Содержание

- 2. M3 nuts 60pcs M3*20mm Round head screws 58pcs M2.5*10mm black screws 2pcs M3*10mm inner hexagon screws

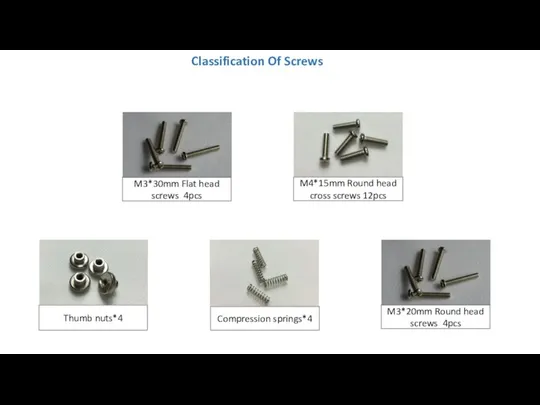

- 3. M4*15mm Round head cross screws 12pcs Compression springs*4 Thumb nuts*4 Classification Of Screws M3*30mm Flat head

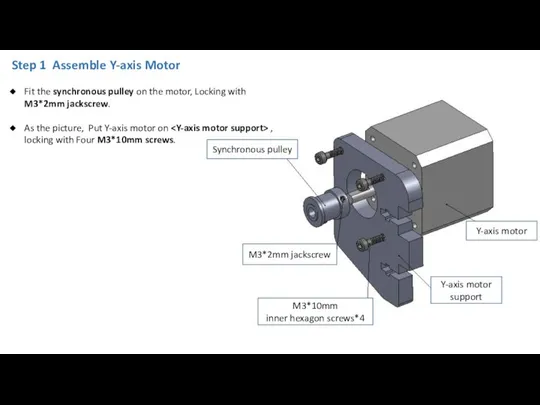

- 4. Step 1 Assemble Y-axis Motor M3*10mm inner hexagon screws*4 Y-axis motor support Y-axis motor M3*2mm jackscrew

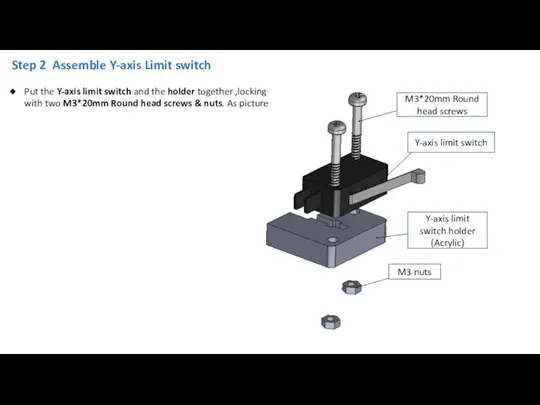

- 5. Step 2 Assemble Y-axis Limit switch Put the Y-axis limit switch and the holder together ,locking

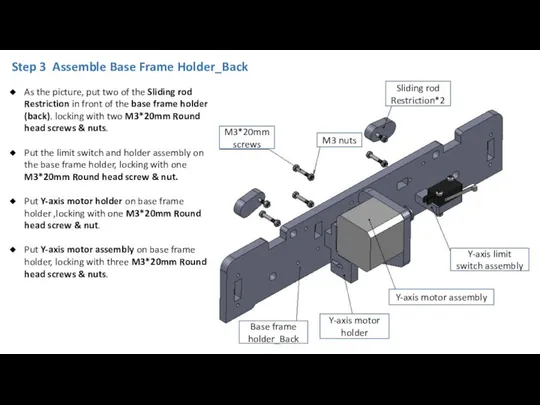

- 6. Step 3 Assemble Base Frame Holder_Back Y-axis motor assembly Sliding rod Restriction*2 M3*20mm screws Y-axis limit

