Содержание

- 2. Application Considerations Please Note : This Product Training information is distributed for informational purposes only It

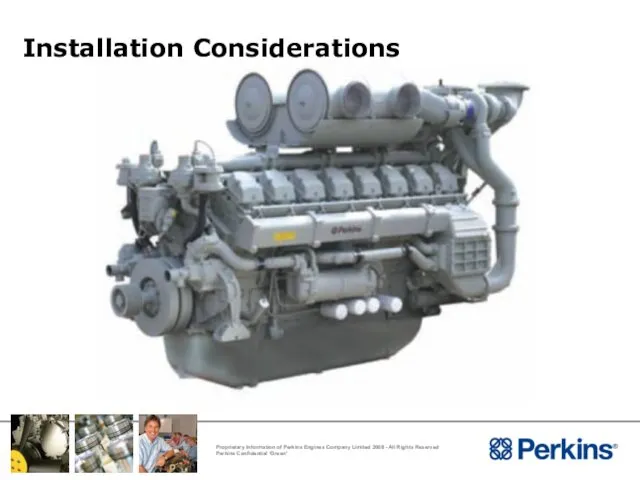

- 3. Installation Considerations

- 4. Installation Considerations

- 5. Installation Considerations

- 6. Installation Considerations

- 7. Installation Considerations Torsional Compatibility Flywheel Housing and Flywheel Engine Room Foundations Mounting Engine Room Layout Ventilation

- 8. Installation Considerations Torsional Compatibility

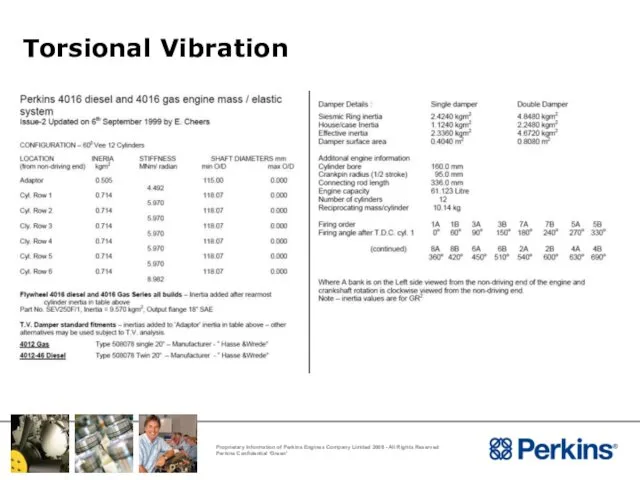

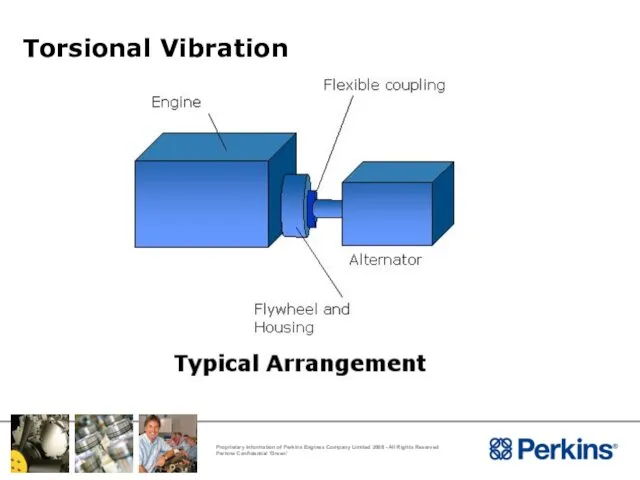

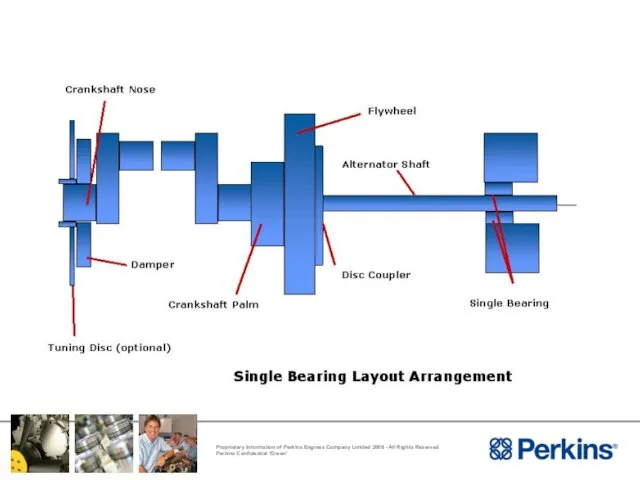

- 9. Torsional Vibration Torsional Vibration Analysis (TVA) ISO 8528 places the onus of ensuring torsional compatibility on

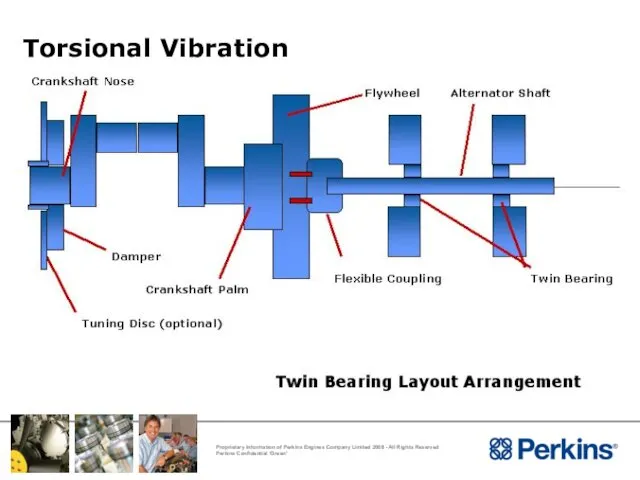

- 10. Torsional Vibration

- 11. Torsional Vibration

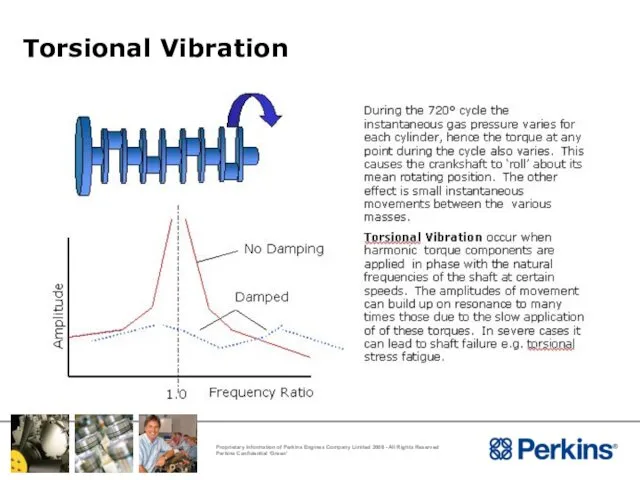

- 12. Torsional Vibration

- 14. Torsional Vibration

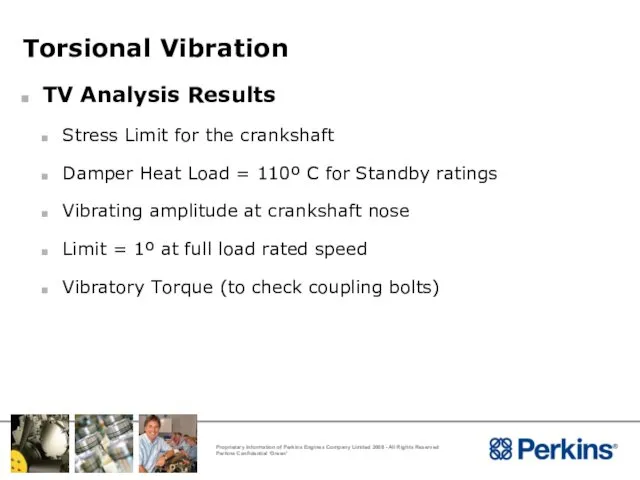

- 15. Torsional Vibration TV Analysis Results Stress Limit for the crankshaft Damper Heat Load = 110º C

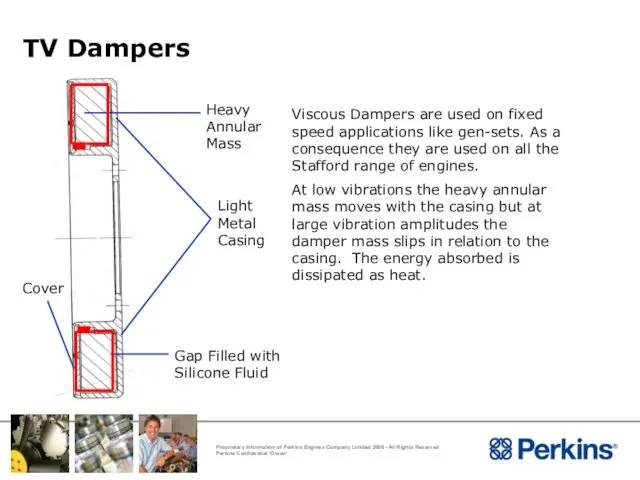

- 16. TV Dampers

- 17. Applications Considerations Flywheel Housing and Flywheel

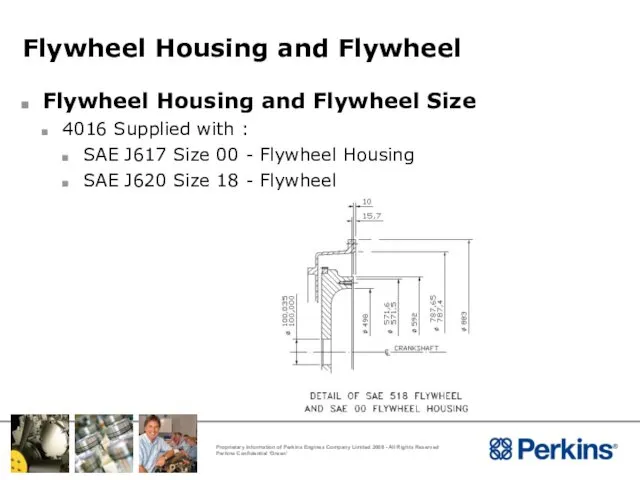

- 18. Flywheel Housing and Flywheel Flywheel Housing and Flywheel Size 4016 Supplied with : SAE J617 Size

- 19. Applications Considerations Engine Room Foundations

- 20. Engine Room Foundations Type of Foundation The engine floor/foundation where the underbase/bearers are fixed is of

- 21. Engine Room Foundations Subsoil - Site The site subsoil must have a bearing strength capable of

- 22. Engine Room Foundations Fixed Concrete Block The fixed concrete block is a proven method The recommended

- 23. Engine Room Foundations Fixed Concrete Block The depth of the concrete block is calculated as follows:

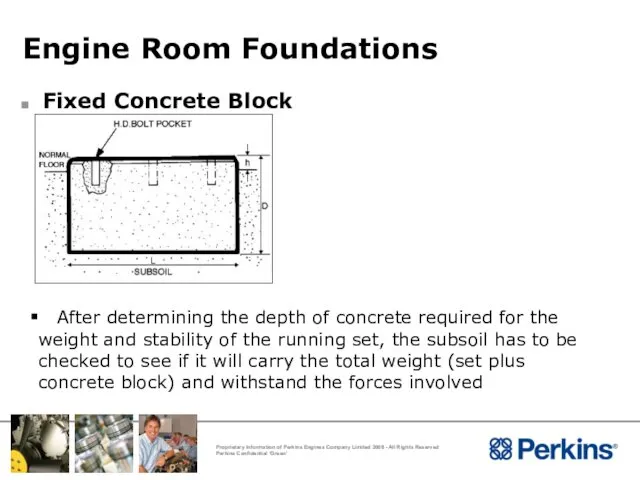

- 24. Engine Room Foundations Fixed Concrete Block After determining the depth of concrete required for the weight

- 25. Installation Considerations Engine Mounting

- 26. Mounting Systems Purpose Of Mounting Systems To secure the engine into the installation Provide adequate support

- 27. Mounting Systems Engine Mountings The type of mountings depend upon the type of installation in which

- 28. Mounting System Types Of Mounting Systems Flexible Mounting Systems Solid Mounting System

- 29. Mounting Systems Types Of Mounting Systems - Flexible Flexible mounting enable the supporting baseframe to be

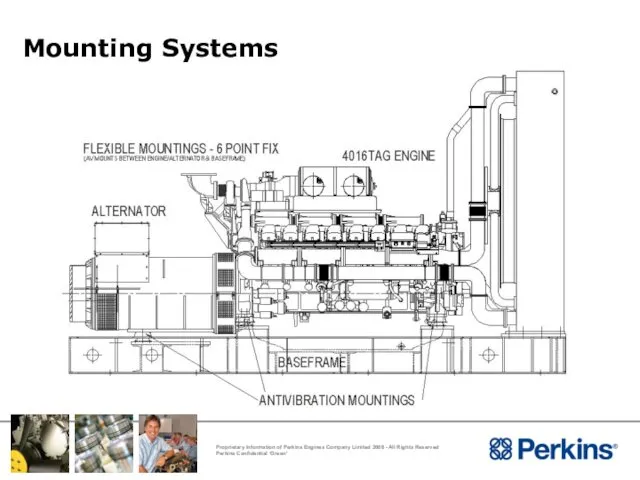

- 30. Mounting Systems

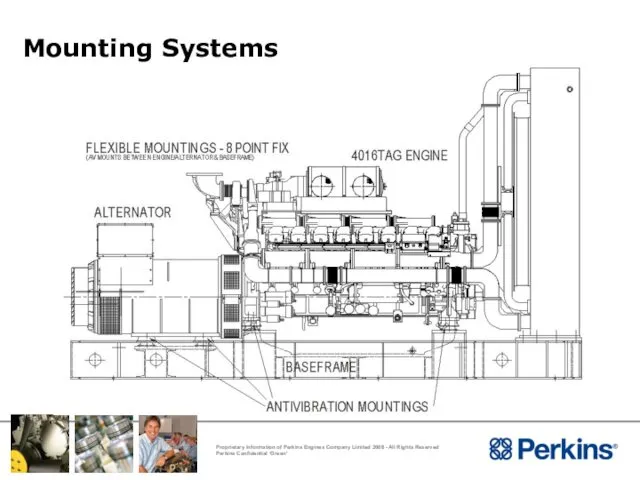

- 31. Mounting Systems

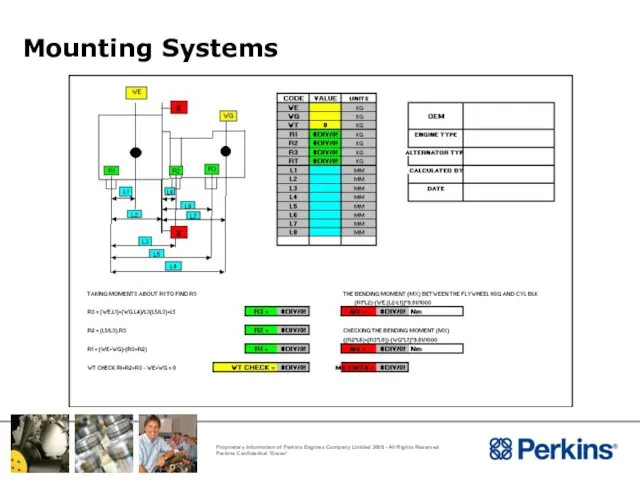

- 32. Mounting Systems Location of Mounts With flexible mounting the location of the mounts are predetermined by

