Содержание

- 2. Things I Hope To Leave You With Share my experience with the rotor controller project Explain

- 3. Motivation For This Project Developed an interest in LEO (Low Earth Orbit) satellites Led to an

- 4. Low Earth Orbit Satellites Basically LEOs are orbital repeaters AMSAT has a lot of information on

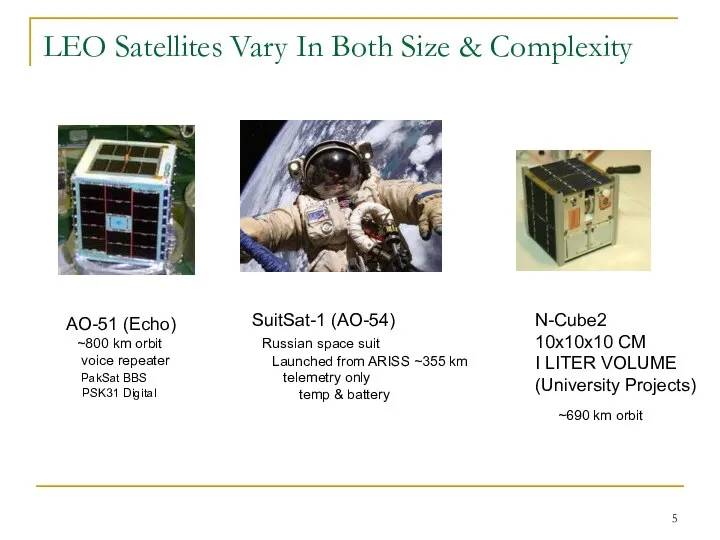

- 5. LEO Satellites Vary In Both Size & Complexity AO-51 (Echo) ~800 km orbit voice repeater PakSat

- 6. Satellite QSOs Are Interesting! There are a lot of “things” involved in working the LEO satellites!

- 7. So Many things – So Little Time! The window for a QSO is often less than

- 8. My Approach To The Project Research the WEB for similar projects Evaluate what I might do

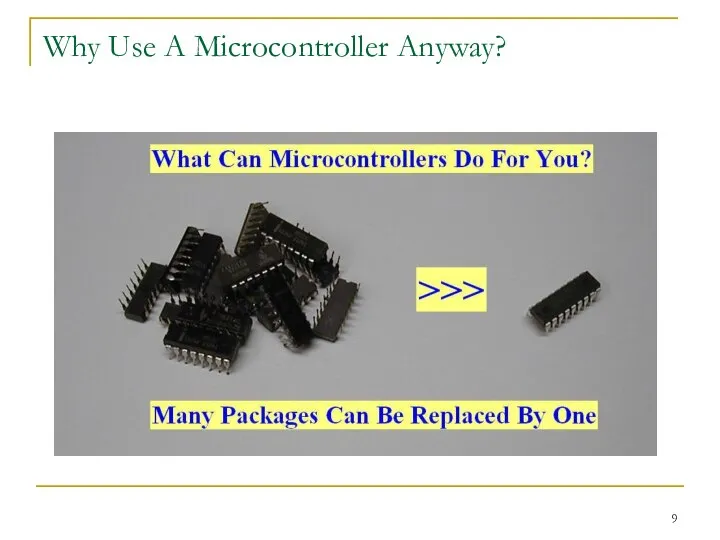

- 9. Why Use A Microcontroller Anyway?

- 10. Choices To Make Features Rotors Software Development tools & Environment Microcontroller

- 11. Desirable Features Work with the Nova tracking software Have 2 main modes: “manual” & “autotrack” Self-calibrate

- 12. The Rotor – You must understand the thing you are trying to control! The Alliance U100

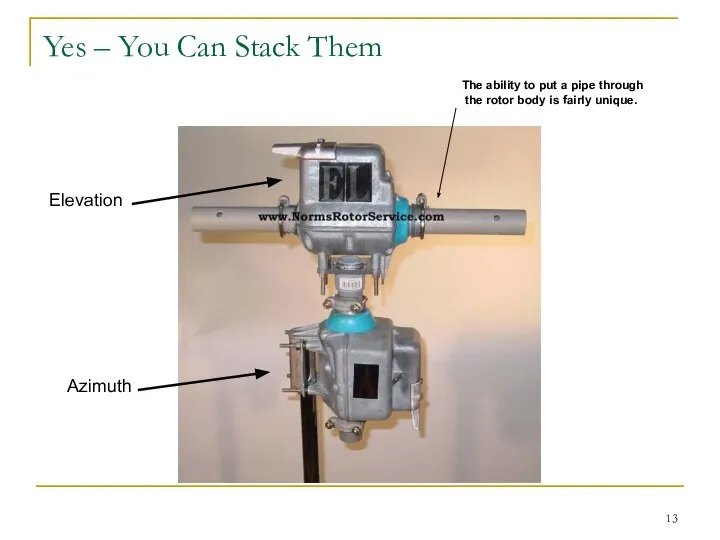

- 13. Yes – You Can Stack Them Azimuth Elevation The ability to put a pipe through the

