Содержание

- 2. Introduction The ability to uniquely identify an object or device is important for authentication. Imperfections, locked

- 4. Objective To analise a proposed simple optical technique to read unique information from nanometer-scale defects in

- 5. Tasks Method Results for WS2 from mechanically exfoliation Results for WS2 from chemical vapor deposition Conclusion

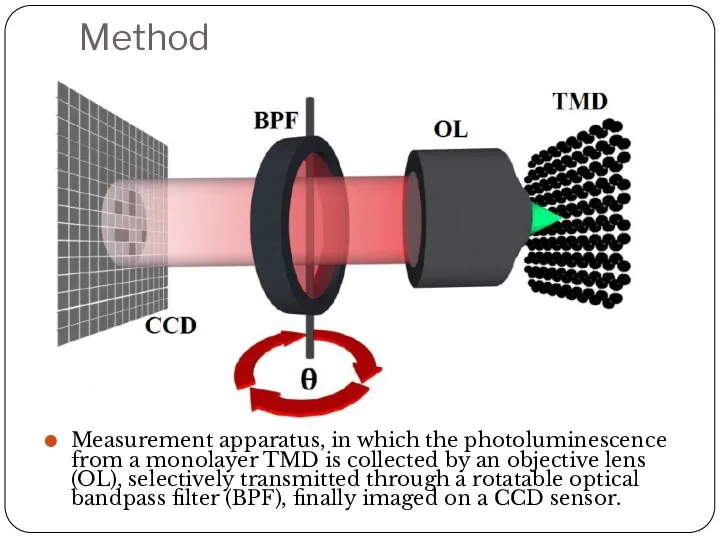

- 6. Method Measurement apparatus, in which the photoluminescence from a monolayer TMD is collected by an objective

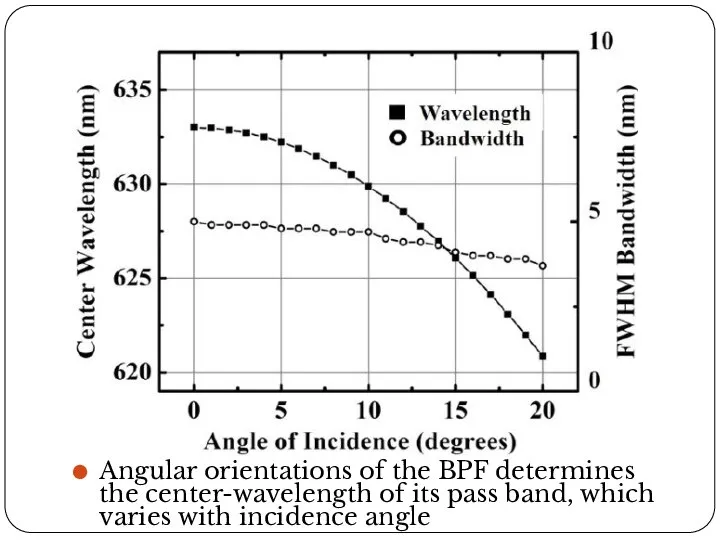

- 7. Angular orientations of the BPF determines the center-wavelength of its pass band, which varies with incidence

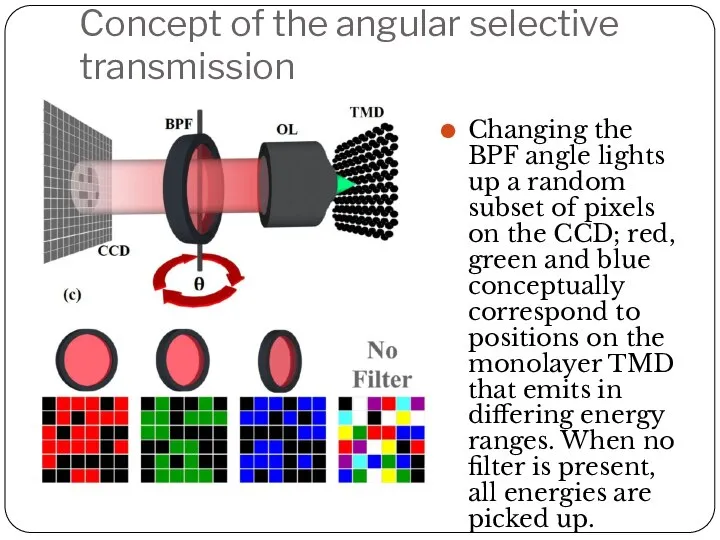

- 8. Concept of the angular selective transmission Changing the BPF angle lights up a random subset of

