Содержание

- 2. INCOTEC GROUP was founded in 1992

- 3. The structure of INCOTEC GROUP was originally created with the aim of provision the utmost effective

- 4. INCOTEC GROUP consisted of the following departments:

- 5. Port Forwarding Department

- 6. Multimodal Transportation Department

- 7. Railway Transportation Department

- 8. Shipping Agency Department

- 9. Survey Department

- 10. Inland Trucking Department

- 11. Customs Clearance Department

- 12. Project Cargo Transportation Department

- 13. In the year of 2001, September 28th, this department got its legal name INCOTEC CARGO Ltd.

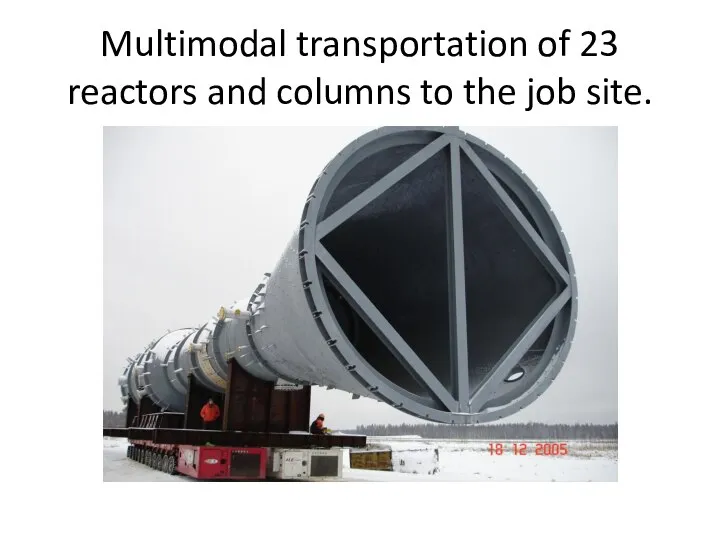

- 14. The year of 2005. Customer: Kirishinefteorgsintez (KINEF)

- 15. Multimodal transportation of 23 reactors and columns to the job site.

- 16. Weight up to 1065 MT each, length up to 69 m. and diameter up to 10,5

- 17. The 1st shipment arrived at the port of St. Petersburg in May on board of geared

- 18. Design works had been carried out and as a result 2 types of barges had been

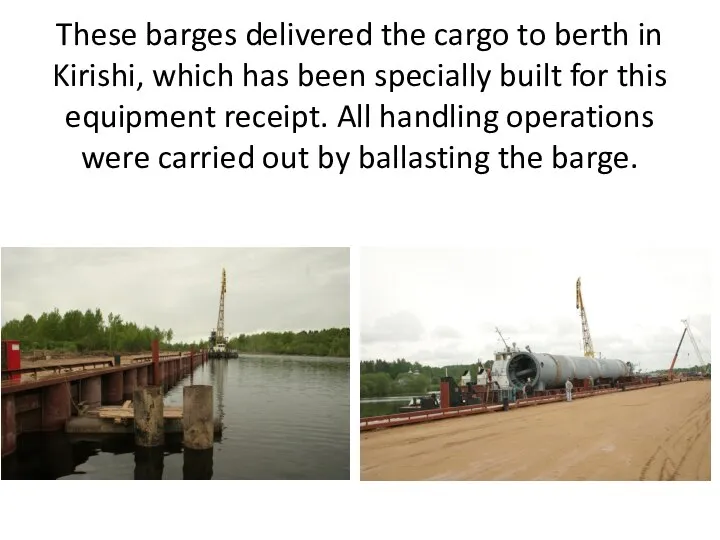

- 19. These barges delivered the cargo to berth in Kirishi, which has been specially built for this

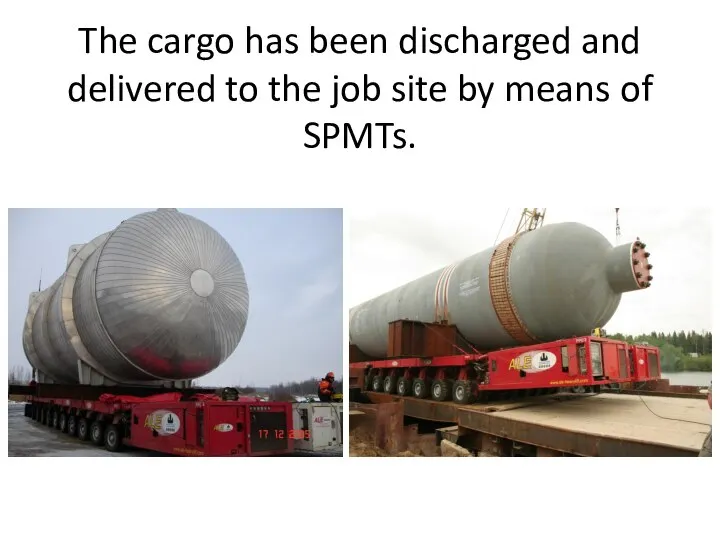

- 20. The cargo has been discharged and delivered to the job site by means of SPMTs.

