Содержание

- 2. What affects ELSD performance? Nebulization Size of droplet formed: consequently determines size of particle Evaporation Efficiency

- 3. Nebulization Increase Neb gas flow ----------- Reduces droplet size Increase Liquid flow --------------- Increases droplet size

- 4. Over the last four years, the number of ELSD manufacturers has increased considerably. Current ELSD manufacturers

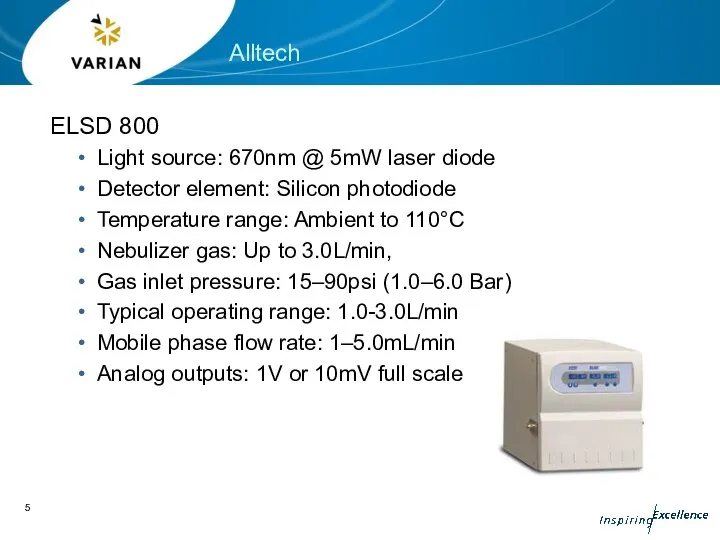

- 5. Alltech ELSD 800 Light source: 670nm @ 5mW laser diode Detector element: Silicon photodiode Temperature range:

- 6. Alltech ELSD 2000ES Light source: 650nm 30mW Laser diode Detector element: Silicon photodiode Temperature range: Ambient

- 7. Alltech ELSD 3300ES Light source: 650nm 30mW Laser diode Silicon photodiode detector Temperature range: Ambient to

- 8. Nebulizer Gas flow adjusted for solvent type No nebulizer temperature control Evaporation Temperature setting dependent on

- 9. SEDEX 85 LT-ELSD Blue light source Expanded software functionality Mass flow controller Remote power-down Automatic gas

- 10. Nebulizer 3.0 SLMs of gas used to nebulize solvents under standard conditions Large volume nebulizer chamber

- 11. Evaporation Long coiled tube which removes large droplets by centrifugal force and provides laminar flow -

- 12. ELSD 2040 Light Source: Tungsten Halogen Lamp Detector Element: PMT Temperature Range: Ambient to 100°C (?)

- 13. Acquity ELSD Designed for UPLC an analysis 80Hz Data rate Sharp peak shape (1.2 - 1.5sec)

- 14. Nebulizer Snap-on design for easy replacement Temperature controllable (% of drift tube temp) Gas pressure/flow set

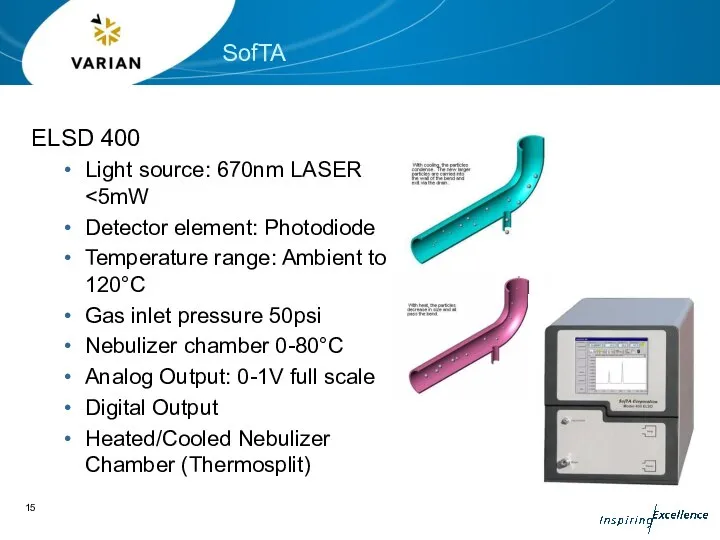

- 15. ELSD 400 Light source: 670nm LASER Detector element: Photodiode Temperature range: Ambient to 120°C Gas inlet

