Содержание

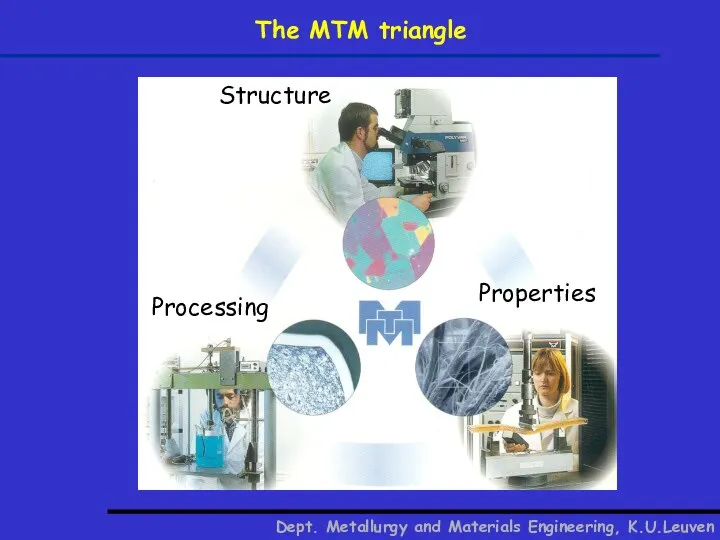

- 2. Dept. Metallurgy and Materials Engineering, K.U.Leuven The MTM triangle Processing Properties Structure

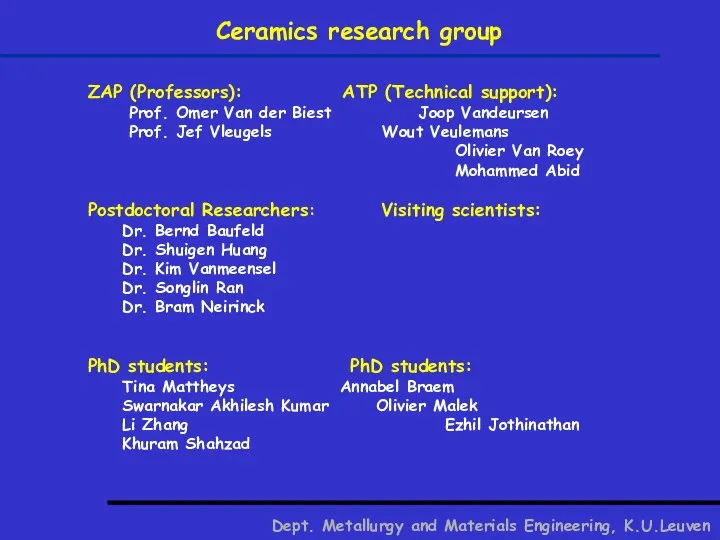

- 3. ZAP (Professors): ATP (Technical support): Prof. Omer Van der Biest Joop Vandeursen Prof. Jef Vleugels Wout

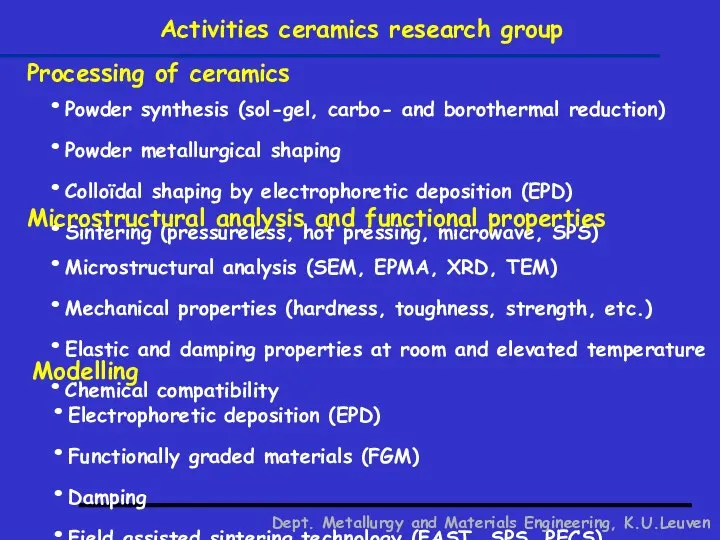

- 4. Activities ceramics research group Powder synthesis (sol-gel, carbo- and borothermal reduction) Powder metallurgical shaping Colloïdal shaping

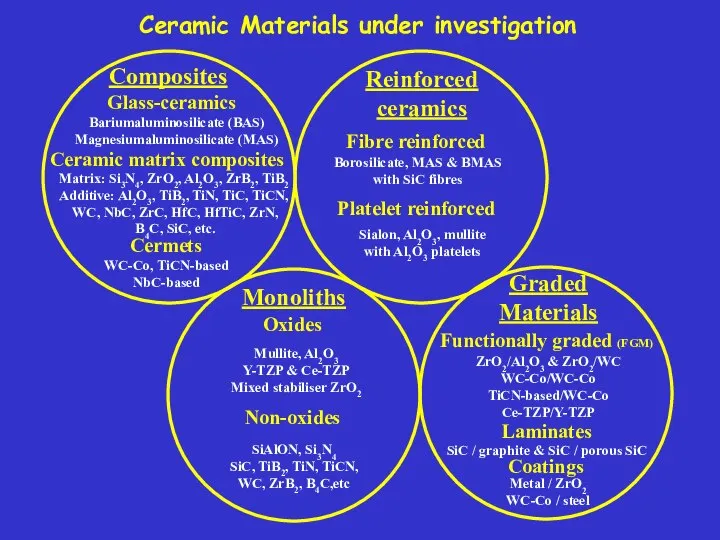

- 5. Ceramic Materials under investigation Monoliths Oxides SiAlON, Si3N4 SiC, TiB2, TiN, TiCN, WC, ZrB2, B4C,etc Composites

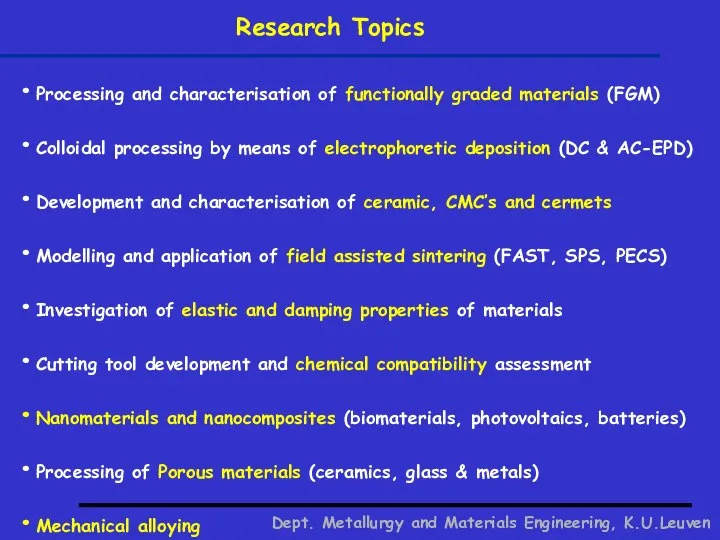

- 6. Dept. Metallurgy and Materials Engineering, K.U.Leuven Research Topics Processing and characterisation of functionally graded materials (FGM)