- 33. Mounting Systems

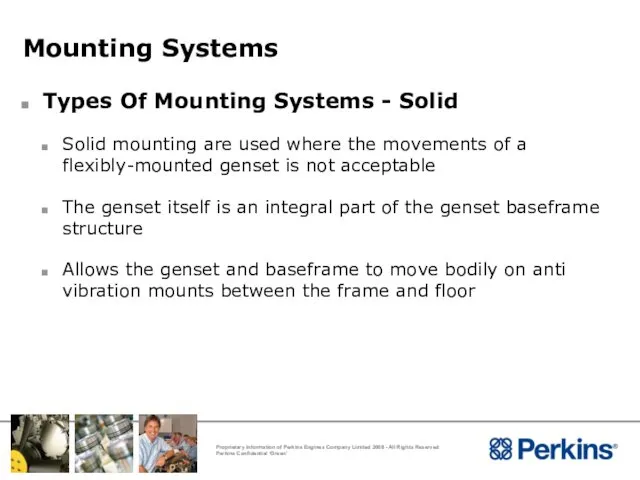

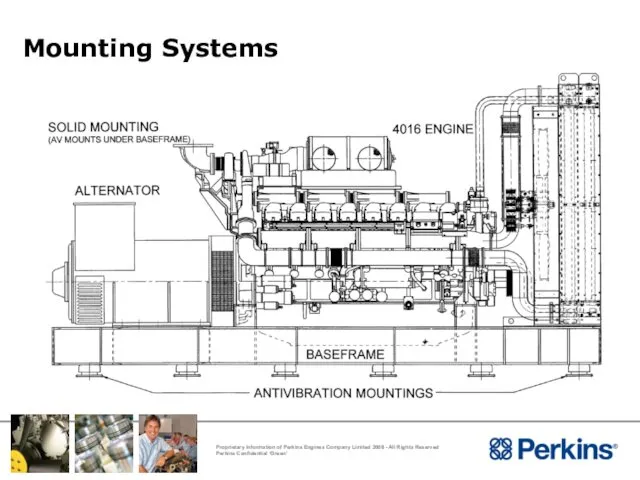

- 34. Mounting Systems Types Of Mounting Systems - Solid Solid mounting are used where the movements of

- 35. Mounting Systems

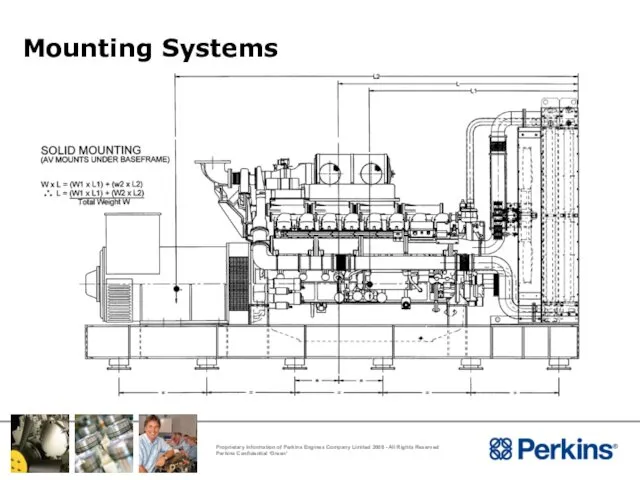

- 36. Mounting Systems Locations Of Mounts With solid mounting the anti vibration mounts should be symmetrically arranged

- 37. Mounting Systems

- 38. Mounting Systems General Considerations No restraints from exhaust pipes, hoses, linkages, etc Are the mounts fitted

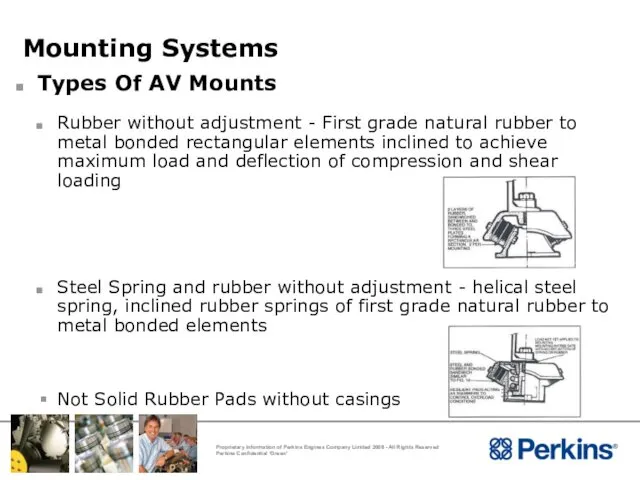

- 39. Mounting Systems Types Of AV Mounts Rubber without adjustment - First grade natural rubber to metal

- 40. Applications Considerations Engine Room layout

- 41. Engine Room Layout Access for Routine Servicing Installation and removal of various components : Cylinder heads

- 42. Engine Room Layout Access for Routine Servicing Maintenance, inspection and replacement of parts : Lubricating oil

- 43. Engine Room Layout Installation Guide lines Avoid plastic and other unsuitable material for fuel piping and

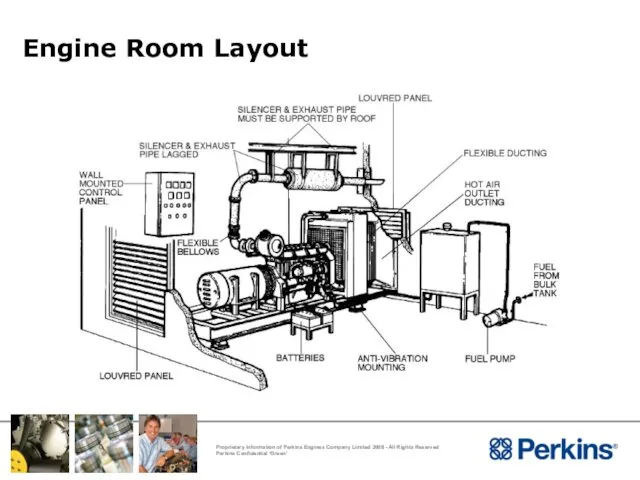

- 44. Engine Room Layout Typical Engine Room Layout Hot air from the radiator ducted outside the engine

- 45. Engine Room Layout

- 46. Installation Considerations Ventilation

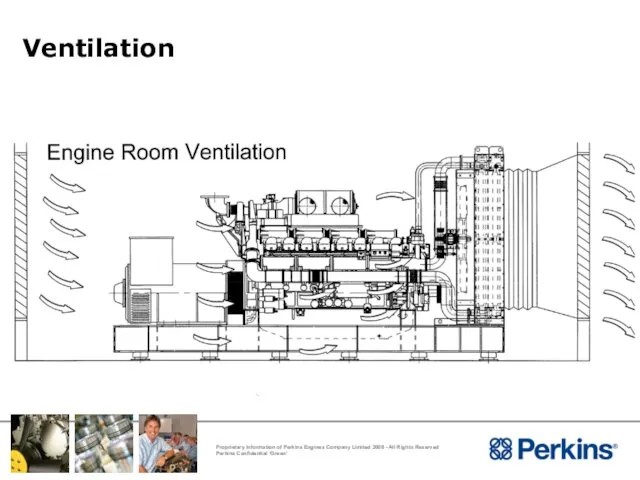

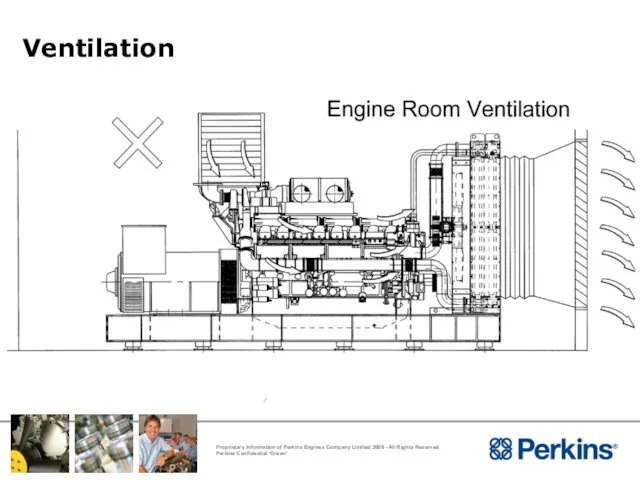

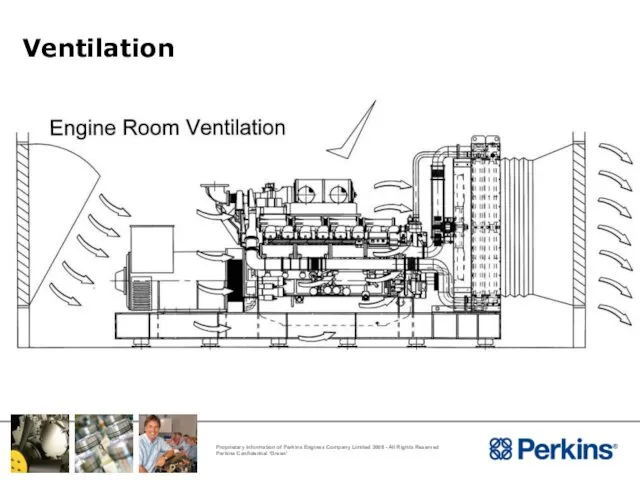

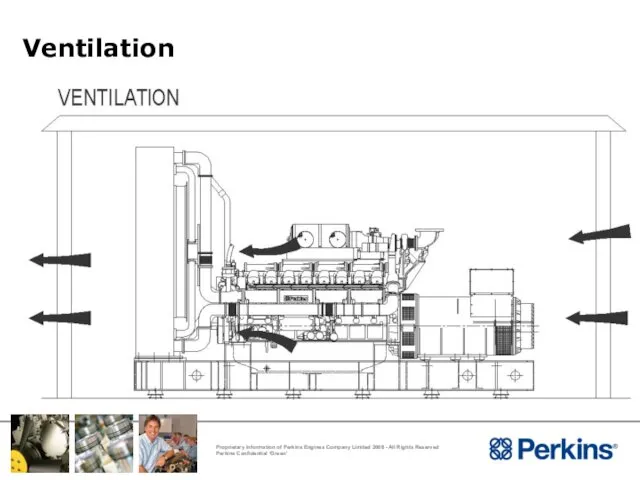

- 47. Ventilation Ventilation Basic principal is to extract hot air from the room and induce air at

- 48. Ventilation

- 49. Ventilation

- 50. Ventilation

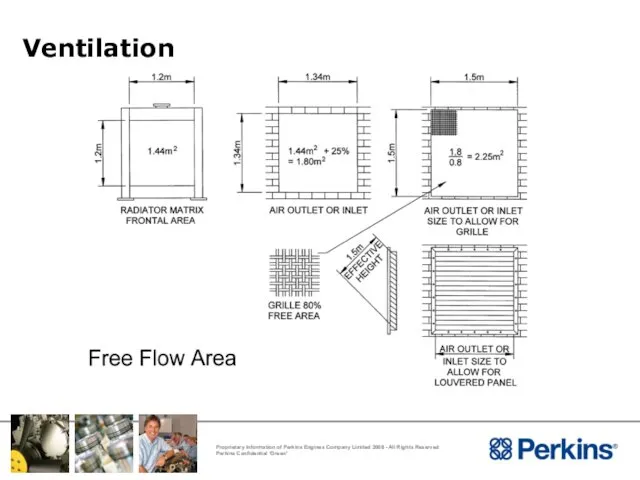

- 51. Ventilation Outlet/Inlet Sizes The outlet opening should have a free flow area approximately 25% larger than

- 52. Ventilation

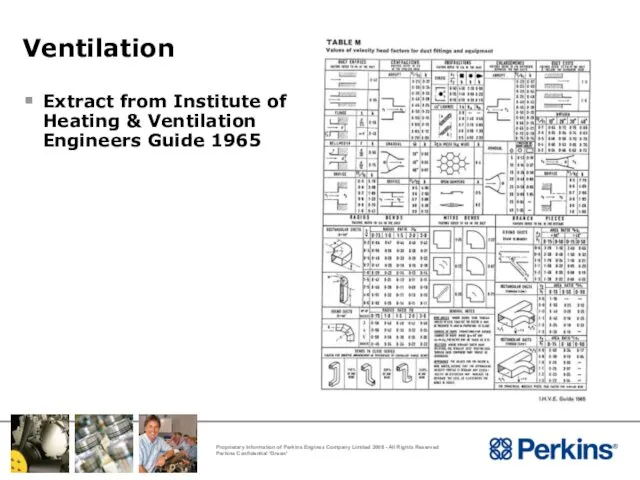

- 53. Ventilation Extract from Institute of Heating & Ventilation Engineers Guide & Wood Practical Guide to Fan

- 54. Ventilation Extract from Institute of Heating & Ventilation Engineers Guide 1965

- 55. Ventilation Duct Resistance Radiator duct allowance must not be exceeded. Exceeding the duct allowance can cause

- 56. PROCEDURE The anemometer measurement should be taken with the engine running at constant speed and no

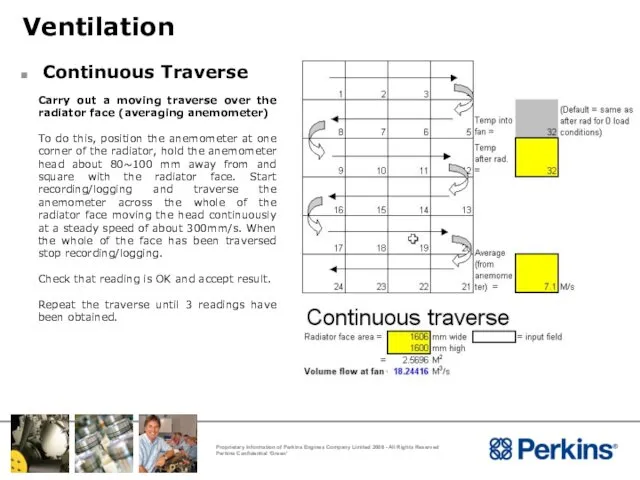

- 57. Ventilation Continuous Traverse Carry out a moving traverse over the radiator face (averaging anemometer) To do

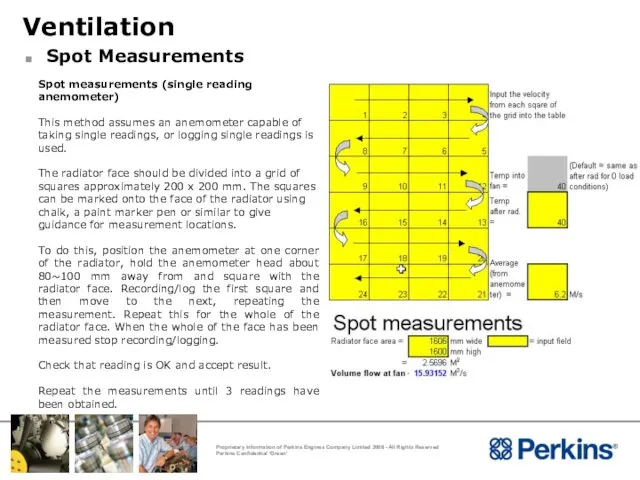

- 58. Ventilation Spot Measurements Spot measurements (single reading anemometer) This method assumes an anemometer capable of taking

- 59. Calculation of results The measured values from either method can then be input to a spreadsheet

