Содержание

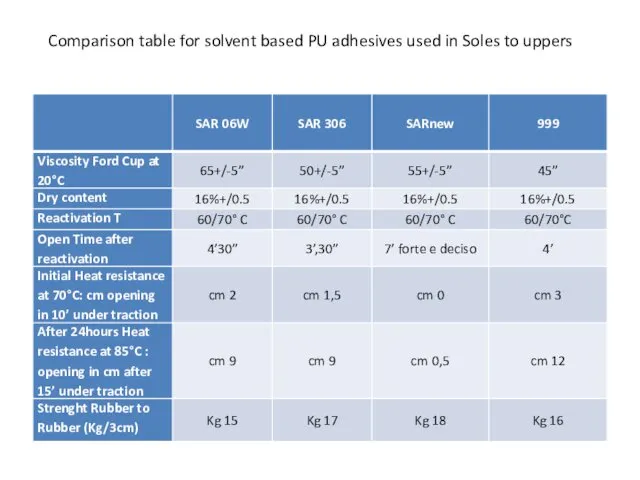

- 2. Comparison table for solvent based PU adhesives used in Soles to uppers

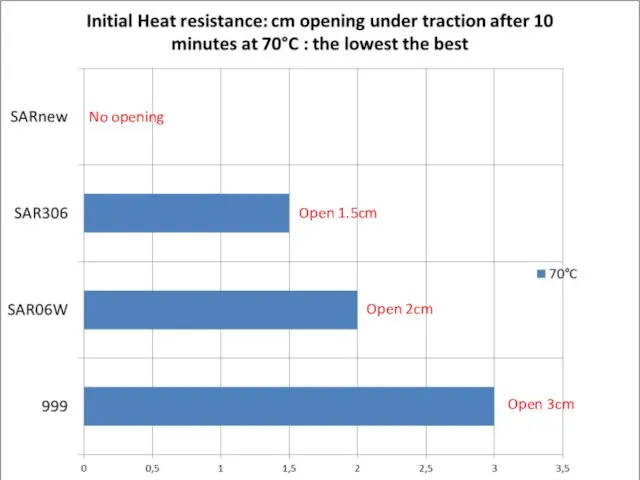

- 4. No opening Open 1.5cm Open 2cm Open 3cm

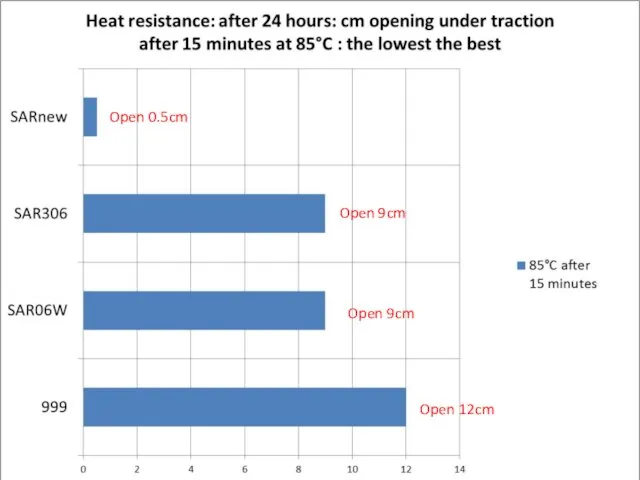

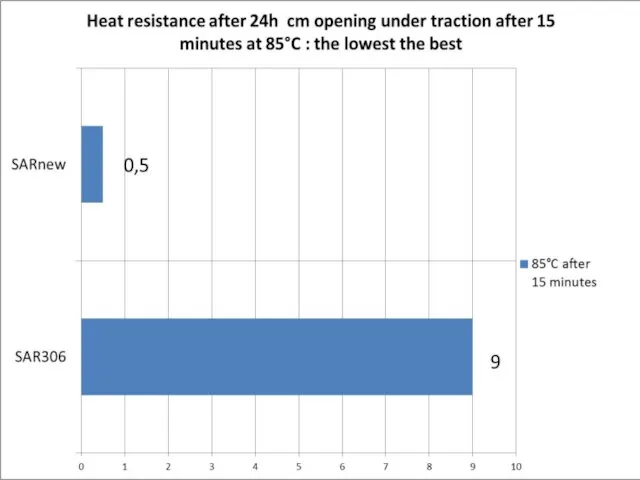

- 5. Open 0.5cm Open 9cm Open 9cm Open 12cm

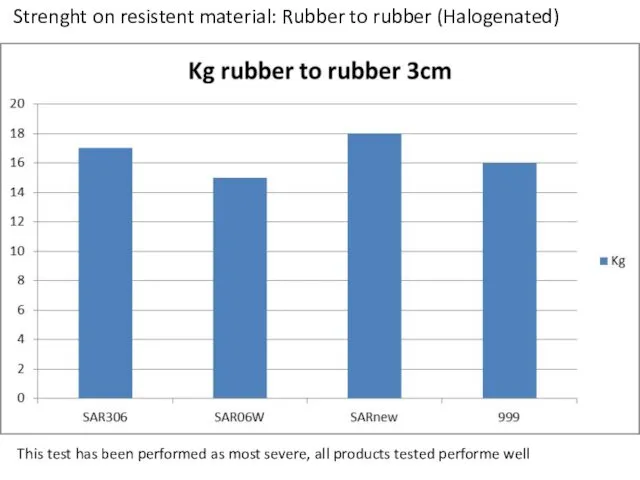

- 6. Strenght on resistent material: Rubber to rubber (Halogenated) This test has been performed as most severe,