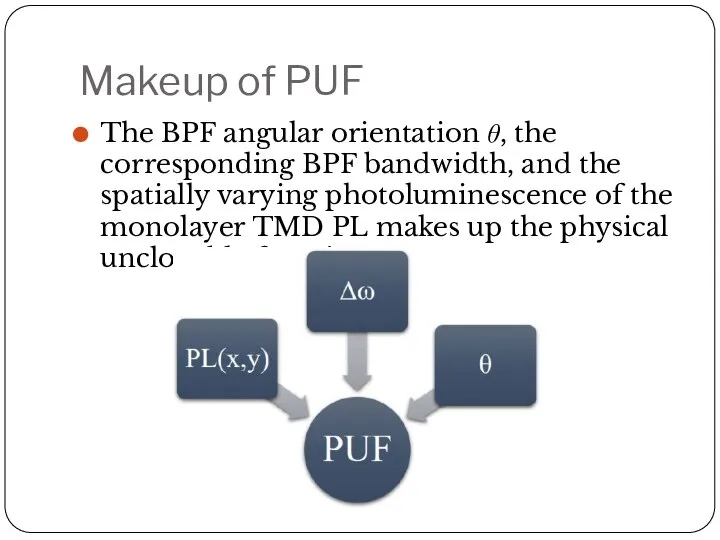

- 9. Makeup of PUF The BPF angular orientation θ, the corresponding BPF bandwidth, and the spatially varying

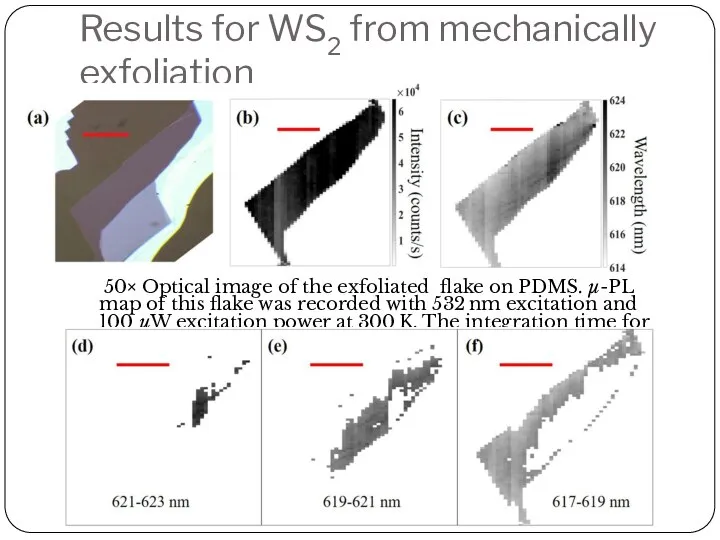

- 10. Results for WS2 from mechanically exfoliation 50× Optical image of the exfoliated flake on PDMS. μ-PL

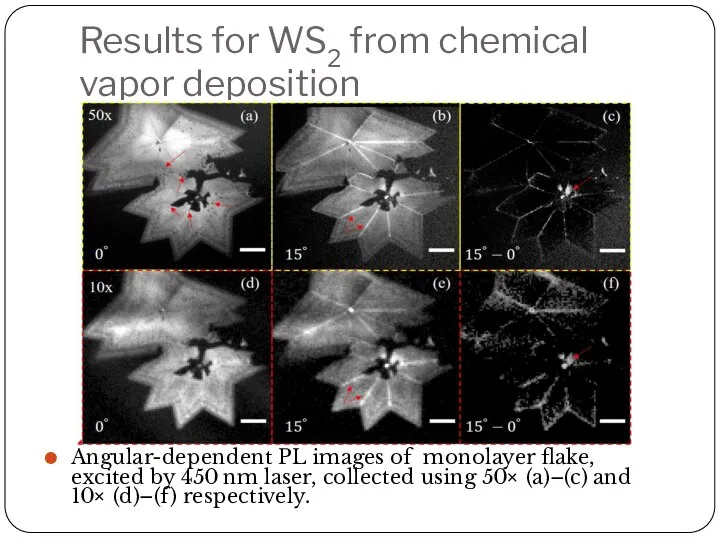

- 11. Results for WS2 from chemical vapor deposition Angular-dependent PL images of monolayer flake, excited by 450