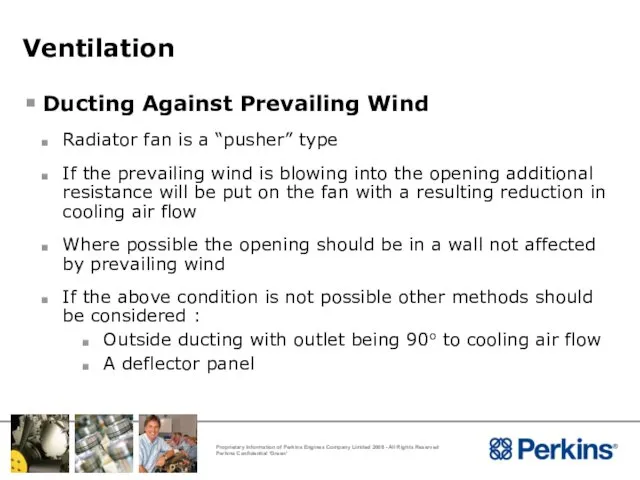

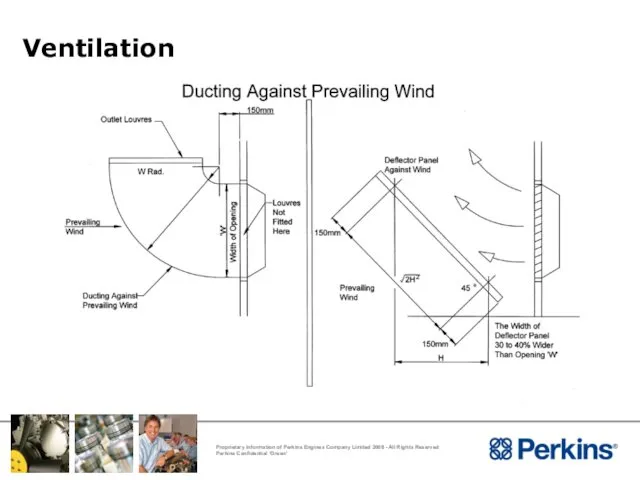

- 60. Ventilation Ducting Against Prevailing Wind Radiator fan is a “pusher” type If the prevailing wind is

- 61. Ventilation

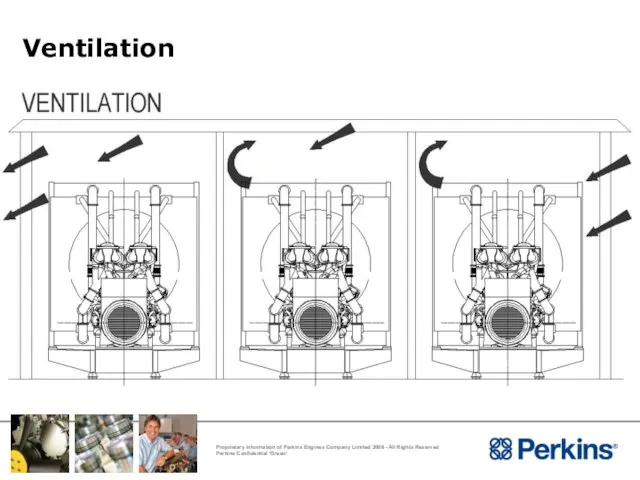

- 62. Ventilation Ventilation – Tropical Conditions To cater for tropical conditions common practice is for the engine

- 63. Ventilation

- 64. Ventilation Ventilation – Tropical Conditions Where multiple gensets are installed in an open sided building it

- 65. Ventilation

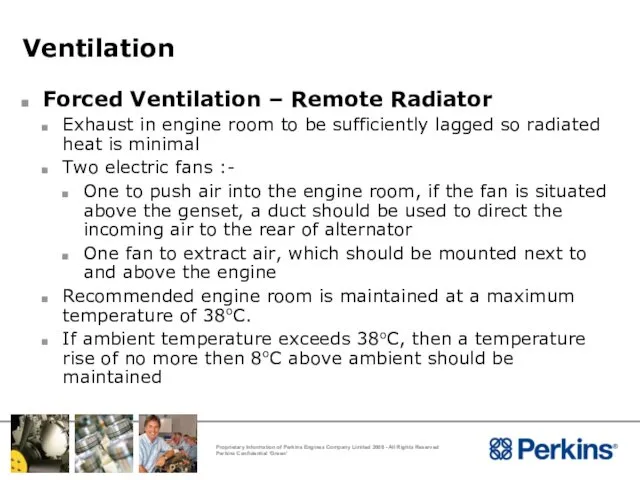

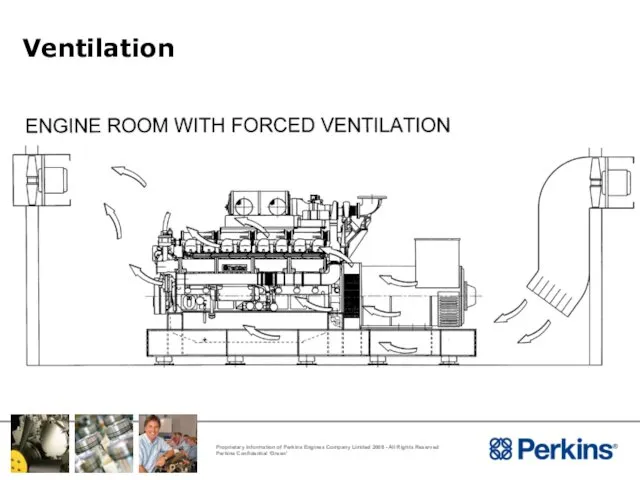

- 66. Ventilation Forced Ventilation – Remote Radiator Exhaust in engine room to be sufficiently lagged so radiated

- 67. Ventilation

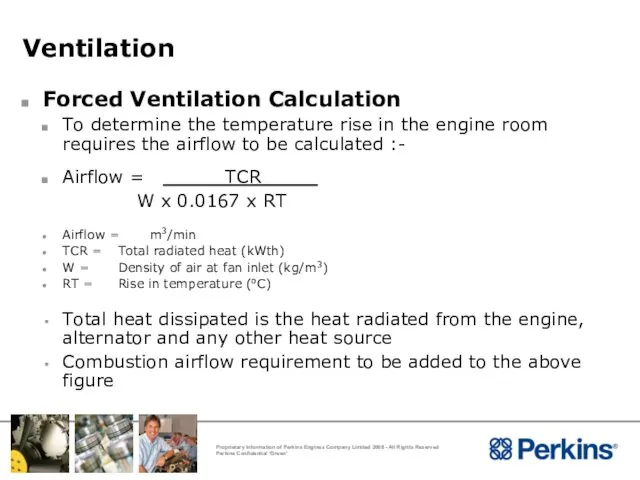

- 68. Ventilation Forced Ventilation Calculation To determine the temperature rise in the engine room requires the airflow

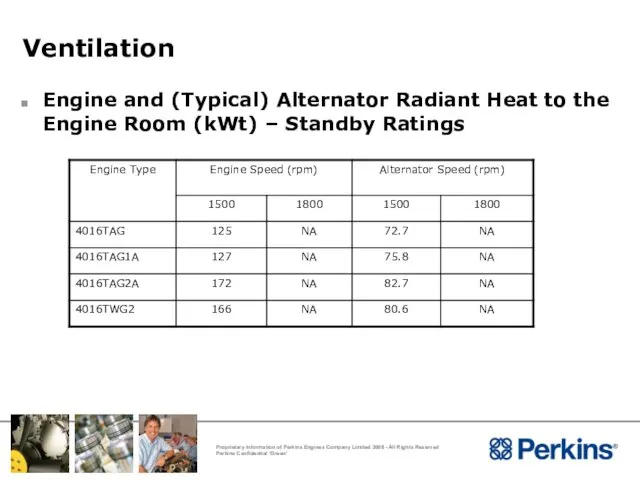

- 69. Ventilation Engine and (Typical) Alternator Radiant Heat to the Engine Room (kWt) – Standby Ratings

- 70. Installation Considerations Exhaust System

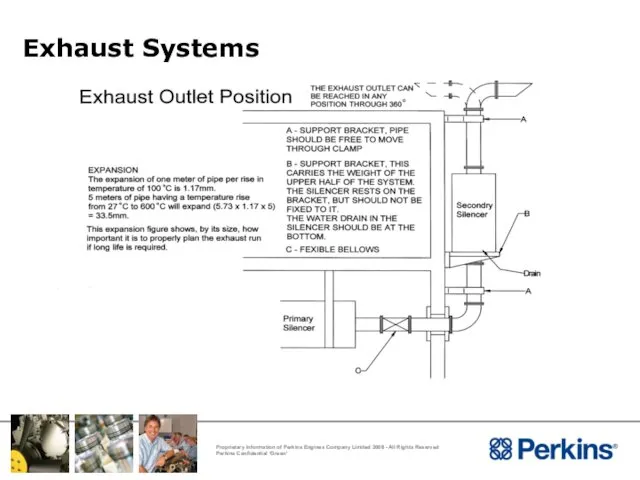

- 71. Exhaust Systems Exhaust System Installation Keep weight off the turbocharger and exhaust outlet elbow by supporting

- 72. Exhaust Systems Do Not :- Pipe multiple engine exhausts into a common system – Each engine

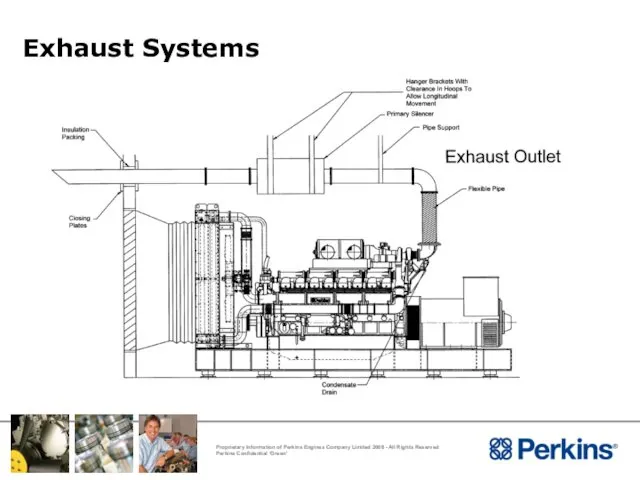

- 73. Exhaust Systems

- 74. Exhaust Systems

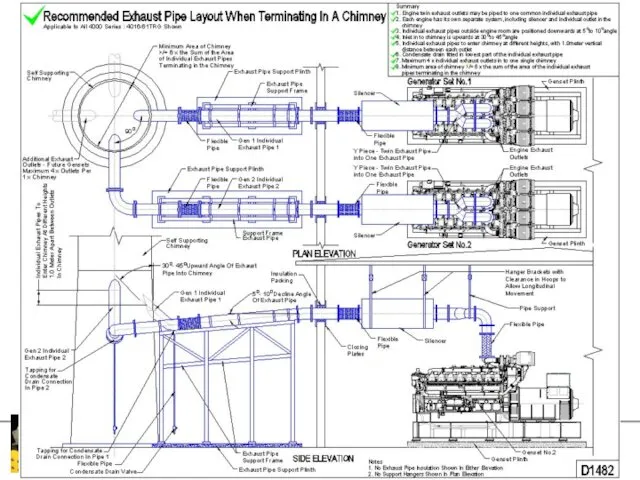

- 75. Exhaust Systems Exhaust System Terminating in Chimney Engine twin exhaust outlets may be piped in to

- 76. Exhaust Systems Exhaust Systems Terminating in Chimney - Multiple Individual exhaust pipes to enter chimney at

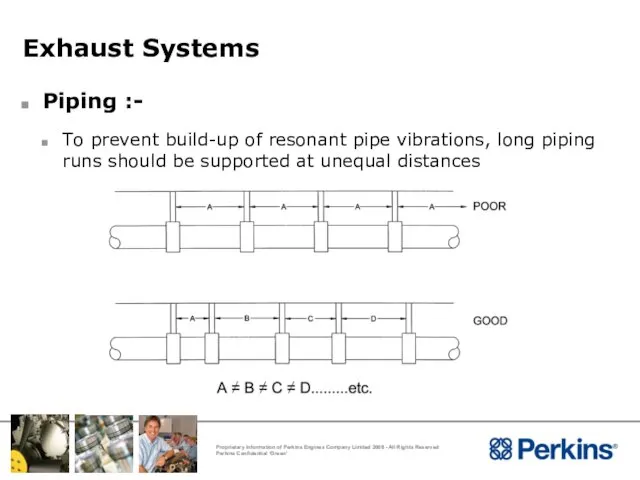

- 79. Exhaust Systems Piping :- To prevent build-up of resonant pipe vibrations, long piping runs should be

- 80. Exhaust Systems Exhaust System Installation The exhaust system should avoid touching or passing close to ;

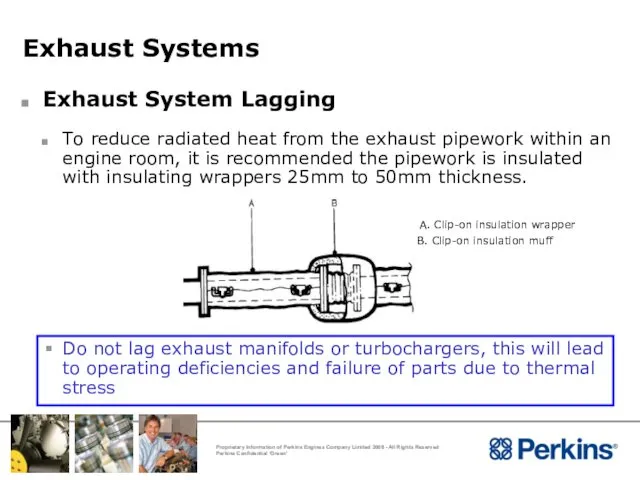

- 81. Exhaust Systems Exhaust System Lagging To reduce radiated heat from the exhaust pipework within an engine

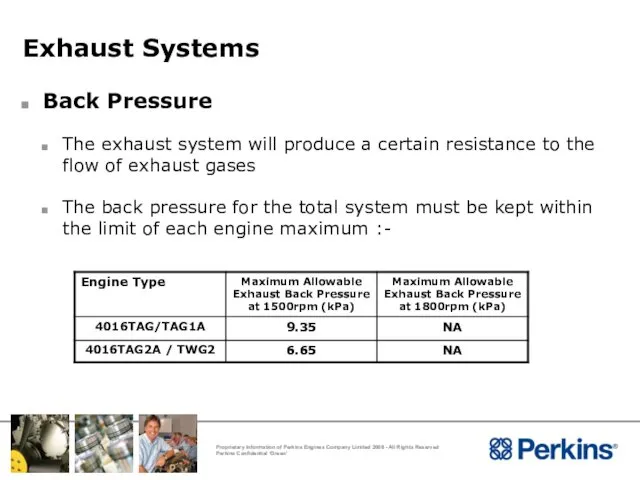

- 82. Exhaust Systems Back Pressure The exhaust system will produce a certain resistance to the flow of

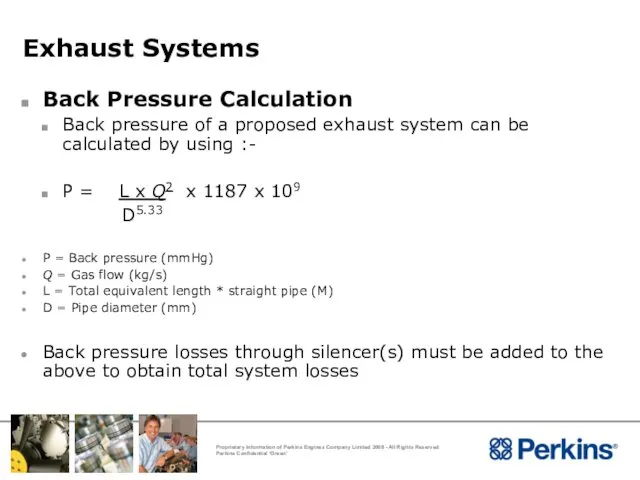

- 83. Exhaust Systems Back Pressure Calculation Back pressure of a proposed exhaust system can be calculated by

- 84. Exhaust Systems Effects of Excessive Exhaust Back Pressure Too high a back pressure leads to: Loss