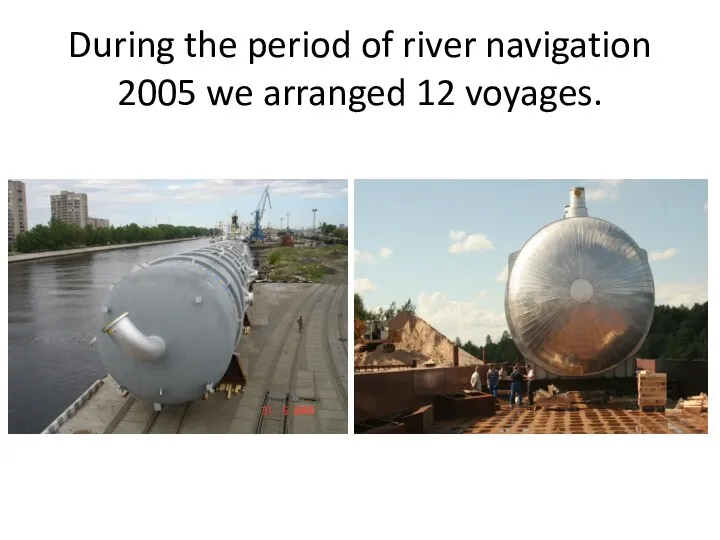

- 21. During the period of river navigation 2005 we arranged 12 voyages.

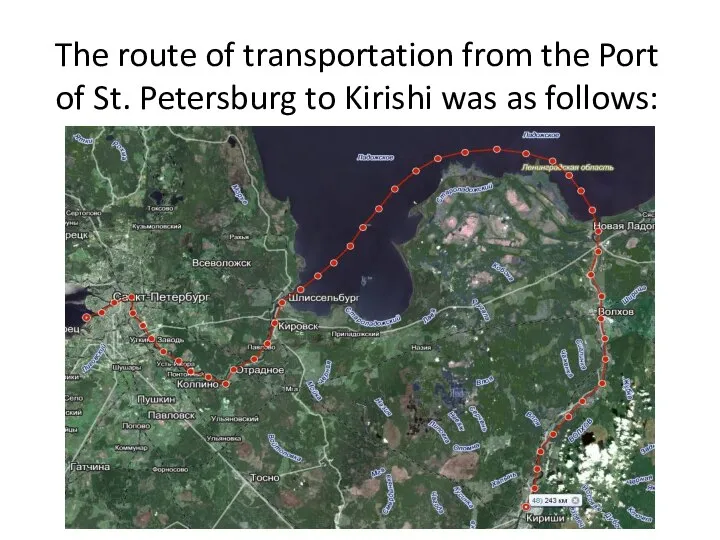

- 22. The route of transportation from the Port of St. Petersburg to Kirishi was as follows:

- 23. Volume shipped - more than 25 000 freight tons.

- 24. The year of 2010 The Customer: Izhorskiye Zavody by order of OMZ (Uralmash – Izhora Group)

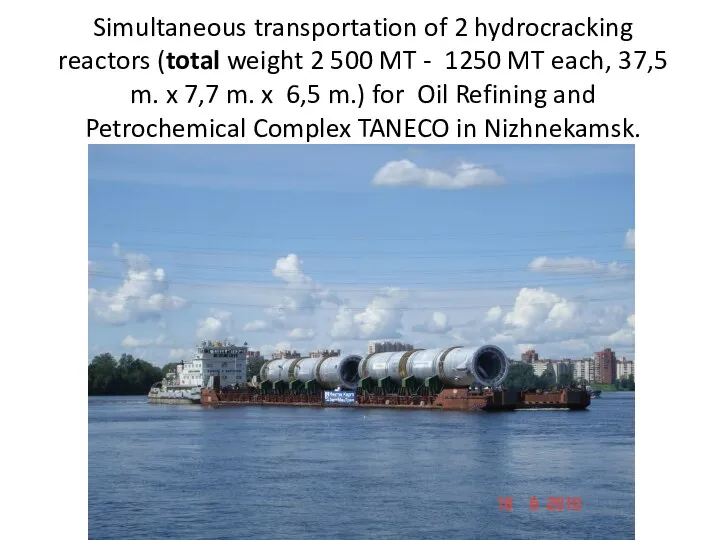

- 25. Simultaneous transportation of 2 hydrocracking reactors (total weight 2 500 MT - 1250 MT each, 37,5