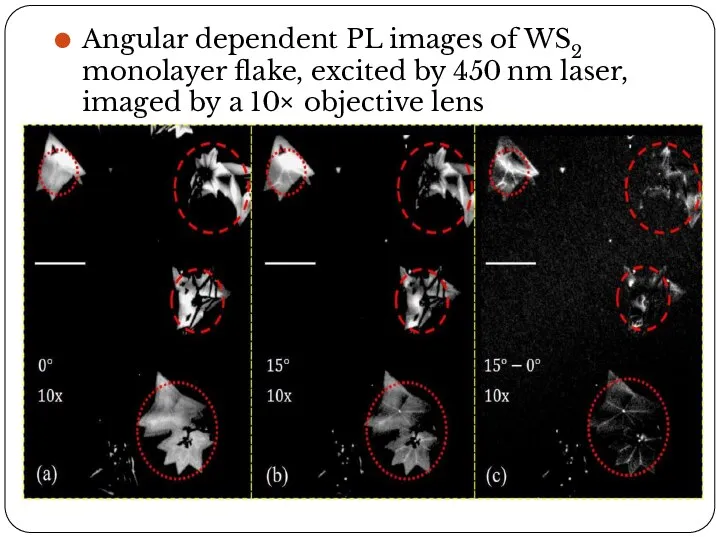

- 12. Angular dependent PL images of WS2 monolayer flake, excited by 450 nm laser, imaged by a

- 14. Скачать презентацию

Масленица Кустодиев Борис Михайлович (1878-1927) (автопортрет) 5 класс Учитель: Перевозникова Е.В.

Масленица Кустодиев Борис Михайлович (1878-1927) (автопортрет) 5 класс Учитель: Перевозникова Е.В. ҚР оңтүстік аймақтарын табиғи газбен жабдықтау мәселелері

ҚР оңтүстік аймақтарын табиғи газбен жабдықтау мәселелері Инфекции

Инфекции Виды, разрезы, сечения

Виды, разрезы, сечения Индукционная плита

Индукционная плита Тематический урок русского языка с элементами ПДД.

Тематический урок русского языка с элементами ПДД. В поисках Истины

В поисках Истины Презентация Совет безопасности РФ

Презентация Совет безопасности РФ Презентация ООО «Допинг» для Freedom концерт-холл

Презентация ООО «Допинг» для Freedom концерт-холл Сохранение и популяризация историко-культурного и природного наследия Арктики: возможности компьютерной игры

Сохранение и популяризация историко-культурного и природного наследия Арктики: возможности компьютерной игры Меланоцитарные и нейрогенные опухоли

Меланоцитарные и нейрогенные опухоли правила личной гигиены Выполнила: Замараева Яна Ученица 4 «В» класса МОУ СОШ № 32 Г.Уссурийск 2011 г.

правила личной гигиены Выполнила: Замараева Яна Ученица 4 «В» класса МОУ СОШ № 32 Г.Уссурийск 2011 г. Liczby w Biblii

Liczby w Biblii Презентация на тему "Авторская технология взаимодействия участников образовательного процесса при организации системы монито

Презентация на тему "Авторская технология взаимодействия участников образовательного процесса при организации системы монито Дэвид Геслак. Упражнения для тренировок с особенными людьми

Дэвид Геслак. Упражнения для тренировок с особенными людьми Работы победителей муниципального этапа областного конкурса детского и юношеского изобразительного искусства «Я рисую

Работы победителей муниципального этапа областного конкурса детского и юношеского изобразительного искусства «Я рисую Школьная или обычная форма

Школьная или обычная форма Влияние занятий роллер спортом на состояние здоровья детей 10-12 лет

Влияние занятий роллер спортом на состояние здоровья детей 10-12 лет Презентация Таможенный платежи кроссворд

Презентация Таможенный платежи кроссворд Модели сущность-связь

Модели сущность-связь Презентация Классическое Средневековье (XI -XV вв.)

Презентация Классическое Средневековье (XI -XV вв.) ß-адреноблокаторы – величайший прорыв в лечении сердечно-сосудистых заболеваний

ß-адреноблокаторы – величайший прорыв в лечении сердечно-сосудистых заболеваний Социально-исторические предпосылки государства и права. Возникновение государства и права

Социально-исторические предпосылки государства и права. Возникновение государства и права Страхование ответственности за загрязнение окружающей среды (экологическое страхование) в России и за рубежом

Страхование ответственности за загрязнение окружающей среды (экологическое страхование) в России и за рубежом Kung fu and chinese martial arts

Kung fu and chinese martial arts Наш друг - спорт

Наш друг - спорт Распространенные заболевания человека

Распространенные заболевания человека Презентация на тему "Интерактивные методы обучения как фактор мотивации качества учебного материала" - скачать презентации п

Презентация на тему "Интерактивные методы обучения как фактор мотивации качества учебного материала" - скачать презентации п