Содержание

- 2. 3D Simulation The wire-frame 3D simulation allows to display on the PC the real machining process,

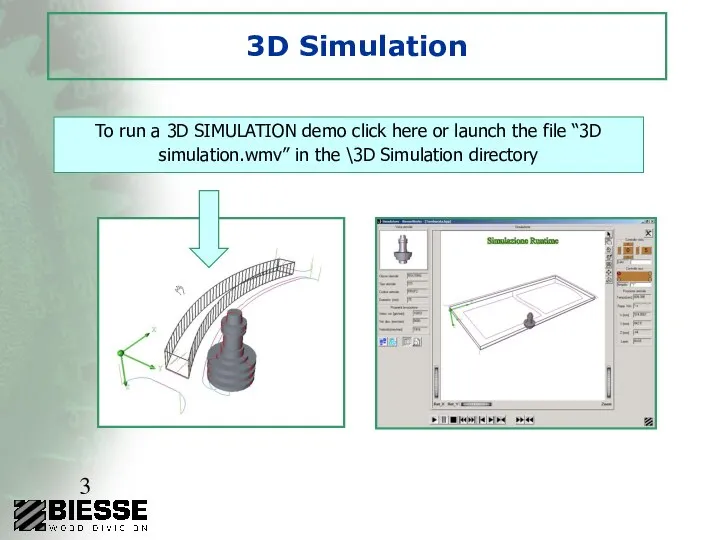

- 3. 3D Simulation To run a 3D SIMULATION demo click here or launch the file “3D simulation.wmv”

- 4. Pocketing and text engraving Automatic calculation of the tool routes necessary for the performance of automatic

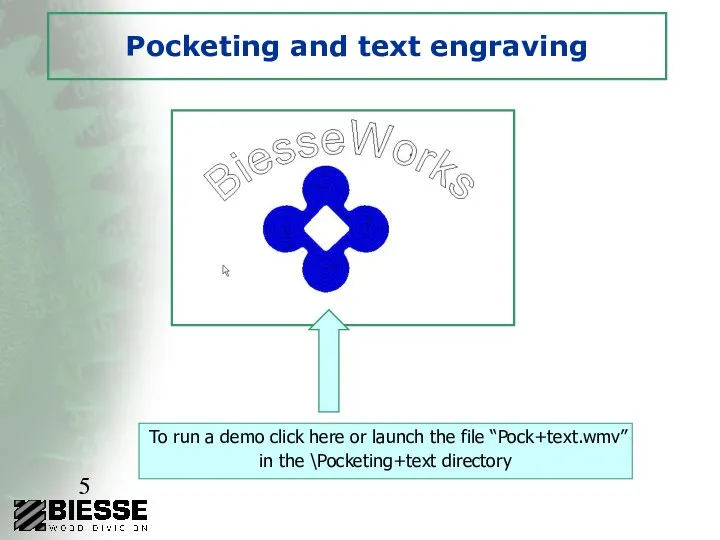

- 5. Pocketing and text engraving To run a demo click here or launch the file “Pock+text.wmv” in

- 6. Sides defined by the operator Creation of linear and circular sides defined by the operator in

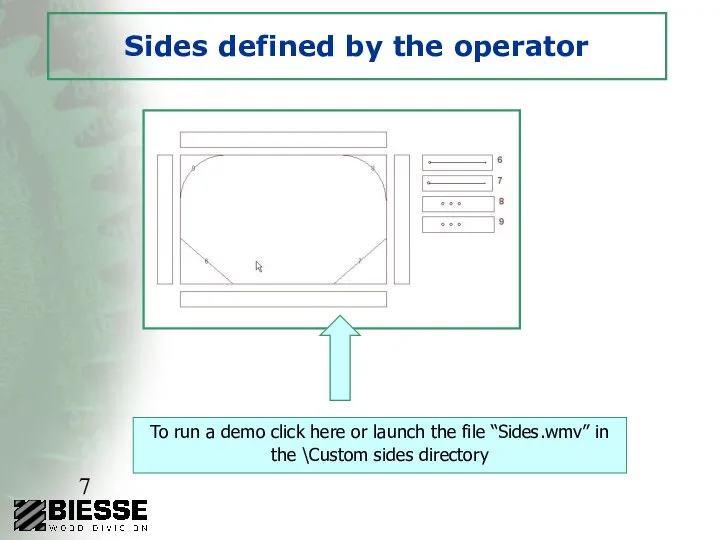

- 7. Sides defined by the operator To run a demo click here or launch the file “Sides.wmv”