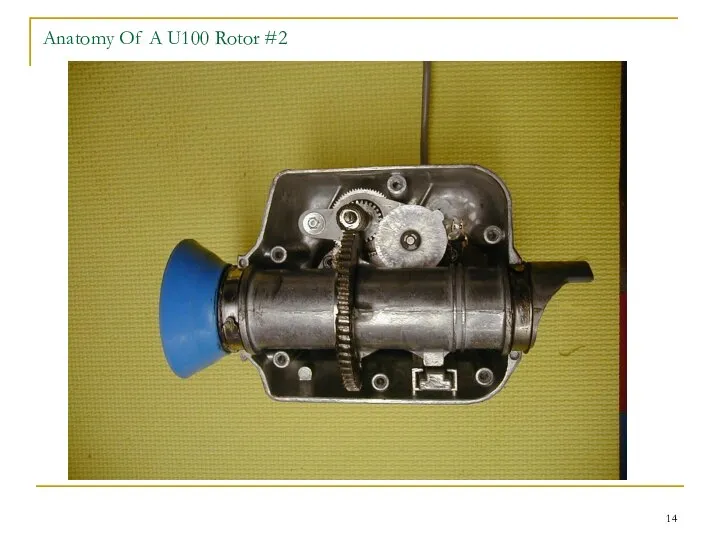

- 14. Anatomy Of A U100 Rotor #2

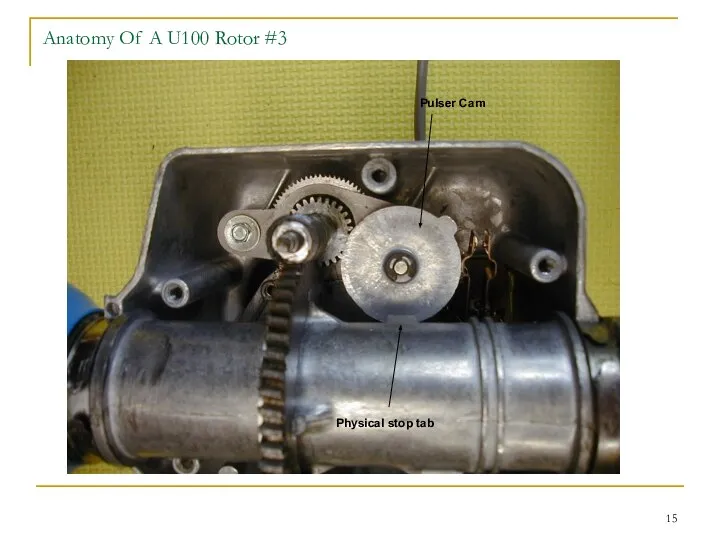

- 15. Anatomy Of A U100 Rotor #3 Physical stop tab Pulser Cam

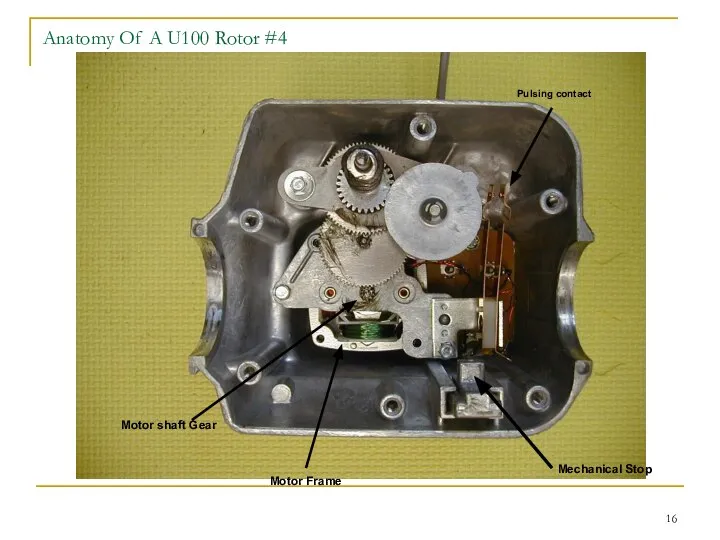

- 16. Anatomy Of A U100 Rotor #4 Motor shaft Gear Pulsing contact Motor Frame Mechanical Stop

