Содержание

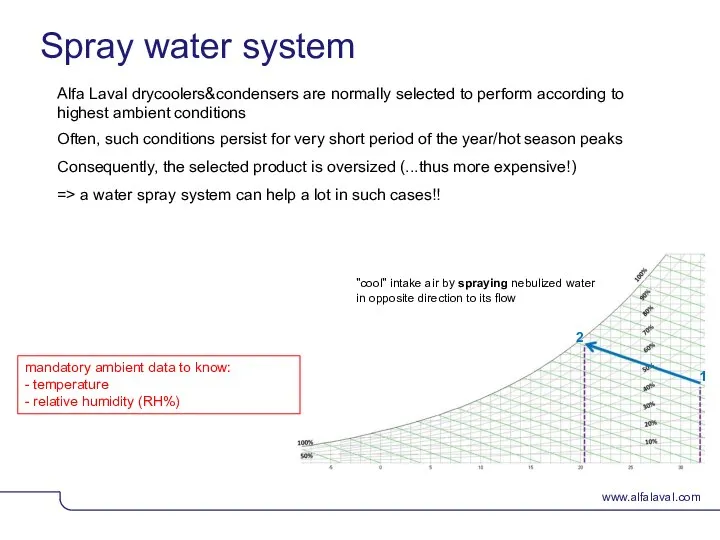

- 2. Spray water system Alfa Laval drycoolers&condensers are normally selected to perform according to highest ambient conditions

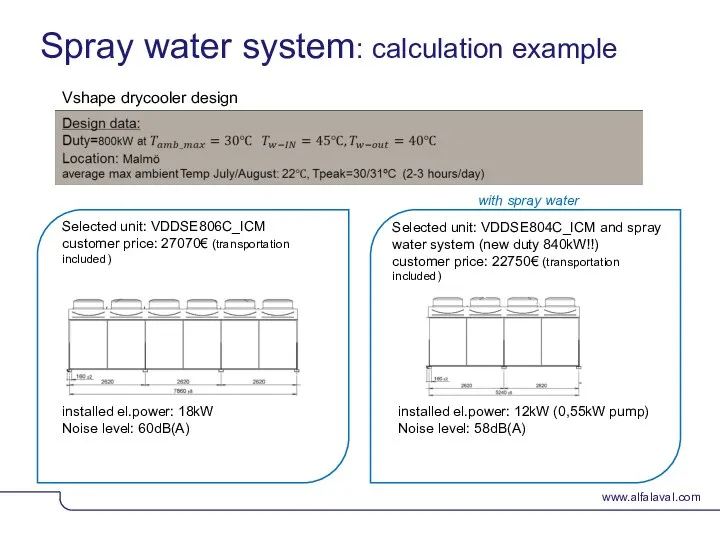

- 3. Spray water system: calculation example Vshape drycooler design Selected unit: VDDSE806C_ICM customer price: 27070€ (transportation included)

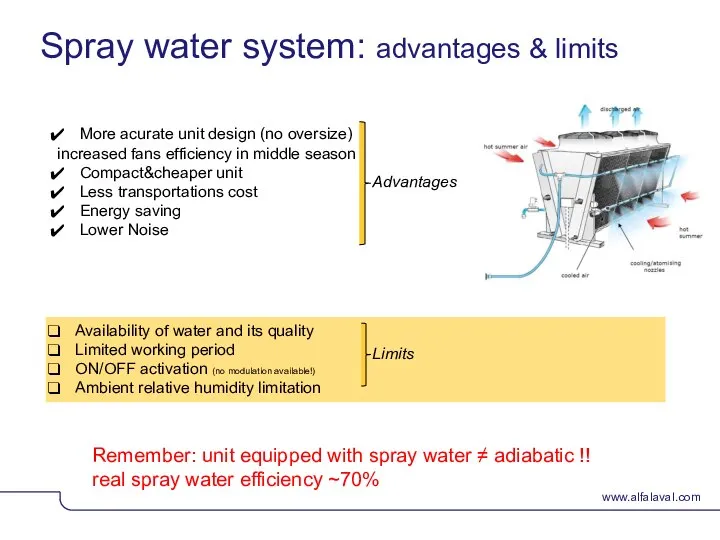

- 4. Spray water system: advantages & limits More acurate unit design (no oversize) increased fans efficiency in