- 8. Parametric Work Table Tooling Creation of parametric rules for the positioning of locking devices, so that

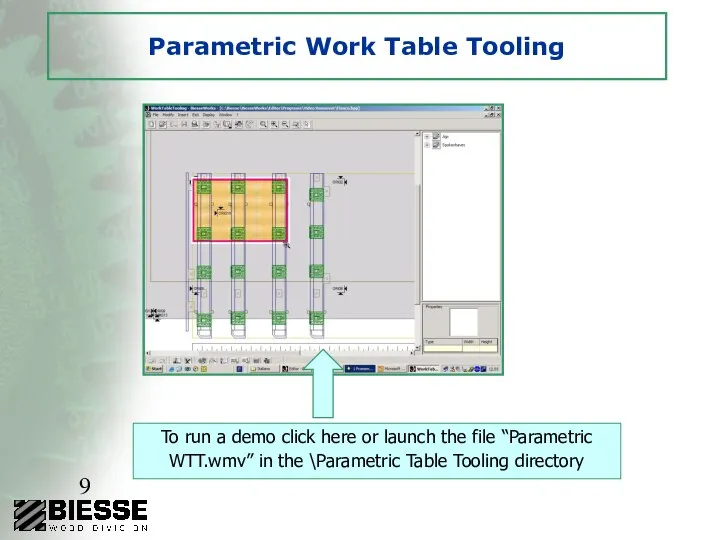

- 9. Parametric Work Table Tooling To run a demo click here or launch the file “Parametric WTT.wmv”

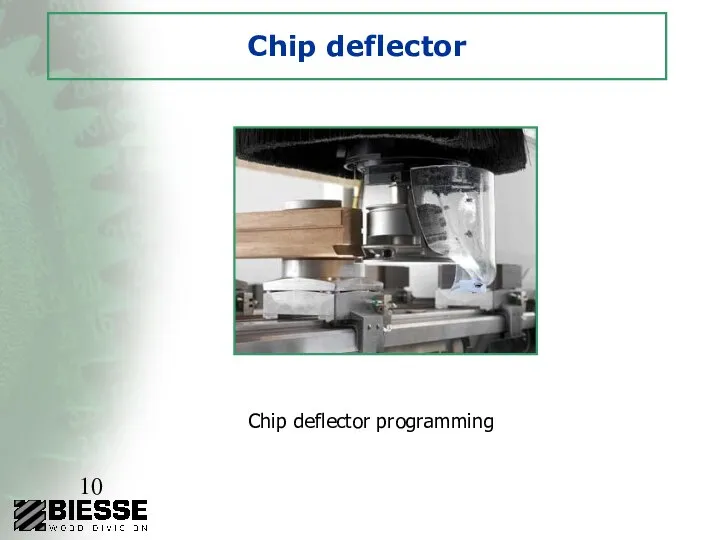

- 10. Chip deflector Chip deflector programming

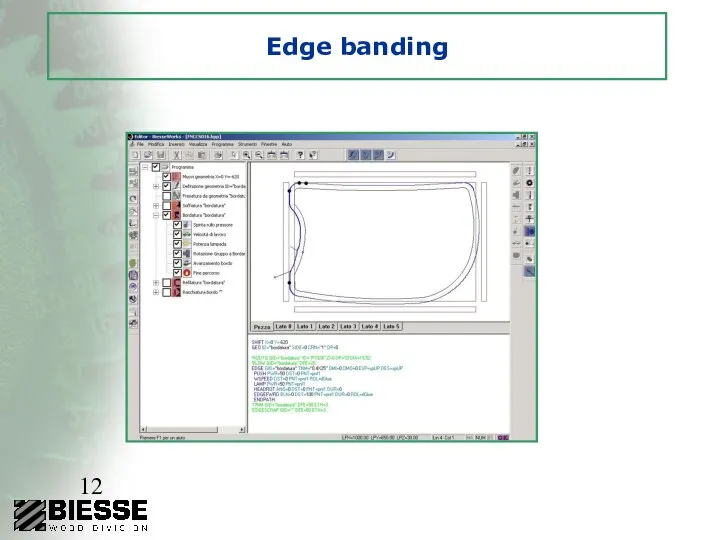

- 11. Edge banding Easy and friendly programming for the edge banding and finishing process Tools for the

