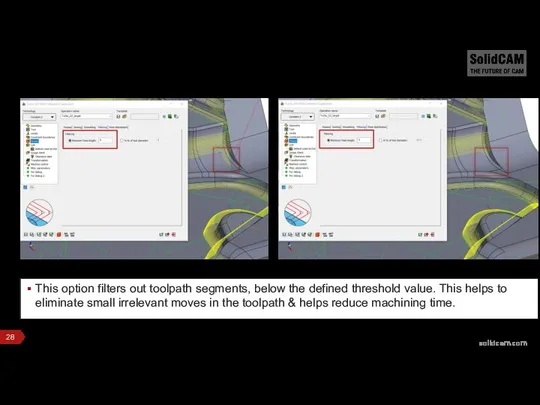

- 28. This option filters out toolpath segments, below the defined threshold value. This helps to eliminate small

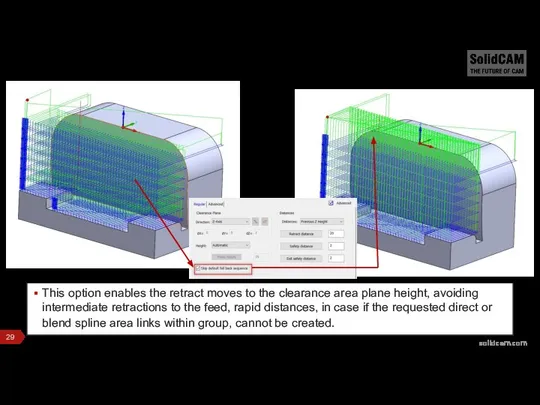

- 29. This option enables the retract moves to the clearance area plane height, avoiding intermediate retractions to

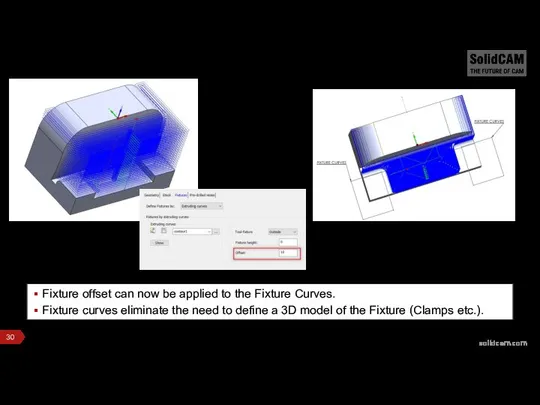

- 30. Fixture offset can now be applied to the Fixture Curves. Fixture curves eliminate the need to

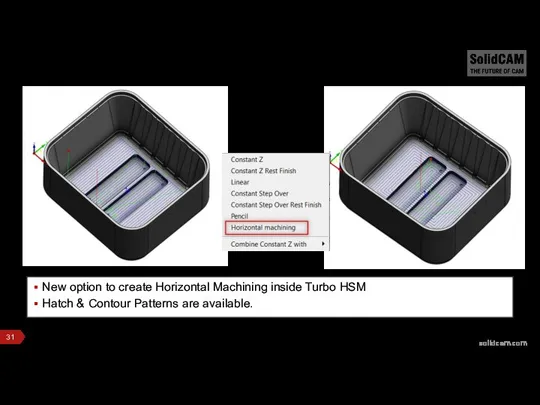

- 31. New option to create Horizontal Machining inside Turbo HSM Hatch & Contour Patterns are available.

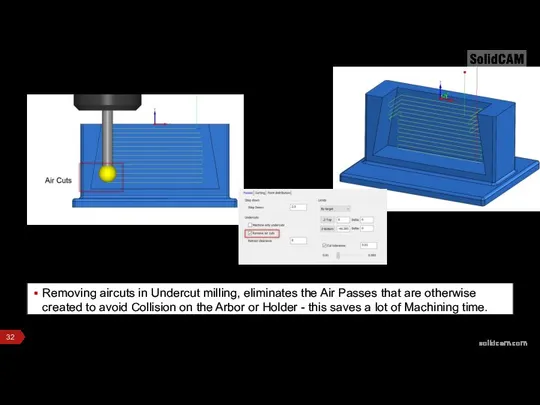

- 32. Removing aircuts in Undercut milling, eliminates the Air Passes that are otherwise created to avoid Collision

