Содержание

- 2. Useful Info

- 3. Review The Principle of Dimensional Homogeneity (PDH)——a rule which is almost a self-evident axiom in physics

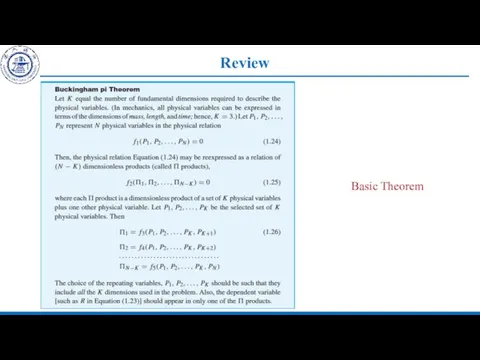

- 4. Review Basic Theorem

- 5. Review Flow similarity By definition, different flows are dynamically similar if: The streamline patterns are geometrically

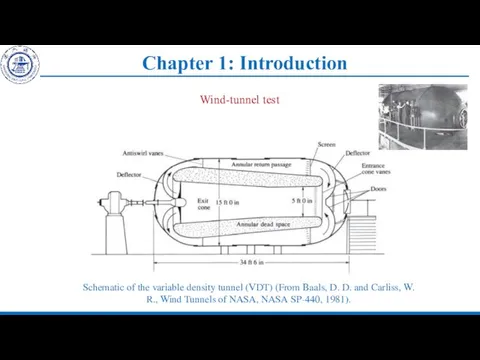

- 6. Chapter 1: Introduction Schematic of the variable density tunnel (VDT) (From Baals, D. D. and Carliss,

- 7. Review Fluid static dynamics: Buoyance Consider the forces along y axis: Positive upward, then— Hydrostatic equation

- 8. Review Type of flow Continuum flow If the orders of magnitude of λ is smaller than

- 9. Review Inviscid flow versus Viscous flow Viscous flow: This transport on a molecular scale gives rise

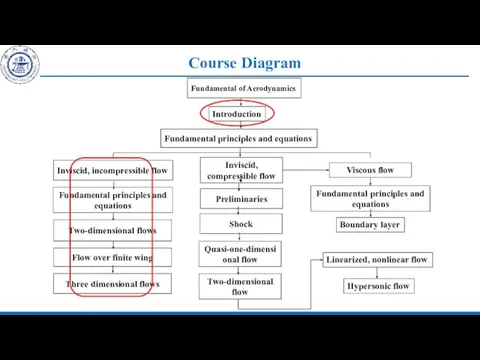

- 10. Course Diagram

- 11. Chapter 1 Learning Targets

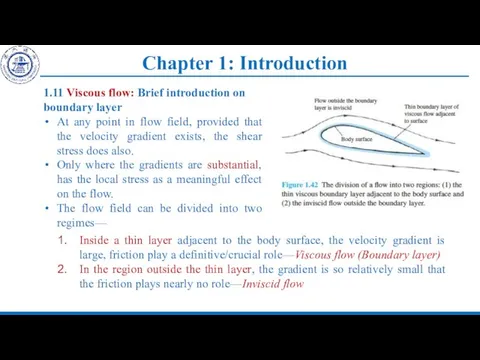

- 12. Chapter 1: Introduction 1.11 Viscous flow: Brief introduction on boundary layer At any point in flow

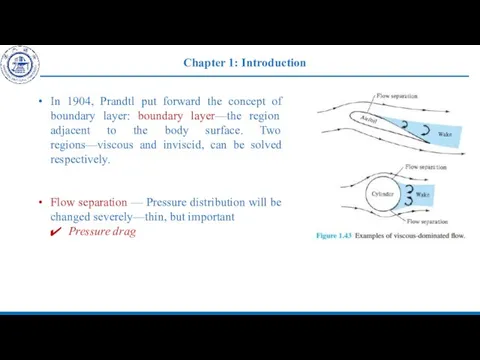

- 13. Chapter 1: Introduction In 1904, Prandtl put forward the concept of boundary layer: boundary layer—the region

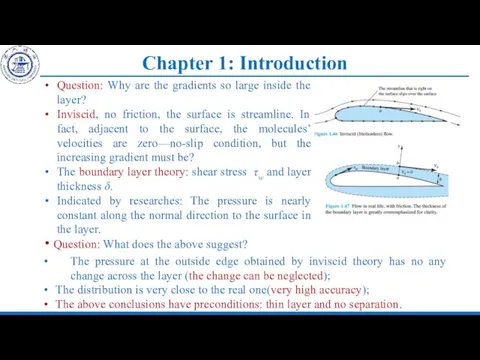

- 14. Chapter 1: Introduction Question: Why are the gradients so large inside the layer? Inviscid, no friction,

