Содержание

- 2. Preparation Beam tube cleaned according to UHV practices. Vacuum fired at 450 C. Assembled into coating

- 3. Coating System 3

- 4. Coating System Overview of system with two Fermilab tubes. Gas introduction flange. Power and cooling connections.

- 5. Titanium Cathode Assembly Insertion of magnet string into Ti cathode.

- 6. The Coating Process Balance temperature, pressure, flow rate, and voltage to control deposition. Start with Argon

- 7. System Disassembly Nitrogen insertion tube attached to titanium cathode still inside chamber. Titanium cathode with nitrogen

- 8. Coating Complete Coating analysis coupons were inserted adjacent to production tubes. Finished Fermilab tube.

- 9. Installed in Main Injector One coated tube installed during Summer 2009 shutdown at MI-521. One uncoated

- 11. Скачать презентацию

What do you see? Who is this woman?

What do you see? Who is this woman? Barbarian 2016 modifications and work plan

Barbarian 2016 modifications and work plan Фразовый глагол get

Фразовый глагол get EducateDell DSP Training

EducateDell DSP Training Telling the time

Telling the time Тема 4 (продолжение). Перевод имен собственных. Транспозиция и калькирование

Тема 4 (продолжение). Перевод имен собственных. Транспозиция и калькирование Food products

Food products [s] [w] [t] [əʊ] [n] [r] [m] [i]

[s] [w] [t] [əʊ] [n] [r] [m] [i] Правила и примеры правописания в английском языке

Правила и примеры правописания в английском языке Past Simple Tense

Past Simple Tense Презентация к уроку английского языка "The Kingdom of the English language" - скачать

Презентация к уроку английского языка "The Kingdom of the English language" - скачать  Обобщающий урок в 10 классе по теме «Молодежные субкультуры»

Обобщающий урок в 10 классе по теме «Молодежные субкультуры» THEMA: THEMA: DIE JAHRESZEITEN

THEMA: THEMA: DIE JAHRESZEITEN  Образование в Великобритании

Образование в Великобритании Regular Verbs

Regular Verbs Презентация к уроку английского языка "University" - скачать бесплатно

Презентация к уроку английского языка "University" - скачать бесплатно United Kingdom of Great Britain DOs and DON’Ts for tourists

United Kingdom of Great Britain DOs and DON’Ts for tourists  Schools in Russia and England. What do we know about it?

Schools in Russia and England. What do we know about it? Презентация к уроку английского языка "NEW YORK" - скачать бесплатно

Презентация к уроку английского языка "NEW YORK" - скачать бесплатно Present Simple. Present Continuous

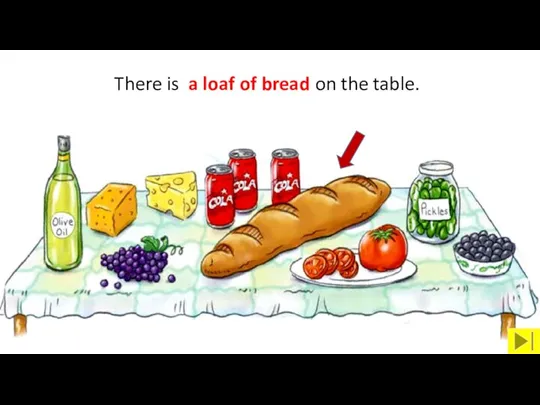

Present Simple. Present Continuous There is a loaf of bread on the table

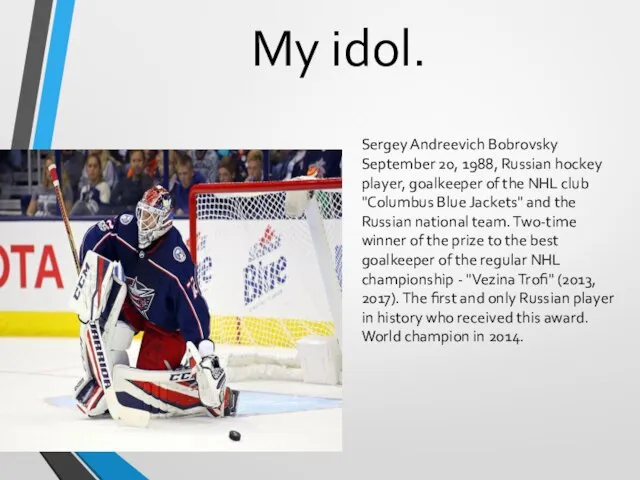

There is a loaf of bread on the table My idol Sergey Andreevich Bobrovsky

My idol Sergey Andreevich Bobrovsky Joseph Mallord William Turner

Joseph Mallord William Turner Ecology In Russia

Ecology In Russia The most popular places in Scotland

The most popular places in Scotland Thomas Hardy (1840-1928) «grieving and courageous painter» A novel Tess of the D’Urbervilles

Thomas Hardy (1840-1928) «grieving and courageous painter» A novel Tess of the D’Urbervilles  Grade 3 What is a noun?

Grade 3 What is a noun? Philosophy of the Newly Modern Times

Philosophy of the Newly Modern Times