- 7. Comparison SAR306 vs 999 Same reactivation Temperature: 60/70°C Dry content similar on compared samples 16,0% vs

- 8. Comparison SAR306 vs SAR06W All measured features are quite similar, within the method tolerance SAR06W has

- 9. Introduce new product on request: SARnew (name to be defined) Same reactivation Temperature than all compared

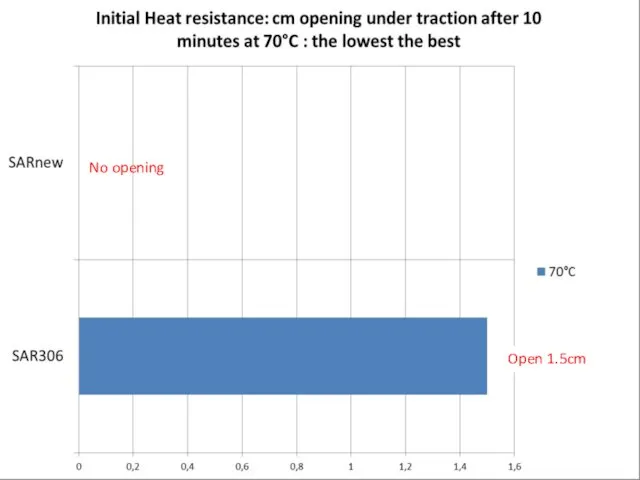

- 11. No opening Open 1.5cm

- 14. Скачать презентацию

Английский язык в ДК Аннино

Английский язык в ДК Аннино Коммуникативная модель Public Relations. (Тема 3)

Коммуникативная модель Public Relations. (Тема 3) Методы маркетинга

Методы маркетинга Введение. Понятие инвестиционной стратегии и ее роль в развитии предприятия

Введение. Понятие инвестиционной стратегии и ее роль в развитии предприятия Новые модели. Носки и гольфы company Conte spa

Новые модели. Носки и гольфы company Conte spa Душевые поддоны и ограждения Victoria Roca

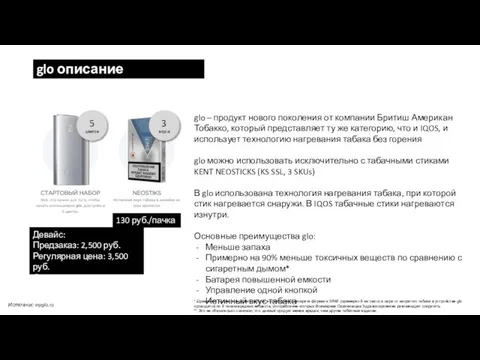

Душевые поддоны и ограждения Victoria Roca Glo - продукт нового поколения от компании Бритиш Американ Тобакко

Glo - продукт нового поколения от компании Бритиш Американ Тобакко Аквапарк и детский лагерь в Очакове

Аквапарк и детский лагерь в Очакове Витаминно-минеральный комплекс алфавит

Витаминно-минеральный комплекс алфавит Коммерческое предложение: Система Олимп-24

Коммерческое предложение: Система Олимп-24 2018 год - год желтой земляной собаки. Выполнение портрета собаки на елочном шарике

2018 год - год желтой земляной собаки. Выполнение портрета собаки на елочном шарике Курс Стань предпринимателем

Курс Стань предпринимателем Promotion agencies in Poland

Promotion agencies in Poland Методика поиска информации в интернете при решении задач конкурентной разведки, на примере системы графического анализа

Методика поиска информации в интернете при решении задач конкурентной разведки, на примере системы графического анализа AeroLabs e-commerce platform

AeroLabs e-commerce platform Повышайте посещаемость вашего сайта. Playfon

Повышайте посещаемость вашего сайта. Playfon Акции ООО Айс-Крим 2000

Акции ООО Айс-Крим 2000 Вкусный эксперт по кашлю и сопутствующему восстановлению

Вкусный эксперт по кашлю и сопутствующему восстановлению Компания Тесли. Ассортимент

Компания Тесли. Ассортимент ЮГ 4 – это мы

ЮГ 4 – это мы Программа обучения и сертификации партнеров APC-MGE

Программа обучения и сертификации партнеров APC-MGE Project: Global Social Media Plan // July Topic: International Day of Friendship Format: image Date: 30 July

Project: Global Social Media Plan // July Topic: International Day of Friendship Format: image Date: 30 July Modul.Life. Модули успеха твоей жизни

Modul.Life. Модули успеха твоей жизни Видеонаблюдение для бизнеса

Видеонаблюдение для бизнеса ООО Мир квартир. Город Санкт-Петербург

ООО Мир квартир. Город Санкт-Петербург Достопримечательности России

Достопримечательности России Компания СДЭК - взаимовыгодное сотрудничество по отправлению корреспонденции и грузов

Компания СДЭК - взаимовыгодное сотрудничество по отправлению корреспонденции и грузов Реклама как феномен культуры в Эквадоре

Реклама как феномен культуры в Эквадоре