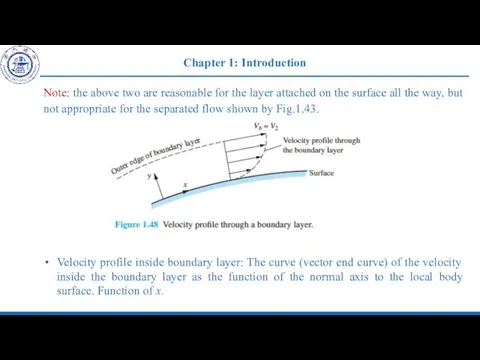

- 15. Chapter 1: Introduction Note: the above two are reasonable for the layer attached on the surface

- 16. Chapter 1: Introduction Temperature profile through the layer: The curve of the temperature through the boundary

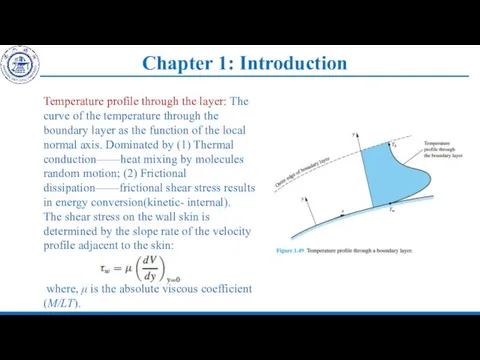

- 17. Chapter 1: Introduction μ variation with temperature: liquid (olive ; soybean- edible oil)—T increase, μ decrease;

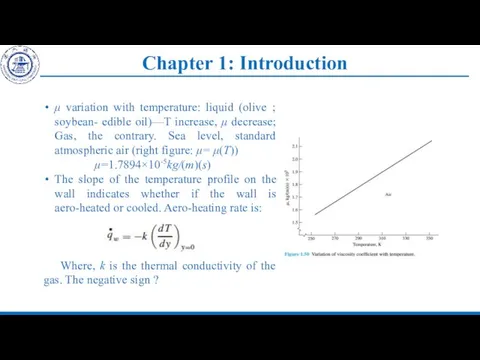

- 18. Chapter 1: Introduction At standard sea level temperature: k=2.53×10-2J/(m)(s)(K) Proportional to the viscous coefficient essentially, i.e

- 19. Chapter 1: Introduction Re effect on boundary layer: Figure below: Development of boundary layer on plate

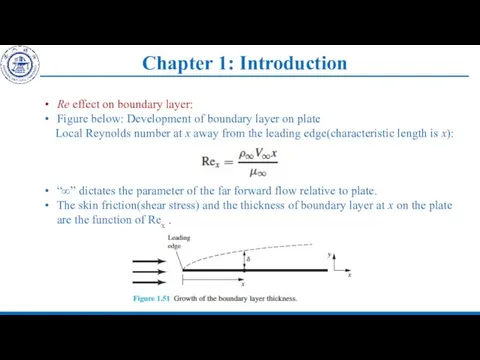

- 20. Chapter 1: Introduction The Reynolds number generally governs the nature of the viscous flow. The basic

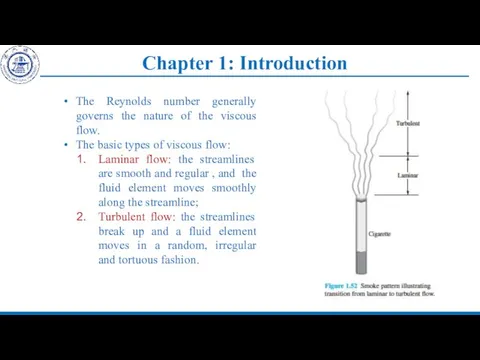

- 21. Chapter 1: Introduction Fig.1.53: Comparison for the two velocity profiles—— Turbulent, relatively “plump”; Laminar, relatively “gradual”.