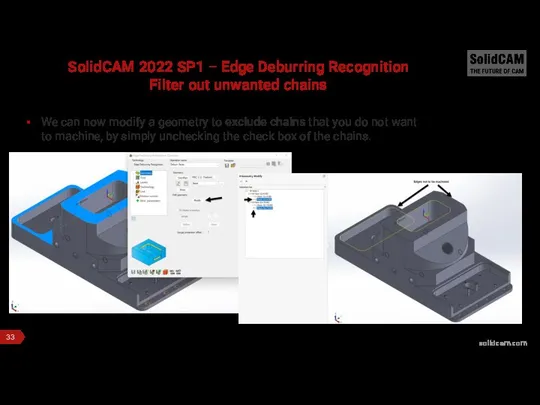

- 33. SolidCAM 2022 SP1 – Edge Deburring Recognition Filter out unwanted chains We can now modify a

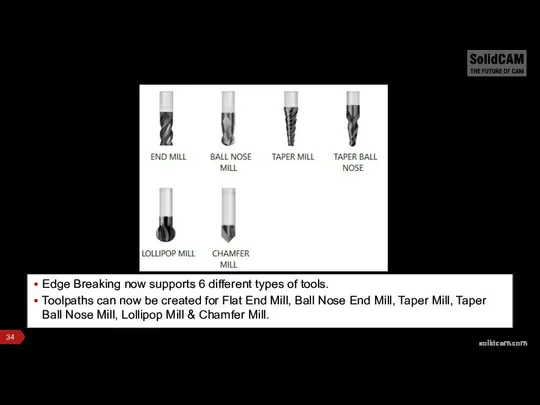

- 34. Edge Breaking now supports 6 different types of tools. Toolpaths can now be created for Flat

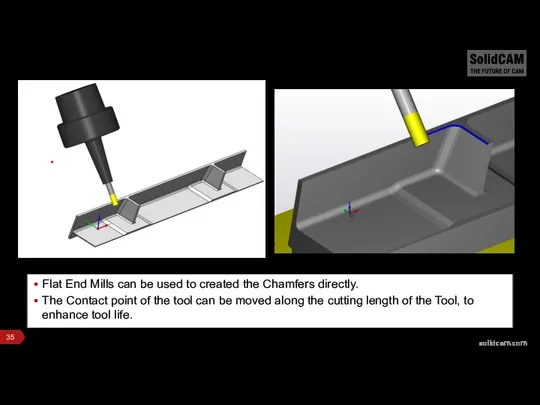

- 35. Flat End Mills can be used to created the Chamfers directly. The Contact point of the

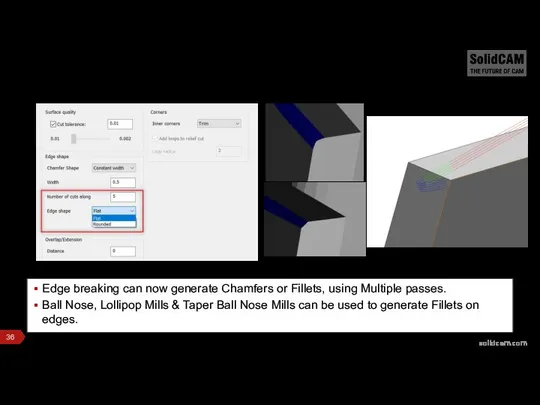

- 36. Edge breaking can now generate Chamfers or Fillets, using Multiple passes. Ball Nose, Lollipop Mills &

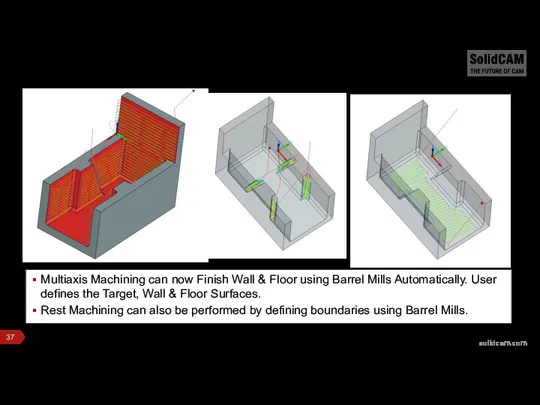

- 37. Multiaxis Machining can now Finish Wall & Floor using Barrel Mills Automatically. User defines the Target,

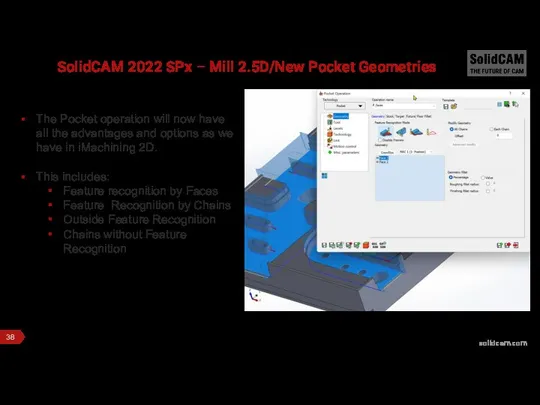

- 38. SolidCAM 2022 SPx – Mill 2.5D/New Pocket Geometries The Pocket operation will now have all the