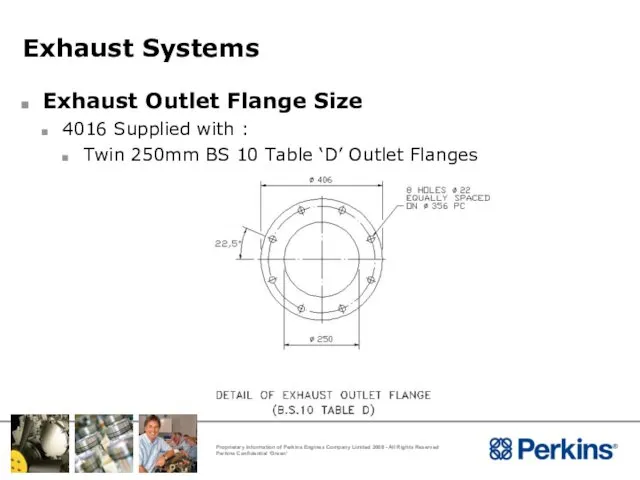

- 85. Exhaust Systems Exhaust Outlet Flange Size 4016 Supplied with : Twin 250mm BS 10 Table ‘D’

- 86. Installation Considerations The Cooling System

- 87. Cooling System Cooling System Requirements Pressure cap setting 70kPa is maintained in the system 98oC top

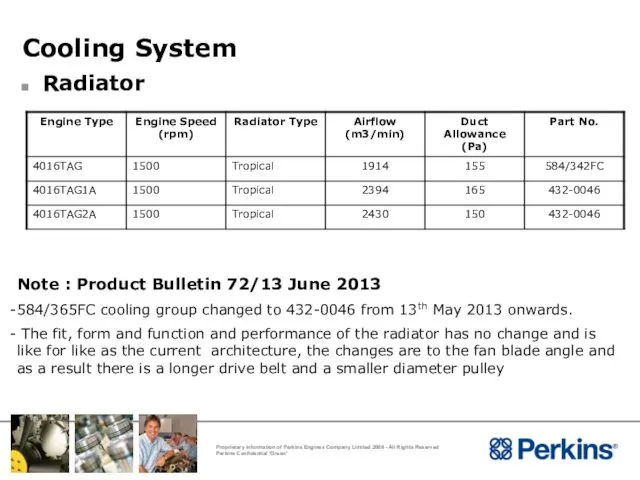

- 88. Cooling System Radiator Note : Product Bulletin 72/13 June 2013 584/365FC cooling group changed to 432-0046

- 89. Cooling System Radiator Construction Fin and tube Pusher fan Mounting Solid direct to baseframe

- 90. Cooling System Air To Air Charge Cooler Reduces induction air temperature Air to air radiator in

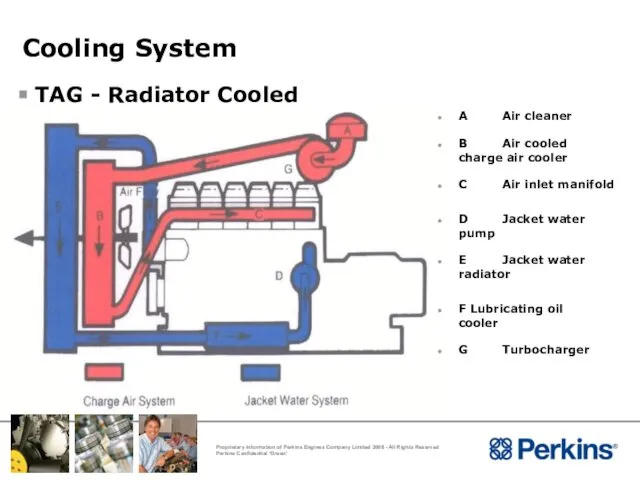

- 91. Cooling System TAG - Radiator Cooled A Air cleaner B Air cooled charge air cooler C

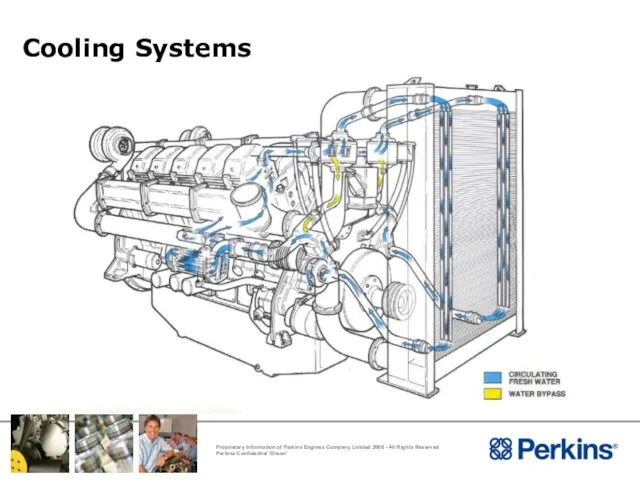

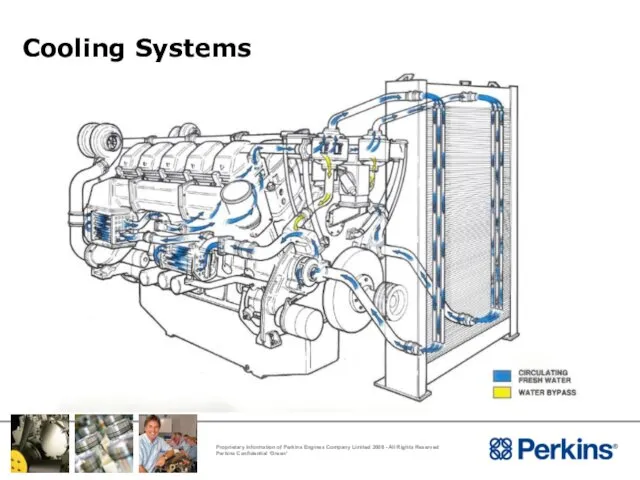

- 92. Cooling Systems

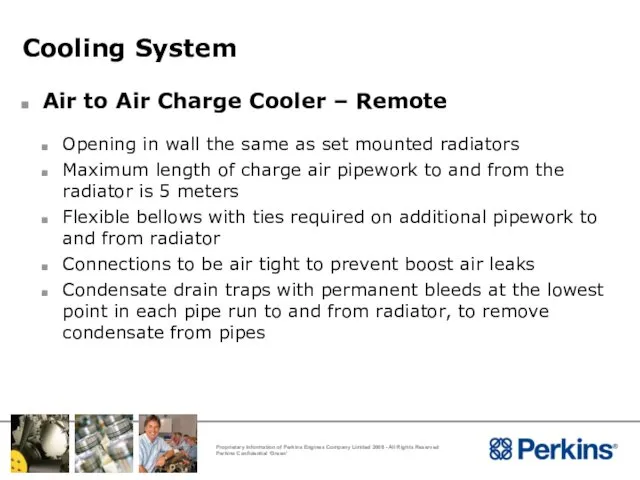

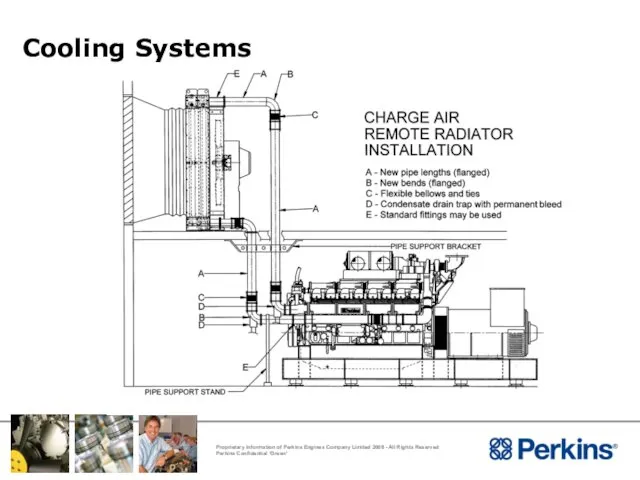

- 93. Cooling System Air to Air Charge Cooler – Remote Opening in wall the same as set

- 94. Cooling Systems

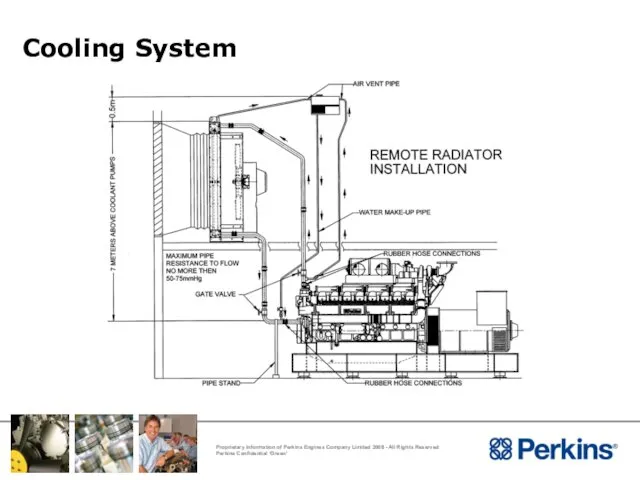

- 95. Cooling System Water Pipe and Pressurized Make-up/Vent System – Remote Coolant pipes to and from radiator

- 96. Cooling System

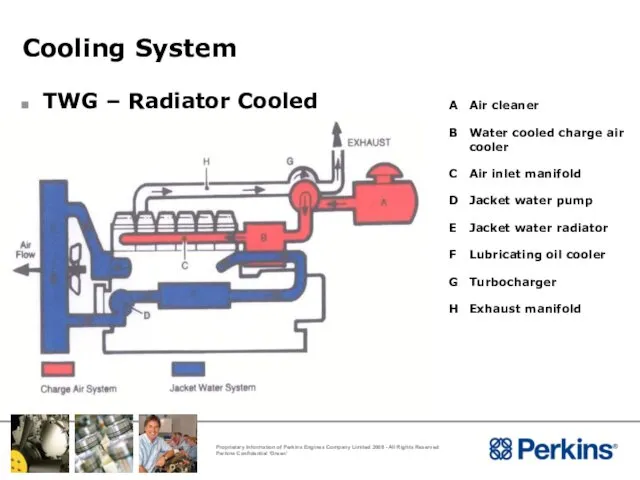

- 97. Cooling System TWG – Radiator Cooled A Air cleaner B Water cooled charge air cooler C

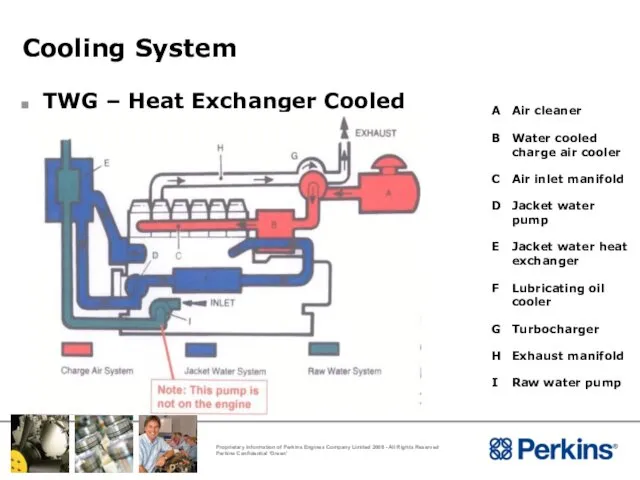

- 98. Cooling System TWG – Heat Exchanger Cooled A Air cleaner B Water cooled charge air cooler

- 99. Cooling Systems

- 100. Cooling System Protection Antifreeze 50% mixture Inhibited ethylene glycol or inhibited propylene glycol Corrosion Inhibitor –

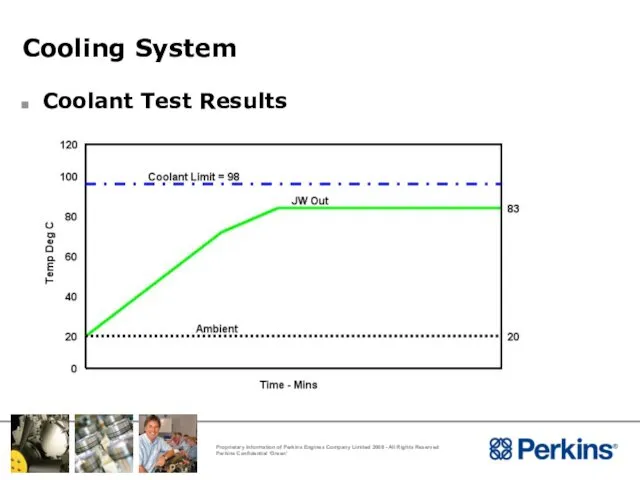

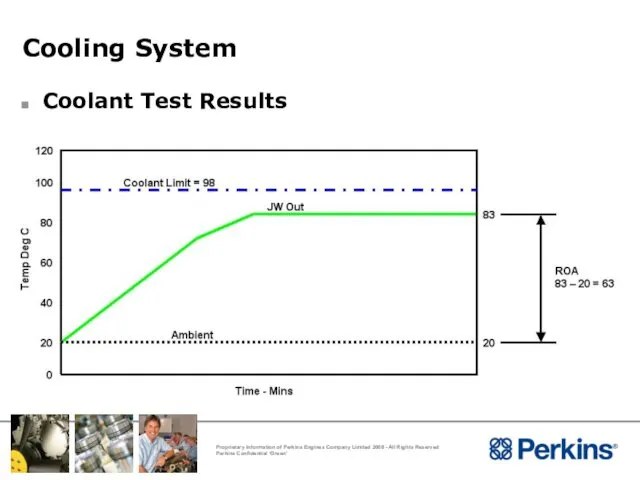

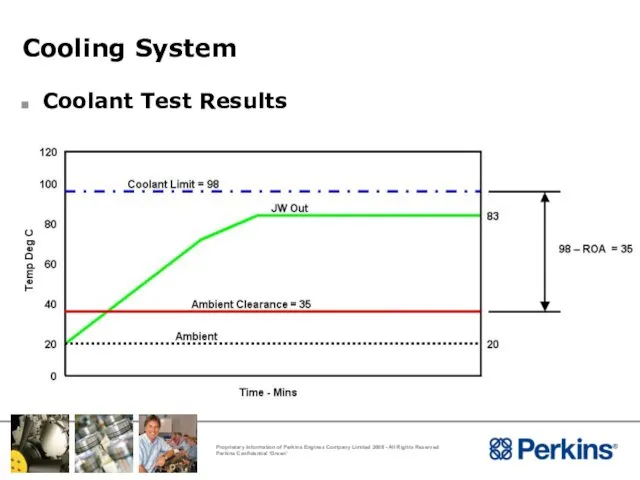

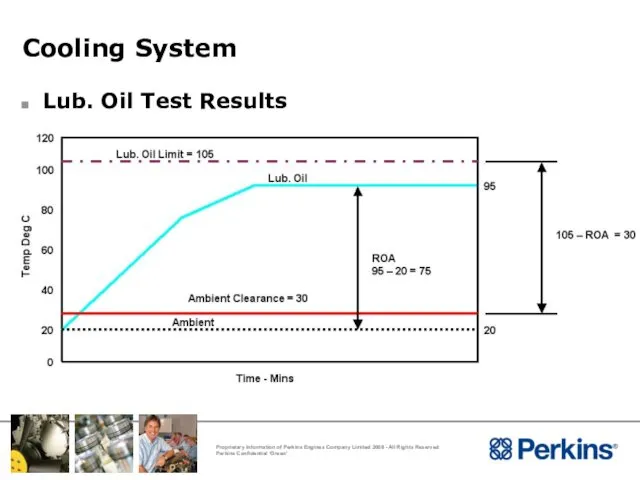

- 101. Cooling System Ambient Clearance Stable Top Tank Temperature - Ambient = Rise Over Ambient (ROA) Limiting