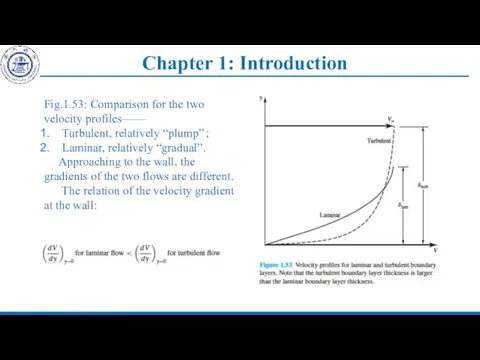

- 22. Chapter 1: Introduction By Eq.1.59: (τw)laminer The important fact: The shear stress of laminar flow is

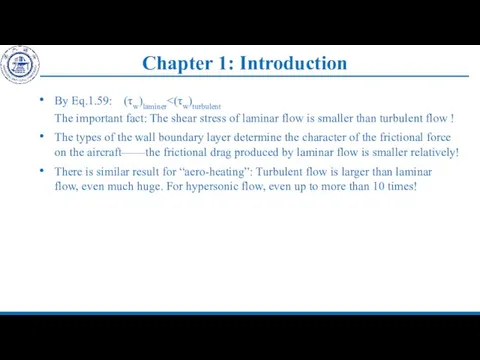

- 23. Chapter 1: Introduction Homework: 1.11, 1.12 Questions for thinking: 1. After released, the hydrogen ball will

- 24. Chapter 1: Introduction 1.12 Applied aerodynamics: Aerodynamic coefficients—— Magnitudes and variations Applied aerodynamics: For the practical

- 25. Chapter 1: Introduction Lift, Drag and moment coefficient are the most frequently used technical terms in

- 26. Chapter 1: Introduction Fig.1.54, Typical drag coefficients of some bodies (fixed attitude) moving in a low

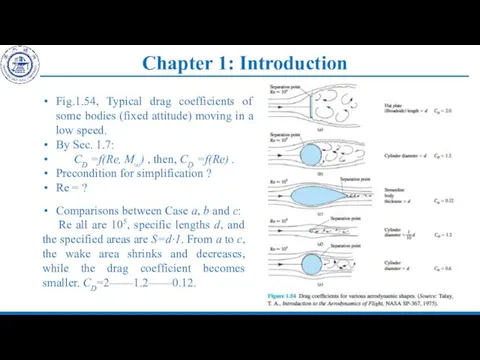

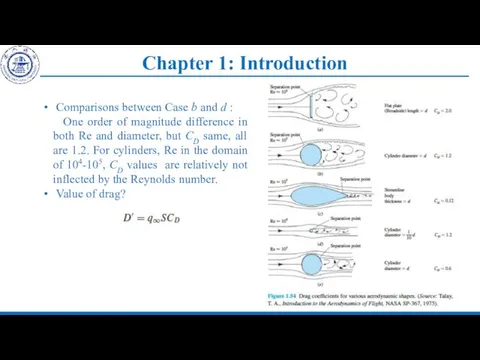

- 27. Chapter 1: Introduction Comparisons between Case b and d : One order of magnitude difference in

- 28. Chapter 1: Introduction Comparisons between Case c and d : Same dynamic pressures, drags are same

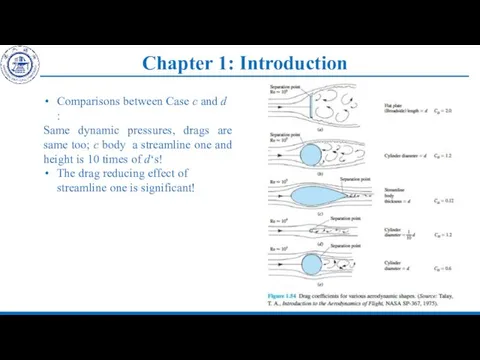

- 29. Chapter 1: Introduction Comparisons between Case b and e : Same diameter, but Ree=100·Reb, and CDe=2·CDb

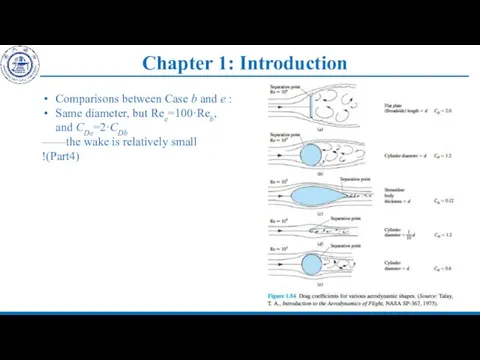

- 30. Chapter 1: Introduction Note:Character parameter(per unit span)—the maximum windward cross-sectional area. The drag coefficients vary from