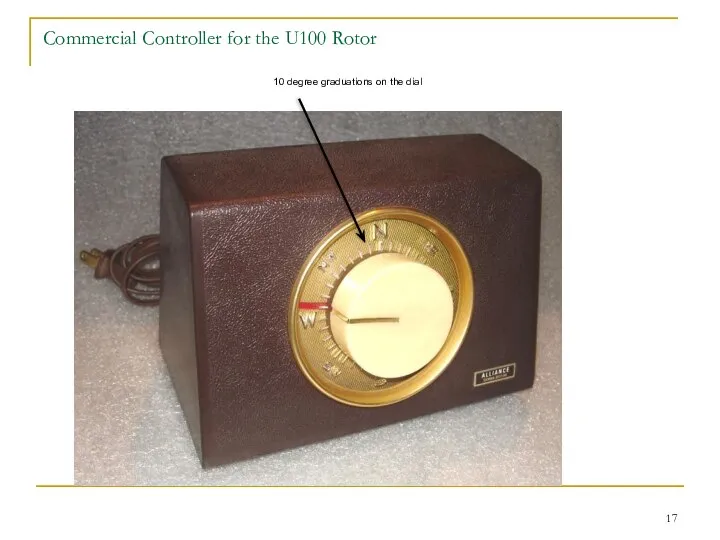

- 17. Commercial Controller for the U100 Rotor 10 degree graduations on the dial

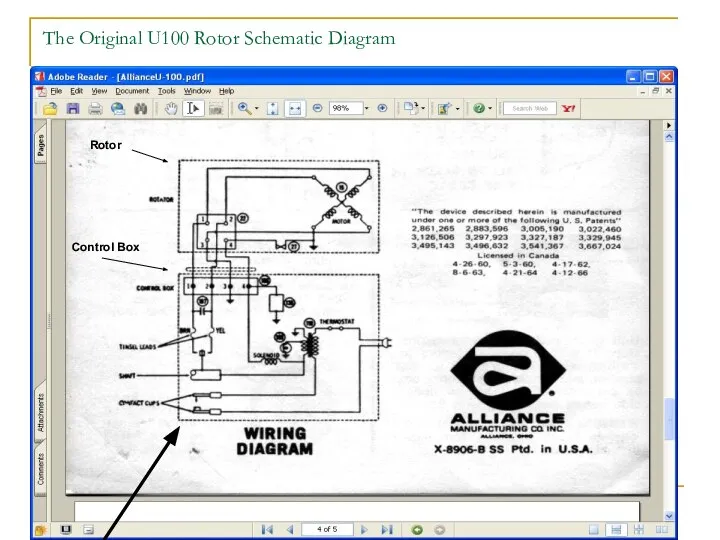

- 18. The Original U100 Rotor Schematic Diagram Rotor Control Box Simply replace this with a Microcontroller System

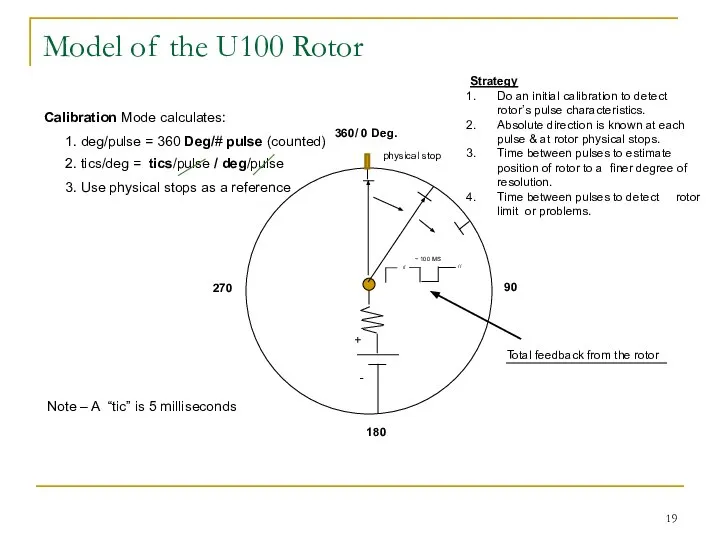

- 19. Model of the U100 Rotor + - 360/ 0 Deg. 180 90 270 2. tics/deg =

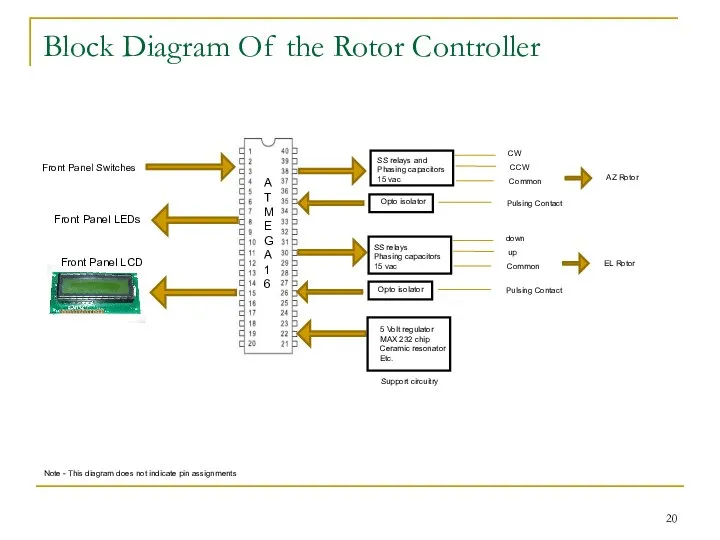

- 20. Block Diagram Of the Rotor Controller Front Panel Switches Front Panel LEDs SS relays and Phasing