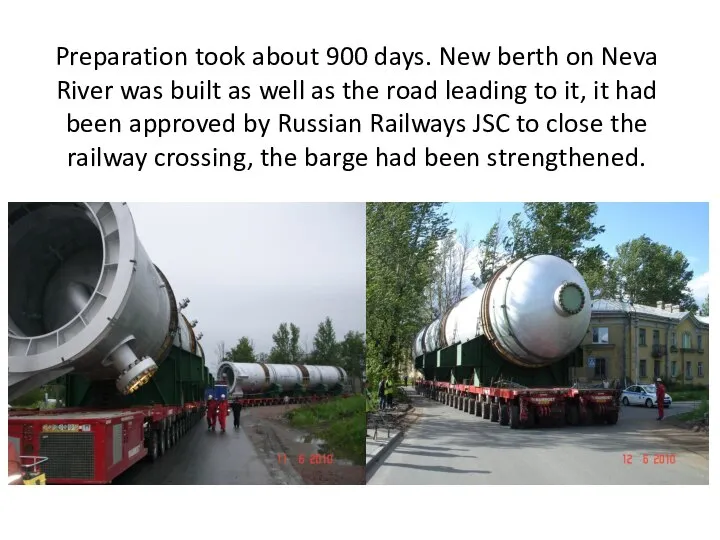

- 26. Preparation took about 900 days. New berth on Neva River was built as well as the

- 27. The specialized dock type berth was built in Nizhnekamsk. The discharging of heavyweight cargo by means

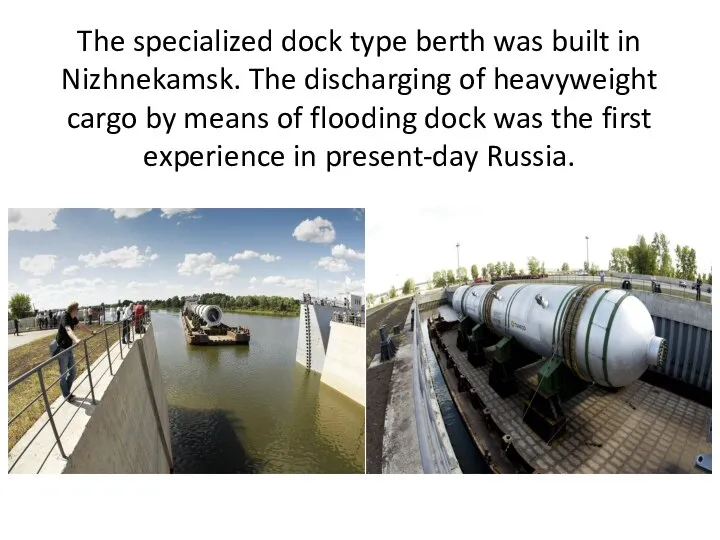

- 28. Loading operations in Saint Petersburg as well as discharging in Nizhnekamsk were held by Ro-Ro method

- 29. Discharging in Nizhnekamsk

- 30. The route from berth on Neva River to Nizhnekamsk was as follows. The distance of about

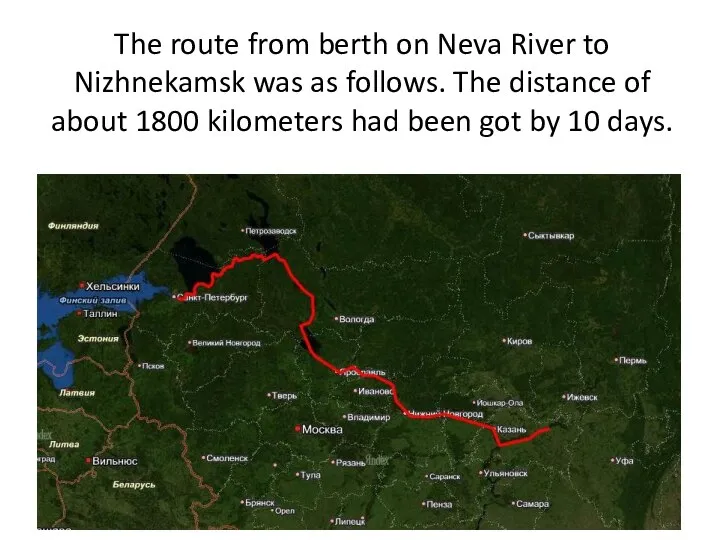

- 31. The project was fulfilled and the cargo was delivered to the Consignee.