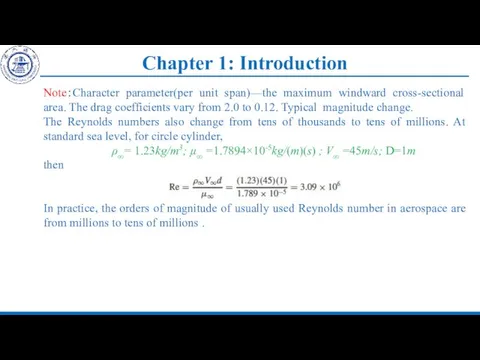

- 31. Chapter 1: Introduction Nature of drag: Axial force, Eq.1.8 becomes—— The aerodynamic drag on any body

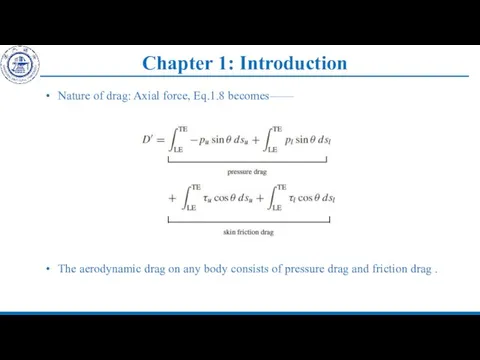

- 32. Chapter 1: Introduction Fig.1.55, the comparison for the relative quantities of two types of drag of

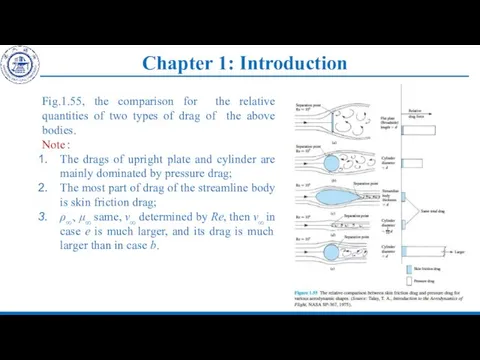

- 33. Chapter 1: Introduction Thus, there are two types of typical aerodynamic shapes: Blunt body: Most part

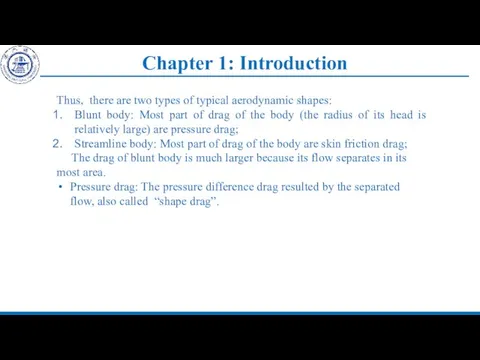

- 34. Chapter 1: Introduction Variation of the plate drag at zero angle of attach with the Reynolds

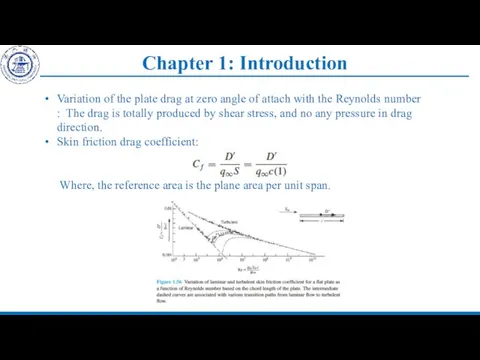

- 35. Chapter 1: Introduction The figure listed above indicates that: Cf strongly depends on Re, of which

- 36. Chapter 1: Introduction NACA63-210 airfoil: With thickness, laminar airfoil—low angle—laminar flow—turbulent one at higher angle, the

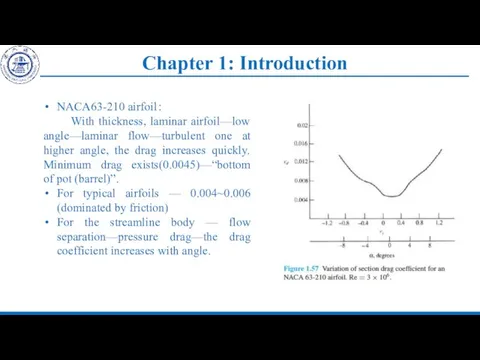

- 37. Chapter 1: Introduction The drag on a low speed airplane : Seversky P-35, the typical fighter