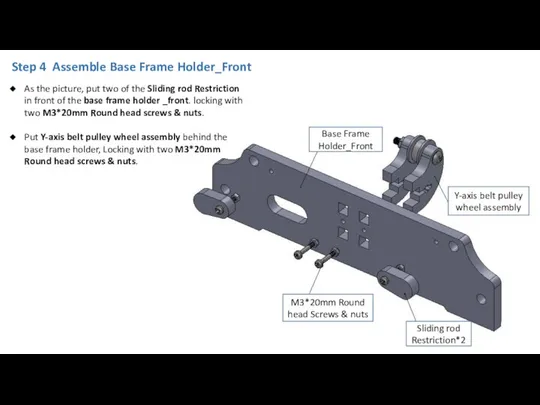

- 7. Step 4 Assemble Base Frame Holder_Front Sliding rod Restriction*2 M3*20mm Round head Screws & nuts Y-axis

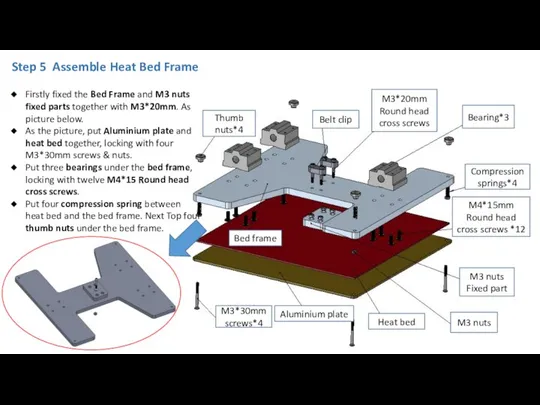

- 8. Aluminium plate M3*30mm screws*4 Heat bed M3 nuts Bed frame Bearing*3 Thumb nuts*4 M4*15mm Round head

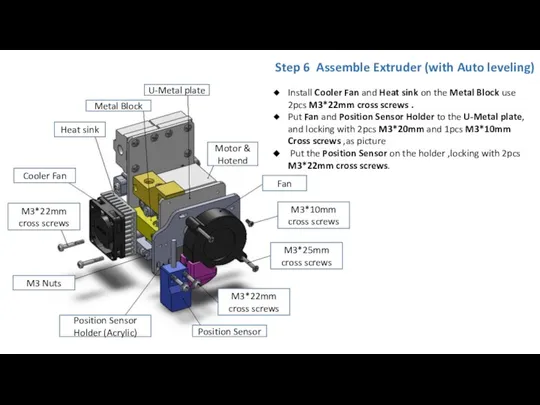

- 9. Position Sensor Step 6 Assemble Extruder (with Auto leveling) U-Metal plate Motor & Hotend Position Sensor

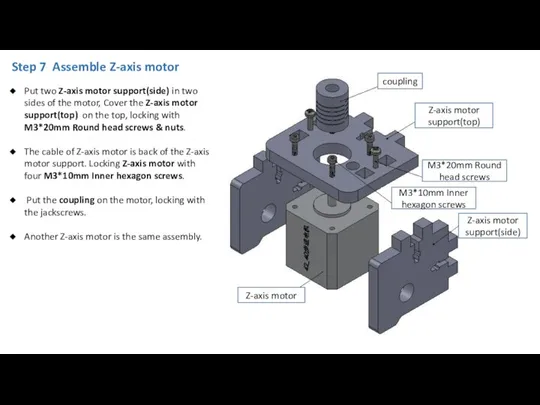

- 10. Step 7 Assemble Z-axis motor coupling M3*20mm Round head screws M3*10mm Inner hexagon screws Z-axis motor

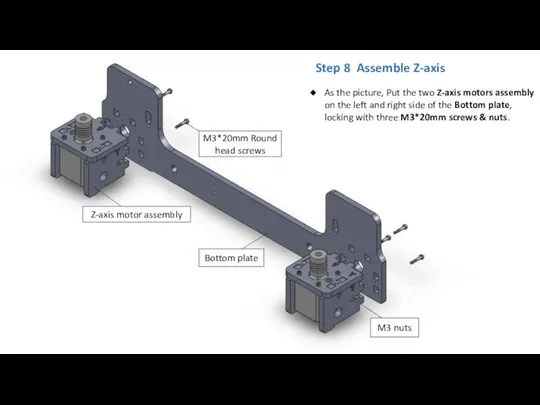

- 11. Z-axis motor assembly Bottom plate M3 nuts M3*20mm Round head screws As the picture, Put the