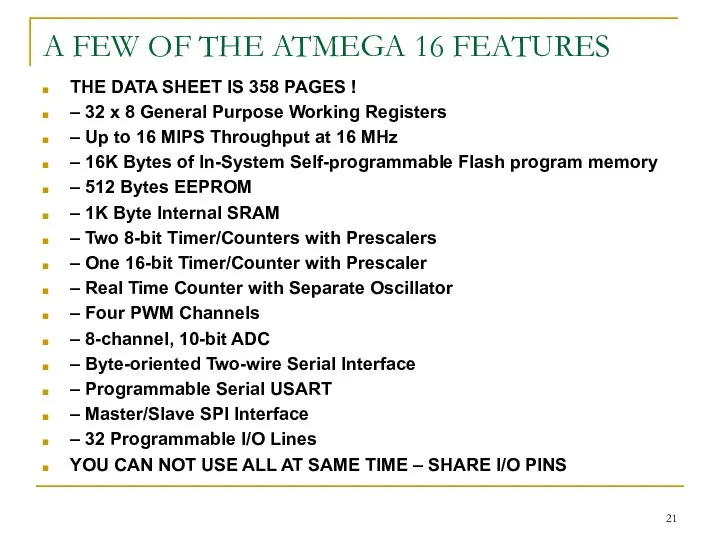

- 21. A FEW OF THE ATMEGA 16 FEATURES THE DATA SHEET IS 358 PAGES ! – 32

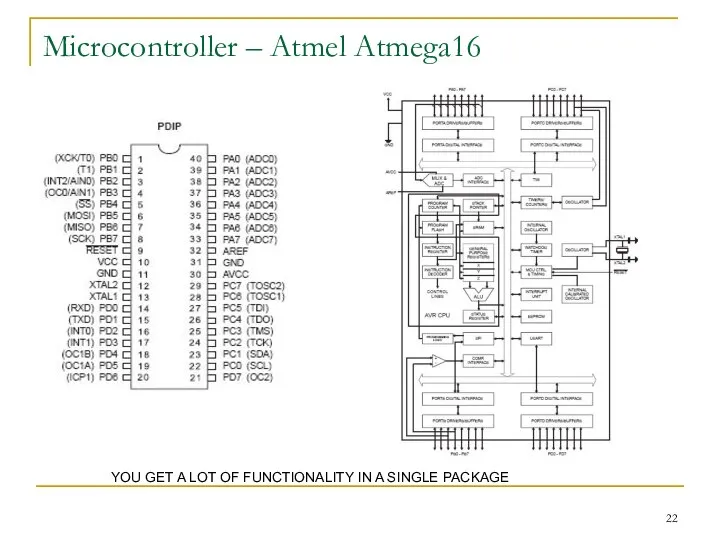

- 22. Microcontroller – Atmel Atmega16 YOU GET A LOT OF FUNCTIONALITY IN A SINGLE PACKAGE

- 23. Microcontroller – Save Time By Buying a Proto board I use this development board for almost

- 24. Partial Schematic of the Rotor Controller System – Rotor interfaces 30 VCT xfmr Solid State Relays

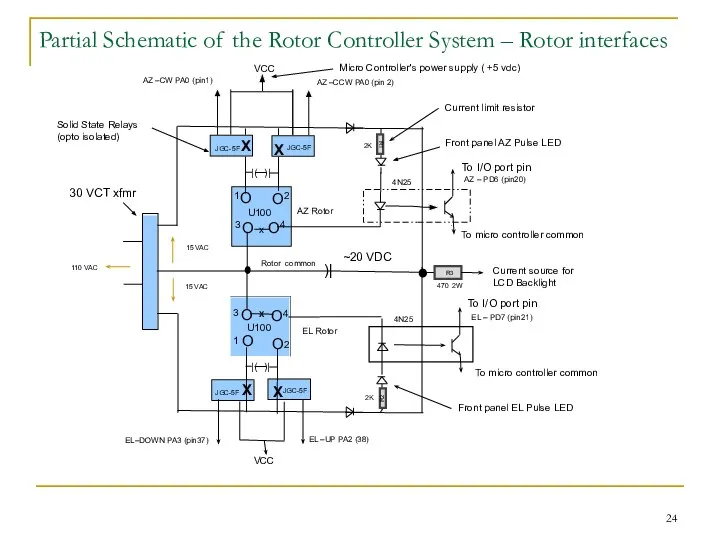

- 25. Front Panel Switches – Interface to the Microcontroller Micro Controller Port assignments (Active low) Port A

