Содержание

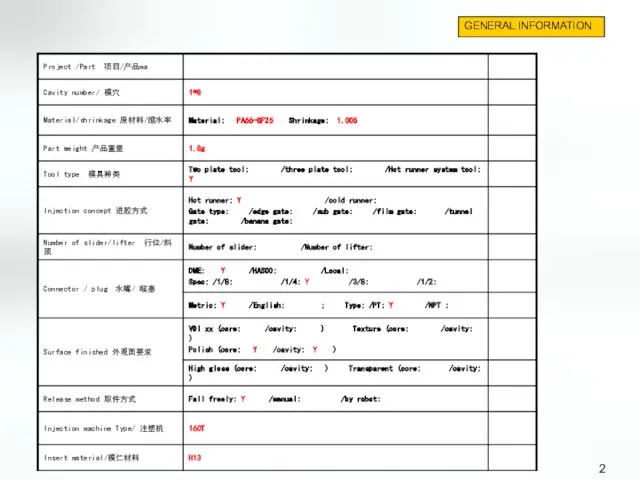

- 2. GENERAL INFORMATION

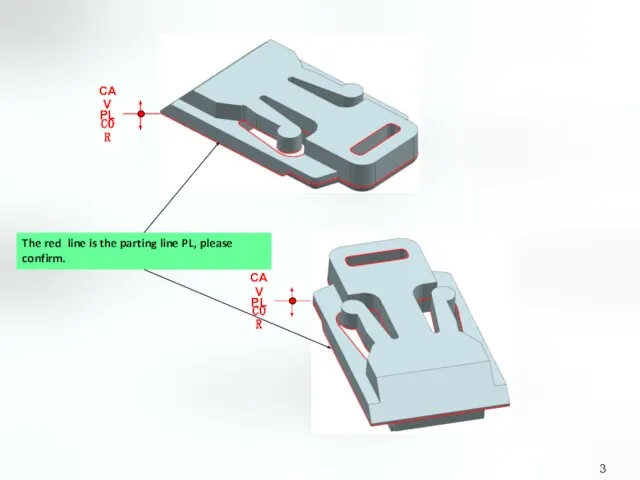

- 3. The red line is the parting line PL, please confirm.

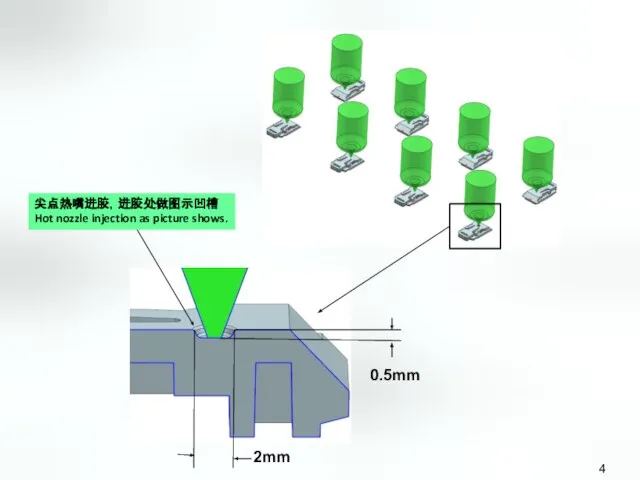

- 4. 2mm 0.5mm 尖点热嘴进胶,进胶处做图示凹槽 Hot nozzle injection as picture shows.

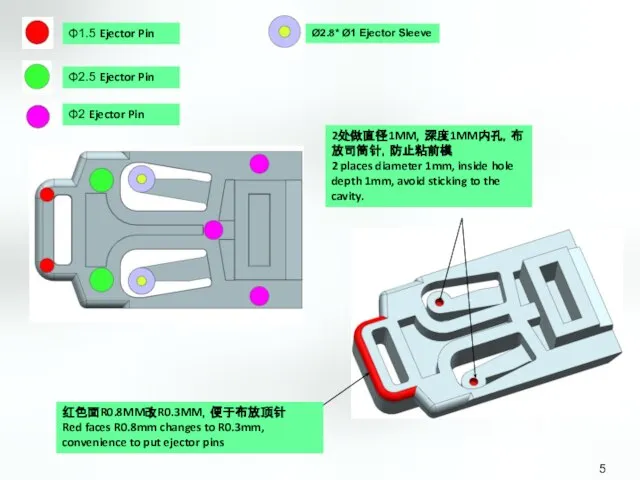

- 5. Φ2.5 Ejector Pin Φ2 Ejector Pin Φ1.5 Ejector Pin Ø2.8* Ø1 Ejector Sleeve 2处做直径1MM,深度1MM内孔,布放司筒针,防止粘前模 2 places

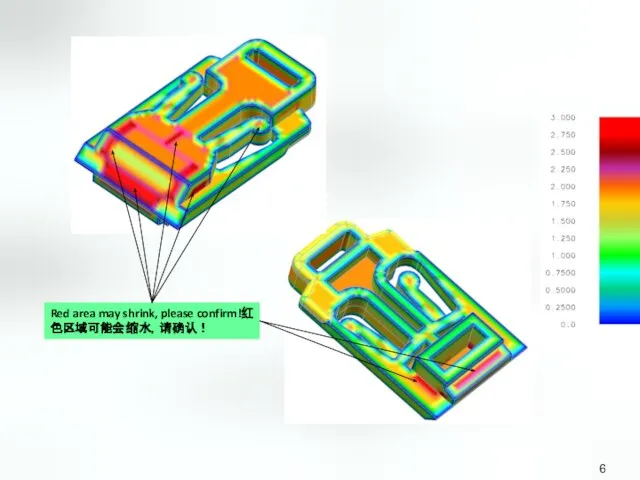

- 6. Red area may shrink, please confirm!红色区域可能会缩水,请确认!