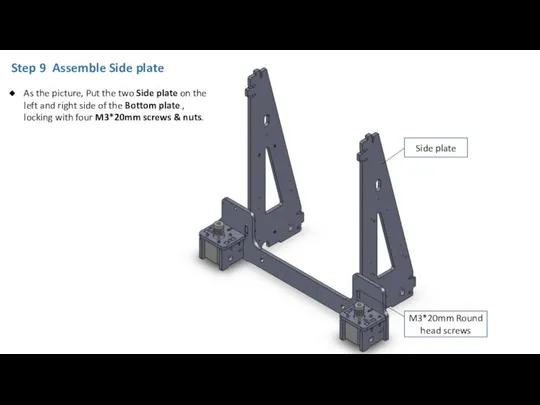

- 12. Step 9 Assemble Side plate As the picture, Put the two Side plate on the left

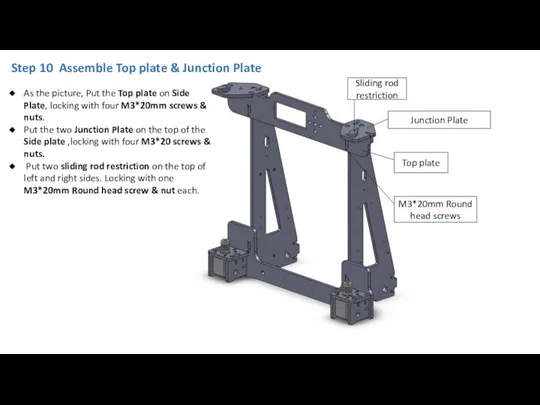

- 13. Step 10 Assemble Top plate & Junction Plate Sliding rod restriction Junction Plate Top plate M3*20mm

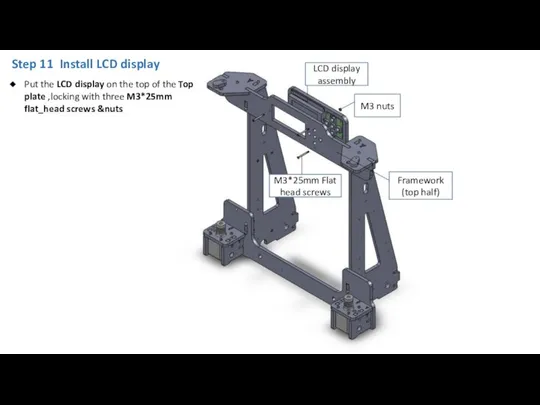

- 14. Step 11 Install LCD display M3 nuts LCD display assembly M3*25mm Flat head screws Framework (top

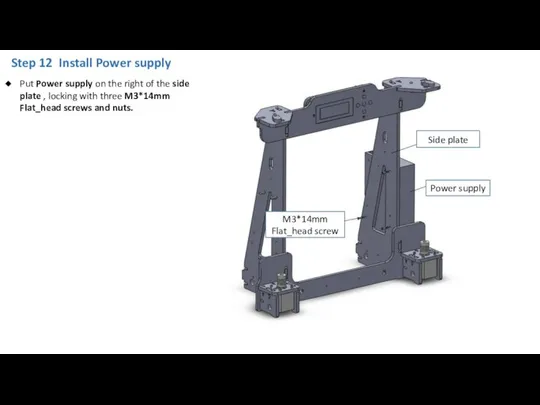

- 15. Step 12 Install Power supply Put Power supply on the right of the side plate ,

