occurrence, there are the following

In addition to the temperature ranges of fundamental differences between these

effects. In contrast to BTRO the effect of HTRO:

is largely eliminated by post-radiation annealing ;

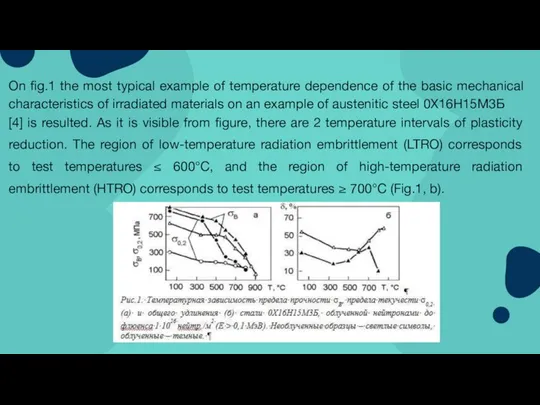

is associated with radiation hardening of the materials Δσ = σobl. - where σobl and σisx are stresses of flow of materials in irradiated and initial states respectively (see fig.1 a);

is associated mainly with a decrease in the uniform elongation of the materials and is not accompanied by a significant change in the lateral contraction.

Accordingly, the BTRO effect is not eliminated by post-radiation annealing and is not normally associated with radiation hardening [5].

Irradiation of metallic materials produces an essential change in the shape and parameters of the hardening curve. The yield strength after high doses of neutron irradiation, for example, in stainless steels increases several times (see, e.g., Fig. 1, a) and in pure annealed metals the flow stresses can increase by more than 10 times [4]. The tensile strength increases to a lesser extent, as can also be seen in Fig. 1, a.

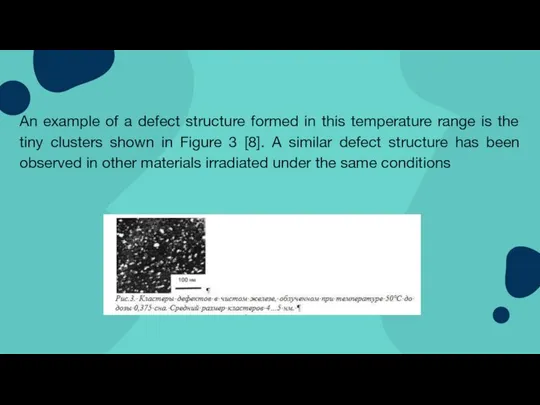

![It is currently believed [1-3] that among structural reactor materials, materials](/_ipx/f_webp&q_80&fit_contain&s_1440x1080/imagesDir/jpg/735809/slide-14.jpg)

Теодолиттер. Оптикалық теодолиттер

Теодолиттер. Оптикалық теодолиттер Сила Лоренца. (Лекции 15-16)

Сила Лоренца. (Лекции 15-16) Лекция №3

Лекция №3  Постоянный ток. Электрический ток в различных средах

Постоянный ток. Электрический ток в различных средах Решение задачи изгиба многослойной упругопластической пластины

Решение задачи изгиба многослойной упругопластической пластины Переходные процессы в линейных электрических цепях

Переходные процессы в линейных электрических цепях Гідростатичний парадокс Автор: Загородня Катерина, учениця 8 класу Новогуйвинської гімназії Житомирського району Житомирськ

Гідростатичний парадокс Автор: Загородня Катерина, учениця 8 класу Новогуйвинської гімназії Житомирського району Житомирськ Простая физика сложных явлений

Простая физика сложных явлений Системы единиц физических величин

Системы единиц физических величин Нерозгалужене коло з активним опором та індуктивністю

Нерозгалужене коло з активним опором та індуктивністю Электролиз меди, цинка, алюминия

Электролиз меди, цинка, алюминия Лучше Северного Сияния, только Северное Сияние…

Лучше Северного Сияния, только Северное Сияние… Определение расстояния до недоступной точки

Определение расстояния до недоступной точки Момент пары сил

Момент пары сил Презентация по физике "Производство и передача электроэнергии" - скачать бесплатно

Презентация по физике "Производство и передача электроэнергии" - скачать бесплатно Характеристики электростатического поля