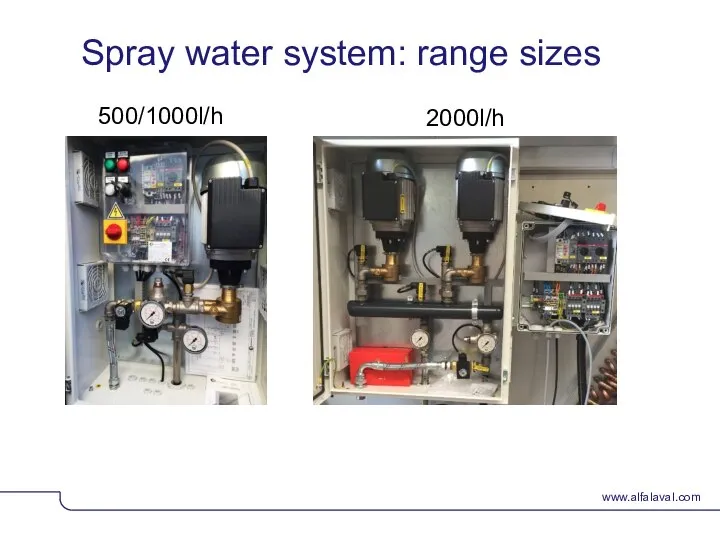

- 5. Spray water system: range sizes 500/1000l/h 2000l/h

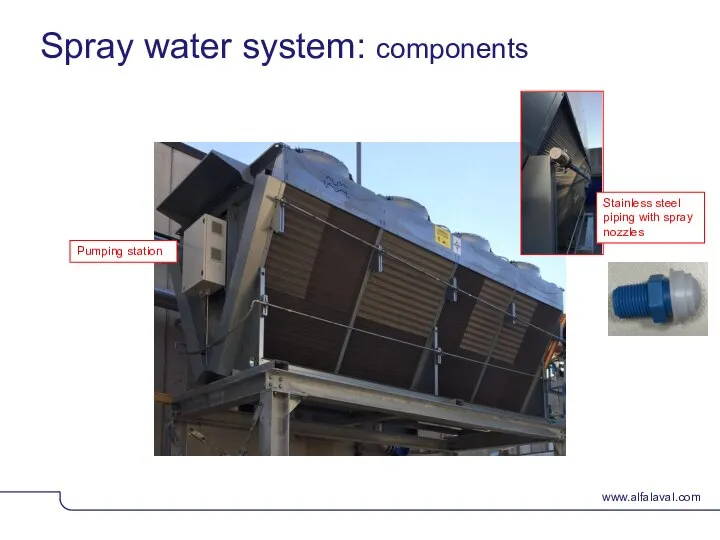

- 6. Spray water system: components Pumping station Stainless steel piping with spray nozzles

