Содержание

- 2. JAP Scheduling means the allocation of resources over time to accomplish specific tasks. Workforce scheduling determines

- 3. JAP The two basic manufacturing environments are: A JOB SHOP (Process focused system) is a process

- 4. JAP Single Processor Scheduling (no alternative routing) In some cases an entire plant can be viewed

- 5. JAP Allocate your customers to ABC-classes A class –strategic customers / most profitable (or other vice

- 6. JAP Typically scheduling is divided to: Rough planning - > Master Production Schedule MPS (months and

- 7. JAP Rough planning – MPS What are the main objectives, reasoning and steps of it?

- 8. JAP TASK 1: Estimating realistic delivery times Specially needed for sales – for customer promises

- 9. JAP TASK 2: Ensuring the resources needed Specially needed to keep the delivery time promises given

- 10. JAP TASK 3: Controlling / managing the work load Specially needed for production planning in order

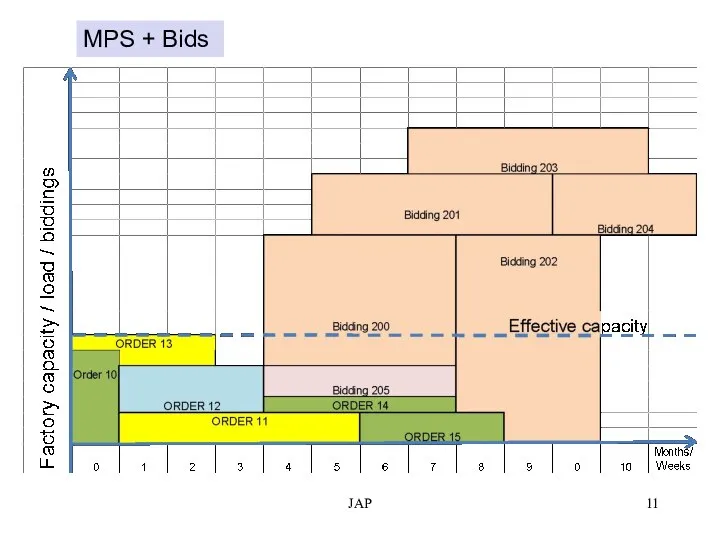

- 11. JAP MPS + Bids

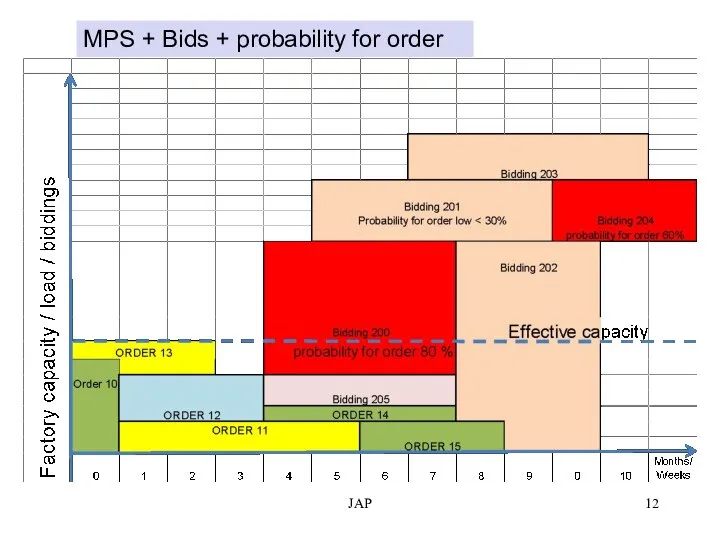

- 12. JAP MPS + Bids + probability for order

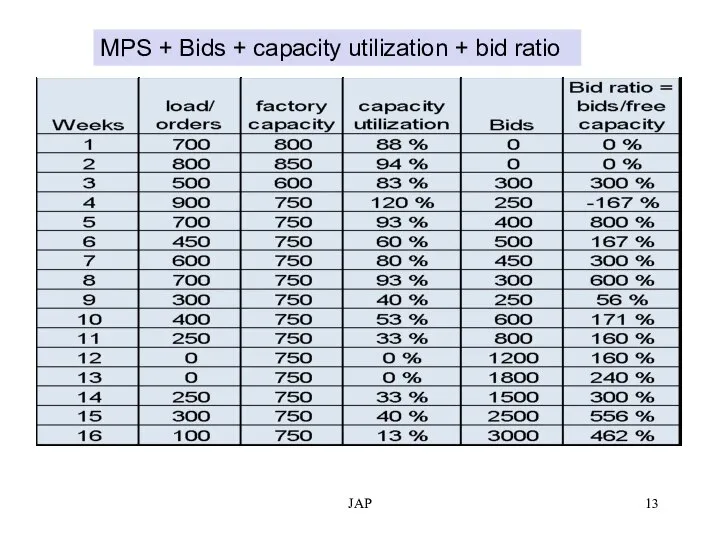

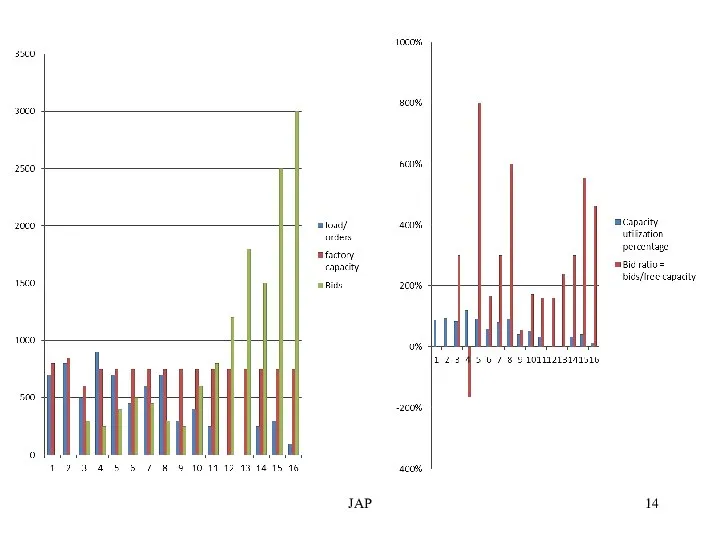

- 13. JAP MPS + Bids + capacity utilization + bid ratio

- 14. JAP

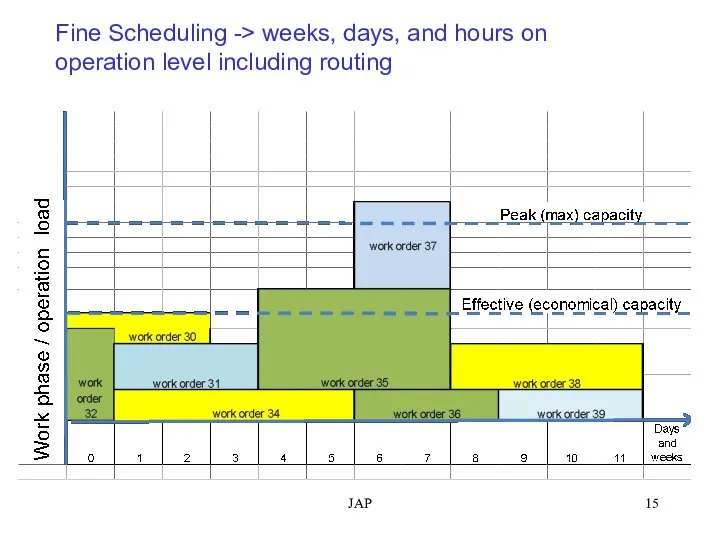

- 15. JAP Fine Scheduling -> weeks, days, and hours on operation level including routing

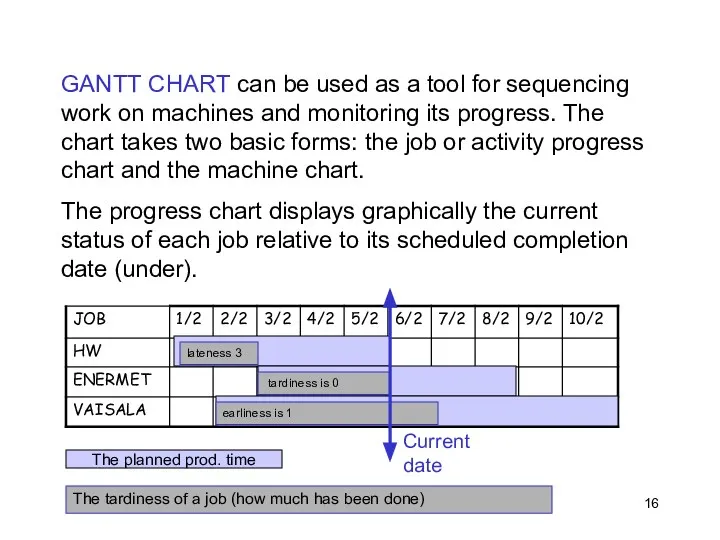

- 16. JAP GANTT CHART can be used as a tool for sequencing work on machines and monitoring

