Содержание

- 2. As you remember of OBJECTIVES? JAP The competence we strive for by this first Operations Management

- 3. The focus of Operations Management course ……… Coping – daily operations - level: Capability to work

- 4. JAP Look on next page: Good to know – general knowledge od OM / Production Important

- 5. CONTENT Introduction to Production Control (good to know) History and perspective of industrial engineering (good to

- 7. Скачать презентацию

Слайд 2

As you remember of OBJECTIVES?

JAP

The competence we strive for by

As you remember of OBJECTIVES?

JAP

The competence we strive for by

this first Operations Management course is that students get familiarized with production/manufacturing and controlling systems, they are able to work in production planning operative tasks, and know the basics of analyzing and developing production systems.

This course is merely an introduction to operations development and management skills, and therefore one of the main focuses is in terminology, basic goals and reasons of different issues and means of control.

This course is merely an introduction to operations development and management skills, and therefore one of the main focuses is in terminology, basic goals and reasons of different issues and means of control.

Слайд 3

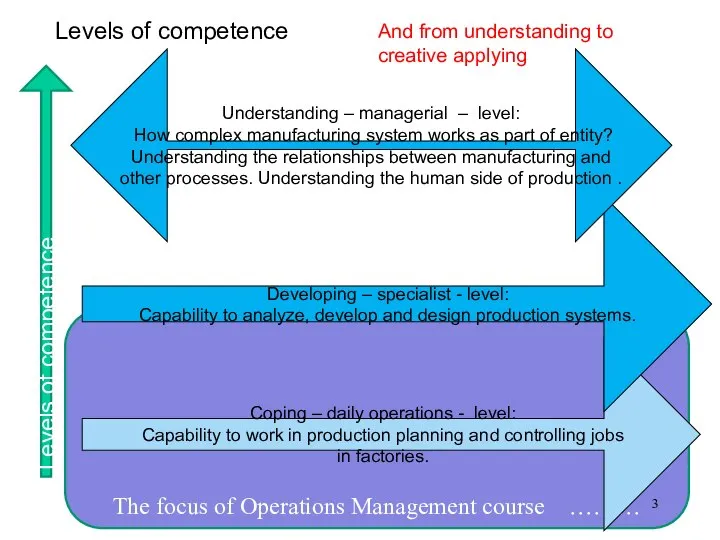

The focus of Operations Management course ………

Coping – daily operations -

The focus of Operations Management course ………

Coping – daily operations -

level:

Capability to work in production planning and controlling jobs

in factories.

Capability to work in production planning and controlling jobs

in factories.

Developing – specialist - level:

Capability to analyze, develop and design production systems.

Understanding – managerial – level:

How complex manufacturing system works as part of entity?

Understanding the relationships between manufacturing and

other processes. Understanding the human side of production .

Levels of competence

Levels of competence

And from understanding to creative applying

Слайд 4

JAP

Look on next page:

Good to know – general knowledge od OM

JAP

Look on next page:

Good to know – general knowledge od OM

/ Production

Important to know - Specific knowledge for planning and implementing OM tasks

Important to know - Specific knowledge for planning and implementing OM tasks

Слайд 5

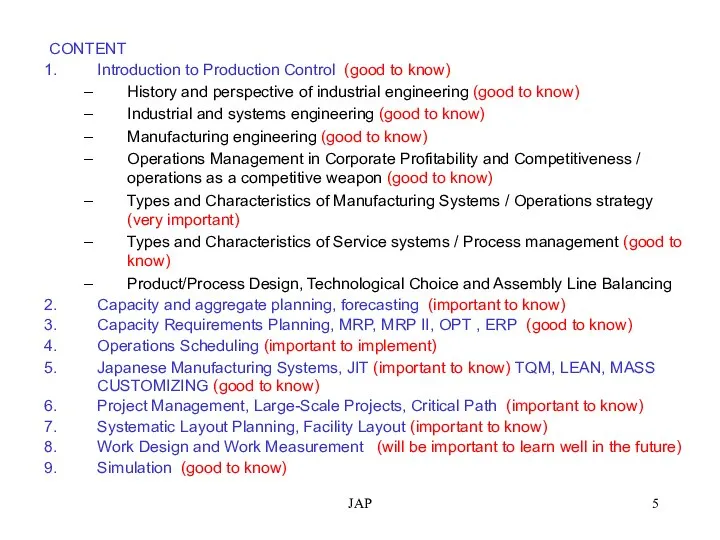

CONTENT

Introduction to Production Control (good to know)

