Содержание

- 2. OPERATIONAL STANDARD SP-AFS « Workshop pre-picking» | July 2012 | 2 Намерения и цели Операционный стандрат

- 3. Principles of Parts/After-Sales Pre-Picking OPERATIONAL STANDARD SP-AFS « Workshop pre-picking» | July 2012 | Improve operational

- 4. Mise en place du Pré-picking PR-APV Workshop pre-picking is used by PEUGEOT approved repairers with more

- 5. THE OPERATIONAL STANDARD OPERATIONAL STANDARD SP-AFS « Workshop pre-picking» | July 2012 | AP/EXCL/EXR

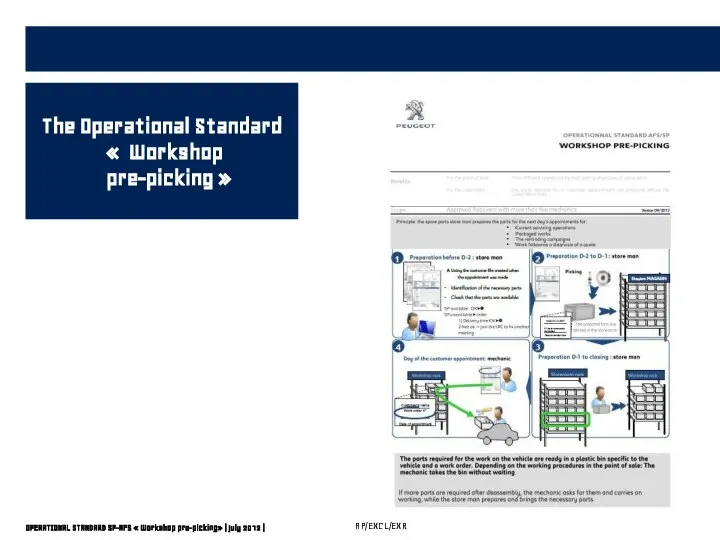

- 6. The Operational Standard « Workshop pre-picking » OPERATIONAL STANDARD SP-AFS « Workshop pre-picking» | July 2012

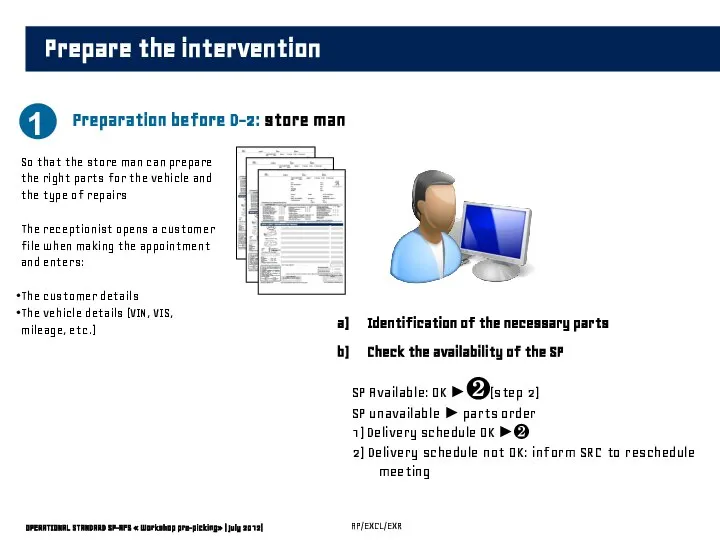

- 7. OPERATIONAL STANDARD SP-AFS « Workshop pre-picking» | July 2012| 1 Preparation before D-2: store man Identification

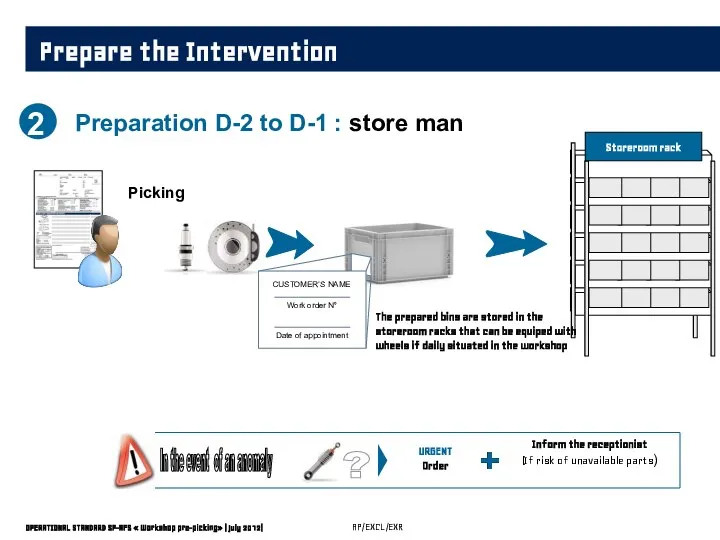

- 8. OPERATIONAL STANDARD SP-AFS « Workshop pre-picking» | July 2012| 2 Preparation D-2 to D-1 : store