- 7. Cutting tool development and chemical compatibility studies DEVELOPMENT OF NEW CUTTING MATERIALS, TOOLS, MACHINE CONCEPTS AND

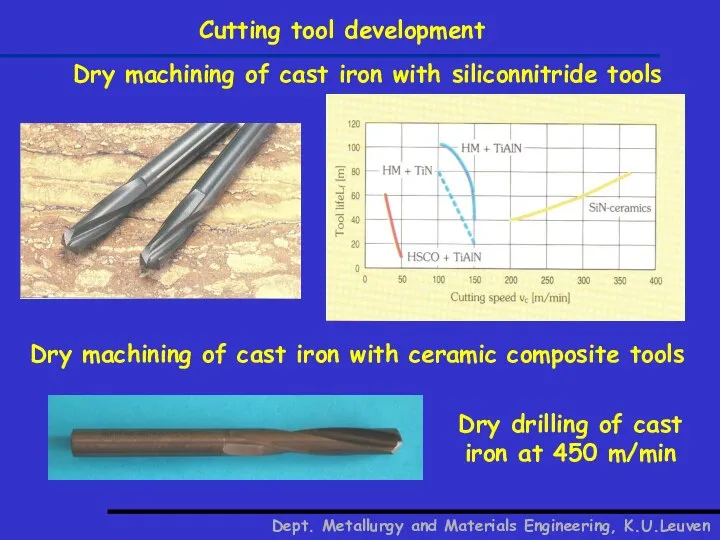

- 8. Cutting tool development Dept. Metallurgy and Materials Engineering, K.U.Leuven Dry machining of cast iron with siliconnitride

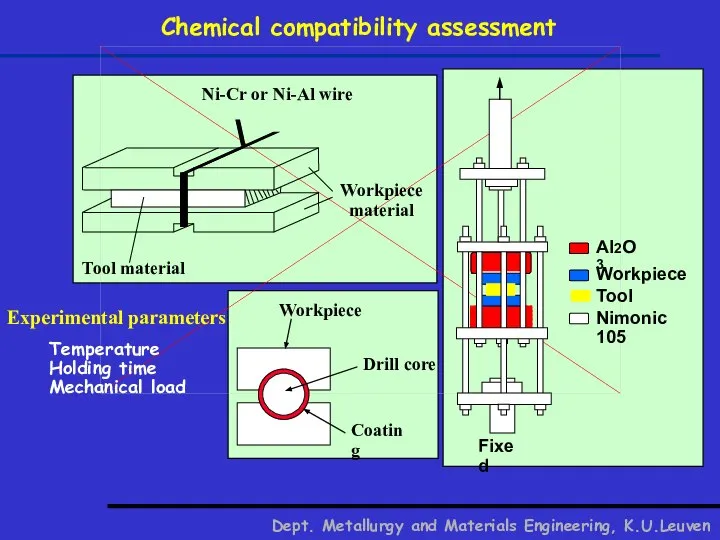

- 9. Chemical compatibility assessment Dept. Metallurgy and Materials Engineering, K.U.Leuven Experimental parameters Temperature Holding time Mechanical load

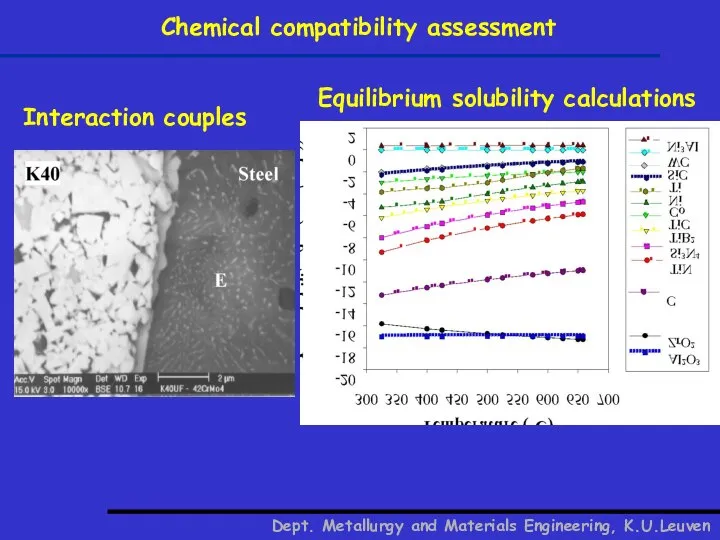

- 10. Dept. Metallurgy and Materials Engineering, K.U.Leuven Chemical compatibility assessment Interaction couples Equilibrium solubility calculations

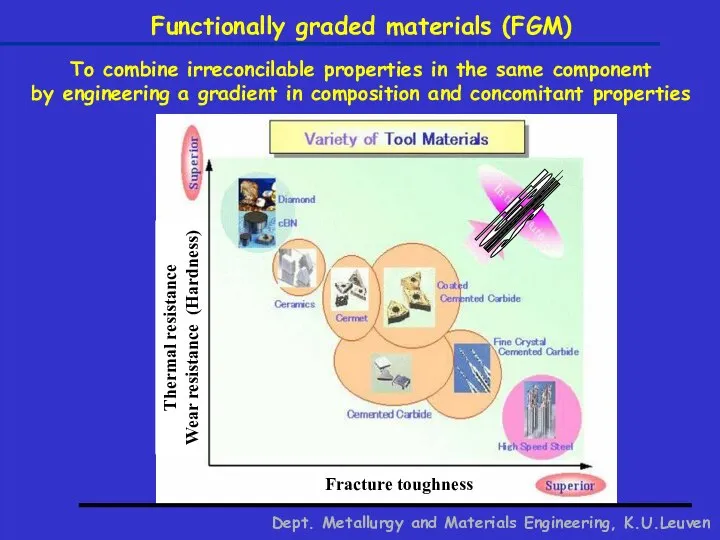

- 11. Dept. Metallurgy and Materials Engineering, K.U.Leuven FGM's Fracture toughness Thermal resistance Wear resistance (Hardness) Functionally graded

- 12. Electrophoretic deposition (EPD) Dept. Metallurgy and Materials Engineering, K.U.Leuven Colloidal processing technique in an electric field

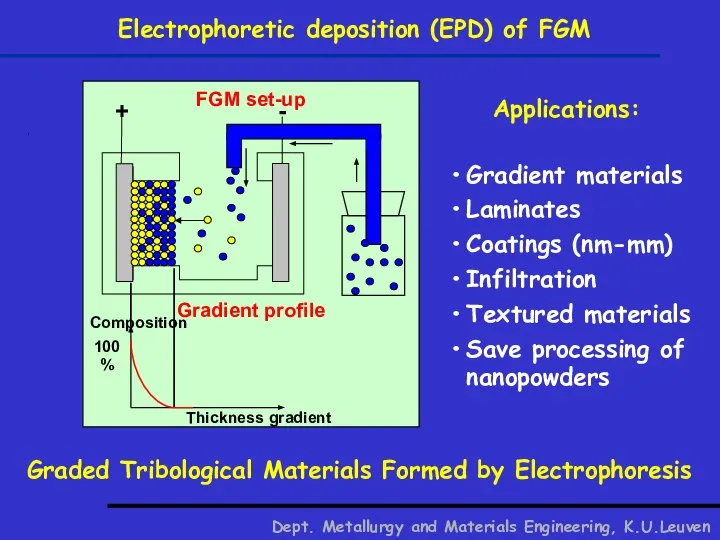

- 13. Electrophoretic deposition (EPD) of FGM Dept. Metallurgy and Materials Engineering, K.U.Leuven Applications: Gradient materials Laminates Coatings