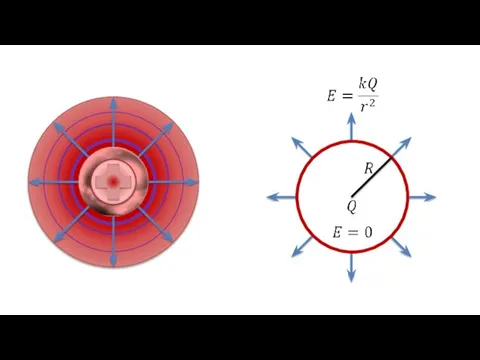

Характеристики электростатического поля Напряженность заряженного шара

Напряженность заряженного шара Michael Faraday

Michael Faraday Свойства твердых тел

Свойства твердых тел Дарсонвалізація. Змінний характер струму

Дарсонвалізація. Змінний характер струму Свойства твёрдых тел, жидкостей и газов

Свойства твёрдых тел, жидкостей и газов Может ли магнит потерять свою силу

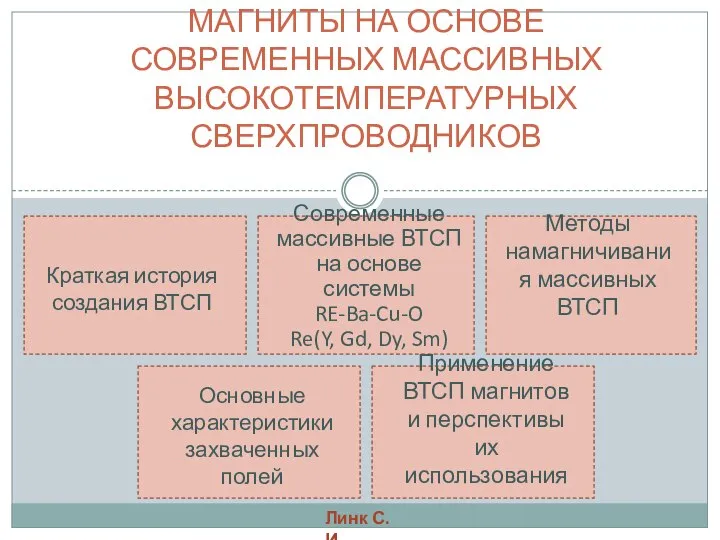

Может ли магнит потерять свою силу Магниты на основе современных массивных высокотемпературных сверхпроводников

Магниты на основе современных массивных высокотемпературных сверхпроводников Линейные электрические цепи. Постоянный ток

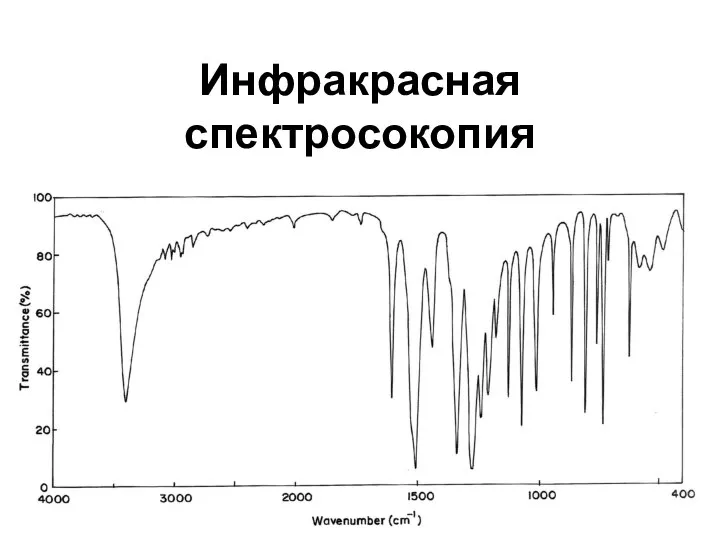

Линейные электрические цепи. Постоянный ток Инфракрасная спектросокопия

Инфракрасная спектросокопия Основное уравнение молекулярно-кинетической теории газов

Основное уравнение молекулярно-кинетической теории газов Измерительные приборы

Измерительные приборы Магнитное поле

Магнитное поле