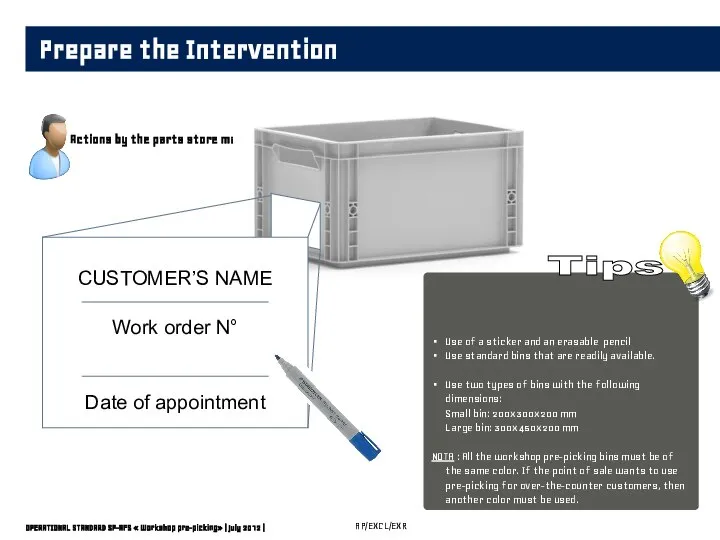

- 9. OPERATIONAL STANDARD SP-AFS « Workshop pre-picking» | July 2012 | Actions by the parts store man

- 10. OPERATIONAL STANDARD SP-AFS « Workshop pre-picking» | July 2012| 3 Preparation D-1 at closure of the

- 11. OPERATIONAL STANDARD SP-AFS « Workshop pre-picking» | July 2012 | 4 Day D, when used by

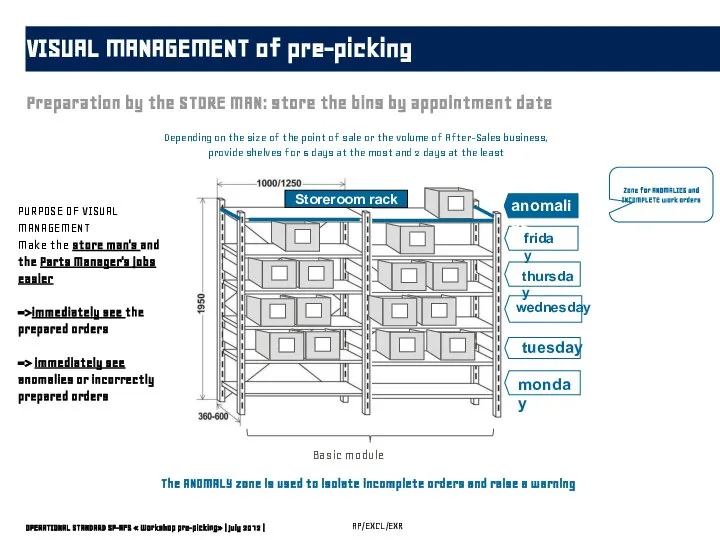

- 12. OPERATIONAL STANDARD SP-AFS « Workshop pre-picking» | July 2012 | VISUAL MANAGEMENT of pre-picking Preparation by

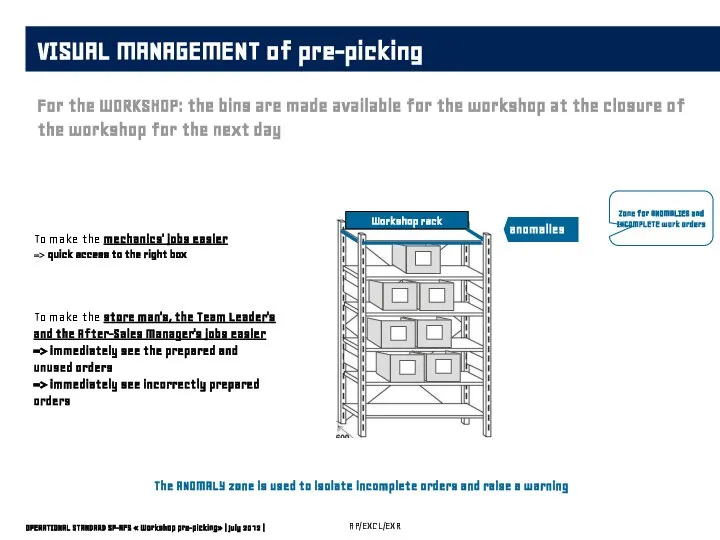

- 13. OPERATIONAL STANDARD SP-AFS « Workshop pre-picking» | July 2012 | VISUAL MANAGEMENT of pre-picking For the