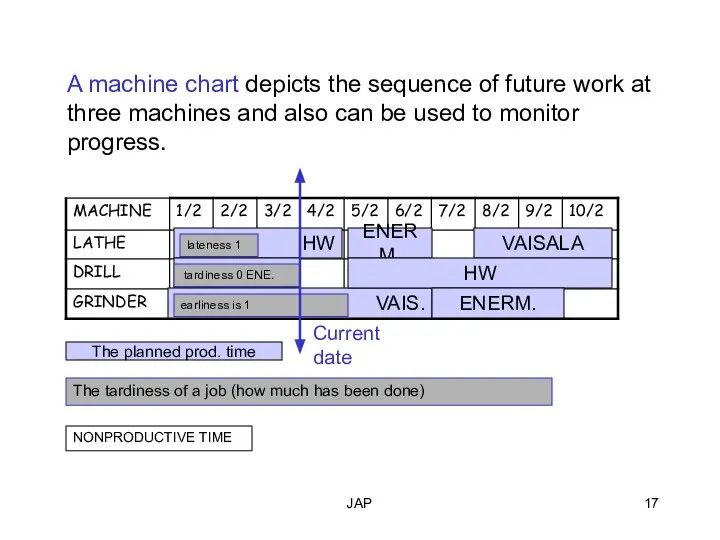

- 17. JAP A machine chart depicts the sequence of future work at three machines and also can

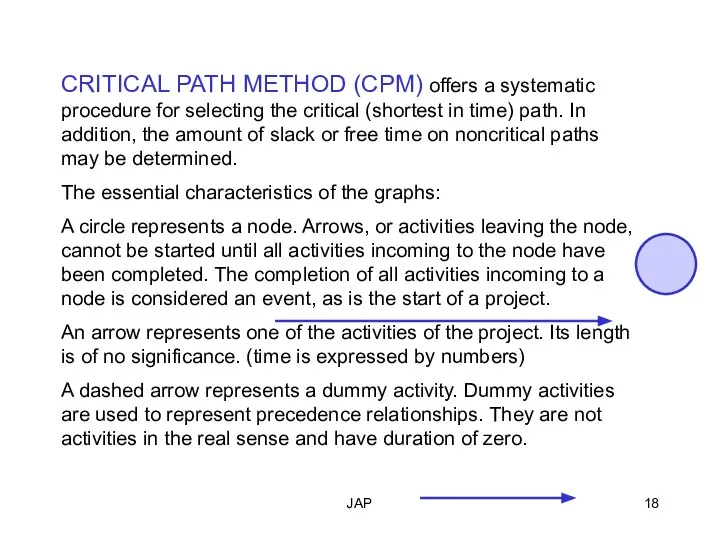

- 18. JAP CRITICAL PATH METHOD (CPM) offers a systematic procedure for selecting the critical (shortest in time)