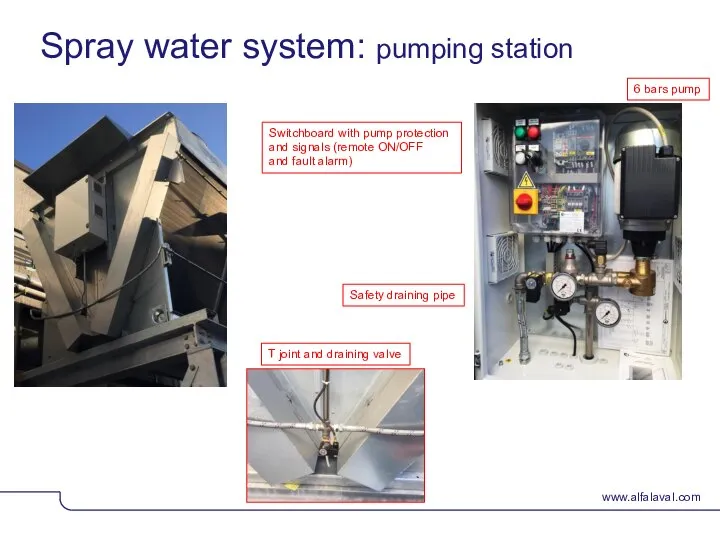

- 7. Spray water system: pumping station Switchboard with pump protection and signals (remote ON/OFF and fault alarm)