- 14. OPERATIONAL STANDARD SP-AFS « Workshop pre-picking» | July 2012 | How to implement the standard? Secure

- 15. OPERATIONAL STANDARD SP-AFS « Workshop pre-picking» | July 2012| How to implement the standard ? The

- 16. OPERATIONAL STANDARD SP-AFS « Workshop pre-picking» | July 2012 | The results achieved by pre-picking For

- 18. Скачать презентацию

Сопровождение на маркетплейсах

Сопровождение на маркетплейсах Выбор оптимального канала распределения

Выбор оптимального канала распределения Кухняры - redesign & recovery

Кухняры - redesign & recovery Особливості реклами в Фінляндії

Особливості реклами в Фінляндії New Balance

New Balance Распродажа французского бренда обуви и одежды. Бренд Charles de Nevel

Распродажа французского бренда обуви и одежды. Бренд Charles de Nevel Ароматизаторы для Авто

Ароматизаторы для Авто Бизнес-модель. Франчайзинг

Бизнес-модель. Франчайзинг Tulip Inn Sofrino Park Hotel. Презентация отеля

Tulip Inn Sofrino Park Hotel. Презентация отеля Тренинг. Скрипты приветсвия и базовые знания для магазинов 5 уценок

Тренинг. Скрипты приветсвия и базовые знания для магазинов 5 уценок Каталог ЭКОSTAR

Каталог ЭКОSTAR Исследование рынка на примере компаний McDonald`s и Burger King

Исследование рынка на примере компаний McDonald`s и Burger King Анализ конкурентоспособности товара по системе 1111-5555

Анализ конкурентоспособности товара по системе 1111-5555 Производство сложной кулинарной продукции для проведения тематического мероприятия в кафе на 40 мест

Производство сложной кулинарной продукции для проведения тематического мероприятия в кафе на 40 мест ПАО “Концерн Хлебпром”

ПАО “Концерн Хлебпром” Маркетинговый подход к принятию управленческих решений. Управление ценой

Маркетинговый подход к принятию управленческих решений. Управление ценой Турагентство ANGELA Tour

Турагентство ANGELA Tour Коммерческое предложение TERABIT

Коммерческое предложение TERABIT Логистические решения для бизнеса

Логистические решения для бизнеса ООО Товарное Хозяйство

ООО Товарное Хозяйство Система управления маркетплейсами

Система управления маркетплейсами Туры LuxeTravel. Путешествуйте с нами

Туры LuxeTravel. Путешествуйте с нами Dr. Tsokur. Подарунковий сертифікат на 10 сеансів

Dr. Tsokur. Подарунковий сертифікат на 10 сеансів Программа лояльности для партнёров холдинга Гарбар гурмэ

Программа лояльности для партнёров холдинга Гарбар гурмэ Новинки косметологии

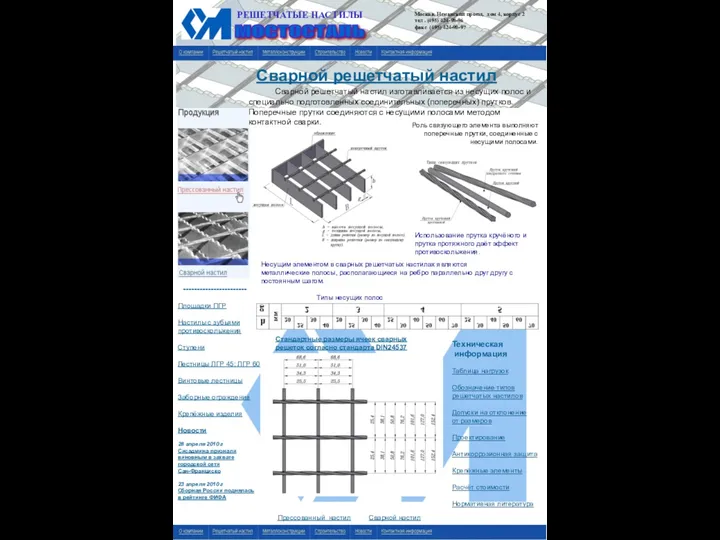

Новинки косметологии Сварной решетчатый настил

Сварной решетчатый настил Сайт Фабрика-продаж

Сайт Фабрика-продаж Концепции Выпускного вечера

Концепции Выпускного вечера