- 32. Years of 2010-2012 The Customer: OJSC TANECO (Nizhnekamsk)

- 33. Since 2010 INCOTEC CARGO Ltd was involved in door-to-door delivery of complete petrochemical equipment (weight up

- 34. CCR Plant delivery from South Korea (direct sailing from Onsan to St. Petersburg) consisted of 6

- 35. For that cargo geared vessel was chartered. She has 2 cranes by 275 MT SWL each.

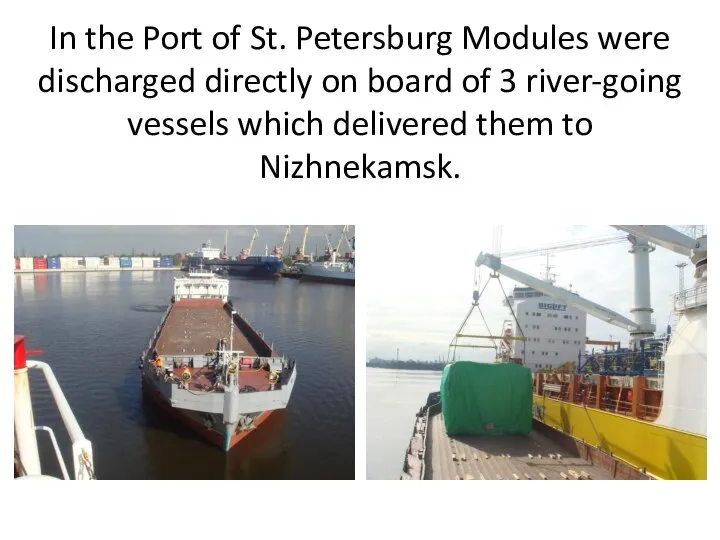

- 36. In the Port of St. Petersburg Modules were discharged directly on board of 3 river-going vessels

- 37. Upon discharging in Nizhnekamsk, Modules were delivered to the job site.

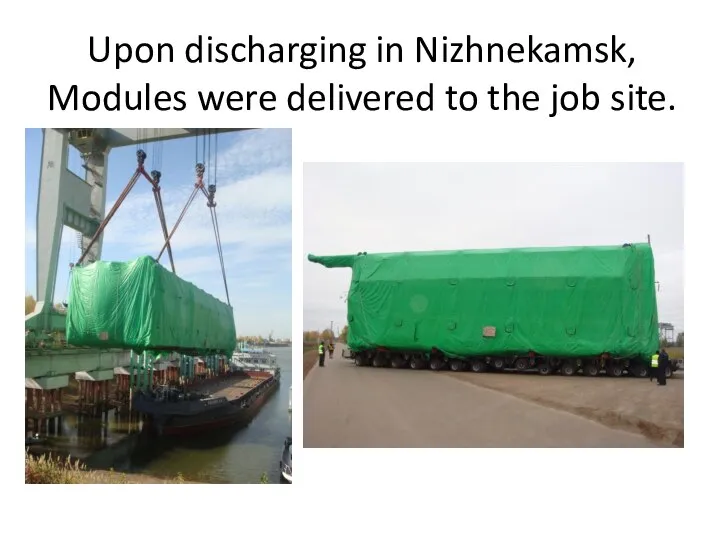

- 38. Delivery of Reactor Column (45 m. length) from Italy

- 39. The total volume of shipped equipment is more than 50 000 freight tons. Deliveries were arranged