History and perspective of industrial

CONTENT

Introduction to Production Control (good to know)

History and perspective of industrial

engineering (good to know)

Industrial and systems engineering (good to know)

Manufacturing engineering (good to know)

Operations Management in Corporate Profitability and Competitiveness / operations as a competitive weapon (good to know)

Types and Characteristics of Manufacturing Systems / Operations strategy (very important)

Types and Characteristics of Service systems / Process management (good to know)

Product/Process Design, Technological Choice and Assembly Line Balancing

Capacity and aggregate planning, forecasting (important to know)

Capacity Requirements Planning, MRP, MRP II, OPT , ERP (good to know)

Operations Scheduling (important to implement)

Japanese Manufacturing Systems, JIT (important to know) TQM, LEAN, MASS CUSTOMIZING (good to know)

Project Management, Large-Scale Projects, Critical Path (important to know)

Systematic Layout Planning, Facility Layout (important to know)

Work Design and Work Measurement (will be important to learn well in the future)

Simulation (good to know)

Industrial and systems engineering (good to know)

Manufacturing engineering (good to know)

Operations Management in Corporate Profitability and Competitiveness / operations as a competitive weapon (good to know)

Types and Characteristics of Manufacturing Systems / Operations strategy (very important)

Types and Characteristics of Service systems / Process management (good to know)

Product/Process Design, Technological Choice and Assembly Line Balancing

Capacity and aggregate planning, forecasting (important to know)

Capacity Requirements Planning, MRP, MRP II, OPT , ERP (good to know)

Operations Scheduling (important to implement)

Japanese Manufacturing Systems, JIT (important to know) TQM, LEAN, MASS CUSTOMIZING (good to know)

Project Management, Large-Scale Projects, Critical Path (important to know)

Systematic Layout Planning, Facility Layout (important to know)

Work Design and Work Measurement (will be important to learn well in the future)

Simulation (good to know)

JAP

Трехэлектродная лампа (триод)

Трехэлектродная лампа (триод) Художественная культура античности. Древний Рим

Художественная культура античности. Древний Рим Концепция производственной демократии

Концепция производственной демократии  Презентация "Средневековое искусство. Время соборов" - скачать презентации по МХК

Презентация "Средневековое искусство. Время соборов" - скачать презентации по МХК Кустарниковый пожар, ситуация - выживание