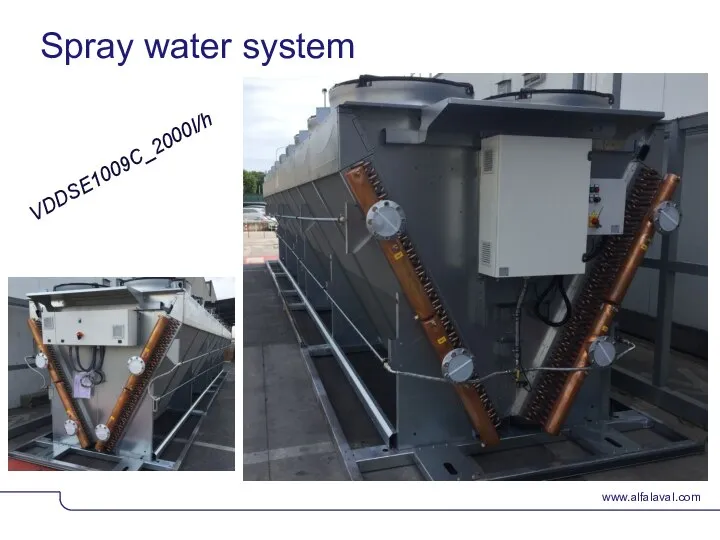

- 8. Spray water system VDDSE1009C_2000l/h

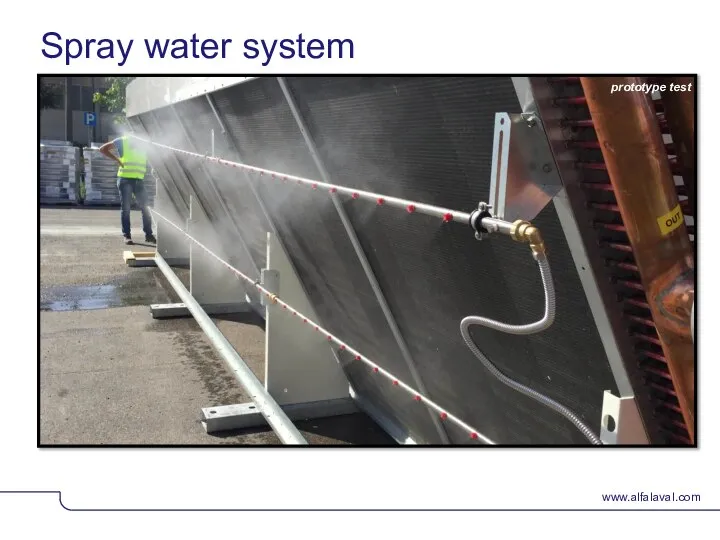

- 9. Spray water system prototype test

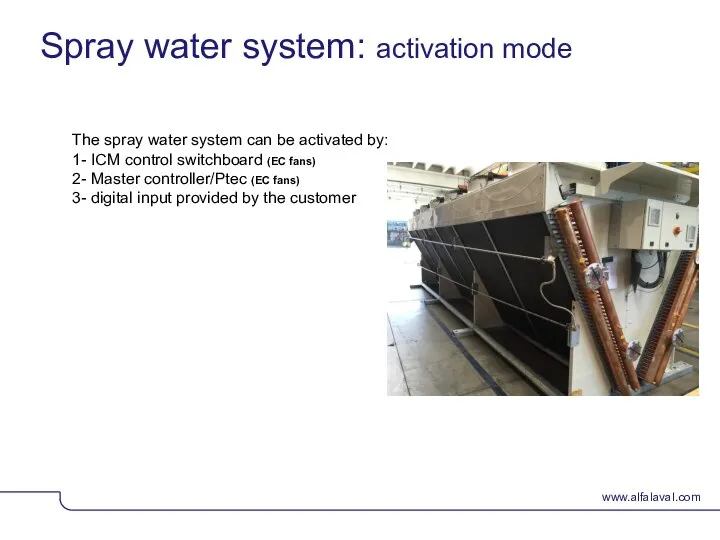

- 10. Spray water system: activation mode The spray water system can be activated by: 1- ICM control

- 11. Spray water system: conclusions Optimal cooling effect is given with RH% below at least 60% (Ambient

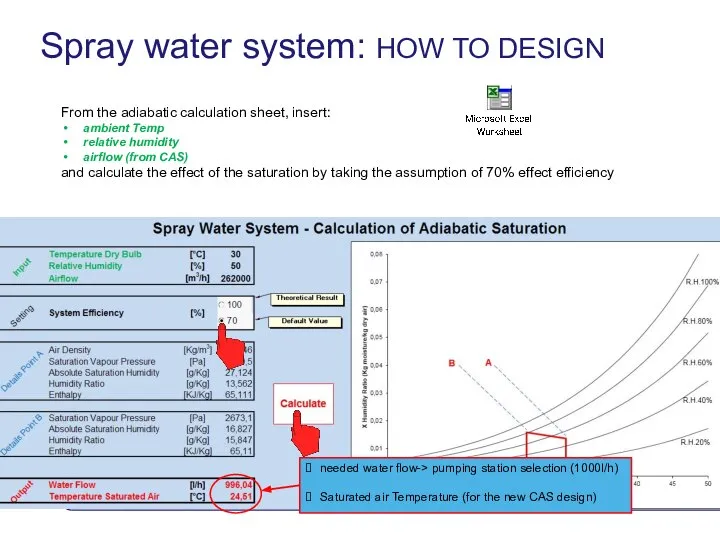

- 12. Spray water system: HOW TO DESIGN From the adiabatic calculation sheet, insert: ambient Temp relative humidity

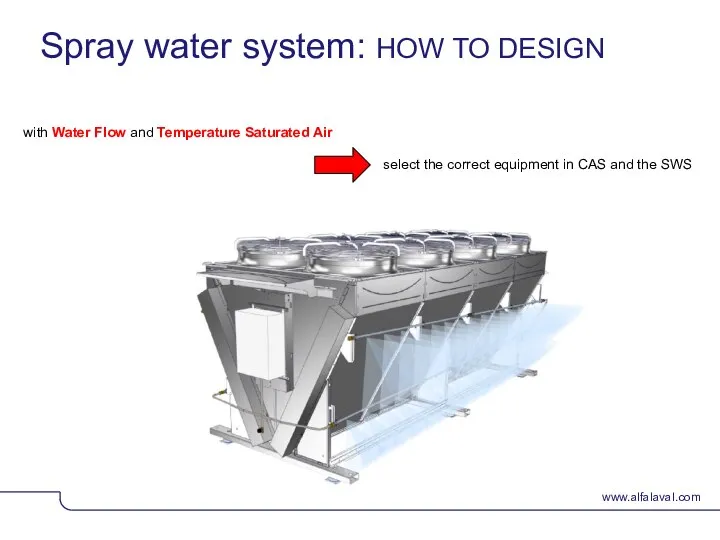

- 13. Spray water system: HOW TO DESIGN with Water Flow and Temperature Saturated Air select the correct