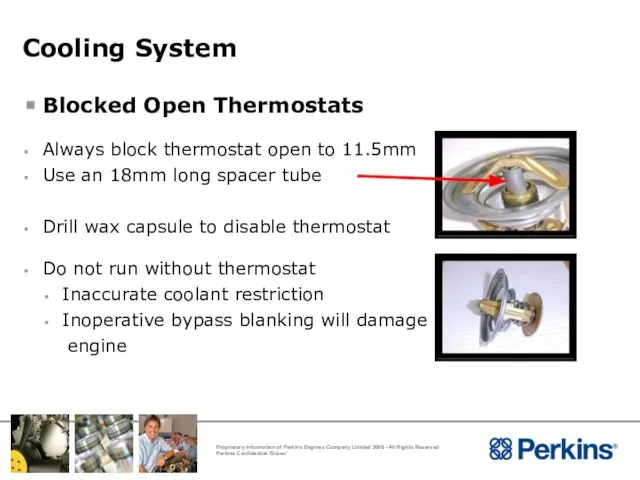

- 102. Cooling System Blocked Open Thermostats Always block thermostat open to 11.5mm Use an 18mm long spacer

- 103. Cooling System Coolant Test Results

- 104. Cooling System Coolant Test Results

- 105. Cooling System Coolant Test Results

- 106. Cooling System Lub. Oil Test Results

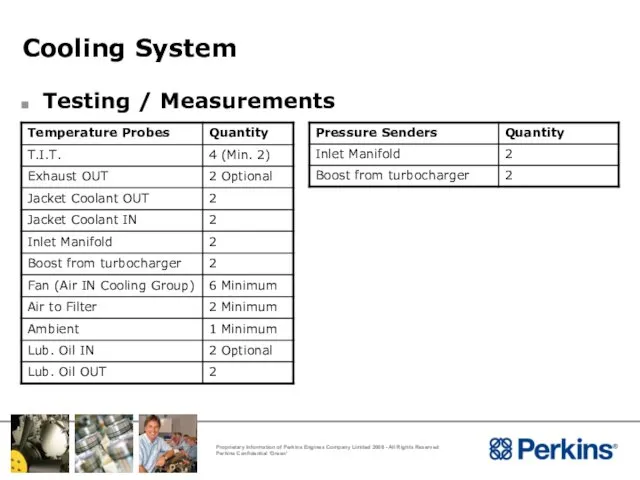

- 107. Cooling System Testing / Measurements

- 108. Cooling System Analysis Of Results Low coolant clearance Excessive duct restriction Re-circulation

- 109. Cooling System De-Aeration Possible Causes Poor filling Poor venting Blockages

- 110. Cooling System De-Aeration Effects of air in water Local boiling Excessive coolant loss Deterioration of water

- 111. Applications Considerations Cold Start

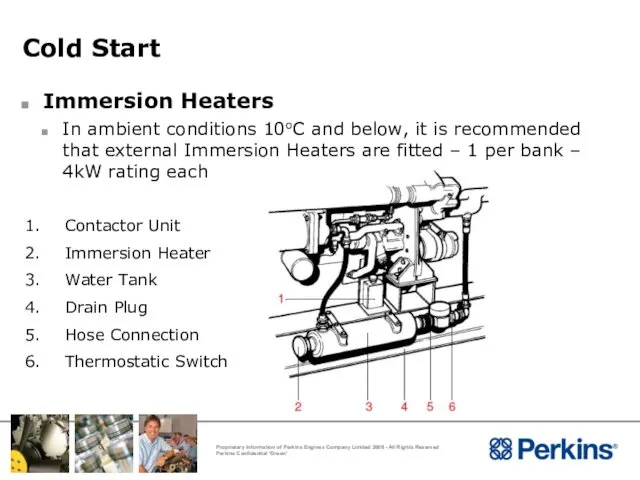

- 112. Cold Start Immersion Heaters In ambient conditions 10oC and below, it is recommended that external Immersion

- 113. Installation Considerations Fuel System

- 114. Fuel System The purpose of the fuel system is to ensure: An ample supply of clean

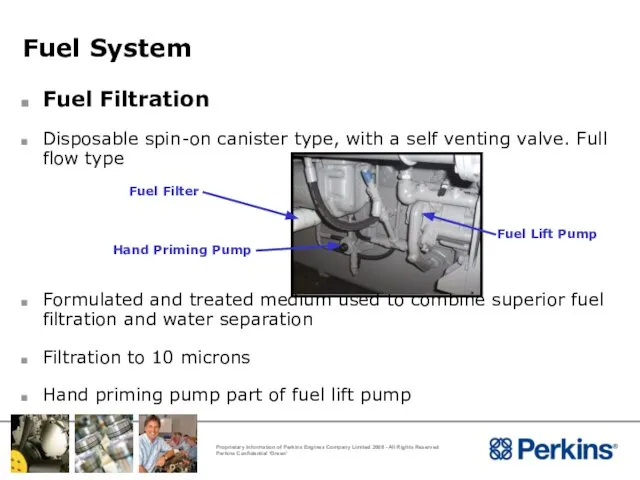

- 115. Fuel System Fuel Filtration Disposable spin-on canister type, with a self venting valve. Full flow type

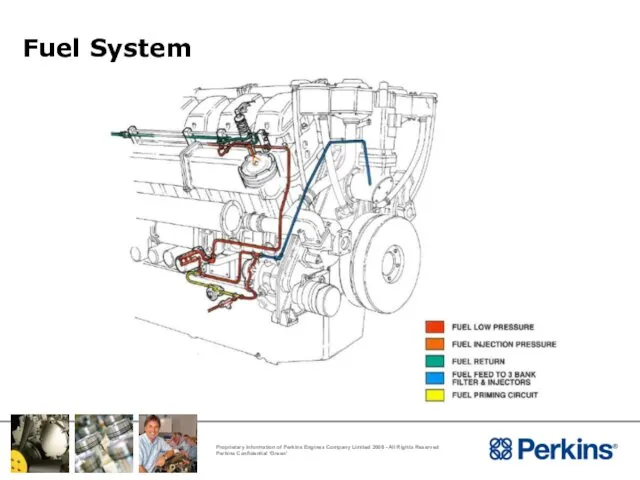

- 116. Fuel System

- 117. Fuel System Fuel Temperature Effect engine performance and emissions if fuel inlet temperature is too high

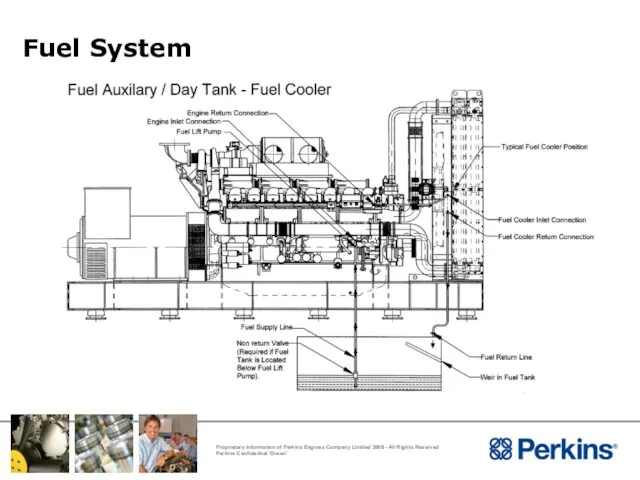

- 118. Fuel System Fuel Cooler If a fuel cooler is required it should be sized to dissipate

- 119. Fuel System

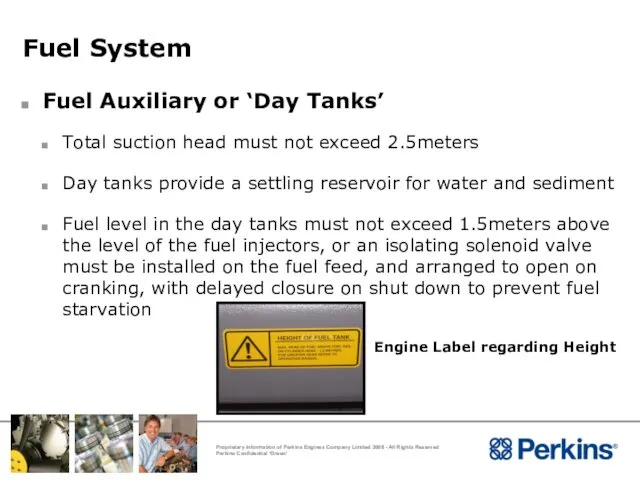

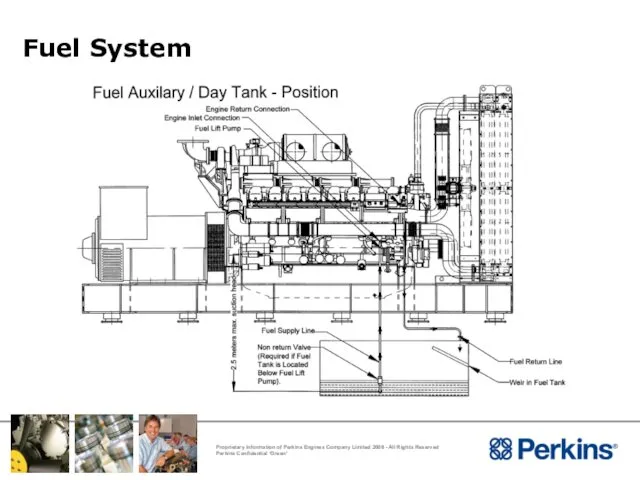

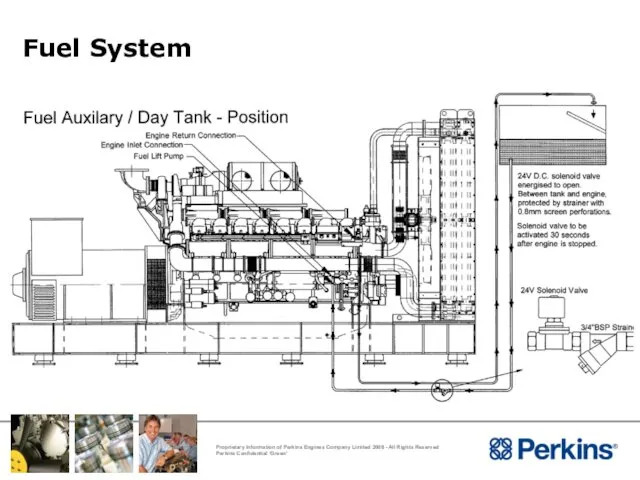

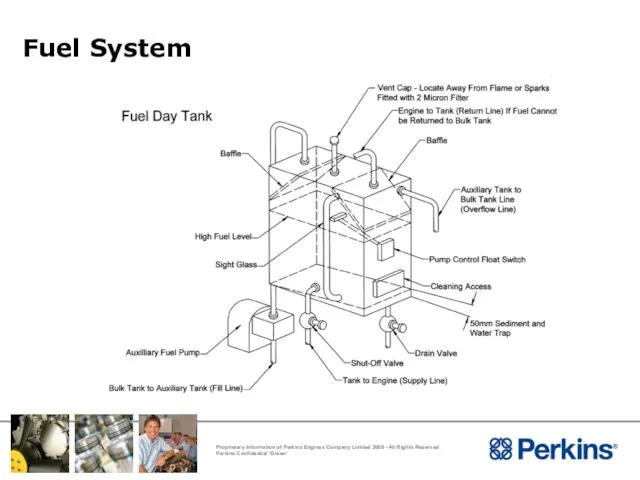

- 120. Fuel System Fuel Auxiliary or ‘Day Tanks’ Total suction head must not exceed 2.5meters Day tanks

- 121. Fuel System

- 122. Fuel System

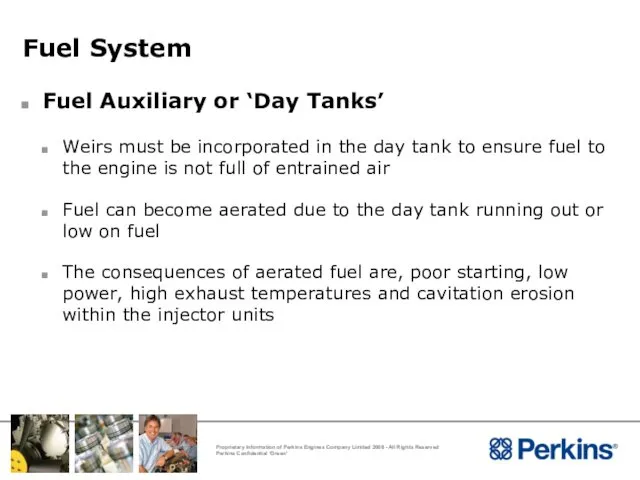

- 123. Fuel System Fuel Auxiliary or ‘Day Tanks’ Weirs must be incorporated in the day tank to

- 124. Fuel System

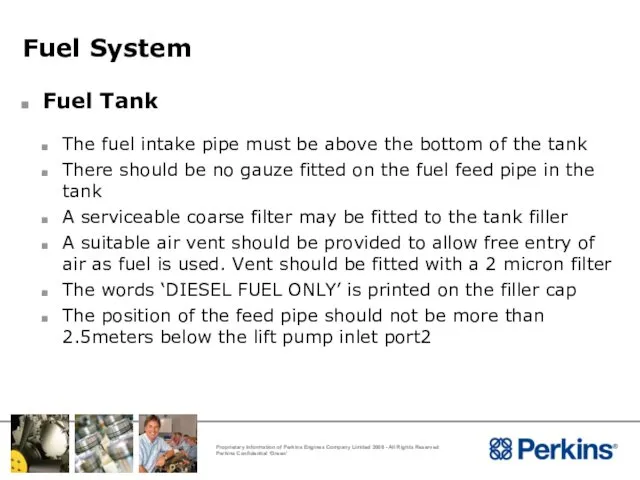

- 125. Fuel System Fuel Tank The fuel intake pipe must be above the bottom of the tank

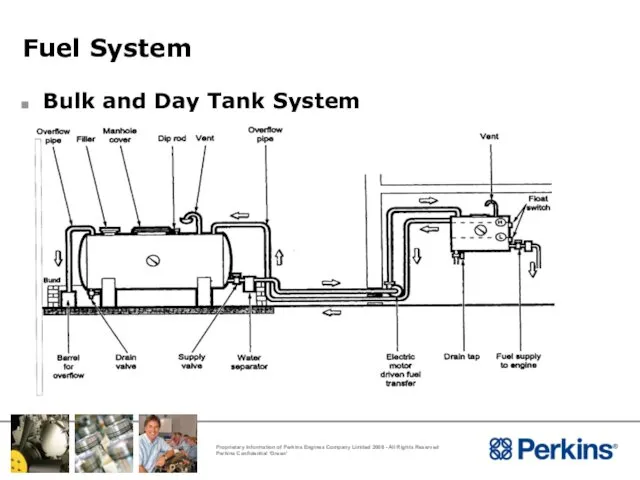

- 126. Fuel System Bulk and Day Tank System

- 127. Fuel System Low Pressure Fuel Pipes Material - Good quality seamless copper pipe, steel or black

- 128. Fuel System Water Trap and Sedimenter A water trap and sedimenter should be installed into all

- 129. Fuel System Engine Piping The low pressure fuel system between fuel filter and fuel return should