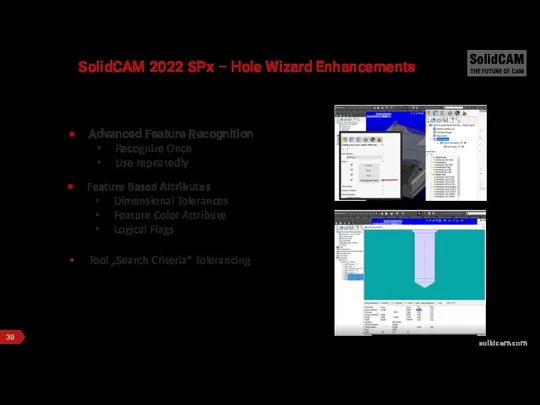

- 39. SolidCAM 2022 SPx – Hole Wizard Enhancements Advanced Feature Recognition Recognize Once Use repeatedly Feature Based

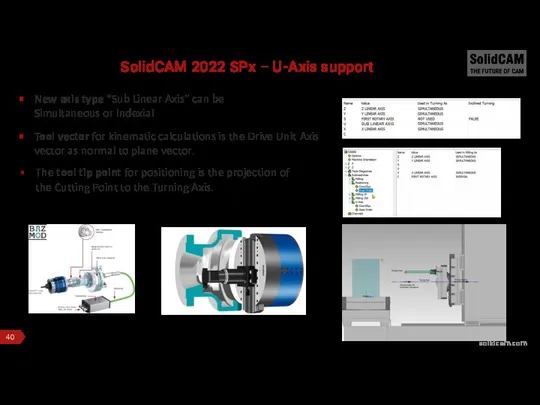

- 40. SolidCAM 2022 SPx – U-Axis support New axis type “Sub Linear Axis” can be Simultaneous or

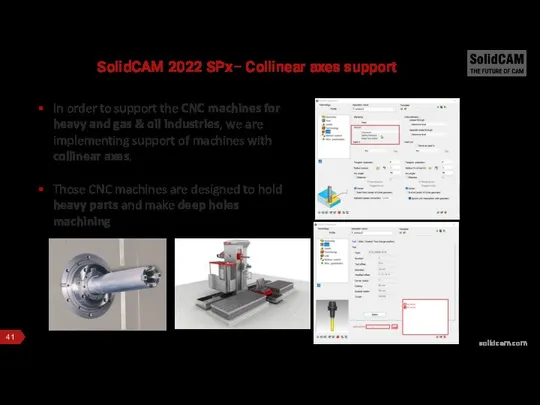

- 41. SolidCAM 2022 SPx– Collinear axes support In order to support the CNC machines for heavy and

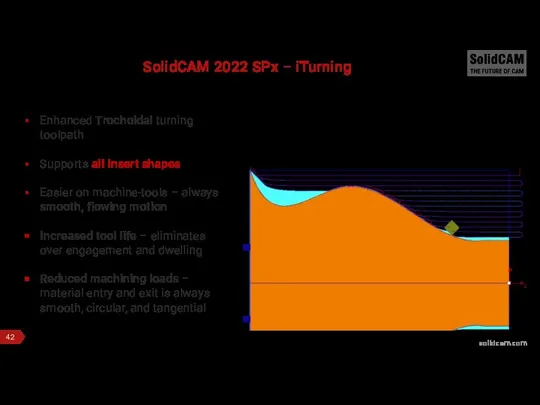

- 42. SolidCAM 2022 SPx – iTurning Enhanced Trochoidal turning toolpath Supports all Insert shapes Easier on machine-tools

- 43. SolidCAM 2022 SPx – Ceratizit Free Turn All familiar turning operations such as roughing, finishing, contour

- 44. SolidCAM 2022 SPx – Sandvik Prime Turning PrimeTurning is a new methodology that enables you to

- 45. SolidCAM 2022 SPx – Thread Whirling (SWISS type) Thread Whirling is a form of the thread