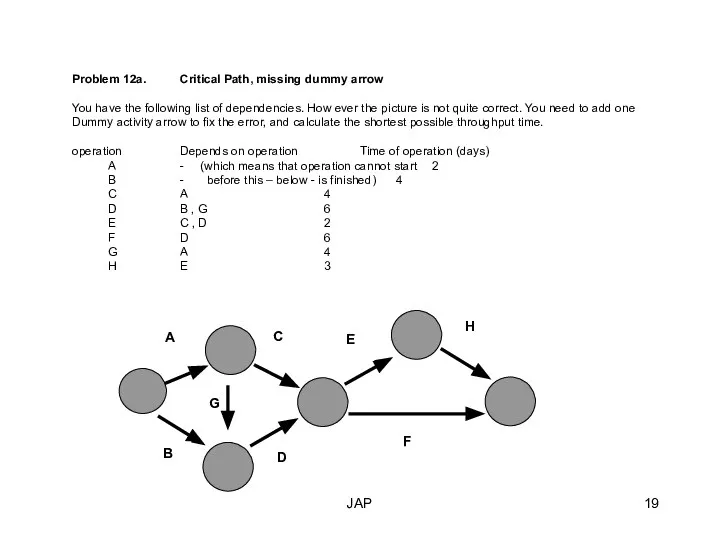

- 19. G A B E F H C D Problem 12a. Critical Path, missing dummy arrow You

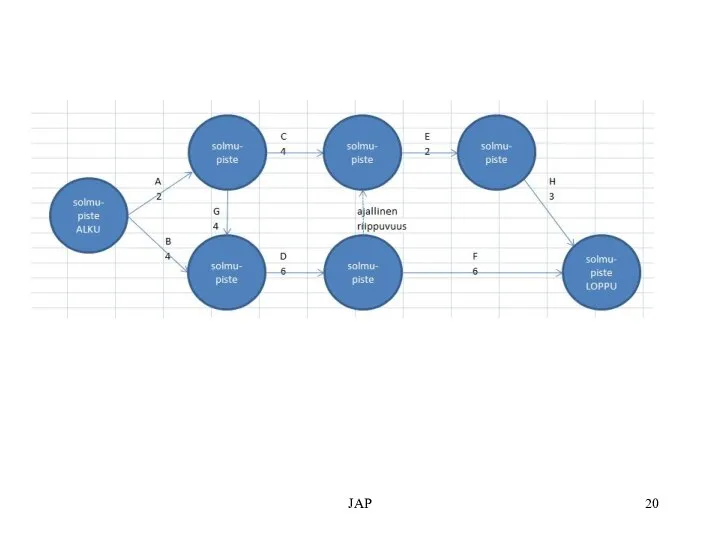

- 20. JAP

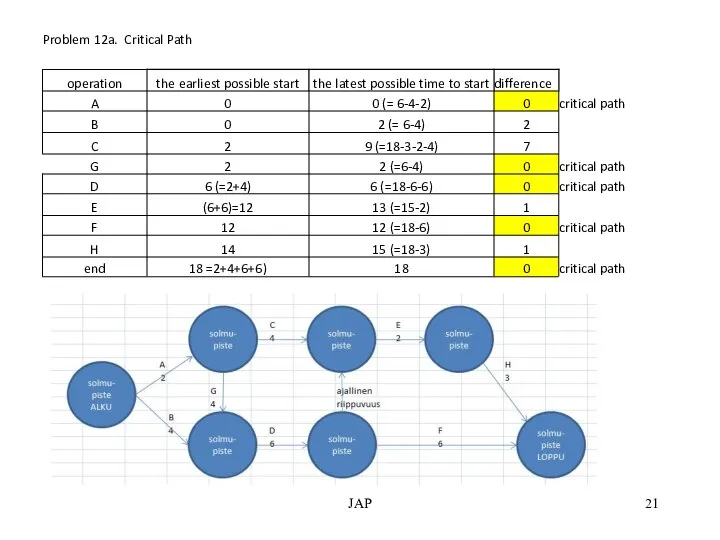

- 21. JAP

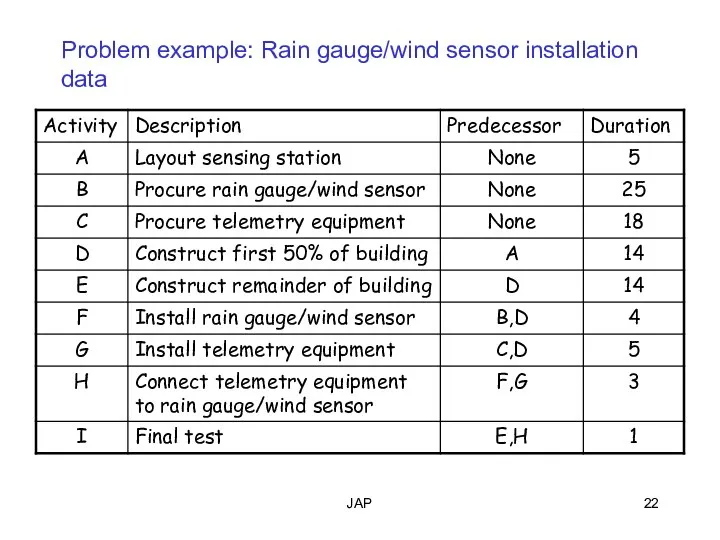

- 22. JAP Problem example: Rain gauge/wind sensor installation data