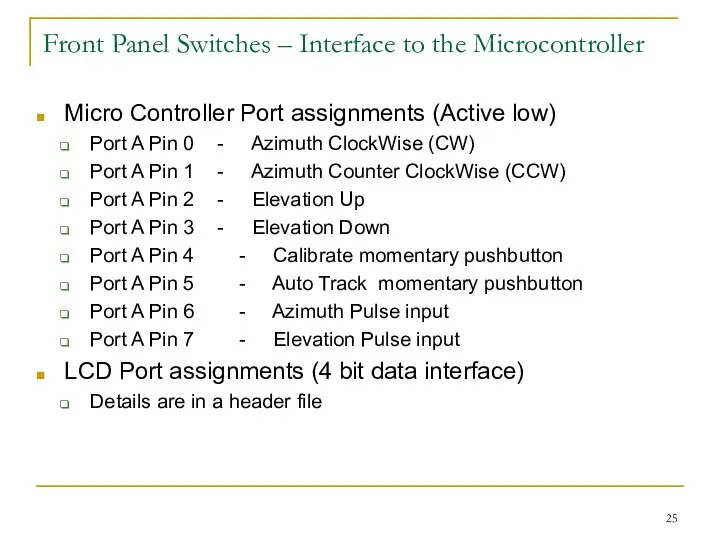

- 26. Development Environment Rotor control cable Debug data Serial port Program flash memory using “avrdude” utility Fedora

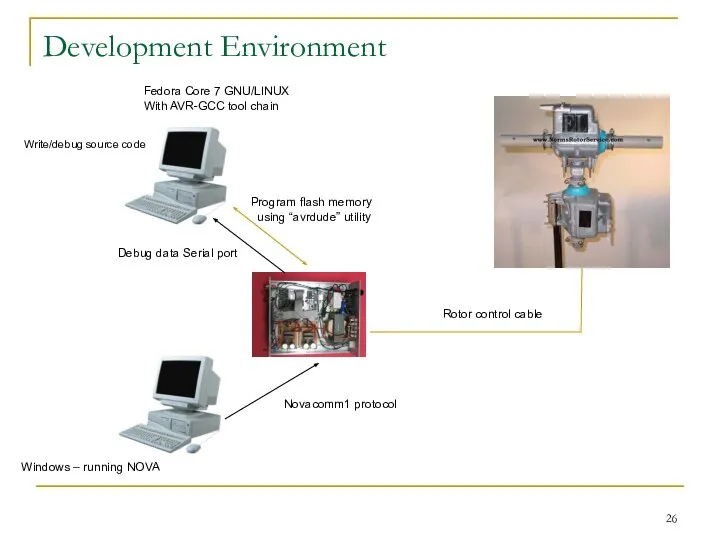

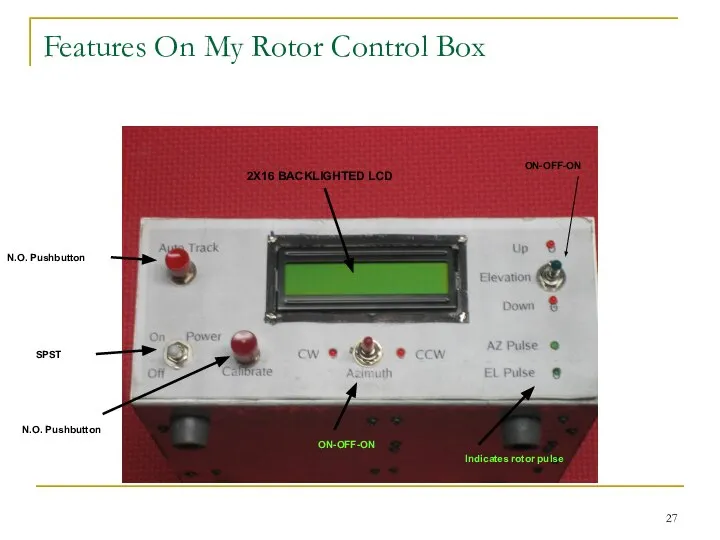

- 27. Features On My Rotor Control Box 2X16 BACKLIGHTED LCD SPST N.O. Pushbutton N.O. Pushbutton ON-OFF-ON ON-OFF-ON