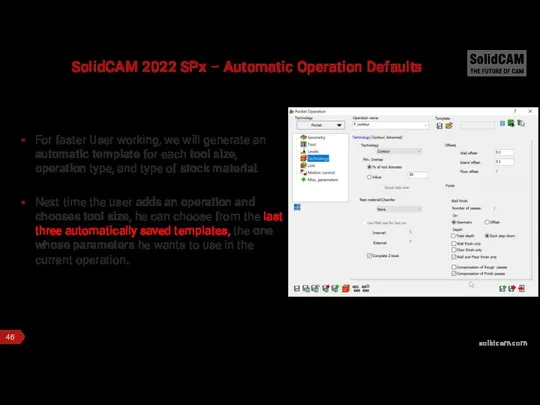

- 46. SolidCAM 2022 SPx – Automatic Operation Defaults For faster User working, we will generate an automatic

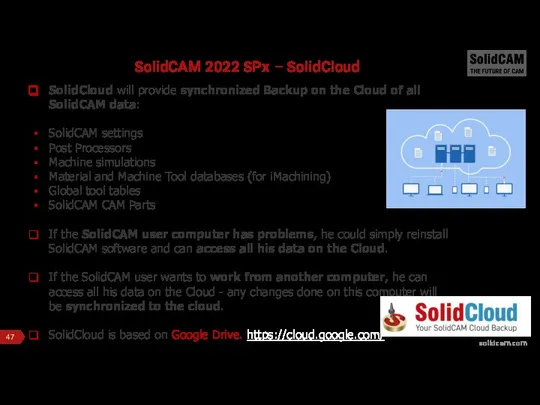

- 47. SolidCAM 2022 SPx – SolidCloud SolidCloud will provide synchronized Backup on the Cloud of all SolidCAM

- 48. SolidCAM Maker Version SolidCAM Maker Version will have the functionality of the Regular Version, except it

- 49. "The best way to predict the future is to create it." – Peter Drucker

- 51. Скачать презентацию

Газобалонная установка пятого поколения. Схема ее устройства и принцип работы

Газобалонная установка пятого поколения. Схема ее устройства и принцип работы Modern mobile phones addiction: reasons and consequences

Modern mobile phones addiction: reasons and consequences Arshan

Arshan Основные функции домашней работы

Основные функции домашней работы ПЯТЬ КЛЮЧЕЙ ОБЩЕНИЯ

ПЯТЬ КЛЮЧЕЙ ОБЩЕНИЯ Как загрузить ДЗ в Эл.дневник

Как загрузить ДЗ в Эл.дневник Истории Наруто

Истории Наруто угадай кто старшая подготовительная группа

угадай кто старшая подготовительная группа Люди из подвала

Люди из подвала Фотоколлаж. Мужской стиль

Фотоколлаж. Мужской стиль Вечнозаветная псалтирь - святорусская редакция. (Псалом 82)

Вечнозаветная псалтирь - святорусская редакция. (Псалом 82) Общие способы получения металлов (часть 1). Понятие о металлургии

Общие способы получения металлов (часть 1). Понятие о металлургии Тестирование по УД. Технологическое оборудование. Токарные станки

Тестирование по УД. Технологическое оборудование. Токарные станки Батыс Қазақстан облысы өнеркәсібі

Батыс Қазақстан облысы өнеркәсібі Sundayfunday

Sundayfunday 20160116_sots_normy._belyavskaya

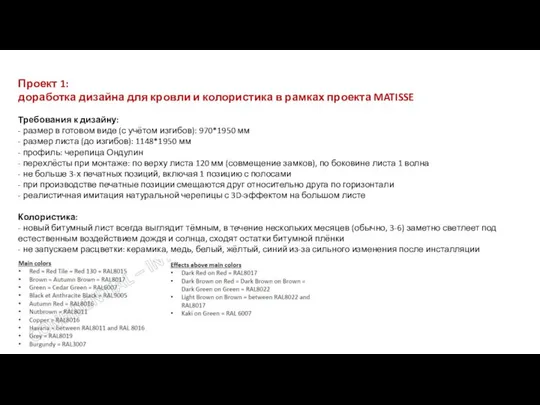

20160116_sots_normy._belyavskaya matisse и ворон

matisse и ворон Бурение скважин

Бурение скважин Б.Г. Ананьев

Б.Г. Ананьев Моя профессия – Банковское Дело

Моя профессия – Банковское Дело Біполярні транзистори

Біполярні транзистори Основы буддизма

Основы буддизма Сказки домовёнка Кузи

Сказки домовёнка Кузи Молодежный парк

Молодежный парк Картотека по экспериментальной деятельности с детьми дошкольного возраста

Картотека по экспериментальной деятельности с детьми дошкольного возраста Наша группа

Наша группа Основы эксплуатации тепловых сетей

Основы эксплуатации тепловых сетей Авилов О.В. Конф. в СПб

Авилов О.В. Конф. в СПб