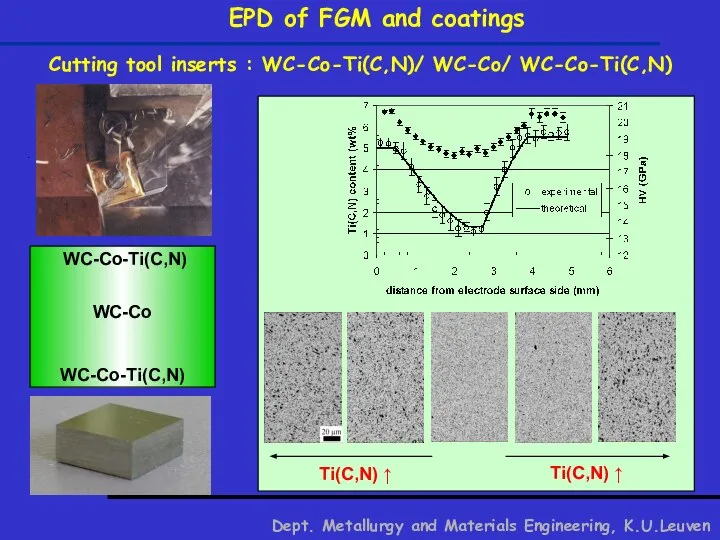

- 14. EPD of FGM and coatings Dept. Metallurgy and Materials Engineering, K.U.Leuven Ti(C,N) ↑ Ti(C,N) ↑ Cutting

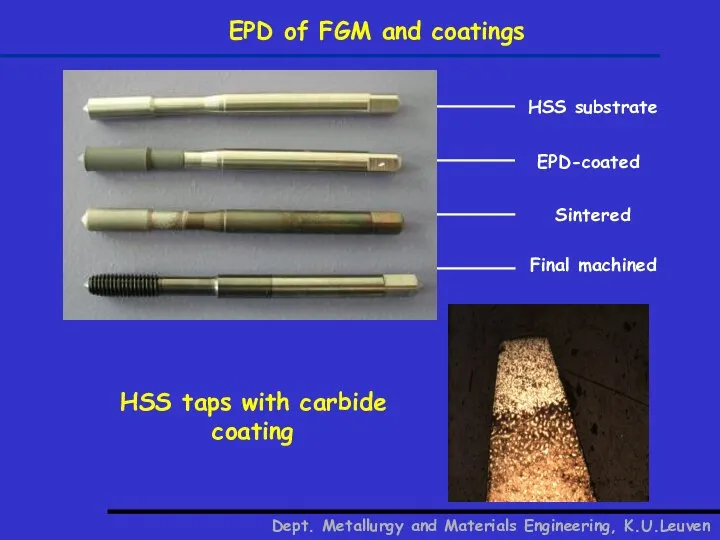

- 15. EPD of FGM and coatings Dept. Metallurgy and Materials Engineering, K.U.Leuven HSS taps with carbide coating

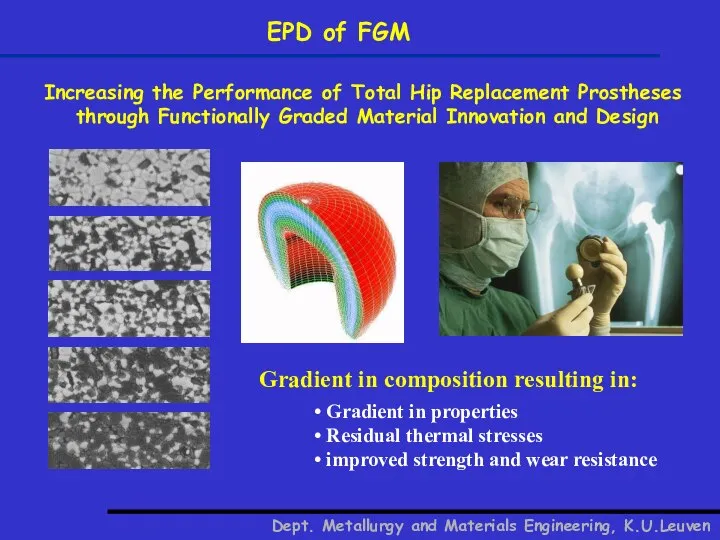

- 16. EPD of FGM Increasing the Performance of Total Hip Replacement Prostheses through Functionally Graded Material Innovation

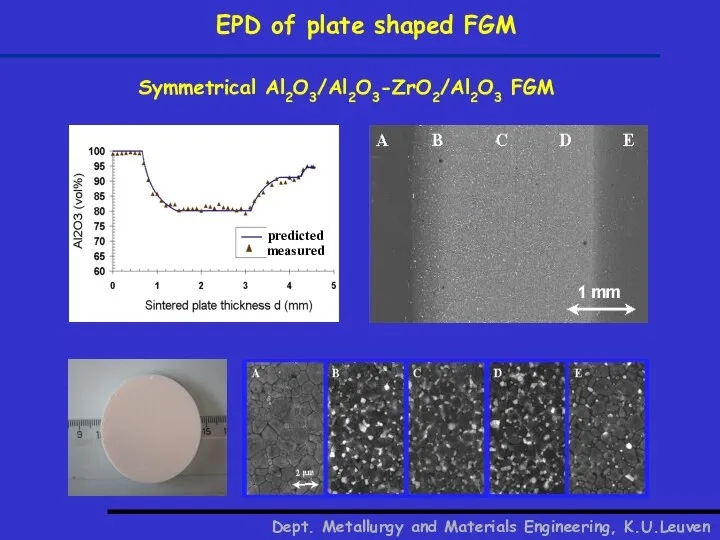

- 17. Symmetrical Al2O3/Al2O3-ZrO2/Al2O3 FGM measured predicted EPD of plate shaped FGM Dept. Metallurgy and Materials Engineering, K.U.Leuven

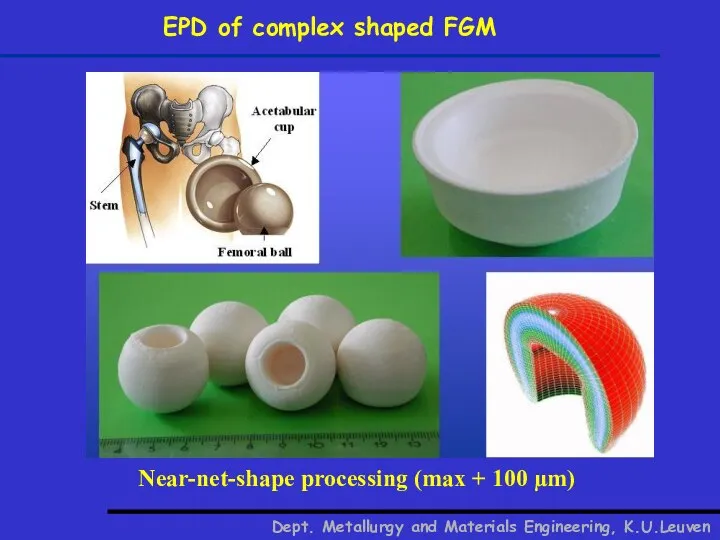

- 18. Near-net-shape processing (max + 100 µm) EPD of complex shaped FGM Dept. Metallurgy and Materials Engineering,