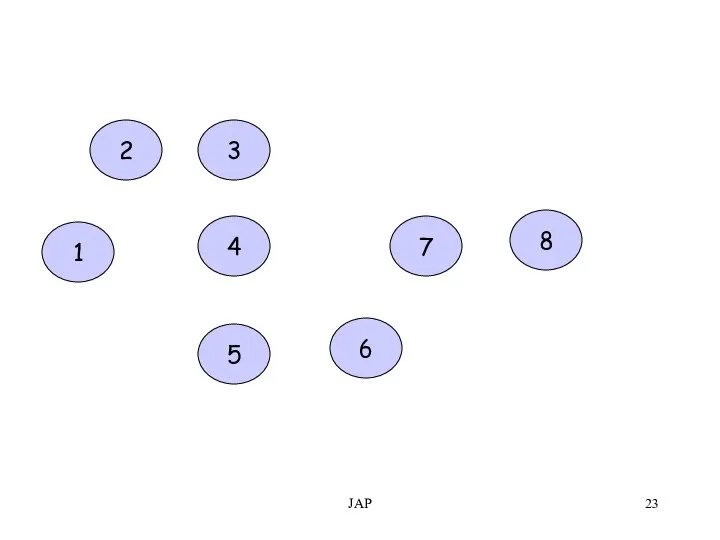

- 23. JAP 1 2 3 4 5 6 7 8

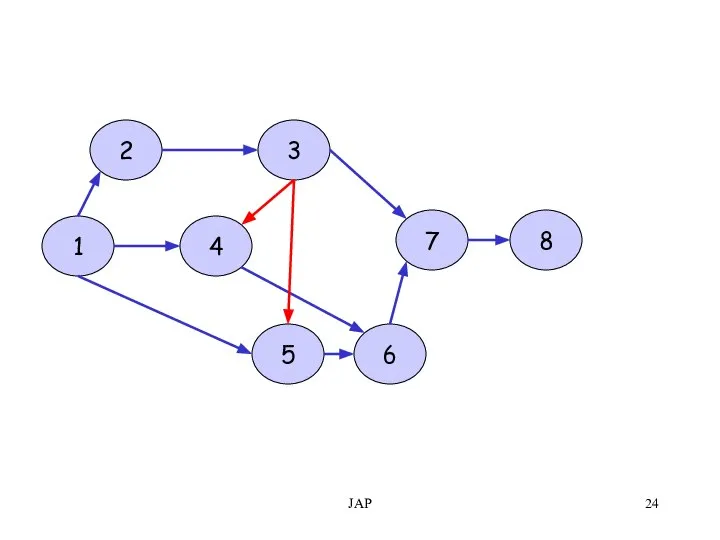

- 24. JAP 1 2 3 4 5 6 7 8

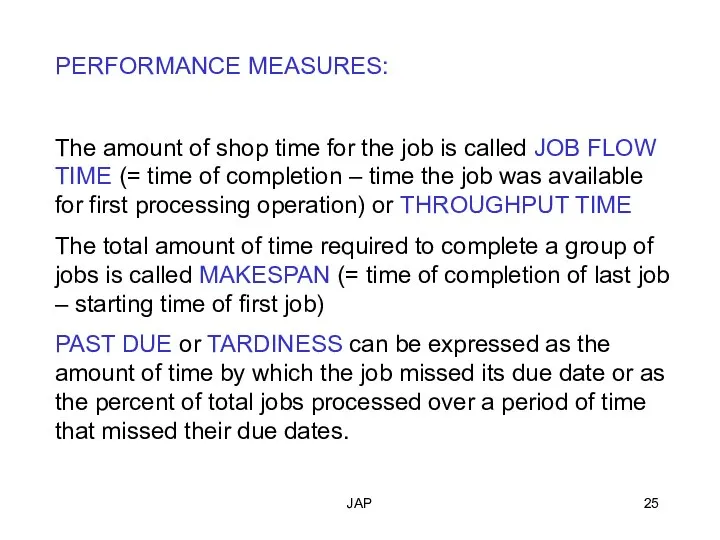

- 25. JAP PERFORMANCE MEASURES: The amount of shop time for the job is called JOB FLOW TIME