- 16. Nebuliser: Thermo-split Technology For difficult to evaporate mobile phases, or high flow rates, the nebulizer chamber

- 17. ZAM 3000 Light source: Tungsten Halogen Detector element: Photomultiplier Temperature range: Ambient to 70°C Nebulizer gas

- 18. Nebulizer For difficult to evaporate mobile phases, or high flow rates, the nebulizer chamber walls are

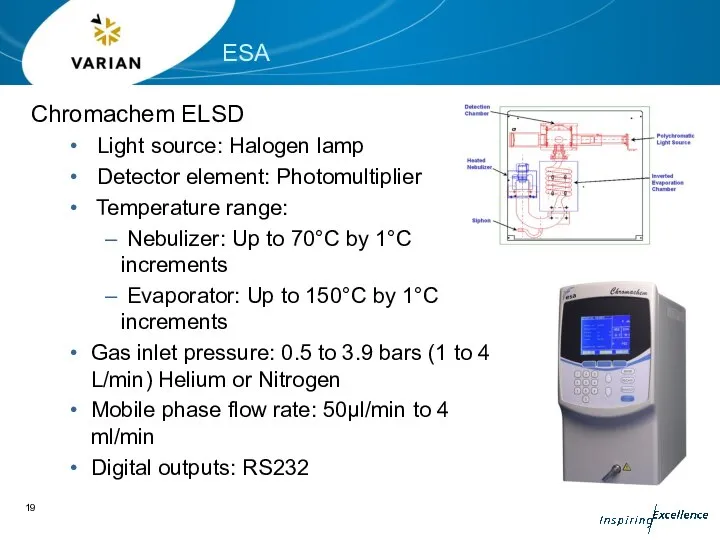

- 19. Chromachem ELSD Light source: Halogen lamp Detector element: Photomultiplier Temperature range: Nebulizer: Up to 70°C by

- 20. Nebulizer Similar design to SEDEX 75 Evaporation Similar design to SEDEX 75 No special design features

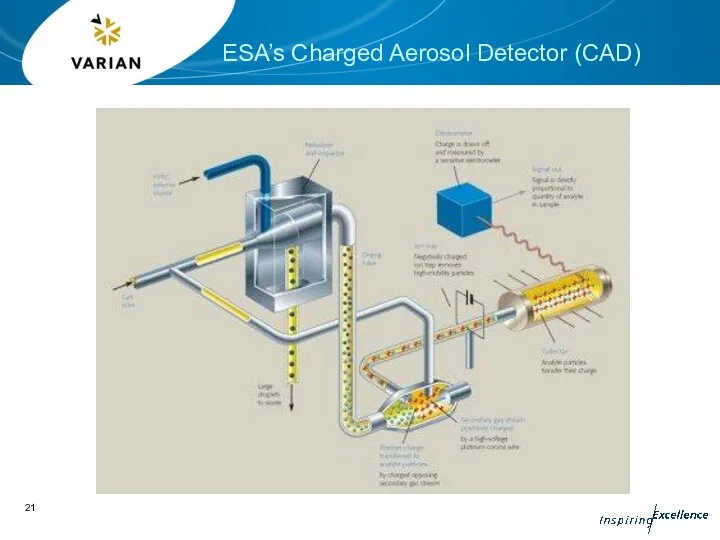

- 21. ESA’s Charged Aerosol Detector (CAD)

- 22. How it works: The column eluent is nebulized with nitrogen, before passing into a heated drift

- 23. This is a non-optical technique and therefore is not bound by scattering laws. Small particles, which

- 24. The technique is dependent on nebulization and evaporation stages. It is gradient sensitive - the response