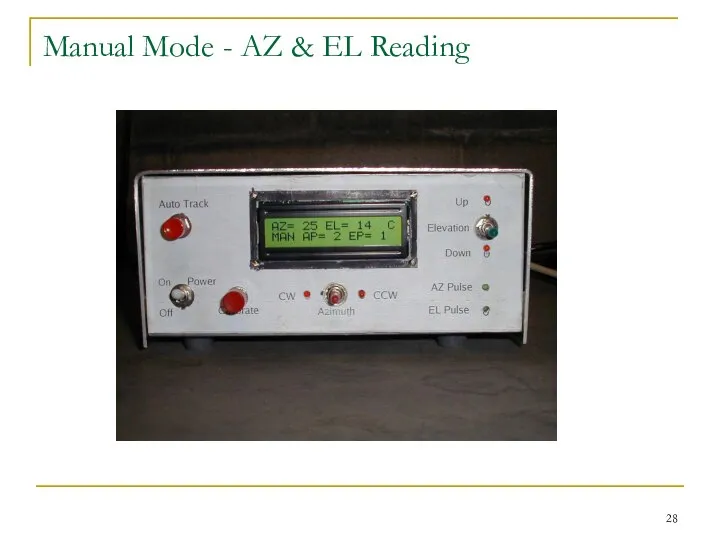

- 28. Manual Mode - AZ & EL Reading

- 29. Auto track mode – tracking AO-10 satellite

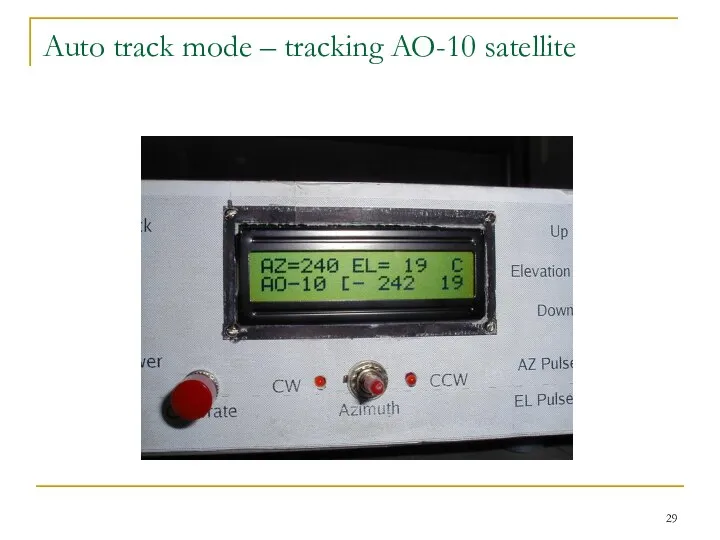

- 30. The Rotor Teststand

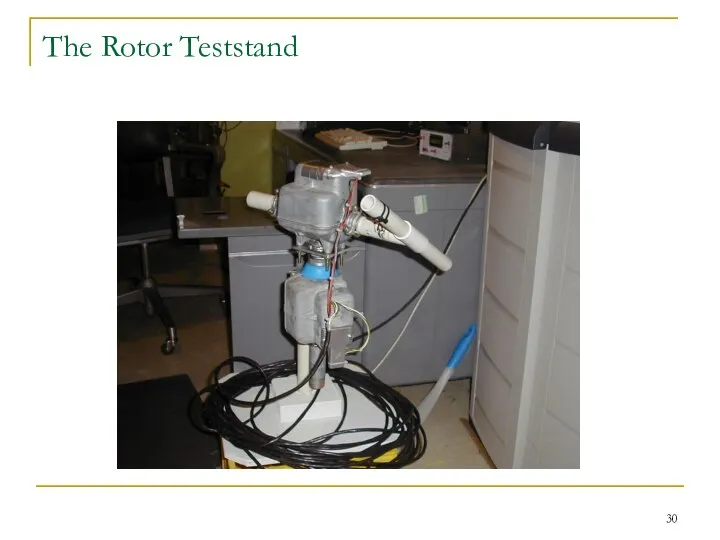

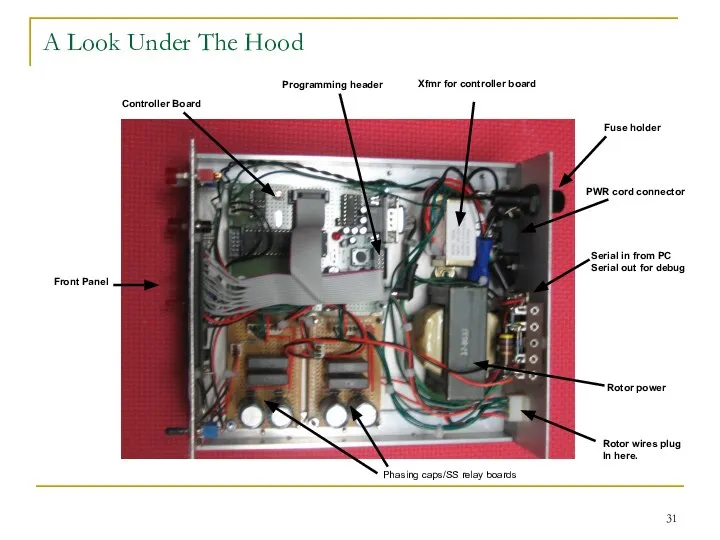

- 31. A Look Under The Hood Rotor power Controller Board Xfmr for controller board Phasing caps/SS relay

