Содержание

- 2. WHAT TO EXPECT IN THIS PRESENTATION? An introduction to Polytronics which involves use of conducting polymers

- 3. Polytronics Involves the usage of electrically conducting polymer or plastics in making electronic circuits . The

- 4. Advantages are : Easy Manufacturability (mass production). Low cost. They can be recycled and reused(decreases environmental

- 5. INKJET PRINTING TECHNOLOGY The huge cost of manufacturing Silicon microchip is due to the large complex

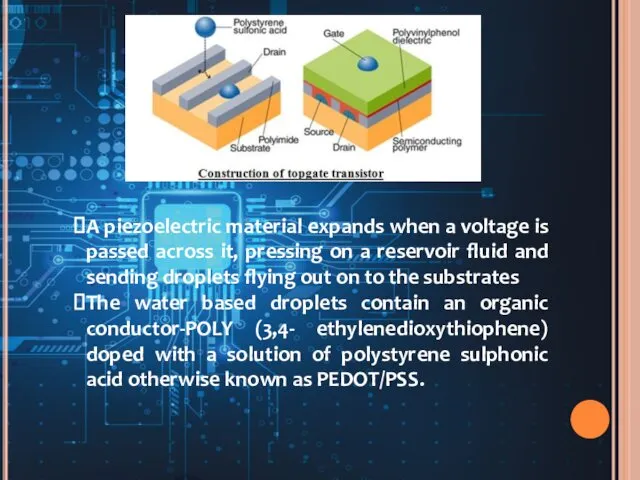

- 6. A piezoelectric material expands when a voltage is passed across it, pressing on a reservoir fluid

- 7. As the droplets dry they become a conducting layer and form source and drain of a

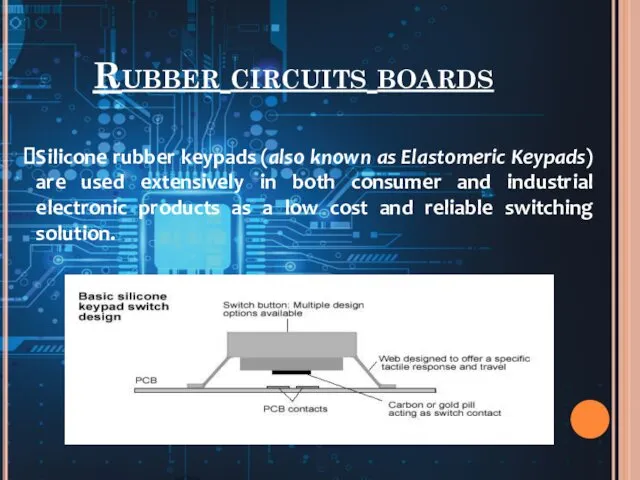

- 8. Rubber circuits boards Silicone rubber keypads (also known as Elastomeric Keypads) are used extensively in both

- 9. In order to make an electronic switch a carbon or gold pill is placed on the

- 10. The technology uses the compression molding properties of silicone rubber to create angled webbing around a

- 11. Plastic batteries Plastic batteries are new type of low power batteries that do not require a

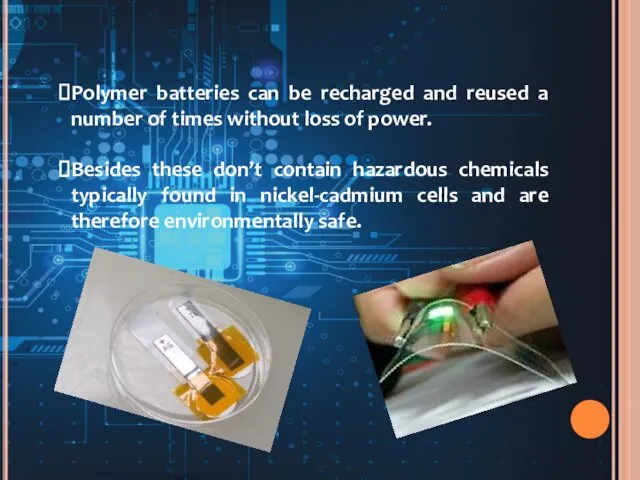

- 12. Polymer batteries can be recharged and reused a number of times without loss of power. Besides

- 13. Electronic paper Made from a display technology called gyricon technology by XEROX , PARC . electrically

- 14. Conclusion Polytronics is going to change the whole world of consumer electronics and form the principal

- 16. Скачать презентацию

ОАО Колор декор, производитель лакокрасочных материалов

ОАО Колор декор, производитель лакокрасочных материалов Развитие внутреннего туризма в России: динамика, прогнозы

Развитие внутреннего туризма в России: динамика, прогнозы Kwork.ru – магазин фриланс-услуг

Kwork.ru – магазин фриланс-услуг Бесплатный 5-дневный онлайн-курс Дизайнер сайтов с нуля до профи

Бесплатный 5-дневный онлайн-курс Дизайнер сайтов с нуля до профи Сбытовая политика АО “Глория Джинс”

Сбытовая политика АО “Глория Джинс” Коммерческое предожение. Поставляем металлопрокат, бетон, блоки, кирпич, утеплитель и другие материалы

Коммерческое предожение. Поставляем металлопрокат, бетон, блоки, кирпич, утеплитель и другие материалы Фанкластик: весь мир в руках твоих

Фанкластик: весь мир в руках твоих RENDEZ-VOUS - европейский стандарт сервиса

RENDEZ-VOUS - европейский стандарт сервиса Беспилотный летательный аппарат Aibot

Беспилотный летательный аппарат Aibot Курс по копирайтингу

Курс по копирайтингу Клуб Рантье

Клуб Рантье Маркетинговый анализ рекламного продукта и продвижение товара, работ, услуг на примере ОАО АРВД

Маркетинговый анализ рекламного продукта и продвижение товара, работ, услуг на примере ОАО АРВД Важные сообщения каталога №10

Важные сообщения каталога №10 Primera Minor Change

Primera Minor Change Проблемы молодежного предпринимательства в Казахстане

Проблемы молодежного предпринимательства в Казахстане Влияние рекламы на потребительское поведение молодежи

Влияние рекламы на потребительское поведение молодежи Перераспределение денежных средств через GPB-i-TRADE (Газпромбанк)

Перераспределение денежных средств через GPB-i-TRADE (Газпромбанк) Реклама в сообществах. Алгоритм

Реклама в сообществах. Алгоритм Успешная работа с YouTube

Успешная работа с YouTube Акции Midea Декабрь 2017 – Январь 2018

Акции Midea Декабрь 2017 – Январь 2018 Плацентарный тоник. TianDe

Плацентарный тоник. TianDe Организационная и маркетинговая части бизнес – плана ООО Dr. Aibolit

Организационная и маркетинговая части бизнес – плана ООО Dr. Aibolit История и достижения. VoiceCommunication

История и достижения. VoiceCommunication Добро пожаловать в команду Хлебник!

Добро пожаловать в команду Хлебник! Пиво премиум класса. Алтайское фирменное

Пиво премиум класса. Алтайское фирменное Маркетинг и реклама туризма в ФРГ. Брошюра по региону озер Оберпфальц

Маркетинг и реклама туризма в ФРГ. Брошюра по региону озер Оберпфальц Роль рекламы и PR-кампаний в туристическом бизнесе на примере отеля МФК Горный г. Санкт-Петербург

Роль рекламы и PR-кампаний в туристическом бизнесе на примере отеля МФК Горный г. Санкт-Петербург Структура текста

Структура текста