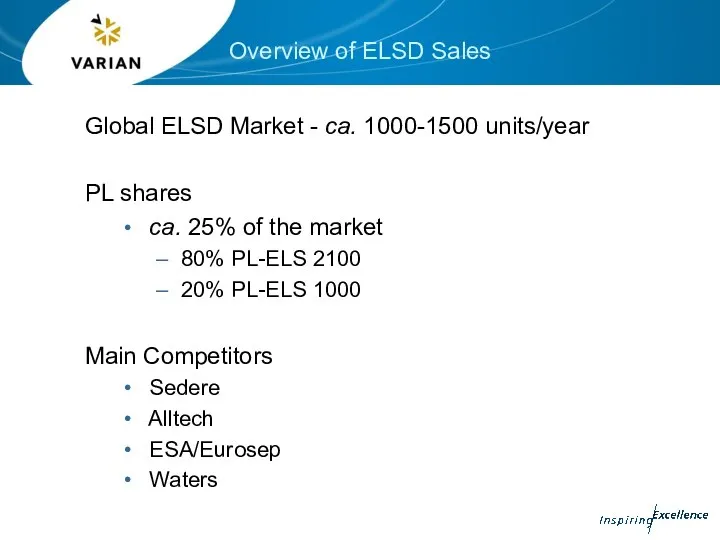

- 25. Overview of ELSD Sales Global ELSD Market - ca. 1000-1500 units/year PL shares ca. 25% of