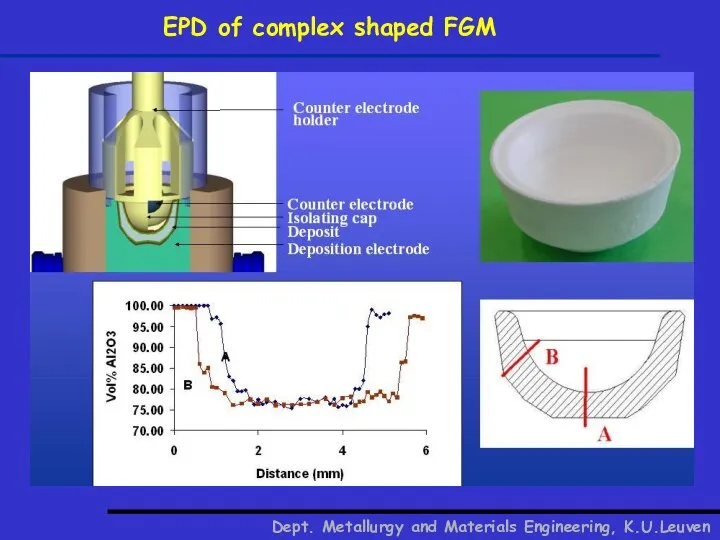

- 19. EPD of complex shaped FGM Dept. Metallurgy and Materials Engineering, K.U.Leuven

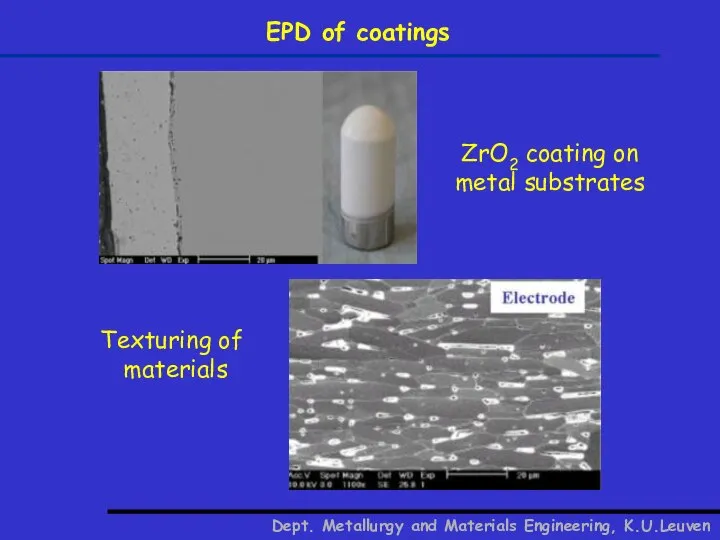

- 20. EPD of coatings Texturing of materials ZrO2 coating on metal substrates Dept. Metallurgy and Materials Engineering,

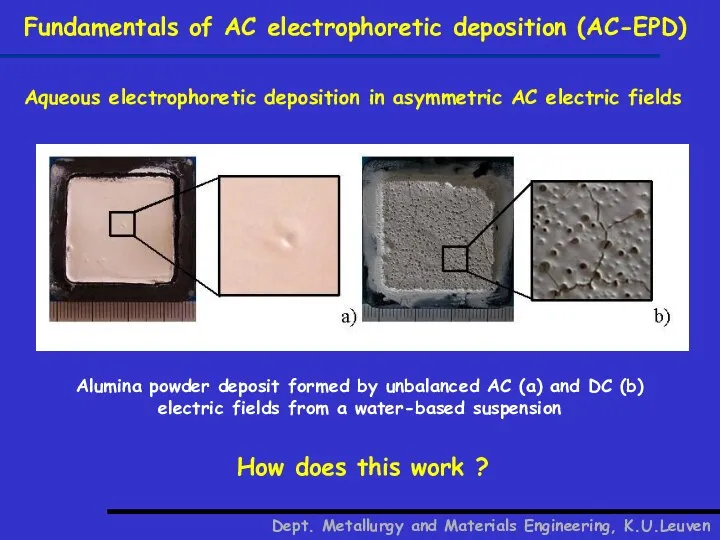

- 21. Dept. Metallurgy and Materials Engineering, K.U.Leuven Fundamentals of AC electrophoretic deposition (AC-EPD) Aqueous electrophoretic deposition in

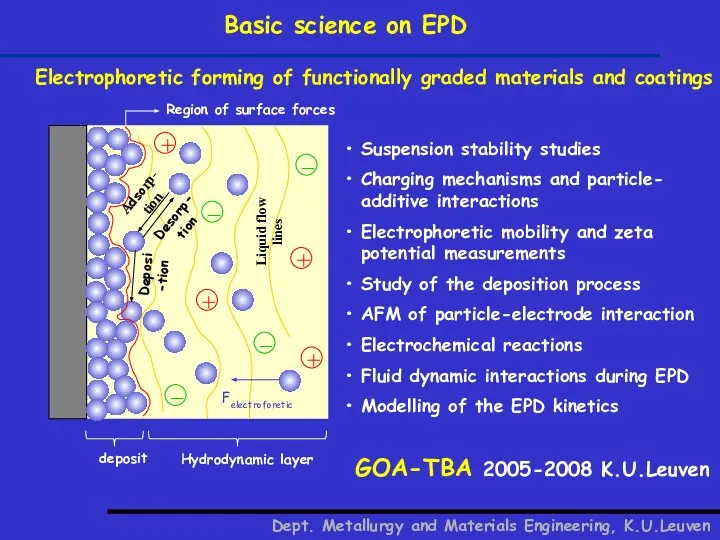

- 22. Basic science on EPD Dept. Metallurgy and Materials Engineering, K.U.Leuven Electrophoretic forming of functionally graded materials

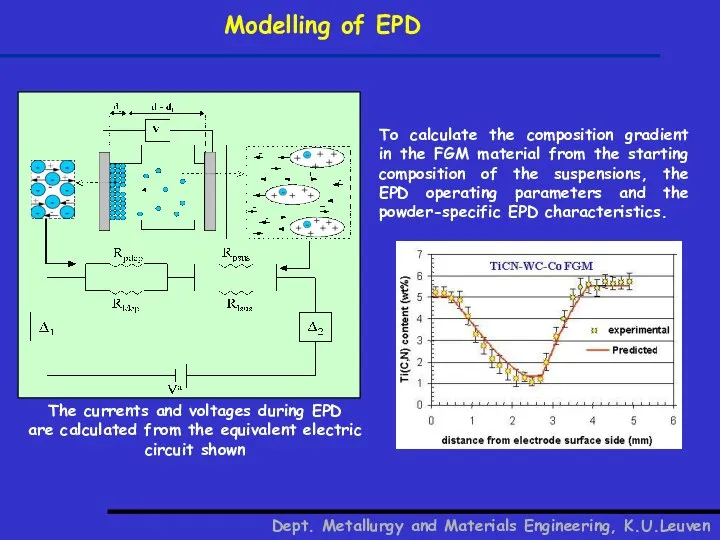

- 23. Modelling of EPD Dept. Metallurgy and Materials Engineering, K.U.Leuven The currents and voltages during EPD are