- 16. Control Board M3 Nuts*8 Plastic Pillars*4 M3*30mm Flat_head Screws *4 Side plate Step 13 Install PCBA

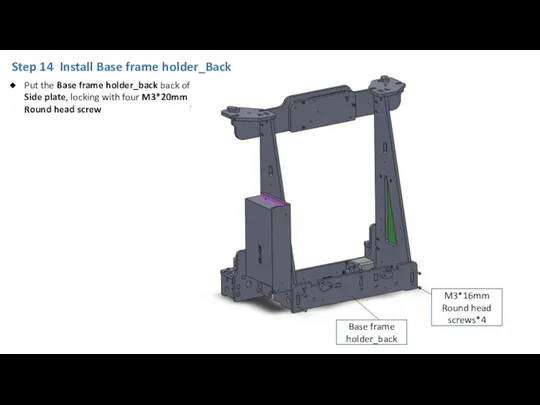

- 17. Step 14 Install Base frame holder_Back Base frame holder_back M3*16mm Round head screws*4 Put the Base

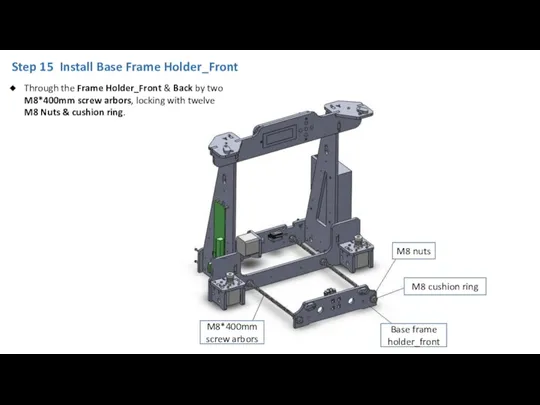

- 18. Step 15 Install Base Frame Holder_Front M8 cushion ring M8*400mm screw arbors Base frame holder_front M8

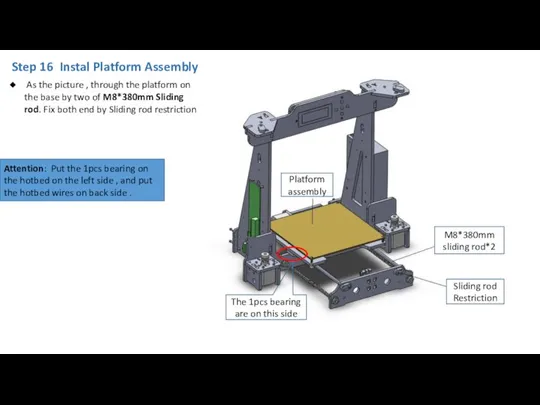

- 19. Step 16 Instal Platform Assembly Platform assembly M8*380mm sliding rod*2 Sliding rod Restriction The 1pcs bearing

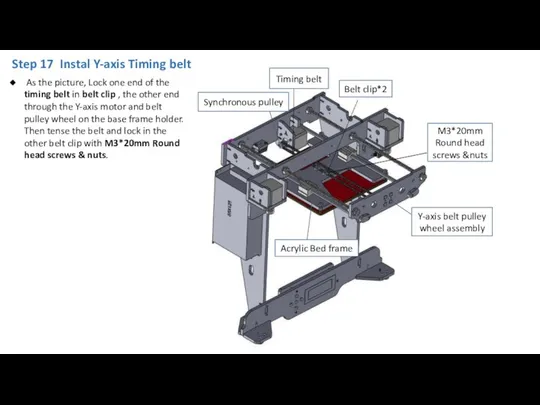

- 20. Acrylic Bed frame Timing belt Belt clip*2 M3*20mm Round head screws &nuts Y-axis belt pulley wheel