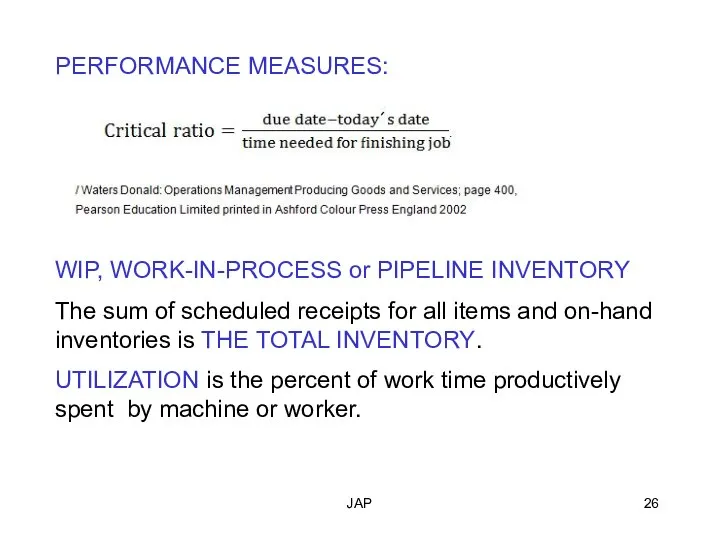

- 26. JAP PERFORMANCE MEASURES: WIP, WORK-IN-PROCESS or PIPELINE INVENTORY The sum of scheduled receipts for all items

- 27. JAP Problem of Economic batch quantity? If you consider a factory that needs to produce an

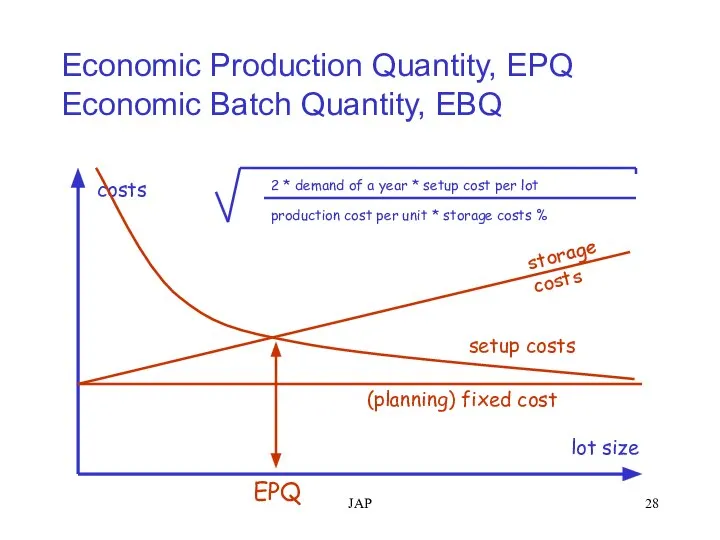

- 28. JAP Economic Production Quantity, EPQ Economic Batch Quantity, EBQ costs lot size (planning) fixed cost storage

- 29. JAP The costs associated with batch production can be categorized as direct and ancillary. Direct costs

- 30. JAP The use of the EBQ method is designed to analyse these problems and provide an

- 31. JAP EXAMPLE of EPQ / EBQ A company makes telephone booths, for a stable market where

- 32. JAP Problem 28. ECONOMIC BATCH SIZE / REPETITIVE ORDER QUANTITIES Replacement parts are supplied from an

- 33. JAP Very difficult EPQ and lot size problem: The demand of an item is 20000 units

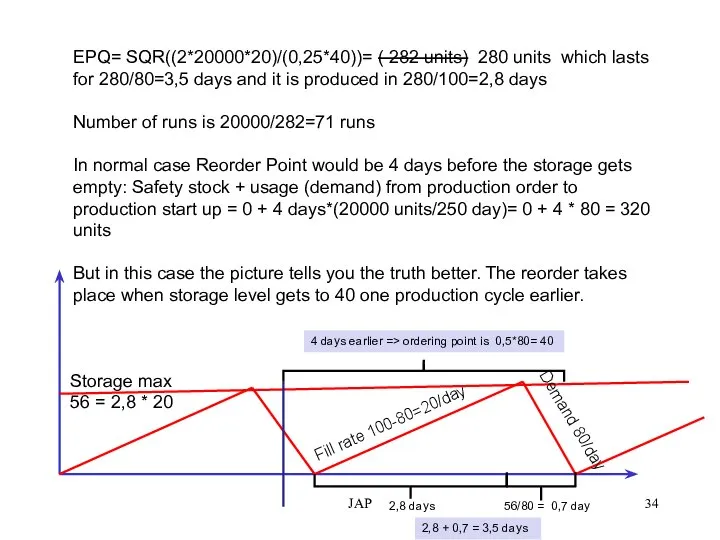

- 34. JAP EPQ= SQR((2*20000*20)/(0,25*40))= ( 282 units) 280 units which lasts for 280/80=3,5 days and it is