- 40. Year of 2012 (November – December) The Customer: Baltiysky Zavod JSC

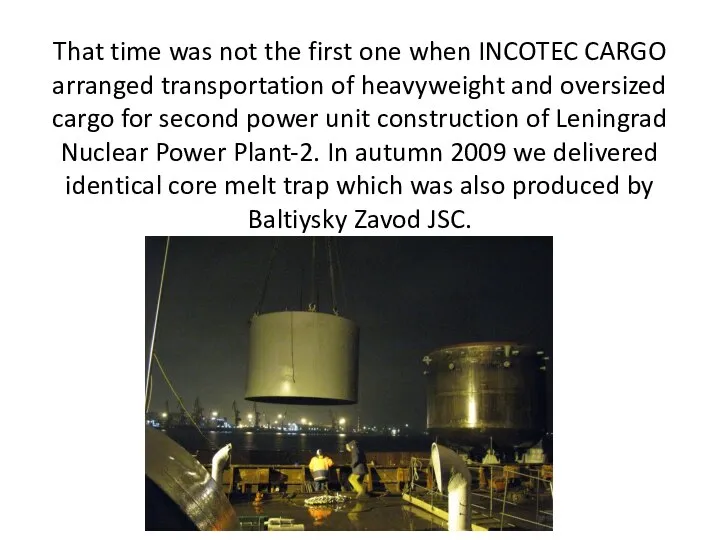

- 41. Delivery of core melt trap with total weight of 770 MT for second power unit of

- 42. The heaviest items (weight up to 161 MT) were delivered by floating crane and then this

- 43. That time was not the first one when INCOTEC CARGO arranged transportation of heavyweight and oversized

- 44. Among our Customers such Companies as: Atomstroyexport JSC Baltiysky Zavod JSC Gazprom podzemremont Orenburg JSC Izhorskiye

- 46. Скачать презентацию

Презентация на тему "Родительская любовь и Воспитание" - скачать презентации по Педагогике

Презентация на тему "Родительская любовь и Воспитание" - скачать презентации по Педагогике Паралимпийский спорт

Паралимпийский спорт Методическое объединение воспитателей тема: Расширение психологического обеспечения учебно-воспитательного процесс

Методическое объединение воспитателей тема: Расширение психологического обеспечения учебно-воспитательного процесс Презентация на тему "Шизофрения" - скачать презентации по Медицине

Презентация на тему "Шизофрения" - скачать презентации по Медицине Предупрежден – вооружен. Екатерина Вершинина, Сергей Нечаев, ООО «Новотелеком» как не давать невыполнимых обещаний. - презентация

Предупрежден – вооружен. Екатерина Вершинина, Сергей Нечаев, ООО «Новотелеком» как не давать невыполнимых обещаний. - презентация Настройка ПИД-регулятора

Настройка ПИД-регулятора Культура одежды и тела в Китае и Японии

Культура одежды и тела в Китае и Японии Самостоятельные занятия по общей физической подготовке

Самостоятельные занятия по общей физической подготовке День молодого избирателя

День молодого избирателя Разработка энергосберегающих мероприятий колпаковой термической печи

Разработка энергосберегающих мероприятий колпаковой термической печи Теория отталкивания электронных пар

Теория отталкивания электронных пар Туристско-рекреационные ресурсы: понятие, структура, оценка

Туристско-рекреационные ресурсы: понятие, структура, оценка Быстрые сортировки

Быстрые сортировки Презентация на тему "Модерн"

Презентация на тему "Модерн" Jesus calms a storm

Jesus calms a storm Интерфейсы ПK

Интерфейсы ПK Автомат по продаже CD и DVD дисков. muvibox11

Автомат по продаже CD и DVD дисков. muvibox11 Возведение заглубленных сооружений способом «Опускного колодца»

Возведение заглубленных сооружений способом «Опускного колодца» «Профессия под микроскопом» СОЦИАЛЬНЫЙ ПЕДАГОГ

«Профессия под микроскопом» СОЦИАЛЬНЫЙ ПЕДАГОГ Дерево целей

Дерево целей Презентация Ассортимент швейных изделий

Презентация Ассортимент швейных изделий Международное движение капитала. Платежный баланс. Дисциплина: Мировая экономика Преподаватель: профессор кафедры МЭО, к.э.н., до

Международное движение капитала. Платежный баланс. Дисциплина: Мировая экономика Преподаватель: профессор кафедры МЭО, к.э.н., до Женский деловой костюм

Женский деловой костюм International Public Law. Lecture 6

International Public Law. Lecture 6 Joyeux Noël et le Nouvel An en France

Joyeux Noël et le Nouvel An en France Презентация Громовия Олеся

Презентация Громовия Олеся Семейно-обрядовый фольклор. Причитания

Семейно-обрядовый фольклор. Причитания PR-Охота! 2010 V Международный форум по связям с общественностью и рекламе Фотоотчет

PR-Охота! 2010 V Международный форум по связям с общественностью и рекламе Фотоотчет