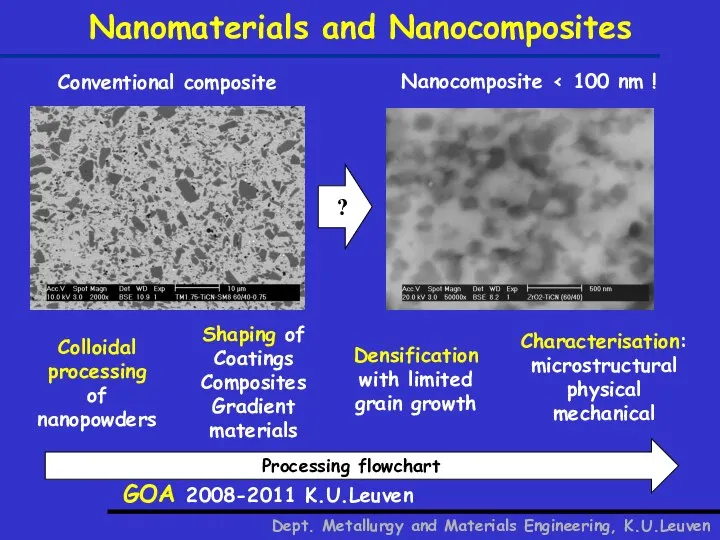

- 24. Dept. Metallurgy and Materials Engineering, K.U.Leuven GOA-TBA 2008-2011 K.U.Leuven Nanocomposite ? Conventional composite Colloidal processing of

- 25. Development of biocompatible coatings 2006-2010 6th Framework Project Project Coordinator: K.U.Leuven Meddelcoat Multifunctional bioresorbable biocompatible coatings

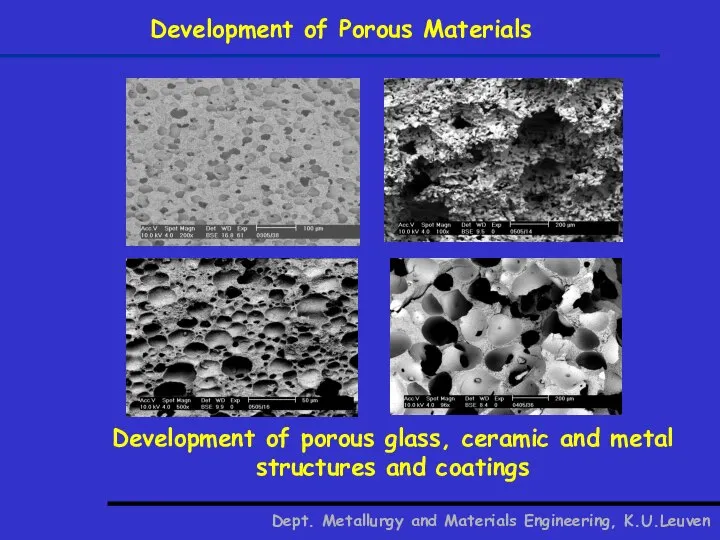

- 26. Development of Porous Materials Dept. Metallurgy and Materials Engineering, K.U.Leuven Development of porous glass, ceramic and

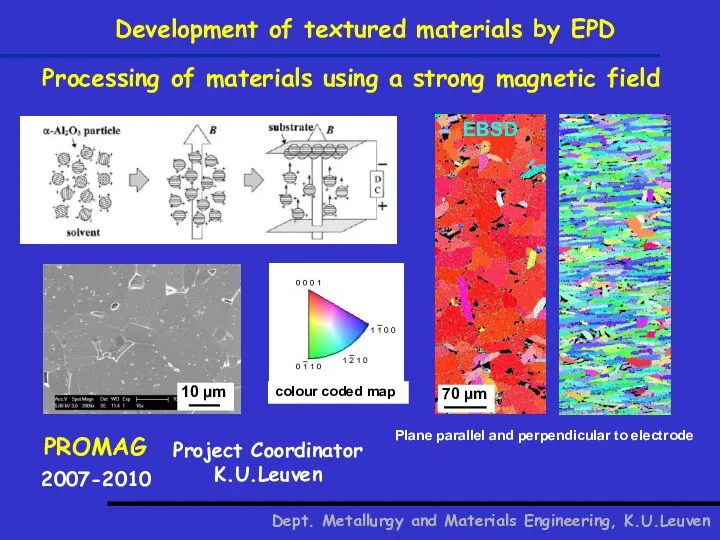

- 27. Dept. Metallurgy and Materials Engineering, K.U.Leuven Processing of materials using a strong magnetic field 2007-2010 SBO

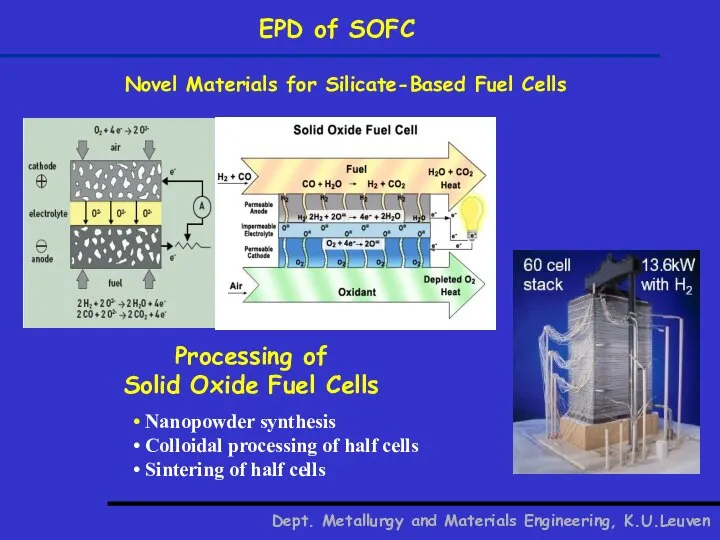

- 28. Dept. Metallurgy and Materials Engineering, K.U.Leuven EPD of SOFC Novel Materials for Silicate-Based Fuel Cells Processing

- 29. Field Assisted Sintering Technology (FAST) Field assisted sintering technology for the densification of nanostructured powders and

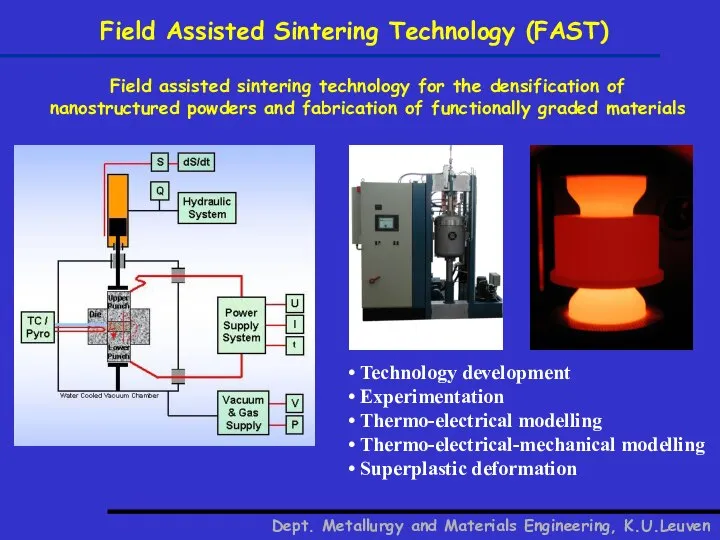

- 30. Field Assisted Sintering Technology (FAST) Dept. Metallurgy and Materials Engineering, K.U.Leuven Ceramic and ceramic-metal nanocomposites (cermets)