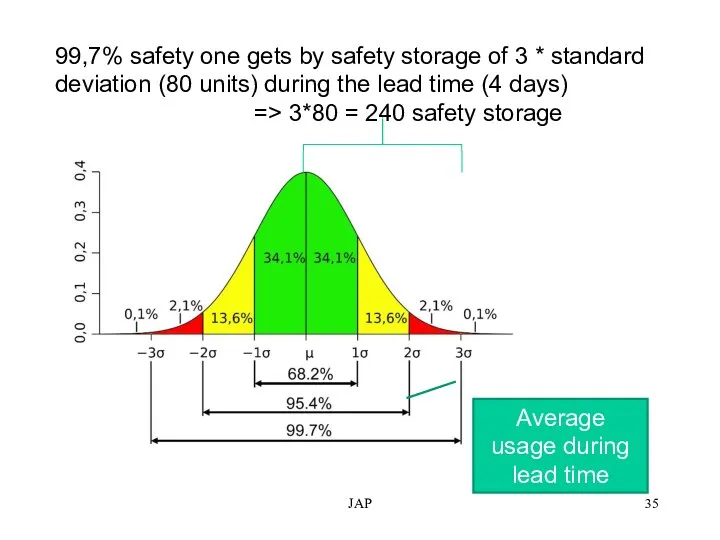

- 35. JAP 99,7% safety one gets by safety storage of 3 * standard deviation (80 units) during

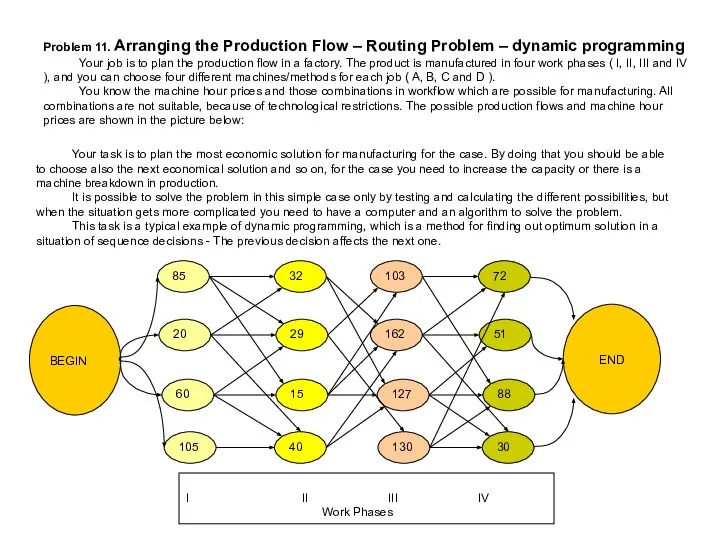

- 36. 85 103 130 127 162 30 88 51 72 32 20 60 105 29 15 40

- 38. Скачать презентацию

История возникновения контрабанды

История возникновения контрабанды Физиология органа зрения и основные зрительные функции

Физиология органа зрения и основные зрительные функции Safepay

Safepay Green_Chess_template

Green_Chess_template Политическая элита и политическое лидерство

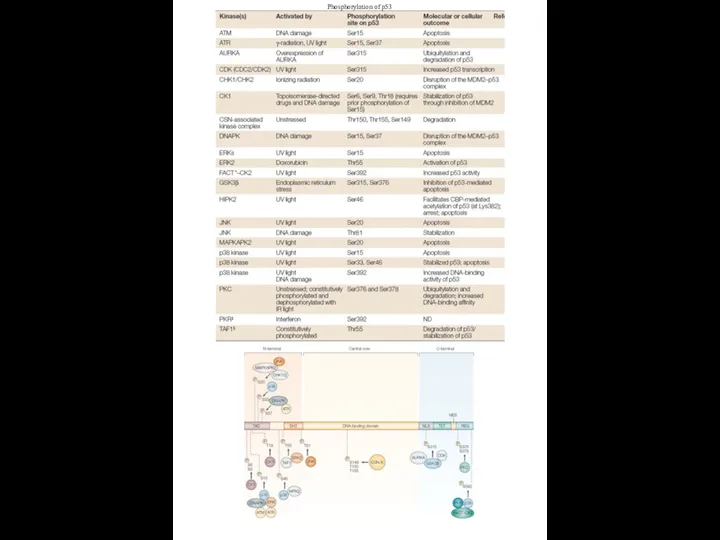

Политическая элита и политическое лидерство p53-2

p53-2 Торжественный Вход Господень в Иерусалим

Торжественный Вход Господень в Иерусалим Русская изба

Русская изба Презентация на тему "Клинические испытания новых лекарственных препаратов" - скачать презентации по Медицине