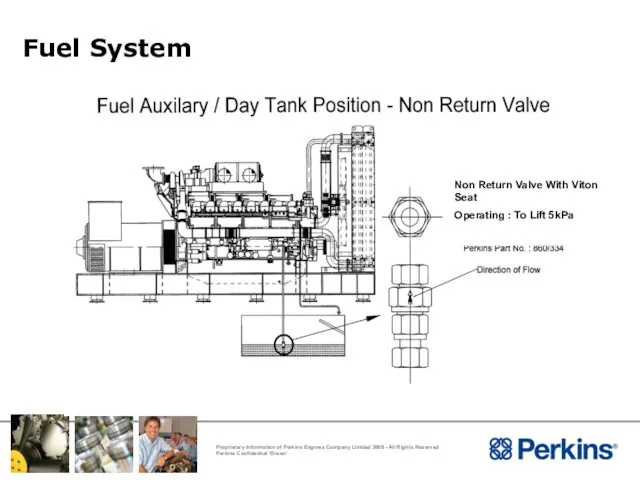

- 130. Fuel System Fuel Auxiliary or ‘Day Tanks’ For day tanks installed below the engine fuel lift

- 131. Fuel System

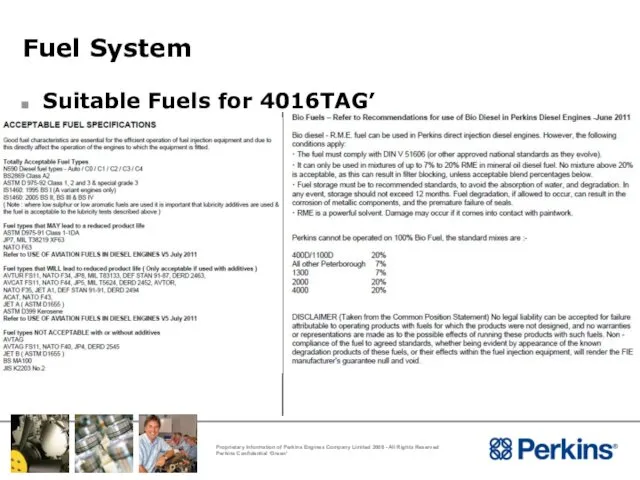

- 132. Fuel System Suitable Fuels for 4016TAG’

- 133. Installation Considerations Lubricating Oil System

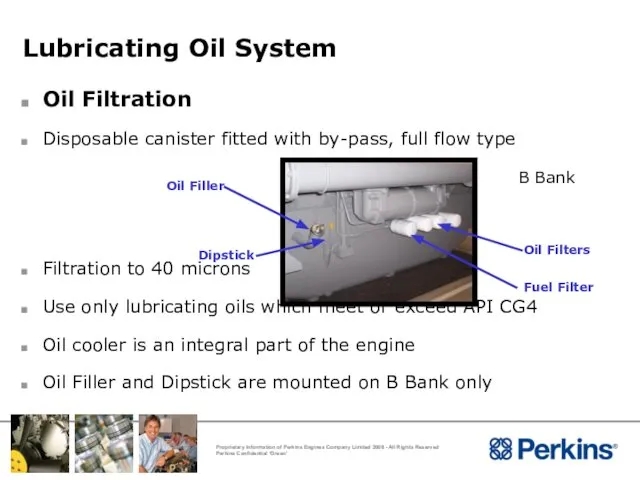

- 134. Lubricating Oil System Oil Filtration Disposable canister fitted with by-pass, full flow type Filtration to 40

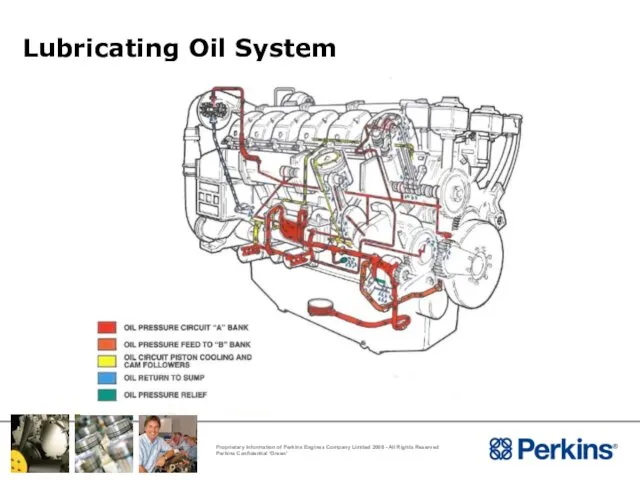

- 135. Lubricating Oil System

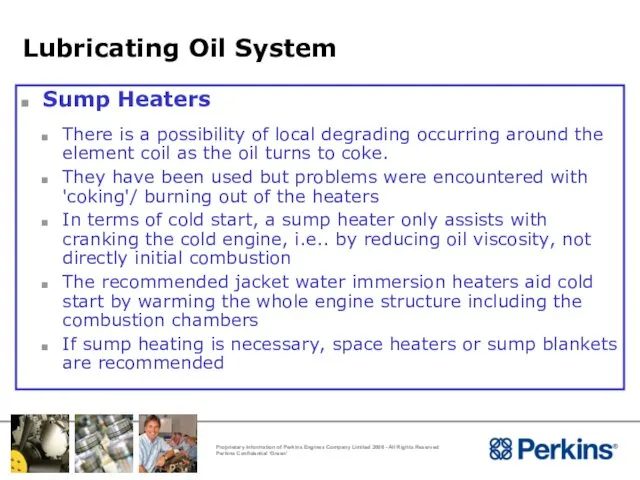

- 136. Lubricating Oil System Sump Heaters There is a possibility of local degrading occurring around the element

- 137. Installation Considerations Crankcase Ventilation

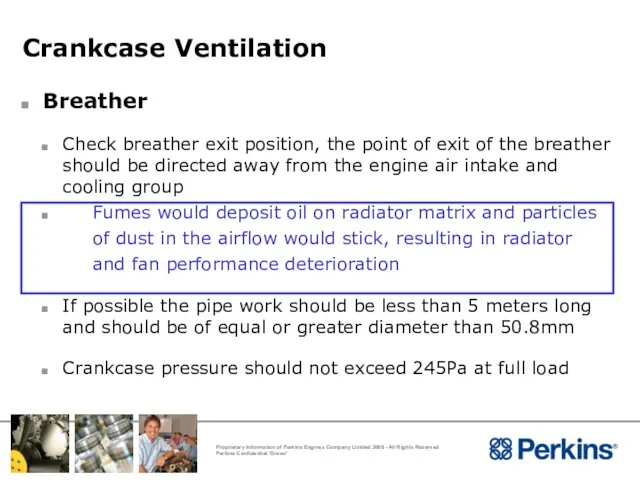

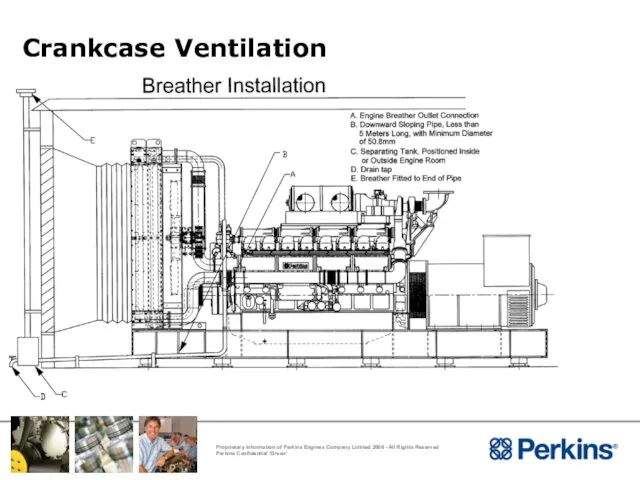

- 138. Crankcase Ventilation Breather Check breather exit position, the point of exit of the breather should be

- 139. Crankcase Ventilation Breather On Vee Form engines with two breathers these can be piped together in

- 140. Crankcase Ventilation

- 141. Installation Considerations Electrical Systems

- 142. Electrical Systems Starter Motors Engines can be supplied with a suitable 24 Volt starter motors Flywheel

- 143. Electrical System Alternator All engines are supplied with a battery charging alternator Alternator output 24 Volt

- 144. Electrical System Batteries There are three main types of battery in circulation these are : Ni-Cad

- 145. Electrical System Good Wiring Practice Ensure suitable cables have been used Where possible cables should be

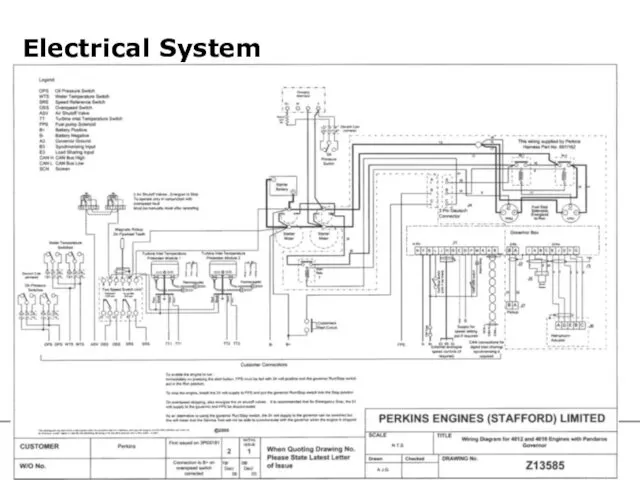

- 146. Electrical System

- 147. Electrical Systems Protection Devices 4016 are fitted with the following shut-down protection as standard : High

- 148. Electrical Systems High Jacket Water Switch (HJW) Set to 101 o C (Rising) A + B

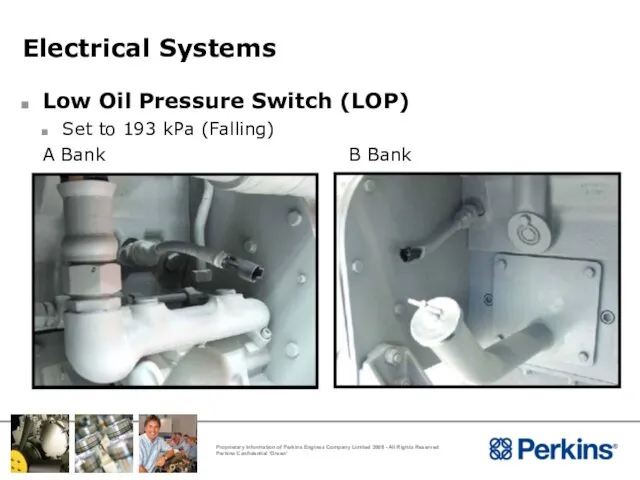

- 149. Electrical Systems Low Oil Pressure Switch (LOP) Set to 193 kPa (Falling) A Bank B Bank

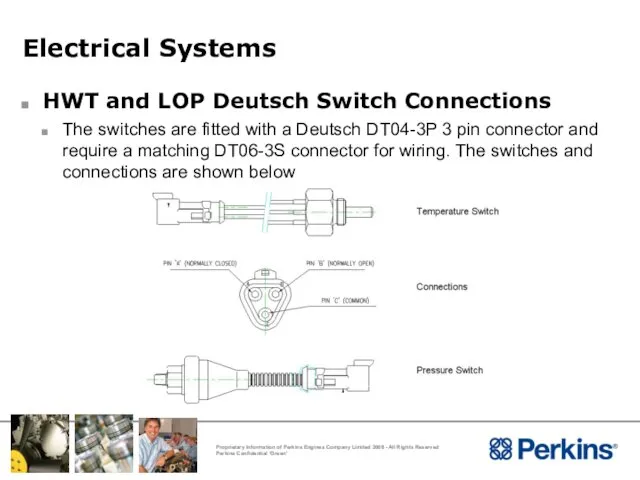

- 150. Electrical Systems HWT and LOP Deutsch Switch Connections The switches are fitted with a Deutsch DT04-3P

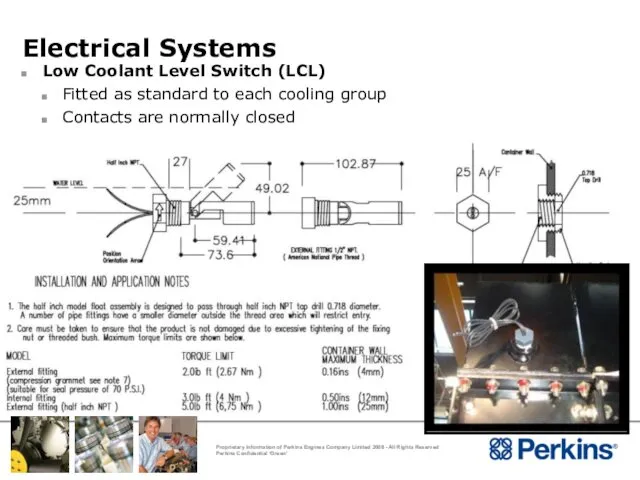

- 151. Electrical Systems Low Coolant Level Switch (LCL) Fitted as standard to each cooling group Contacts are

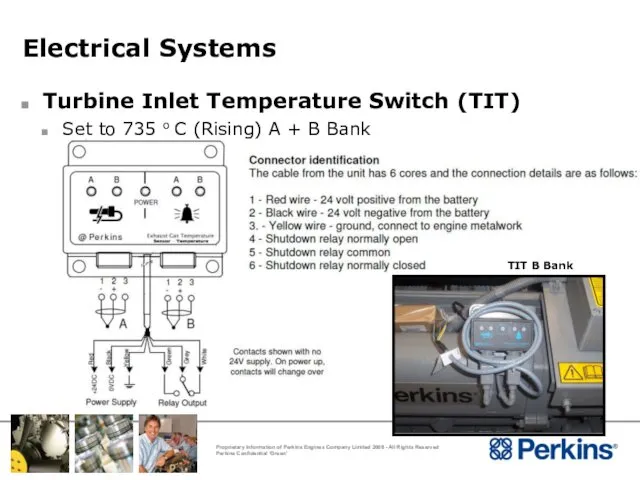

- 152. Electrical Systems Turbine Inlet Temperature Switch (TIT) Set to 735 o C (Rising) A + B

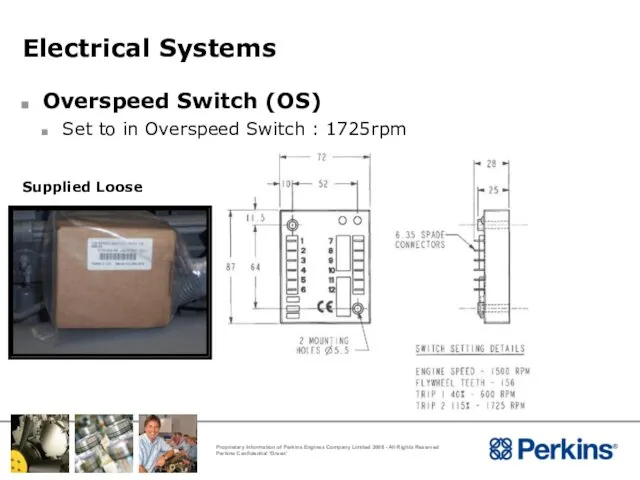

- 153. Electrical Systems Overspeed Switch (OS) Set to in Overspeed Switch : 1725rpm Supplied Loose

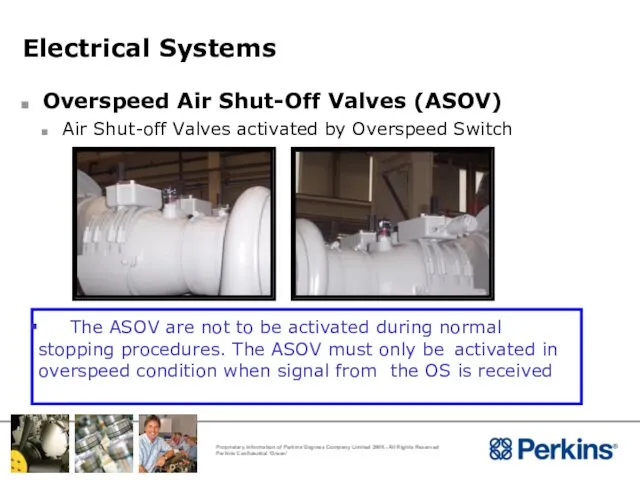

- 154. Electrical Systems Overspeed Air Shut-Off Valves (ASOV) Air Shut-off Valves activated by Overspeed Switch The ASOV