- 31. Field Assisted Sintering Technology (FAST) Dept. Metallurgy and Materials Engineering, K.U.Leuven FE-modelling of the temperature distribution

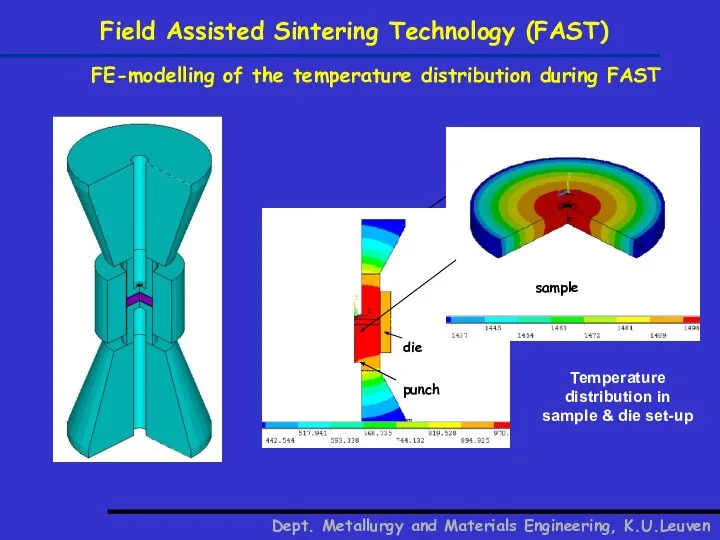

- 32. High temperature equipment Dept. Metallurgy and Materials Engineering, K.U.Leuven SPS Equipment Properties: pulsed electric current: 0

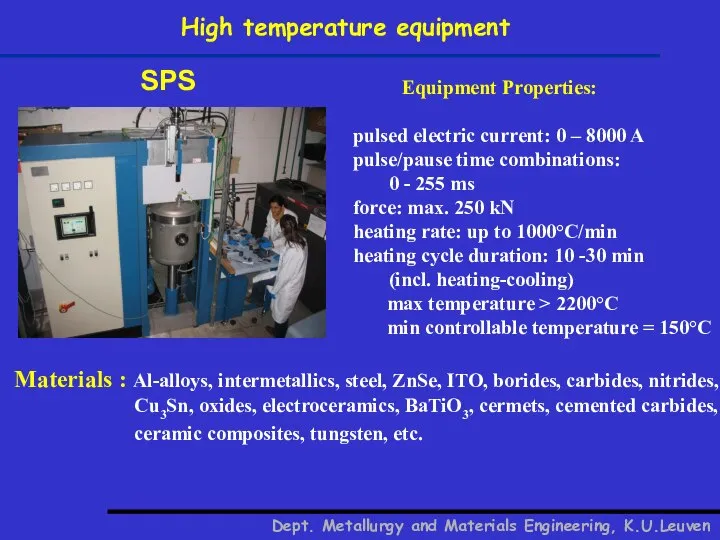

- 33. Electro-conductive ceramic composites For electrical discharge machining (EDM) and wear applications Dept. Metallurgy and Materials Engineering,

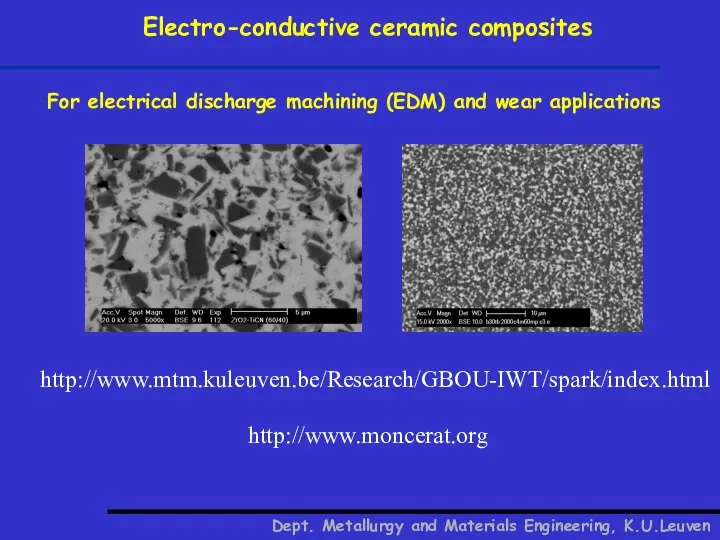

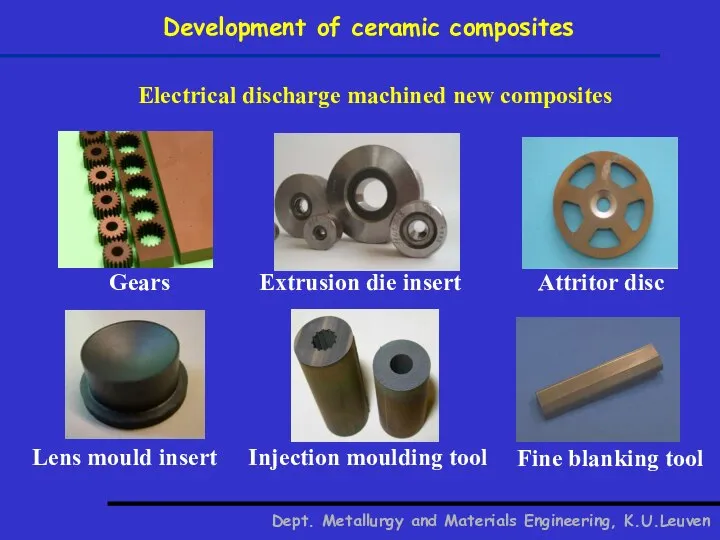

- 34. Development of ceramic composites Dept. Metallurgy and Materials Engineering, K.U.Leuven Electrical discharge machined new composites Gears

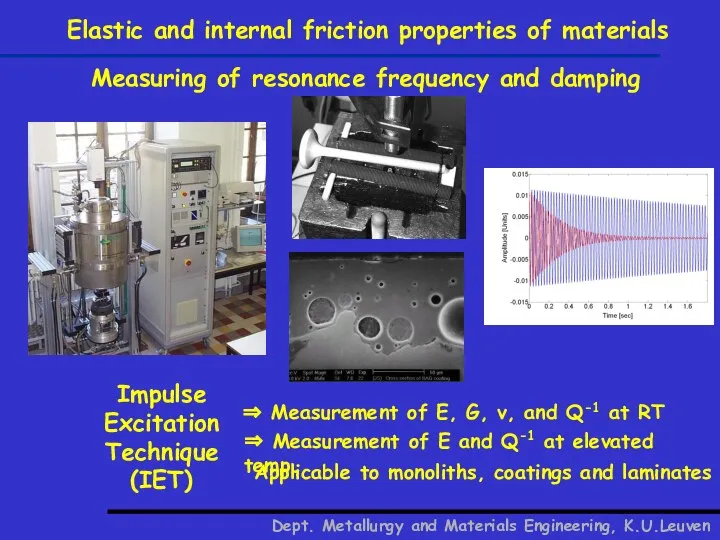

- 35. Elastic and internal friction properties of materials Impulse Excitation Technique (IET) Dept. Metallurgy and Materials Engineering,