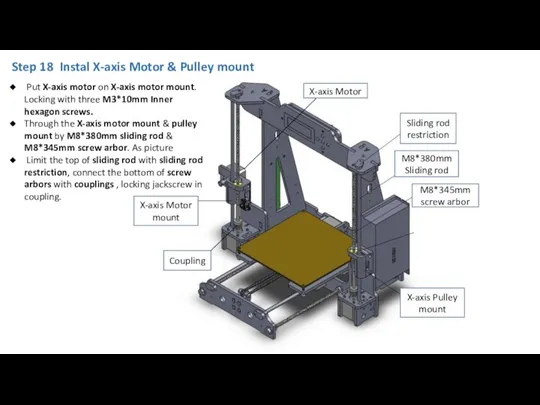

- 21. Sliding rod restriction M8*380mm Sliding rod Coupling M8*345mm screw arbor X-axis Pulley mount X-axis Motor mount

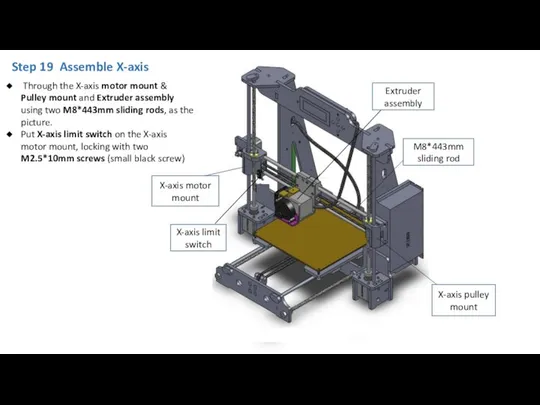

- 22. Step 19 Assemble X-axis X-axis motor mount X-axis pulley mount M8*443mm sliding rod Extruder assembly X-axis

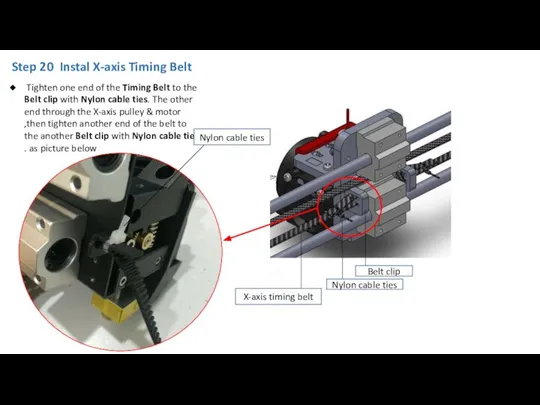

- 23. Step 20 Instal X-axis Timing Belt X-axis timing belt Tighten one end of the Timing Belt

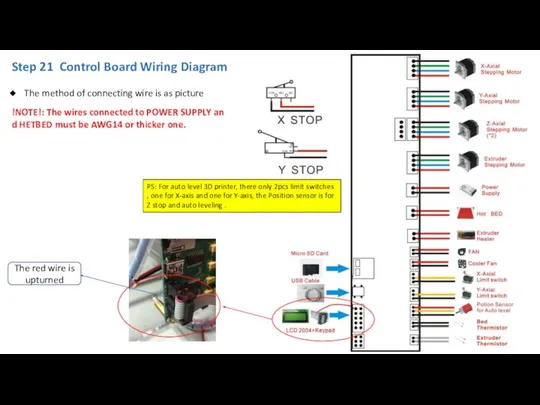

- 24. Step 21 Control Board Wiring Diagram The method of connecting wire is as picture !NOTE!: The

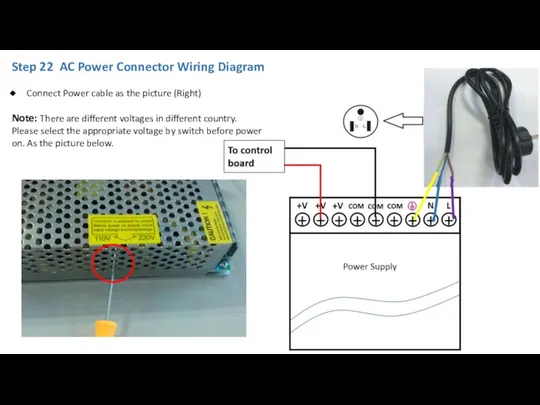

- 25. Step 22 AC Power Connector Wiring Diagram Connect Power cable as the picture (Right) Note: There