- 15. Скачать презентацию

20160329_yunyy_zashchitnik_rodiny_stasik_merkulov_-_3

20160329_yunyy_zashchitnik_rodiny_stasik_merkulov_-_3 Bluetooth технологиясы

Bluetooth технологиясы Год Российской науки

Год Российской науки Установочное практическое занятие ЗСП-4 курс ЗПГС-2 курс

Установочное практическое занятие ЗСП-4 курс ЗПГС-2 курс Активные формы и методы, используемые в процессе трудового обучения Штукатурно-малярное дело

Активные формы и методы, используемые в процессе трудового обучения Штукатурно-малярное дело Lexicography. Types of dictionaries

Lexicography. Types of dictionaries Қазақстанда өнеркәсіптің дамуы

Қазақстанда өнеркәсіптің дамуы команда 10, задача 12

команда 10, задача 12 Анализ проекта

Анализ проекта Летающий робот для диагностики нефтепровода

Летающий робот для диагностики нефтепровода Биметаллические термометры, модель 55, промышленная серия. (S5550; R5502; A5500)

Биметаллические термометры, модель 55, промышленная серия. (S5550; R5502; A5500) дс37 Кононова

дс37 Кононова Луганский природный заповедник

Луганский природный заповедник Определение тепловой мощности системы отопления. Практика 4

Определение тепловой мощности системы отопления. Практика 4 20180406_yaponskie_trehstishiya

20180406_yaponskie_trehstishiya Тенденции изменения семьи и брака в современном обществе

Тенденции изменения семьи и брака в современном обществе Игра Русская цивилизация 2017-2025. Расклад. Как происходит смена власти при раскладе

Игра Русская цивилизация 2017-2025. Расклад. Как происходит смена власти при раскладе Биполярный транзистор

Биполярный транзистор TMS320F28035. Состав периферийных устройств. Порты ввода/вывода. Менеджер прерываний

TMS320F28035. Состав периферийных устройств. Порты ввода/вывода. Менеджер прерываний Логика текста

Логика текста Актуальные вопросы борьбы с коррупцией

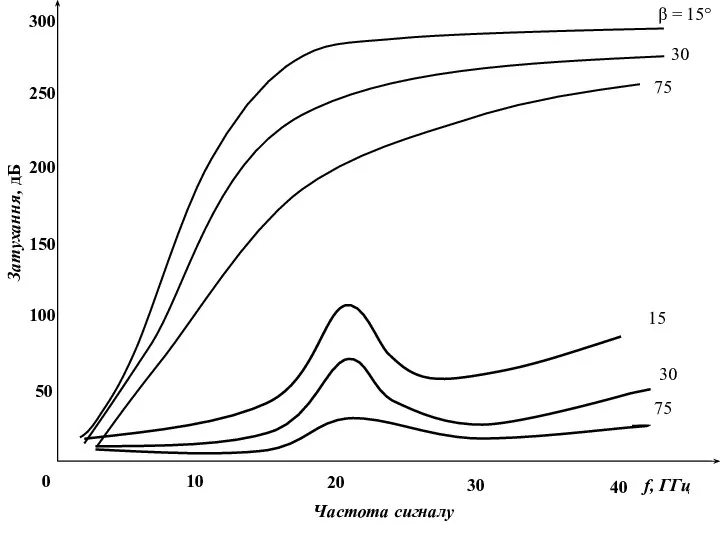

Актуальные вопросы борьбы с коррупцией Рис 2

Рис 2 Герои мультфильмов и их влияние на детей

Герои мультфильмов и их влияние на детей Живые системы и экосистемы

Живые системы и экосистемы 20160728_chehov

20160728_chehov Liver pancreas

Liver pancreas Буквы разные писать

Буквы разные писать Коса -девичья краса

Коса -девичья краса