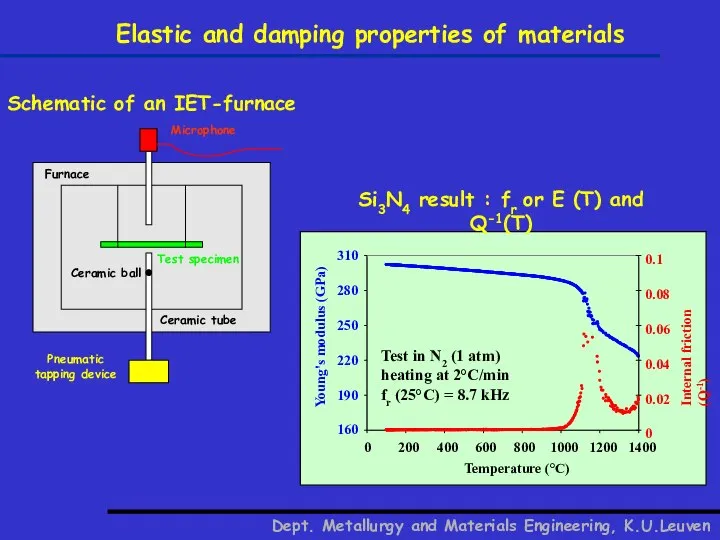

- 36. Elastic and damping properties of materials Dept. Metallurgy and Materials Engineering, K.U.Leuven Schematic of an IET-furnace

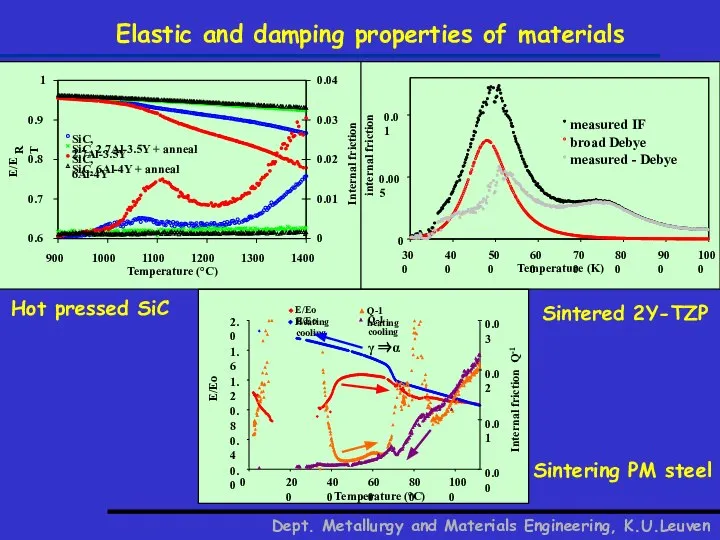

- 37. Elastic and damping properties of materials Dept. Metallurgy and Materials Engineering, K.U.Leuven Hot pressed SiC Sintered

- 38. Dept. Metallurgy and Materials Engineering, K.U.Leuven Structural Integrity of Ceramic Multilayers and Coatings” Elastic and damping

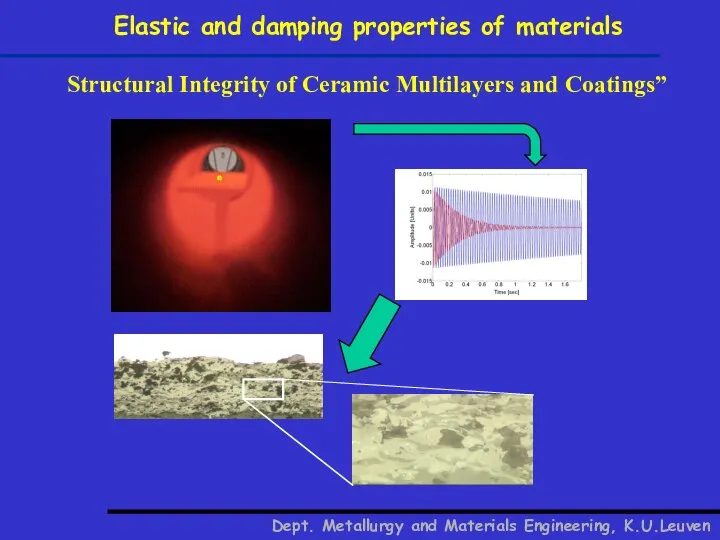

- 39. Selective laser sintering and melting Dept. Metallurgy and Materials Engineering, K.U.Leuven Direct rapid manufacturing of metallic

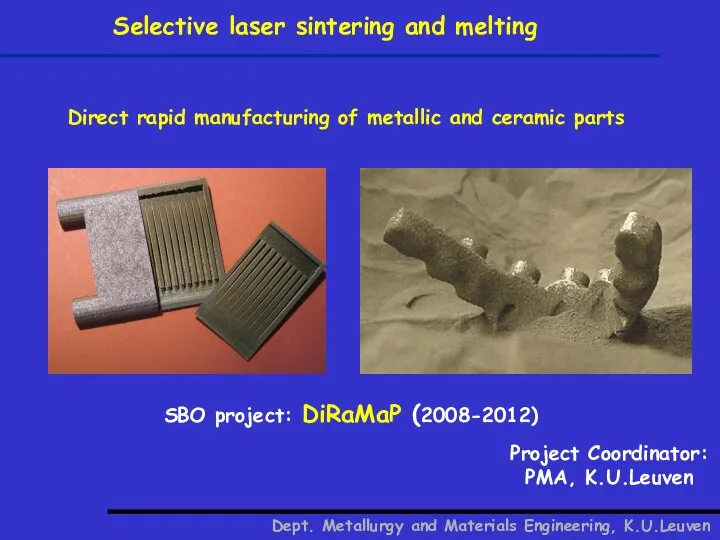

- 40. Dept. Metallurgy and Materials Engineering, K.U.Leuven Solution Deposition Technologies for CIGS and TCO Powder-based opposed to

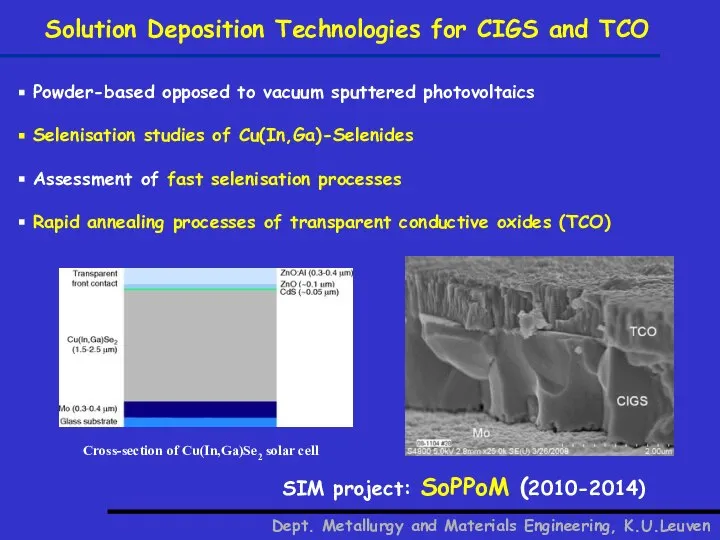

- 41. Publications ceramics research group Dept. Metallurgy and Materials Engineering, K.U.Leuven