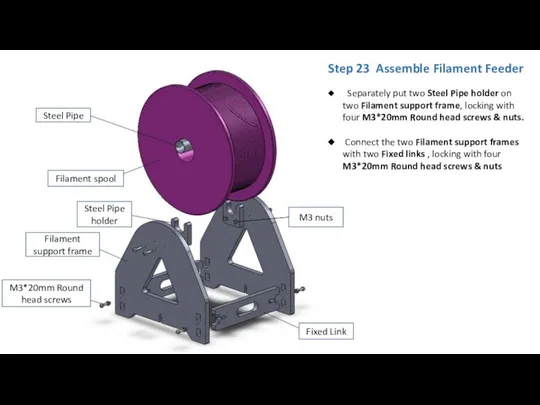

- 26. Filament spool Filament support frame Fixed Link Steel Pipe M3*20mm Round head screws M3 nuts Steel

- 28. Скачать презентацию

Программно-методический комплект «ДЕТСТВО»

Программно-методический комплект «ДЕТСТВО» Калькуляция себестоимости с полным распределением затрат и по переменным издержкам

Калькуляция себестоимости с полным распределением затрат и по переменным издержкам Экранизированная классика

Экранизированная классика История и виды гребного спорта

История и виды гребного спорта Жаңа замандағы саяси ой

Жаңа замандағы саяси ой Holidays in Andorra

Holidays in Andorra Instructions for use edit in Google Slides edit in Powerpoint®

Instructions for use edit in Google Slides edit in Powerpoint® ушыбы - презентация для начальной школы

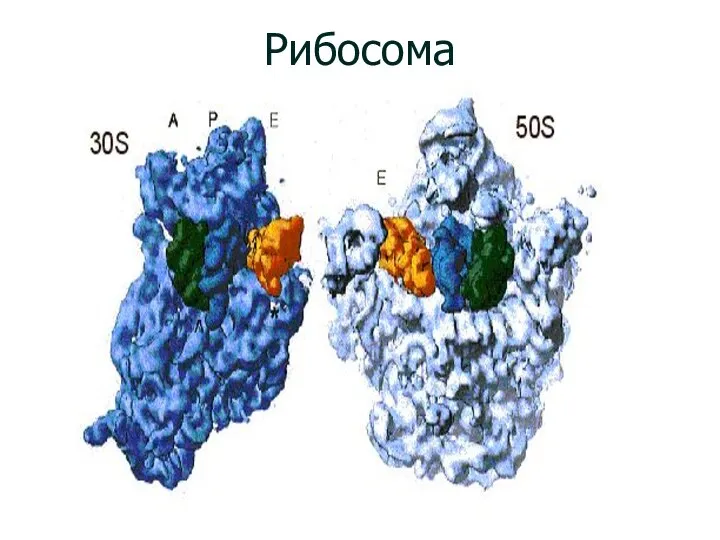

ушыбы - презентация для начальной школы Рибосома

Рибосома  Иконопись и православие (устройство храма, основные термины, иконы)

Иконопись и православие (устройство храма, основные термины, иконы) Валеология – наука о здоровом образе жизни (ЗОЖ) учитель СОШ № 2 г. Колпашева Панова Г. В.

Валеология – наука о здоровом образе жизни (ЗОЖ) учитель СОШ № 2 г. Колпашева Панова Г. В. Святкування Різдва

Святкування Різдва Hockey-Russia

Hockey-Russia ГОРОДЕЦКИЕ КОНИ

ГОРОДЕЦКИЕ КОНИ НОВАЯ СЕРИЯ УЧЕБНЫХ ПОСОБИЙ

НОВАЯ СЕРИЯ УЧЕБНЫХ ПОСОБИЙ Система связи миллиметрового диапазона волн

Система связи миллиметрового диапазона волн Ребования федеральных государственных образовательных стандартов к процессу физкультурного образования школьников

Ребования федеральных государственных образовательных стандартов к процессу физкультурного образования школьников Кто такие оптимисты?