- 12. Edge banding

- 14. Скачать презентацию

Наши национальные денежные знаки - презентация для начальной школы_

Наши национальные денежные знаки - презентация для начальной школы_ Обробка інформації в обліковій системі

Обробка інформації в обліковій системі Кормушки для птиц

Кормушки для птиц кредитно-денежная система

кредитно-денежная система P-Урок 04 Равномерное прямолинейное движение

P-Урок 04 Равномерное прямолинейное движение Кафедра микробиологии, вирусологии и иммунологии КазНМУ Электронное пособие на тему: Алгоритм лабораторной диагностики уроге

Кафедра микробиологии, вирусологии и иммунологии КазНМУ Электронное пособие на тему: Алгоритм лабораторной диагностики уроге Лесли Алвин Уайт

Лесли Алвин Уайт Чарльз Роберт Дарвин: фрагменты жизни

Чарльз Роберт Дарвин: фрагменты жизни Разработка Internet- и Web-приложений. Изучаем JavaScript. (Лекция 4)

Разработка Internet- и Web-приложений. Изучаем JavaScript. (Лекция 4) Event-менеджмент Выполнили Симбирская О. В. , Шаляпина О. Н., МАОУ «Гимназия №2» В. Новгород 2012 год

Event-менеджмент Выполнили Симбирская О. В. , Шаляпина О. Н., МАОУ «Гимназия №2» В. Новгород 2012 год Презентация "УПРАВЛЕНИЕ КАЧЕСТВОМ логистических процессов" - скачать презентации по Экономике

Презентация "УПРАВЛЕНИЕ КАЧЕСТВОМ логистических процессов" - скачать презентации по Экономике Обработка ошибок

Обработка ошибок Organization of the Diplomatic protocol in Italy

Organization of the Diplomatic protocol in Italy Производственная практика. ООО «Сибирская ярмарка»

Производственная практика. ООО «Сибирская ярмарка» Филимоновская игрушка

Филимоновская игрушка Техника торцевания

Техника торцевания Содержание курса - Как стать успешным в XXI веке?Содержание курса Эти навыки дает программа «Учимся с INTEL» - 15 занятий! Расписание зан

Содержание курса - Как стать успешным в XXI веке?Содержание курса Эти навыки дает программа «Учимся с INTEL» - 15 занятий! Расписание зан Художник- портретист Александр Шилов Учитель русского языка и литературы Жукова Татьяна Анатольевна

Художник- портретист Александр Шилов Учитель русского языка и литературы Жукова Татьяна Анатольевна Нейрофизиология программы

Нейрофизиология программы  Винайдення автобуса

Винайдення автобуса ГЕОЛОГИЧЕСКАЯ ДЕЯТЕЛЬНОСТЬ РЕК И ВРЕМЕННЫХ ПОТОКОВ

ГЕОЛОГИЧЕСКАЯ ДЕЯТЕЛЬНОСТЬ РЕК И ВРЕМЕННЫХ ПОТОКОВ Нейронная регуляция 1. Отличие нейронной регуляции от гуморальной. 2. Рефлекторный принцип регуляции. 3. Физиологическая харак

Нейронная регуляция 1. Отличие нейронной регуляции от гуморальной. 2. Рефлекторный принцип регуляции. 3. Физиологическая харак Интеграция различных подходов к менеджменту Выполнил: Студент 41 БЖД Гильматдинов М.М.

Интеграция различных подходов к менеджменту Выполнил: Студент 41 БЖД Гильматдинов М.М. Договор синдицированного кредита по российскому праву Иван Борисов Vice President, Legal counsel

Договор синдицированного кредита по российскому праву Иван Борисов Vice President, Legal counsel  Художник-воин-патриот Монографический урок по творчеству Василия Васильевича Верещагина 1842-1904

Художник-воин-патриот Монографический урок по творчеству Василия Васильевича Верещагина 1842-1904 Музеи. Парки. Усадьбы

Музеи. Парки. Усадьбы Праздник Святой Троицы

Праздник Святой Троицы История возникновения петербургской росписи

История возникновения петербургской росписи