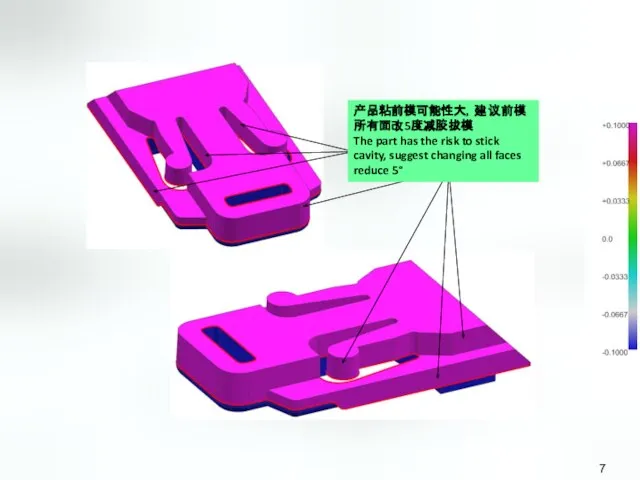

- 7. 产品粘前模可能性大,建议前模所有面改5度减胶拔模 The part has the risk to stick cavity, suggest changing all faces reduce 5°

- 8. As picture shows, add mold cavity number(1……8). the text height 1.5mm, text bulge 0.1mm, please confirm.

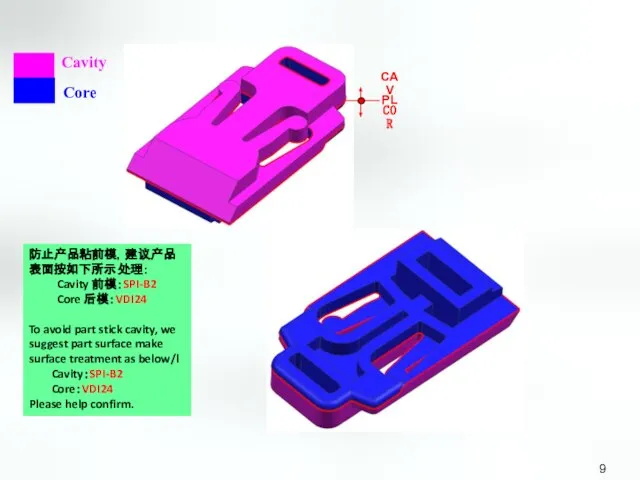

- 9. 防止产品粘前模,建议产品表面按如下所示处理: Cavity 前模:SPI-B2 Core 后模:VDI24 To avoid part stick cavity, we suggest part surface make surface

- 11. Скачать презентацию

Религия. Всё о религии и не только

Религия. Всё о религии и не только 20151213_pamyatki_po_istorii_i_obshchestvoznaniyu_

20151213_pamyatki_po_istorii_i_obshchestvoznaniyu_ Проект Радость приносим всем

Проект Радость приносим всем Материнская плата

Материнская плата Красная книга Липецкой области

Красная книга Липецкой области Социолингвистика

Социолингвистика ПГУ контактного типа

ПГУ контактного типа Jieguoh team

Jieguoh team Цвет как средство выражения: тихие (глухие) и звонкие цвета

Цвет как средство выражения: тихие (глухие) и звонкие цвета Образ Александра Невского в культуре и искусстве

Образ Александра Невского в культуре и искусстве Кафедра ТЭС. Курсовой проект

Кафедра ТЭС. Курсовой проект Электроизмерительные приборы. Часть 1.1

Электроизмерительные приборы. Часть 1.1 Перлит в современных видах бетона

Перлит в современных видах бетона К. Г. Паустовский. Заячьи лапы. Природа и человек в произведении

К. Г. Паустовский. Заячьи лапы. Природа и человек в произведении Проектируем дирижабль

Проектируем дирижабль Материалы и ресурсы

Материалы и ресурсы Планировочное зонирование города Севастополя

Планировочное зонирование города Севастополя Механизация и технология доения коров

Механизация и технология доения коров Билиглернин тергини

Билиглернин тергини Қысқатолқынды пеш

Қысқатолқынды пеш Компания Модуль

Компания Модуль дети войны

дети войны Roditelskoe_sobranie_2022

Roditelskoe_sobranie_2022 Блокировочные связи в цепях управления А.Д

Блокировочные связи в цепях управления А.Д 20130426_osvoenie_zemli_amurskoy

20130426_osvoenie_zemli_amurskoy Графика Петровского времени

Графика Петровского времени класс УРОК №27 Олимпийские игры

класс УРОК №27 Олимпийские игры СПРОС

СПРОС