Кто такие оптимисты? Системный анализ и теория систем

Системный анализ и теория систем Лето со Смешариками - презентация для начальной школы

Лето со Смешариками - презентация для начальной школы Большой теннис

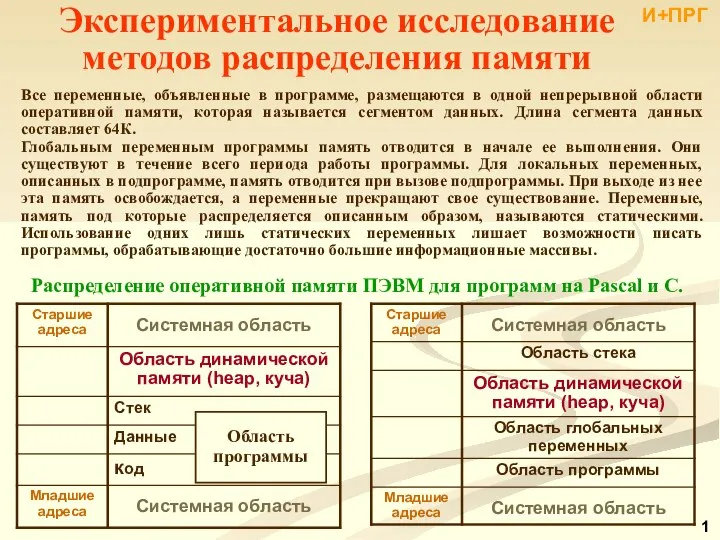

Большой теннис Распределение оперативной памяти ПЭВМ для программ на Pascal и С

Распределение оперативной памяти ПЭВМ для программ на Pascal и С Теория измерения культур Герта Хофстеда

Теория измерения культур Герта Хофстеда Центральный административный округ. Территориальное строительство. 1- й Николощеповский пер., вл. 6, стр.1

Центральный административный округ. Территориальное строительство. 1- й Николощеповский пер., вл. 6, стр.1 P-CAD — система автоматизированного проектирования многослойных печатных плат вычислительных и радиоэлектронных устройств

P-CAD — система автоматизированного проектирования многослойных печатных плат вычислительных и радиоэлектронных устройств Деловой протокол в переговорном процессе

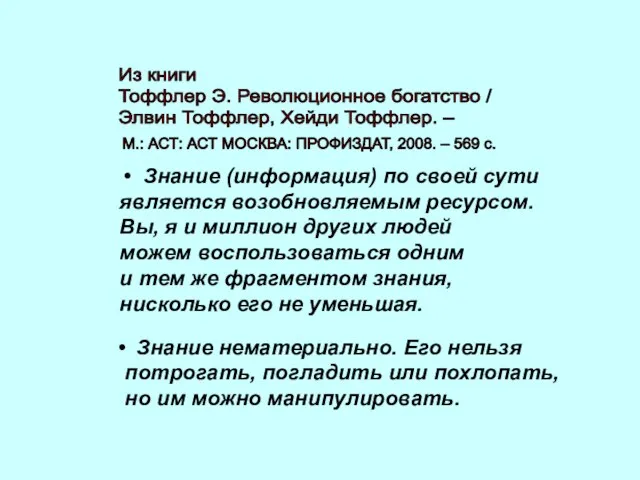

Деловой протокол в переговорном процессе Знание (информация) по своей сути является возобновляемым ресурсом. Вы, я и миллион других людей можем воспользоваться одним и тем

Знание (информация) по своей сути является возобновляемым ресурсом. Вы, я и миллион других людей можем воспользоваться одним и тем  Искусство иконописи Византии (урок МХК в 10 классе)

Искусство иконописи Византии (урок МХК в 10 классе)