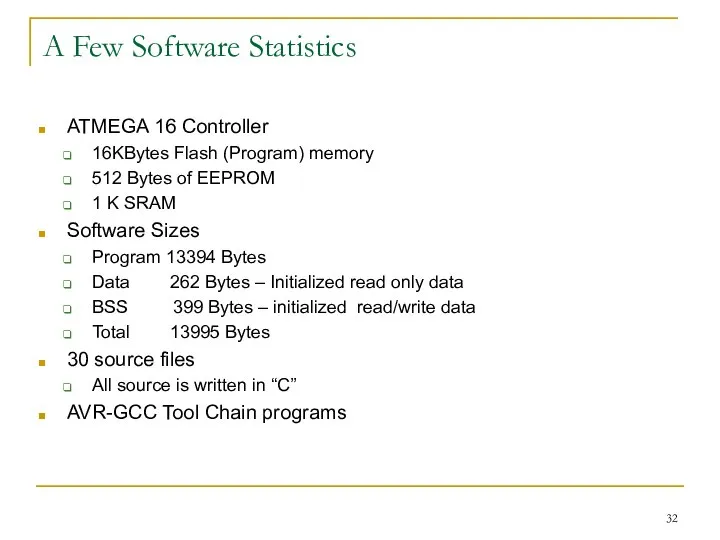

- 32. A Few Software Statistics ATMEGA 16 Controller 16KBytes Flash (Program) memory 512 Bytes of EEPROM 1

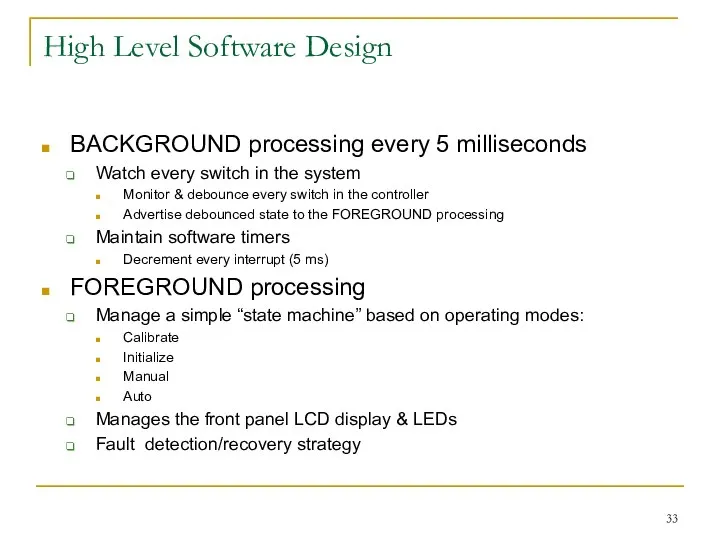

- 33. High Level Software Design BACKGROUND processing every 5 milliseconds Watch every switch in the system Monitor

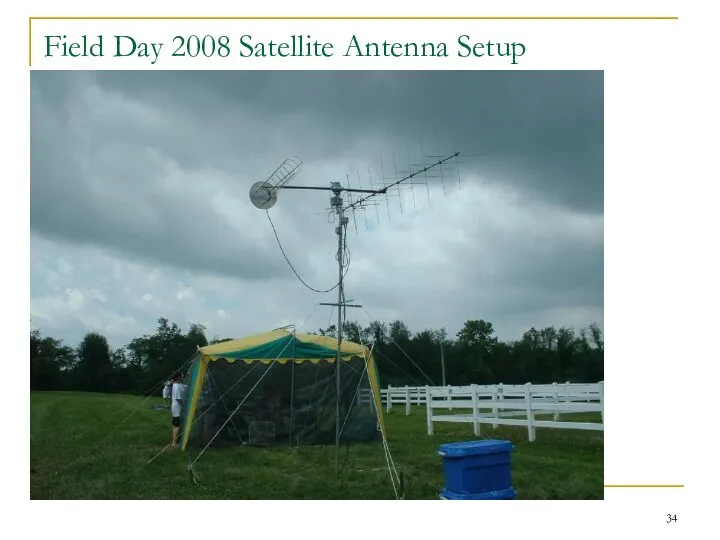

- 34. Field Day 2008 Satellite Antenna Setup

- 35. Performance Of The Controller Used successfully in last two Field Days Sensitive to drag on the

- 36. Things Left Undone Need to get a better schematic in electronic form Scattered around in a

- 37. Closing Thoughts About Antenna Rotors Pulsers have many issues to consider Resolution - must interpolate Calibration

- 39. Скачать презентацию

Азаматтық құқық негіздері. Меншік құқығы

Азаматтық құқық негіздері. Меншік құқығы Разработка технологического проекта кузнечно-рессорного участка на АТП

Разработка технологического проекта кузнечно-рессорного участка на АТП Боги Древнего Египта

Боги Древнего Египта Антон Семенович Макаренко (1888—1939) Талантливый педагог-новатор, одним из создателей стройной системы коммунистического восп

Антон Семенович Макаренко (1888—1939) Талантливый педагог-новатор, одним из создателей стройной системы коммунистического восп Психологические закономерности общения. Специфика их проявления. Подготовил: Студент группы Ю092 Виноградская Екатерина

Психологические закономерности общения. Специфика их проявления. Подготовил: Студент группы Ю092 Виноградская Екатерина ФИНАНСОВЫЕ РЕСУРСЫ И ИХ ИСТОЧНИКИ Подготовили: студентки ФТД-2 группы Т-104 Глушак Ю., Лотышева А.