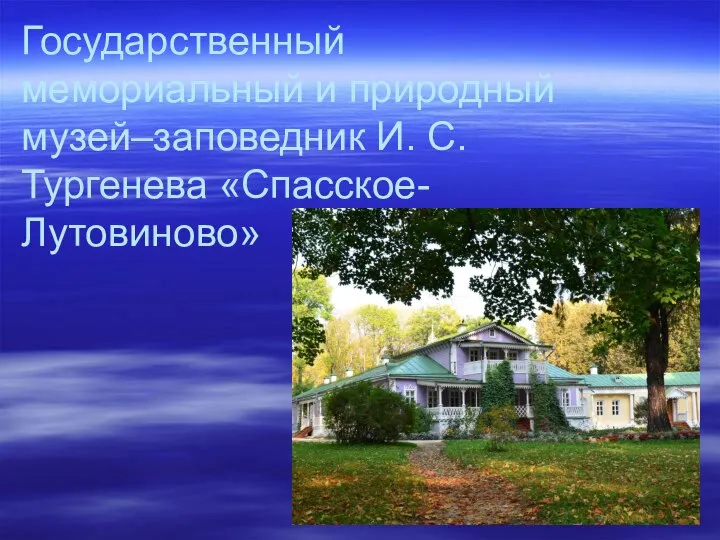

Презентация на тему "Клинические испытания новых лекарственных препаратов" - скачать презентации по Медицине Государственный мемориальный и природный музей–заповедник И.С. Тургенева «Спасское-Лутовиново»

Государственный мемориальный и природный музей–заповедник И.С. Тургенева «Спасское-Лутовиново» Обработка результатов динамических испытаний строительных конструкций

Обработка результатов динамических испытаний строительных конструкций Мощность и КПД электрических машин

Мощность и КПД электрических машин Меры длины Выполнил ученик 3 Б класса СОШ № 27 города Чебоксары Троешестов Степан

Меры длины Выполнил ученик 3 Б класса СОШ № 27 города Чебоксары Троешестов Степан ИБС

ИБС Логистическая цепочка создания стоимости Исаева Катерина Казакова Катя ДС - 07

Логистическая цепочка создания стоимости Исаева Катерина Казакова Катя ДС - 07  Годуновская и строгановская школы иконописи. Искусство парсуны. Симон Ушаков

Годуновская и строгановская школы иконописи. Искусство парсуны. Симон Ушаков День Прикордонних військ України

День Прикордонних військ України Занятие №3. Педагогическая и психологическая оценка уровня образования и развития обучающихся на ступени начального общего об

Занятие №3. Педагогическая и психологическая оценка уровня образования и развития обучающихся на ступени начального общего об Изменчивость и ее формы

Изменчивость и ее формы Основные положения экологического права

Основные положения экологического права автор Позляева Инна Леонидовна МОУ Речицкая средняя школа Московская область

автор Позляева Инна Леонидовна МОУ Речицкая средняя школа Московская область  Ein Besuch auf dem Weihnachtsmarkt

Ein Besuch auf dem Weihnachtsmarkt Хімія металургійних процесів. Теорія сплавів

Хімія металургійних процесів. Теорія сплавів Решение задач на движение 4 класс - презентация для начальной школы

Решение задач на движение 4 класс - презентация для начальной школы Берёзовоё царство- хорошее лекарство Автор проекта : обучающийся 2 класса Клишин Владислав МОУ «Старосеславинская средняя общ

Берёзовоё царство- хорошее лекарство Автор проекта : обучающийся 2 класса Клишин Владислав МОУ «Старосеславинская средняя общ Образование и наука в первой половине XIX века

Образование и наука в первой половине XIX века Разновидности футбола

Разновидности футбола ВЛИЯНИЕ ЭКСТРАГЕНИТАЛЬНЫХ ЗАБОЛЕВАНИЙ МАТЕРИ И ВРЕДНЫХ ФАКТОРОВ НА ПЛОД

ВЛИЯНИЕ ЭКСТРАГЕНИТАЛЬНЫХ ЗАБОЛЕВАНИЙ МАТЕРИ И ВРЕДНЫХ ФАКТОРОВ НА ПЛОД