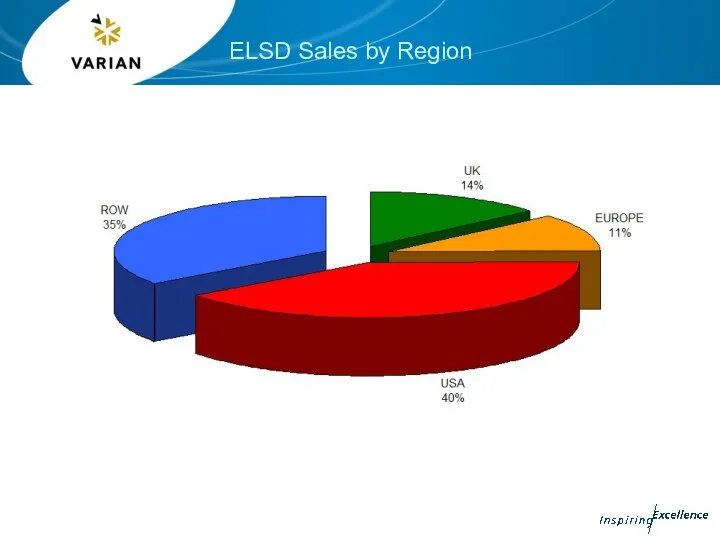

- 26. ELSD Sales by Region

- 27. Competitor Overview

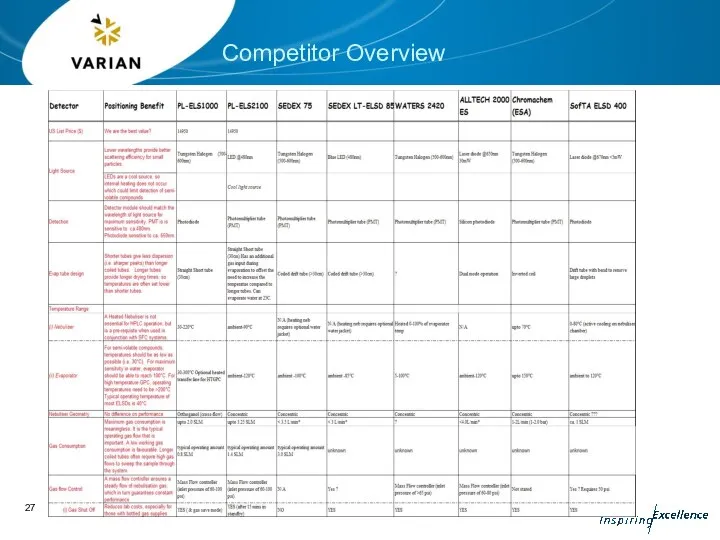

- 28. Competitor Overview

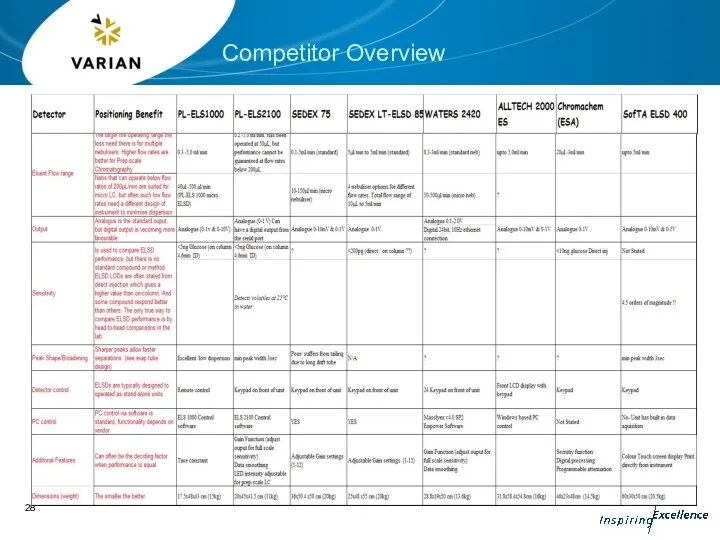

- 30. Скачать презентацию

Тепловые двигатели и нагнетатели. Многоступенчатый компрессор

Тепловые двигатели и нагнетатели. Многоступенчатый компрессор М. В. Ломоносов – великий переводчик

М. В. Ломоносов – великий переводчик Закон Ома. Светодиоды. Кнопки. Виды кнопок и переключателей

Закон Ома. Светодиоды. Кнопки. Виды кнопок и переключателей ГЕОМЕТРИЧЕСКАЯ ОПТИКА

ГЕОМЕТРИЧЕСКАЯ ОПТИКА  Динамика вращательного движения (динамика абсолютно твёрдого тела)

Динамика вращательного движения (динамика абсолютно твёрдого тела) Презентация по физике "Мячи Взаимодействие Энергия" - скачать

Презентация по физике "Мячи Взаимодействие Энергия" - скачать  Экзотические субстанции

Экзотические субстанции Законы физики

Законы физики Прямой метод решения уравнений в матричной форме. Организация итерационного процесса. Проблема сходимости численных схем

Прямой метод решения уравнений в матричной форме. Организация итерационного процесса. Проблема сходимости численных схем Основные законы динамики. Принцип Даламбера. Техническая механика

Основные законы динамики. Принцип Даламбера. Техническая механика Разработка рекомендаций по снижению величины основного сопротивления движения автосамосвала и увеличения сцепления с дорогой

Разработка рекомендаций по снижению величины основного сопротивления движения автосамосвала и увеличения сцепления с дорогой Тема: Действие электрического тока на организм человека. Урок изучения нового материала. 9 класс Автор: Старкова Г.В.

Тема: Действие электрического тока на организм человека. Урок изучения нового материала. 9 класс Автор: Старкова Г.В.  Атомның планетарлық моделі

Атомның планетарлық моделі Стационарное свободное двумерное течение жидкости внутри двугранного угла с движущимися стенками

Стационарное свободное двумерное течение жидкости внутри двугранного угла с движущимися стенками А.С. Попов, изобретатель радио

А.С. Попов, изобретатель радио Электротехника. Операторный метод анализа переходных процессов. (Лекция 13)

Электротехника. Операторный метод анализа переходных процессов. (Лекция 13) Аўтаматызацыя вымярэнняў і дыстанцыйнае кіраванне тэхналагічнымі аб’ектамі нафтаправоднага транспарту

Аўтаматызацыя вымярэнняў і дыстанцыйнае кіраванне тэхналагічнымі аб’ектамі нафтаправоднага транспарту Источники энергии для сварки

Источники энергии для сварки Тепломассообмен в биосфере. Введение, некоторые математические понятия

Тепломассообмен в биосфере. Введение, некоторые математические понятия Центр тяжести. Условия равновесия тел

Центр тяжести. Условия равновесия тел Задачи

Задачи Методика фракционного фототермолиза Asclepion

Методика фракционного фототермолиза Asclepion Сила тяжести. Вес тела. Сила упругости

Сила тяжести. Вес тела. Сила упругости  Изучение микроструктуры процессов релаксации в плазме

Изучение микроструктуры процессов релаксации в плазме Optimalizace procesu obrábění hliníkových profilů

Optimalizace procesu obrábění hliníkových profilů урок физики в 7 классе подготовила Вавилова В.Н. МБОУ СОШ№8 г.Ельца

урок физики в 7 классе подготовила Вавилова В.Н. МБОУ СОШ№8 г.Ельца Презентация ИСПАРЕНИЕ 8 класс

Презентация ИСПАРЕНИЕ 8 класс  Основы равновесной термодинамики

Основы равновесной термодинамики