ФИНАНСОВЫЕ РЕСУРСЫ И ИХ ИСТОЧНИКИ Подготовили: студентки ФТД-2 группы Т-104 Глушак Ю., Лотышева А. Тайны грибного царства - презентация для начальной школы_

Тайны грибного царства - презентация для начальной школы_ Введение в офтальмологию

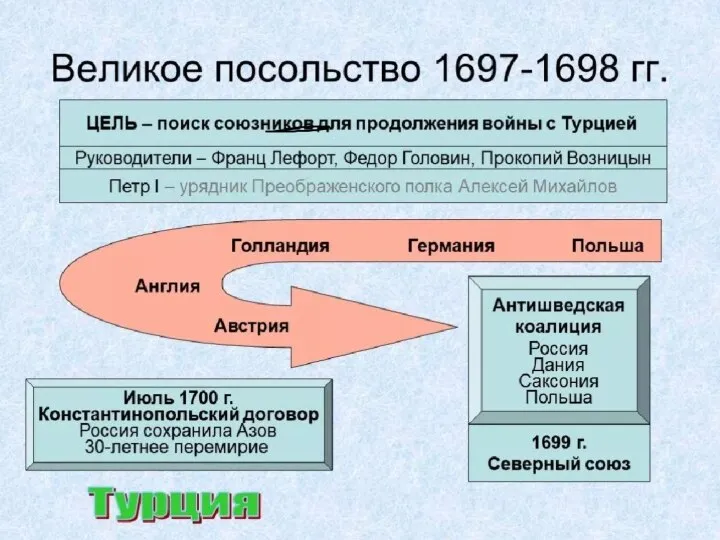

Введение в офтальмологию северная+война

северная+война Тайм-менеджмент / Самоменеджмент Материалы 1 лекции

Тайм-менеджмент / Самоменеджмент Материалы 1 лекции  ФУНКЦІОНАЛЬНІ СТРАТЕГІЇ ПІДПРИЄМСТВА В СИСТЕМІ СТРАТЕГІЧНОГО МЕНЕДЖМЕНТУ

ФУНКЦІОНАЛЬНІ СТРАТЕГІЇ ПІДПРИЄМСТВА В СИСТЕМІ СТРАТЕГІЧНОГО МЕНЕДЖМЕНТУ Презентация на тему "Формирование правильной осанки средствами ритмической гимнастики" - скачать презентации по Медицине

Презентация на тему "Формирование правильной осанки средствами ритмической гимнастики" - скачать презентации по Медицине простые, сложные, эквиваленнтыные процентные ставки

простые, сложные, эквиваленнтыные процентные ставки  Организация управления предприятием

Организация управления предприятием Гра «Змійка»

Гра «Змійка» Delphi. Объекто - ориентированное программирование

Delphi. Объекто - ориентированное программирование St. Patrick’s Day

St. Patrick’s Day Фильтрация выпрямленного напряжения

Фильтрация выпрямленного напряжения Как появился мобильный телефон

Как появился мобильный телефон Устное народное творчество. Малые жанры фольклора

Устное народное творчество. Малые жанры фольклора Профессионально-прикладная физическая подготовка (ППФП)

Профессионально-прикладная физическая подготовка (ППФП)  Юриспруденция

Юриспруденция  Массивы

Массивы Традиционная русская одежда

Традиционная русская одежда АВТОМАТИЗАЦИЯ РАЗРАБОТКИ, ВНЕДРЕНИЯ И УЛУЧШЕНИЯ

АВТОМАТИЗАЦИЯ РАЗРАБОТКИ, ВНЕДРЕНИЯ И УЛУЧШЕНИЯ  Мембранные методы

Мембранные методы Презентация "Изобразительного искусства" - скачать презентации по МХК

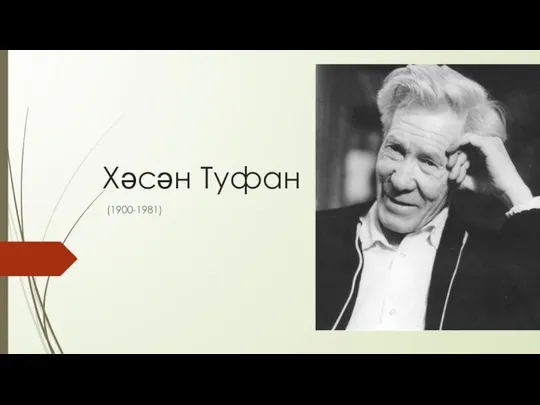

Презентация "Изобразительного искусства" - скачать презентации по МХК Хәсән Туфан (Миннегалиева Р. 11 А)

Хәсән Туфан (Миннегалиева Р. 11 А)