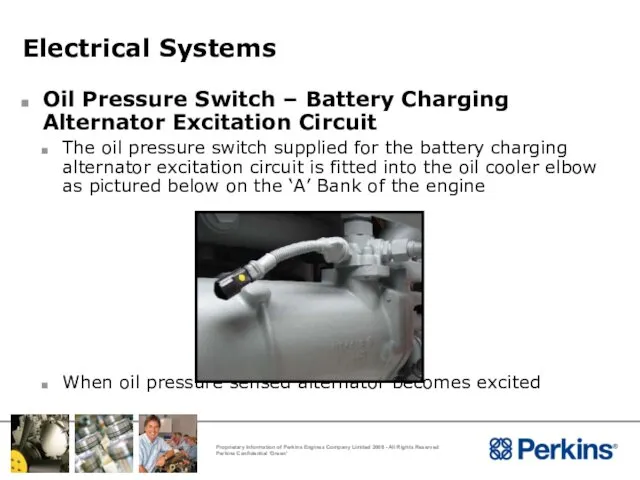

- 155. Electrical Systems Oil Pressure Switch – Battery Charging Alternator Excitation Circuit The oil pressure switch supplied

- 156. Applications Considerations Air Induction System

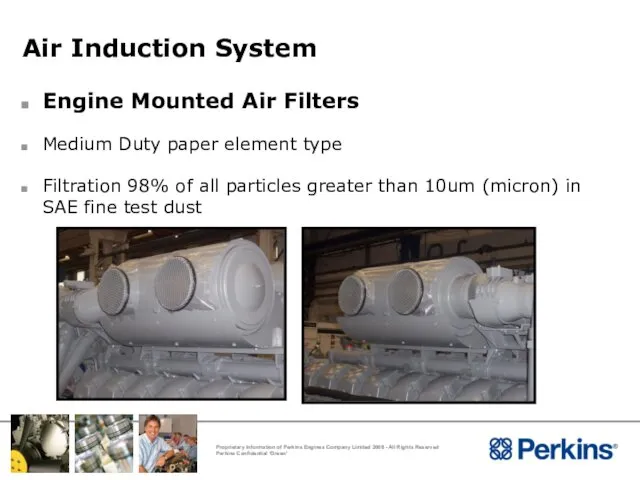

- 157. Air Induction System Engine Mounted Air Filters Medium Duty paper element type Filtration 98% of all

- 158. Air Induction System Air Restriction Indicator Fitted as standard to each air filter element The indicators

- 159. Air Induction System Oil Bath Air Filters Perkins do not recommend the use of oil bath

- 160. Air Induction System Oil Bath Air Filters Another potentially disastrous problem is that the oil bath

- 161. Installation Considerations Noise Control

- 162. Noise Control Factors Influencing Noise Radiator fan Induction system Exhaust system Vibration

- 163. Noise Control Insulation and Absorption There are many different ways of reducing noise which are individual

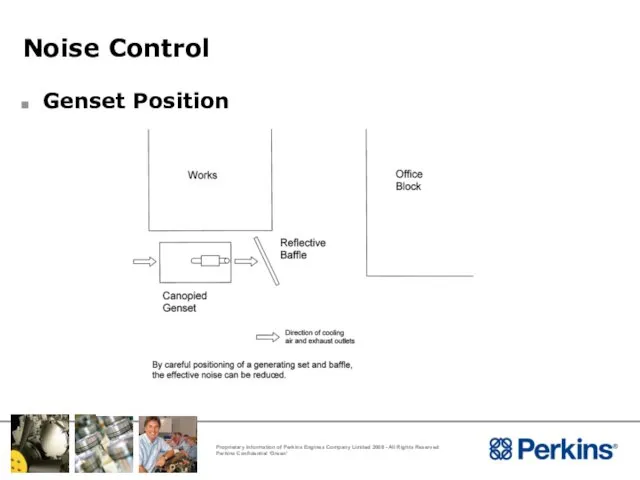

- 164. Noise Control Genset Position

- 165. Noise Control ‘Free Field’ Noise escaping from the engine room into a ‘Free Field’ area will

- 166. Noise Control ‘Semi-Reverberant Field’ If the area around the engine room include other building or reflective

- 167. Installation Considerations Governing

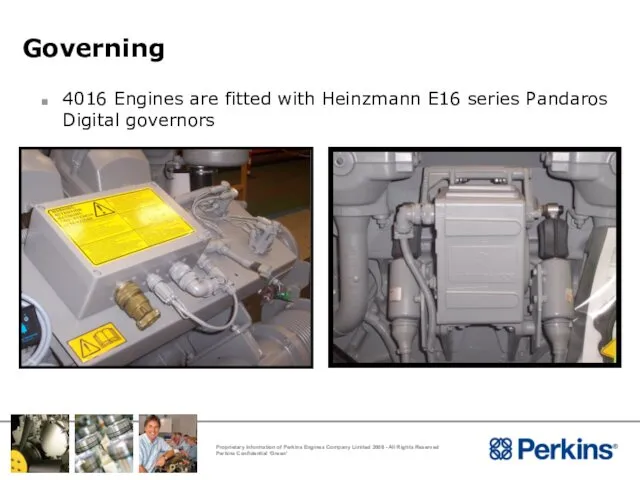

- 168. Governing 4016 Engines are fitted with Heinzmann E16 series Pandaros Digital governors

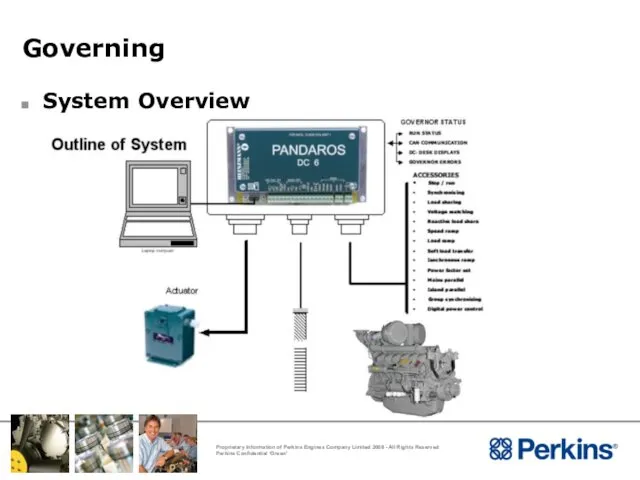

- 169. Governing System Overview

- 170. Governing Configuration The engine will be configured are shown below: Speed 1500rpm or 1800rpm Droop /

- 171. Governing Changing the configuration of the governor In order to change the configuration of the engine

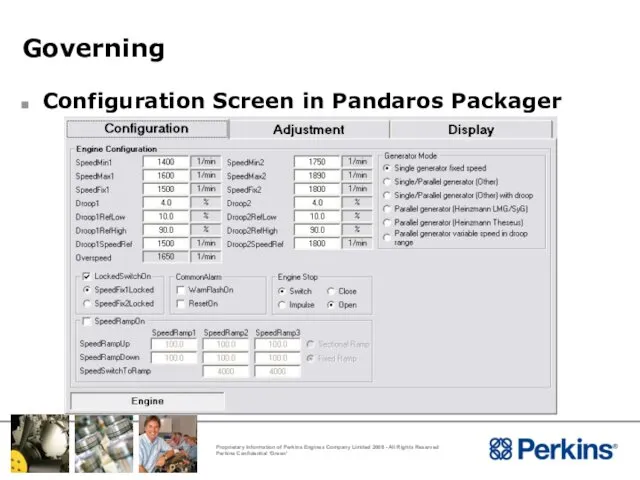

- 172. Governing Configuration Screen in Pandaros Packager

- 173. Governing Single generator fixed speed Select the button for Single generator fixed speed on the Generator

- 174. Governing Parallel Generator to Heinzmann LSU/Sync When the Generator Mode - Parallel generator option is selected,

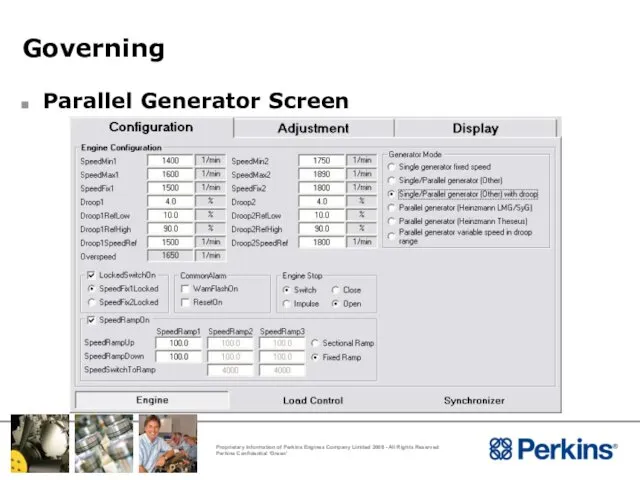

- 175. Governing Parallel Generator Screen

- 176. Governing Parallel generator other LSU/Sync There are many possible variations of load sharing and requirements for

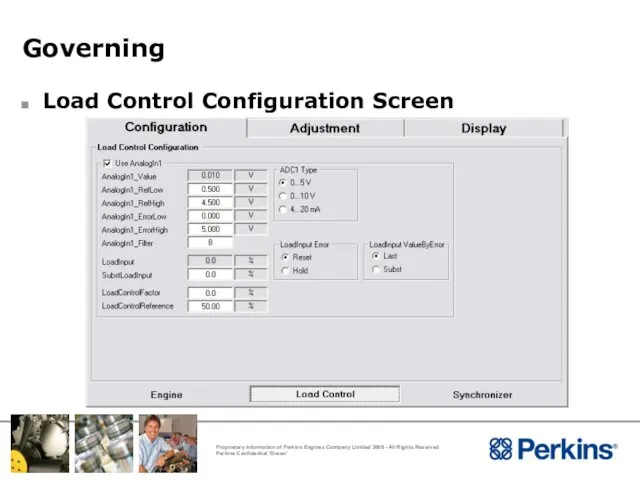

- 177. Governing Load Control Configuration Screen

- 178. Governing Parallel generator other LSU/Sync ADC 1_Type - The parameter enables the selection of the type

- 179. Governing Parallel generator other LSU/Sync AnalogIn1_ErrorLow - AnalogIn1_ErrorLow sets the lowest value at which analogue 1

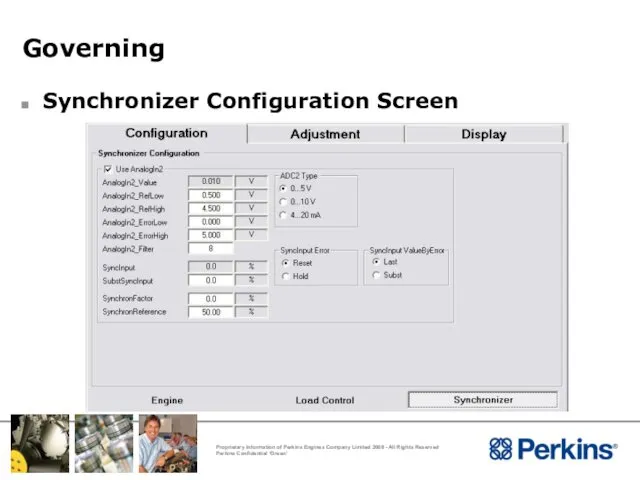

- 180. Governing Synchronizer Configuration Screen

- 181. Governing Parallel generator other LSU/Sync ADC 2_Type - The parameter enables the correct selection of input

- 182. Governing Parallel generator other LSU/Sync AnalogIn2_ErrorLow - sets the lowest value at which the analogue 2

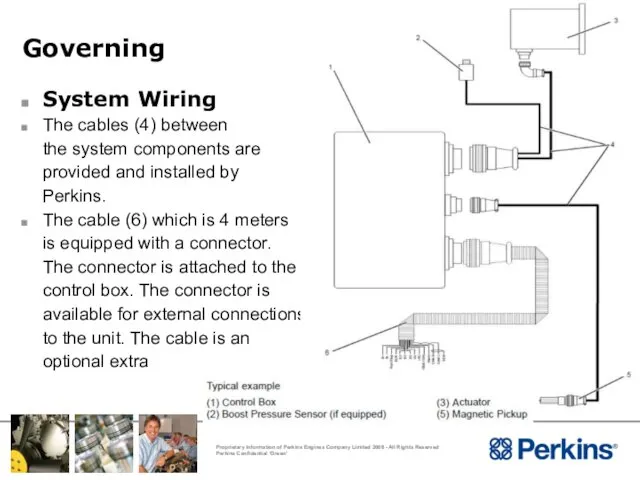

- 183. Governing System Wiring The cables (4) between the system components are provided and installed by Perkins.

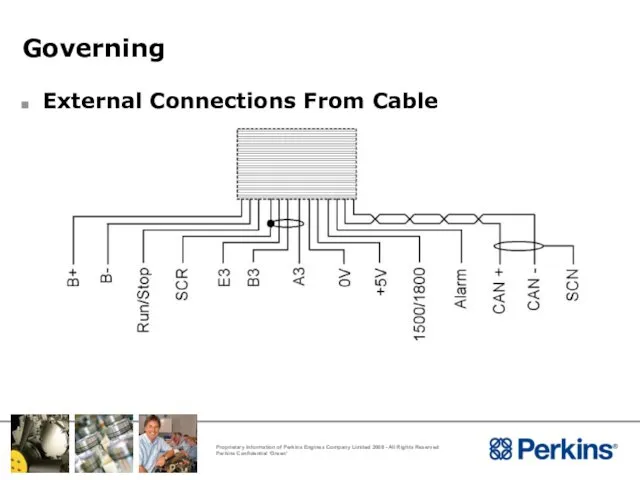

- 184. Governing External Connections From Cable

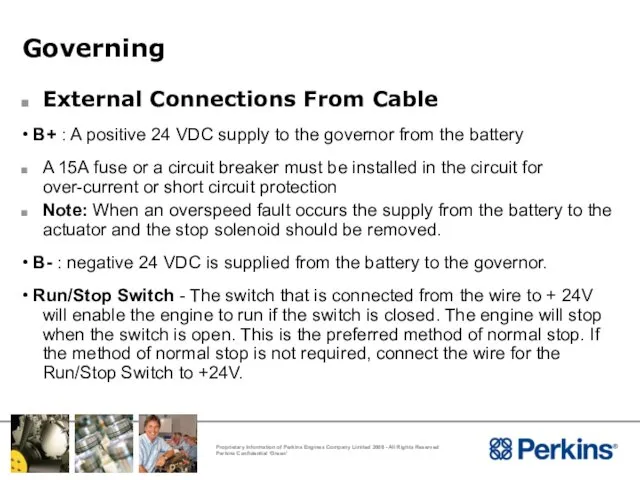

- 185. Governing External Connections From Cable • B+ : A positive 24 VDC supply to the governor