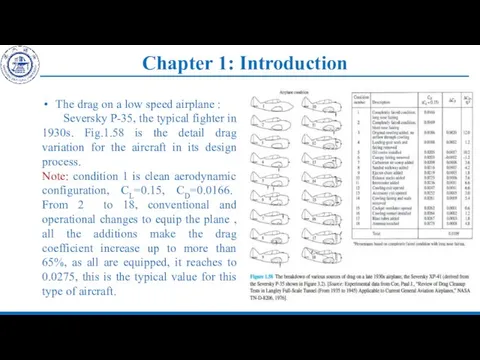

- 38. Chapter 1: Introduction Question: As Mach number increases, how will the drag coefficient change ? Northrop

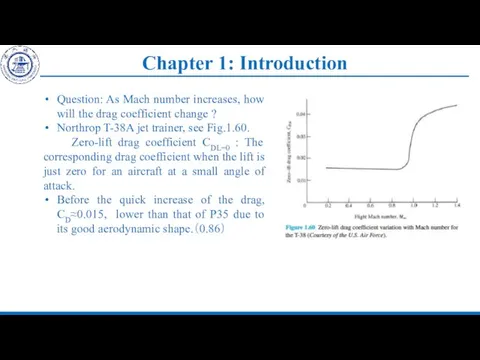

- 39. Chapter 1: Introduction Typical order of magnitude of lift coefficient: Fig.1.61-NACA63-210 airfoil ‘s lift curve—cl in

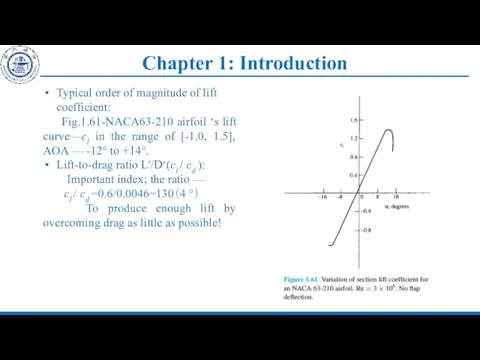

- 40. Chapter 1: Introduction Lift coefficient for full aircraft: Fig.1.62- CL-α curve for T38 : added the

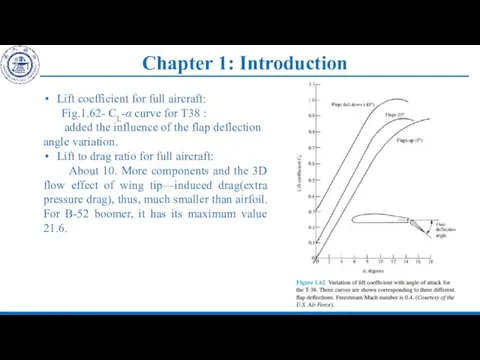

- 41. Chapter 1: Introduction The order of magnitude of moment coefficient : Fig.1.63-cm.c/4 curve for NACA63-210 airfoil.

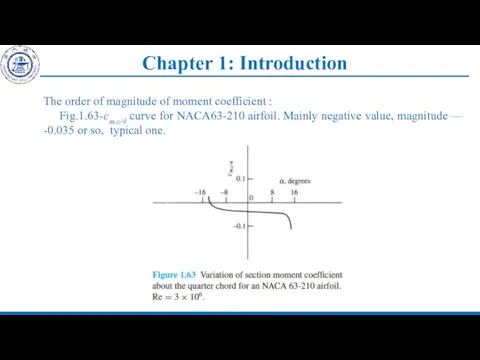

- 42. Chapter 1: Introduction Homework: p1.16、p1.18 Thinking work: Can all the drag come down to pressure drag

- 43. Chapter 1: Introduction The key points and difficult points in this chapter Key points: Fundamental aerodynamics