Кустарниковый пожар, ситуация - выживание Обработка исключений

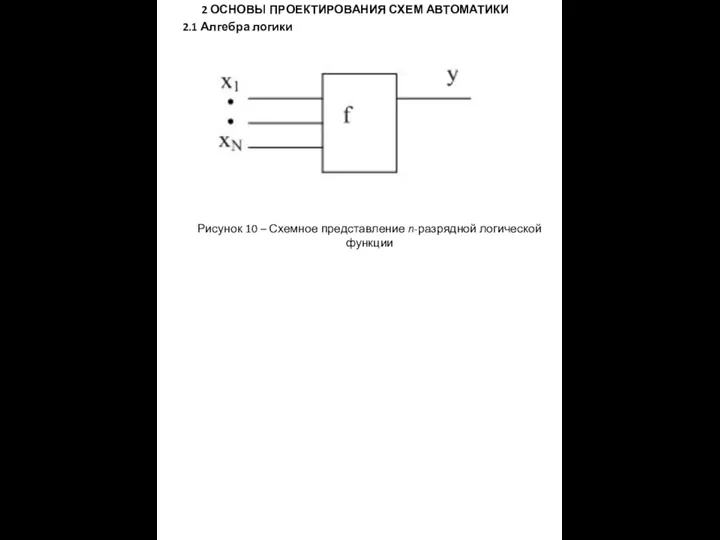

Обработка исключений Основы проектирования схем автоматики

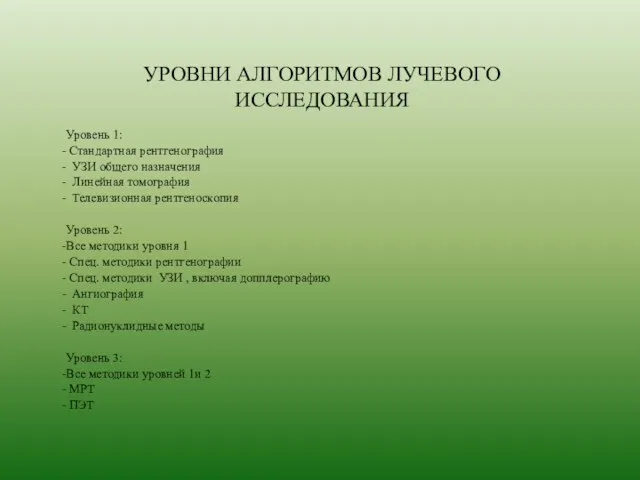

Основы проектирования схем автоматики УРОВНИ АЛГОРИТМОВ ЛУЧЕВОГО ИССЛЕДОВАНИЯ Уровень 1: Стандартная рентгенография УЗИ общего назначения Линейная томография

УРОВНИ АЛГОРИТМОВ ЛУЧЕВОГО ИССЛЕДОВАНИЯ Уровень 1: Стандартная рентгенография УЗИ общего назначения Линейная томография  Презентация Основные направления деятельности ФТС на 2011-2013 годы

Презентация Основные направления деятельности ФТС на 2011-2013 годы Месторождение Ахваз

Месторождение Ахваз Инновации и инновационная деятельность, как объект управления. (Тема 3, вопросы 4-10)

Инновации и инновационная деятельность, как объект управления. (Тема 3, вопросы 4-10) Харганатская средняя общеобразовательная школа Сюрреализм Выполнила: Будаева Э.А, учитель русского языка и литературы

Харганатская средняя общеобразовательная школа Сюрреализм Выполнила: Будаева Э.А, учитель русского языка и литературы  Прямая адресация памяти

Прямая адресация памяти Аудитория Уанета Январь 2011 г. gemiusAudience

Аудитория Уанета Январь 2011 г. gemiusAudience Представления о технических и программных средствах телекоммуникационных технологий. Лекция 33. Тема 5.1

Представления о технических и программных средствах телекоммуникационных технологий. Лекция 33. Тема 5.1 Структура мікропроцесорного пристрою. Архітектурні особливості мікропроцесорів. Поняття про систему команд. (Тема 4)

Структура мікропроцесорного пристрою. Архітектурні особливості мікропроцесорів. Поняття про систему команд. (Тема 4) ВИЧ – инфекция и нейросифилис

ВИЧ – инфекция и нейросифилис Студенческий хоккей в США

Студенческий хоккей в США Анималотерапия Лекарственные свойства животных «ВРАЧ ЛЕЧИТ - ПРИРОДА ИСЦЕЛЯЕТ!» Гиппократ.

Анималотерапия Лекарственные свойства животных «ВРАЧ ЛЕЧИТ - ПРИРОДА ИСЦЕЛЯЕТ!» Гиппократ. Методический семинар. Движение в радость

Методический семинар. Движение в радость Значение слова пассия

Значение слова пассия Модели деловой карьеры

Модели деловой карьеры Проектно - исследовательская работа Мой прадед Выполнила: Ученица 2а класса Школы 7 Гайдышева Екатерина Руководитель проекта: Л.В. Л

Проектно - исследовательская работа Мой прадед Выполнила: Ученица 2а класса Школы 7 Гайдышева Екатерина Руководитель проекта: Л.В. Л Семинар ГТО

Семинар ГТО Хранение информации в файлах. На примере c#

Хранение информации в файлах. На примере c# Рыхлая соединительная ткань. Соединительные ткани со специальными свойствами

Рыхлая соединительная ткань. Соединительные ткани со специальными свойствами Как будет проходить обучение

Как будет проходить обучение Иосиф Бродский

Иосиф Бродский