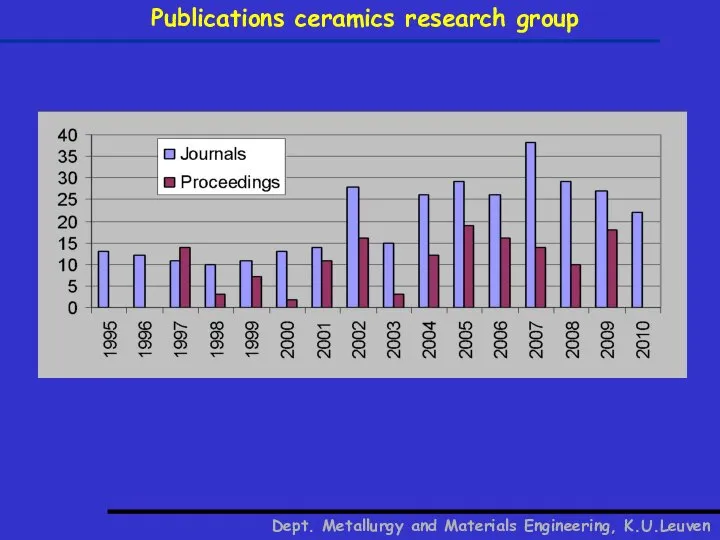

- 43. Скачать презентацию

Растяжение и сжатие

Растяжение и сжатие Звукоусиливающий тракт

Звукоусиливающий тракт Імена вчених на вулицях Харкова

Імена вчених на вулицях Харкова Восстановление железных дорог

Восстановление железных дорог  “Эластичность спроса и предложения”

“Эластичность спроса и предложения” Атріумні будівлі - як приклад еко-архітектури

Атріумні будівлі - як приклад еко-архітектури Competitive physical activity - sport

Competitive physical activity - sport Формы права

Формы права Государственный Таможенный Комитет Республика Беларусь

Государственный Таможенный Комитет Республика Беларусь Урок 10. Вычислительные умения и навыки. Схема. Сравнение длин отрезков - презентация для начальной школы

Урок 10. Вычислительные умения и навыки. Схема. Сравнение длин отрезков - презентация для начальной школы Биография Ньютона

Биография Ньютона Гигиеническая характеристика окружающей среды в современных условиях. Физические свойства воздуха и их гигиеническое значение

Гигиеническая характеристика окружающей среды в современных условиях. Физические свойства воздуха и их гигиеническое значение «TIS-Рабочее время» Система учета рабочего времени сотрудников. - презентация

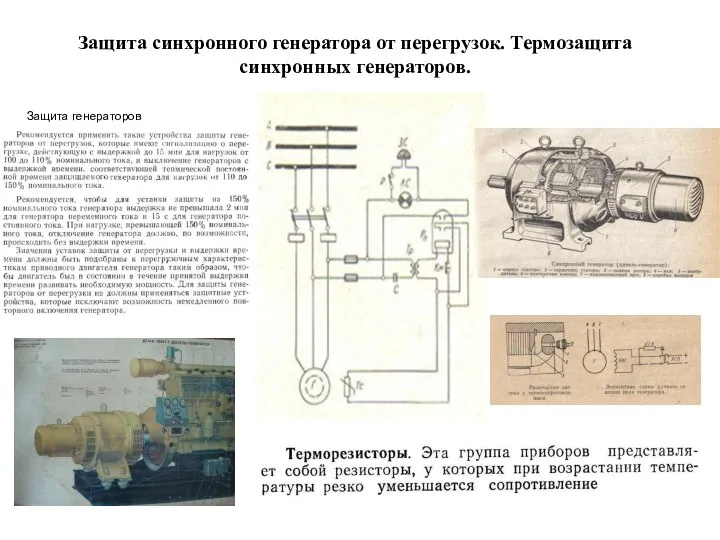

«TIS-Рабочее время» Система учета рабочего времени сотрудников. - презентация Защита синхронного генератора от перегрузок. Техническое обслуживание судовых электроприводов. (Билет 10)

Защита синхронного генератора от перегрузок. Техническое обслуживание судовых электроприводов. (Билет 10) Плетение лентами

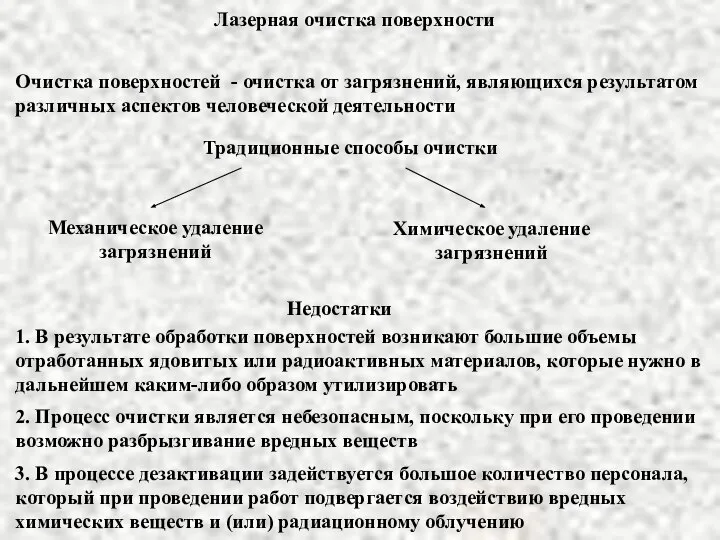

Плетение лентами Лазерная очистка поверхности

Лазерная очистка поверхности  Қазақстан Халқы Ассемблеясы саяси институт ретінде

Қазақстан Халқы Ассемблеясы саяси институт ретінде Правовая охрана окружающей среды в странах СНГ Маркина Александра Ю124Б

Правовая охрана окружающей среды в странах СНГ Маркина Александра Ю124Б Русская лапта

Русская лапта Презентация Философия Фрэнсиса Бэкона

Презентация Философия Фрэнсиса Бэкона Құқықты іске асыру және қолдану. Құқық нормаларына түсінік беру

Құқықты іске асыру және қолдану. Құқық нормаларына түсінік беру Последствия внутриличностных конфликтов Выполнили: Стародворов Вадим Ращупкин Артем

Последствия внутриличностных конфликтов Выполнили: Стародворов Вадим Ращупкин Артем Изделия из дерева на заказ

Изделия из дерева на заказ ООО «Велосипедный клуб «МИНСК»

ООО «Велосипедный клуб «МИНСК» Проект по продвижению комплекса ГТО

Проект по продвижению комплекса ГТО Верные ответы к музыкальному конкурсу:

Верные ответы к музыкальному конкурсу: Субъекты управления

Субъекты управления  Общие сведения об автоматическом управлении производственными процессами, классификация систем автоматического регулирования

Общие сведения об автоматическом управлении производственными процессами, классификация систем автоматического регулирования