- 44. Chapter 1: Introduction Summation

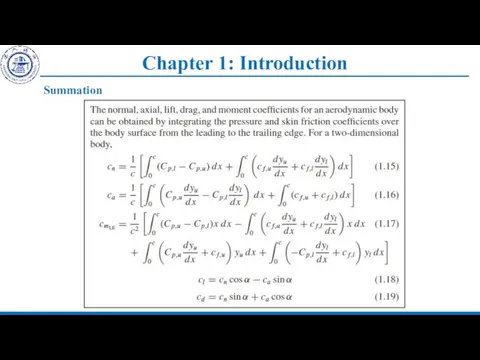

- 45. Chapter 1: Introduction Summation

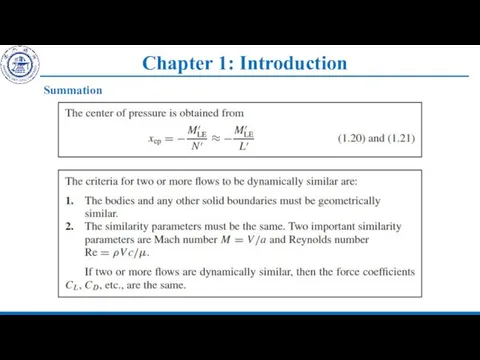

- 47. Скачать презентацию

Физика и безопасность дорожного движения

Физика и безопасность дорожного движения Закон сохранения энергии

Закон сохранения энергии Освещение. Свет и тень

Освещение. Свет и тень Великий инженер Василий Григорьевич Шухов Авторы: учащиеся 8 «Б» класса МОУ «Киришский лицей» Ленинградская область г. Кириши

Великий инженер Василий Григорьевич Шухов Авторы: учащиеся 8 «Б» класса МОУ «Киришский лицей» Ленинградская область г. Кириши  Токопроводящие пластмассы

Токопроводящие пластмассы Тема: «Мир звука». Выполнила: ученица 11 «А» класса МОУ «СОШ № 95 им. Н. Щукина п.Архара» Сахнова Ольга Александровна.

Тема: «Мир звука». Выполнила: ученица 11 «А» класса МОУ «СОШ № 95 им. Н. Щукина п.Архара» Сахнова Ольга Александровна. Влияние излучения на прорастание семян

Влияние излучения на прорастание семян Презентация по физике "Строение ядра" - скачать

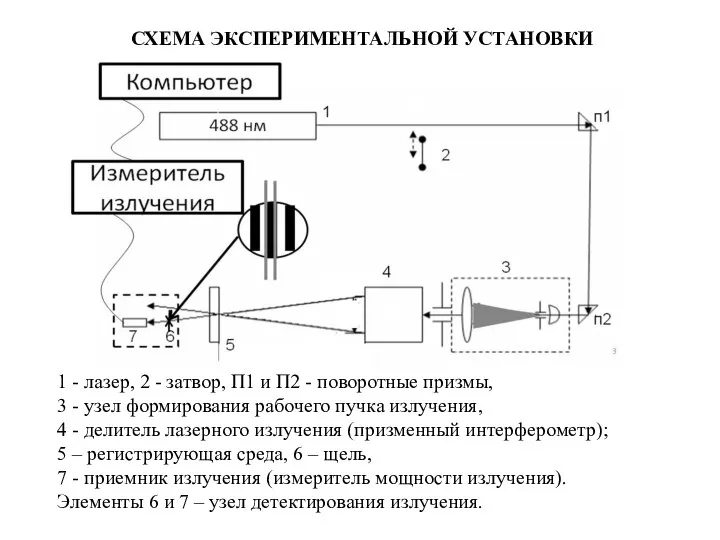

Презентация по физике "Строение ядра" - скачать  Схема экспериментальной установки

Схема экспериментальной установки 8 класс 2009

8 класс 2009 История и основные понятия науки о материалах

История и основные понятия науки о материалах Сорбционные процессы. (Лекция 2)

Сорбционные процессы. (Лекция 2) Равновесие тел урок физики, 10 класс

Равновесие тел урок физики, 10 класс  Производство передачи и использование электрической энергии

Производство передачи и использование электрической энергии Фізичні терміни. Атом

Фізичні терміни. Атом Для 10 класса (базовый уровень) Учитель МБОУ СОШ № 151 Кравцова И.А.

Для 10 класса (базовый уровень) Учитель МБОУ СОШ № 151 Кравцова И.А.  Теория Большого Взрыва. The Big Bang Theory

Теория Большого Взрыва. The Big Bang Theory Радиоактивность. История открытия

Радиоактивность. История открытия Химическая эволюция и биогенез

Химическая эволюция и биогенез Ядерний реактор Будова та принцип дії

Ядерний реактор Будова та принцип дії  Кипение. Испарение

Кипение. Испарение Лекция 12

Лекция 12  Фундаментальные опыты в оптике

Фундаментальные опыты в оптике Виды излучений

Виды излучений Деформация и механические свойства материалов

Деформация и механические свойства материалов Постоянный электрический ток. Причины электрического тока

Постоянный электрический ток. Причины электрического тока Строение атома

Строение атома Презентация по физике Законы Ньютона

Презентация по физике Законы Ньютона