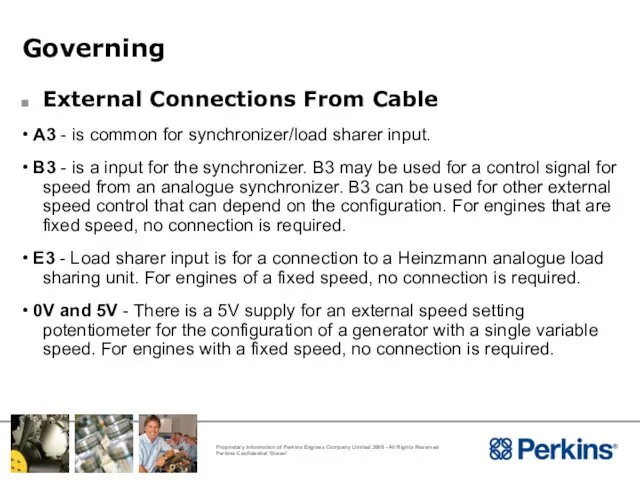

- 186. Governing External Connections From Cable • A3 - is common for synchronizer/load sharer input. • B3

- 187. Governing External Connections From Cable • Alarm - This is a digital output in order to

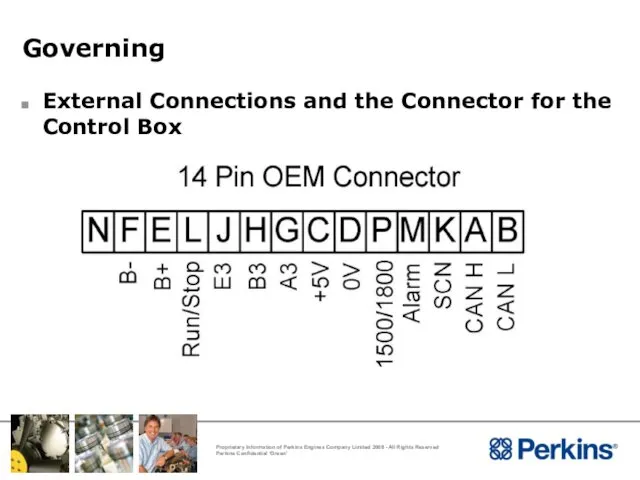

- 188. Governing External Connections and the Connector for the Control Box

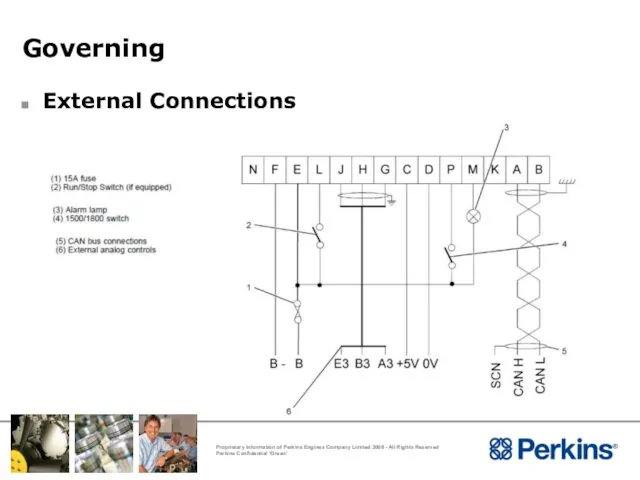

- 189. Governing External Connections

- 190. Governing Cable Sizes The cables for the supply for the battery must be 1.5 square mm

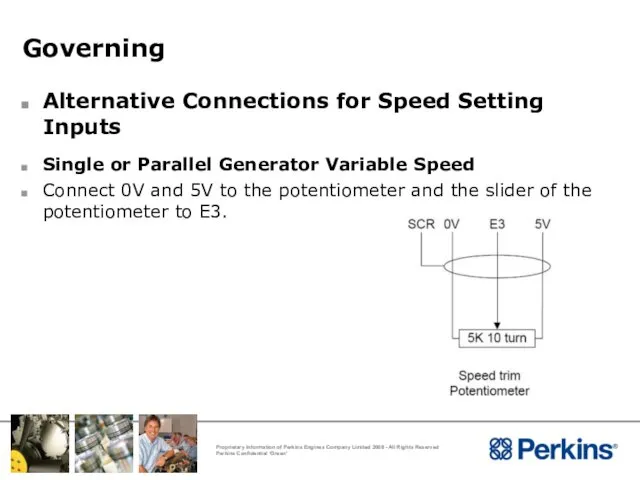

- 191. Governing Alternative Connections for Speed Setting Inputs Single or Parallel Generator Variable Speed Connect 0V and

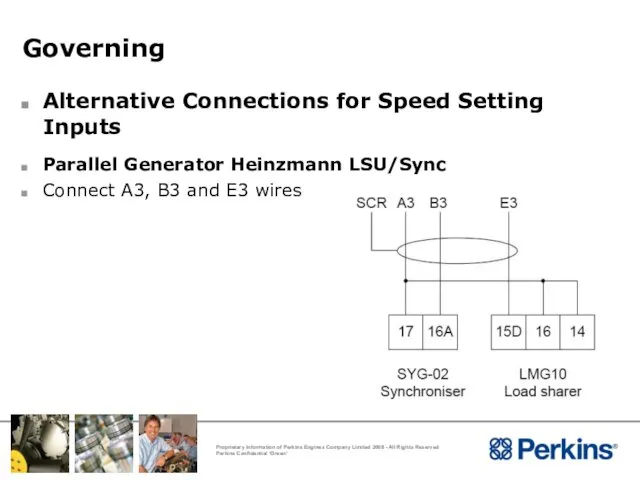

- 192. Governing Alternative Connections for Speed Setting Inputs Parallel Generator Heinzmann LSU/Sync Connect A3, B3 and E3

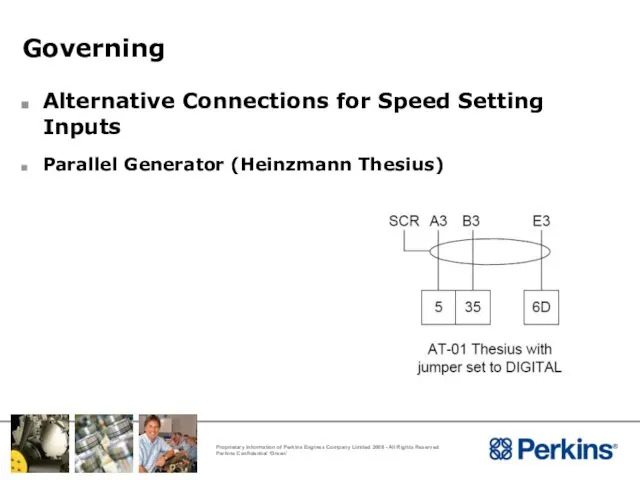

- 193. Governing Alternative Connections for Speed Setting Inputs Parallel Generator (Heinzmann Thesius)

- 194. Governing Governor Performance to ISO 3046 Part 4 4016 to ISO 8528-12 and G2 limits stated

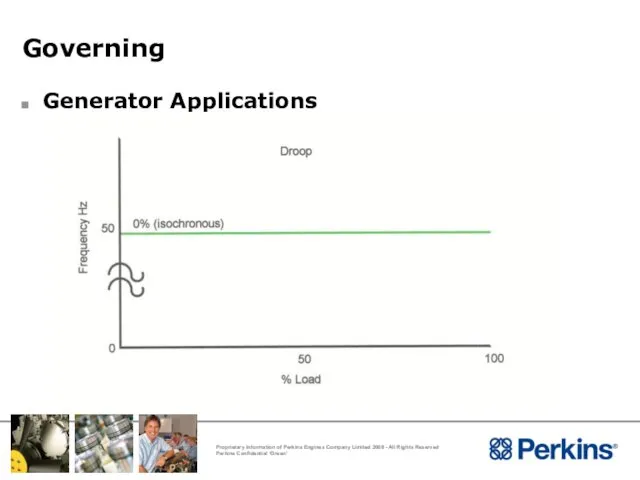

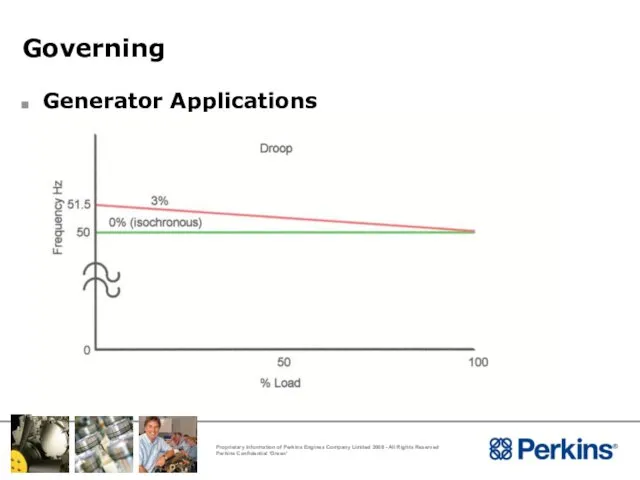

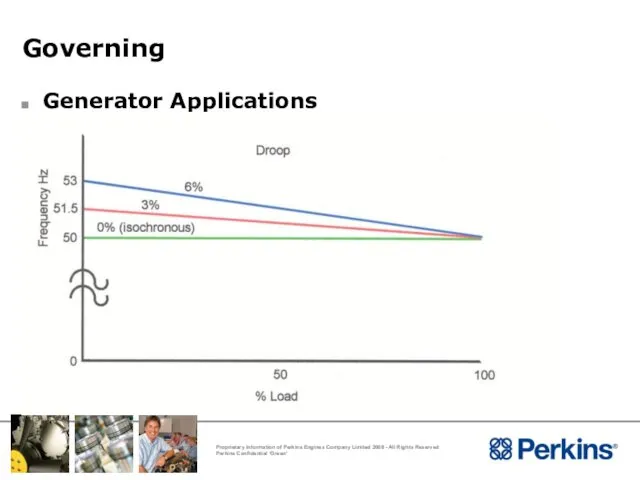

- 195. Governing Generator Applications

- 196. Governing Generator Applications

- 197. Governing Generator Applications

- 198. Installation Considerations Multiple Gensets Installation

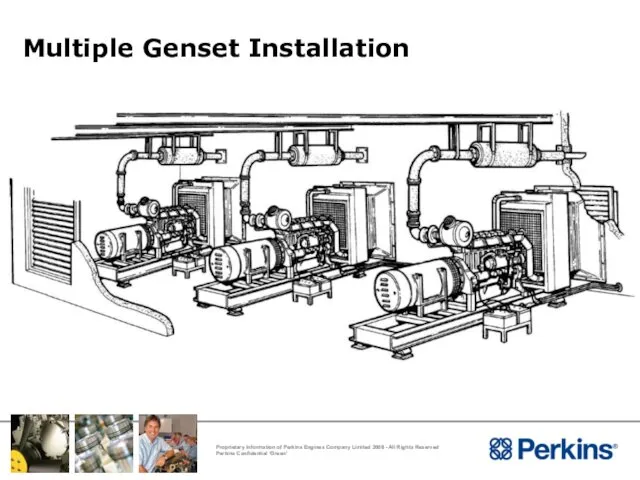

- 199. Multiple Genset Installation General – same guidelines as for single unit Each genset to have it’s

- 200. Multiple Genset Installation

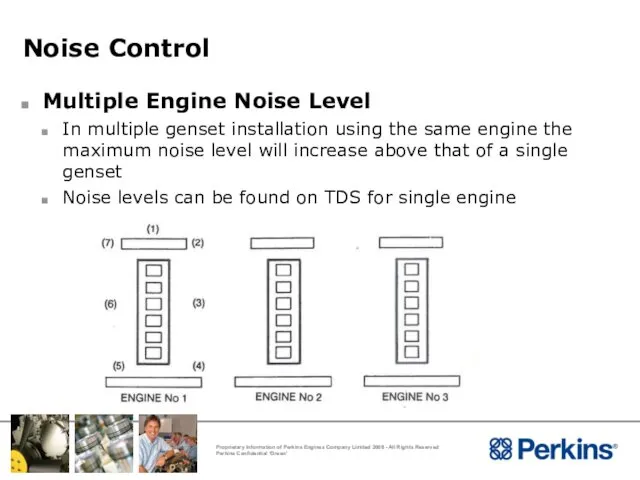

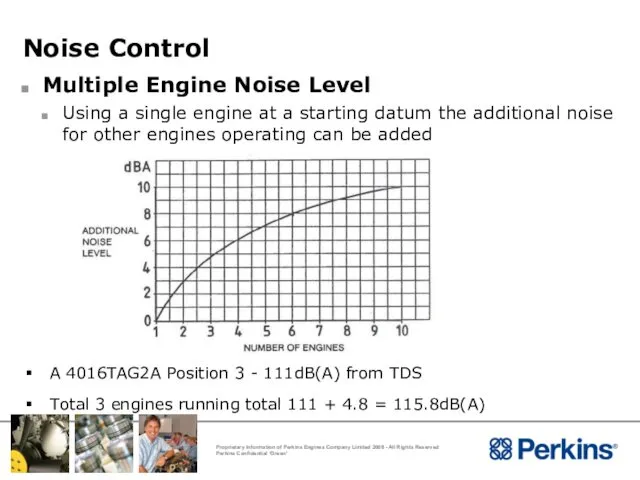

- 201. Noise Control Multiple Engine Noise Level In multiple genset installation using the same engine the maximum

- 202. Noise Control Multiple Engine Noise Level Using a single engine at a starting datum the additional

- 203. Installation Considerations Data Available To Support Installations

- 204. Technical Data Sheet Technical Data Sheet (TDS) A full set of TDS are available from Perkins

- 205. General Arrangement Drawings General Arrangement Drawings (GA drawings) A full set of GA drawings for Electropaks’

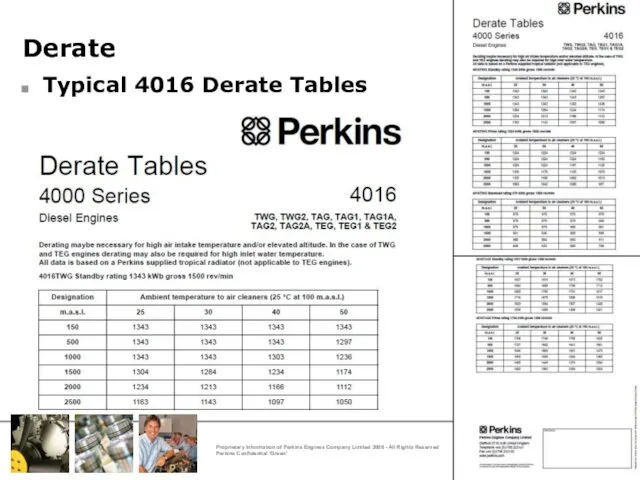

- 206. Derate Derate Derate means reducing the engines maximum power rating at normal temperatures and pressure conditions

- 207. Derate Typical 4016 Derate Tables

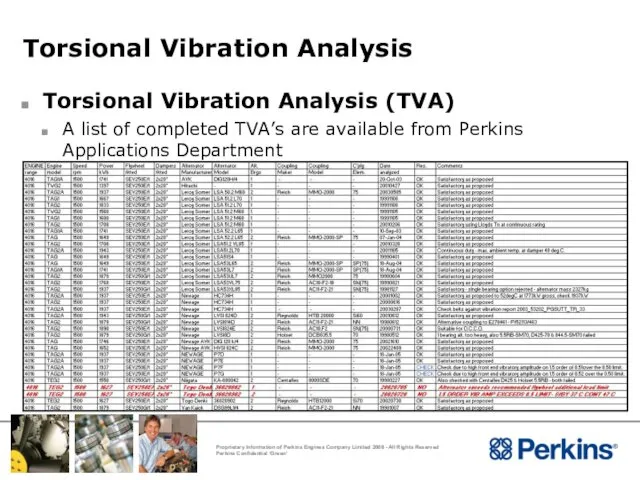

- 208. Torsional Vibration Analysis Torsional Vibration Analysis (TVA) A list of completed TVA’s are available from Perkins

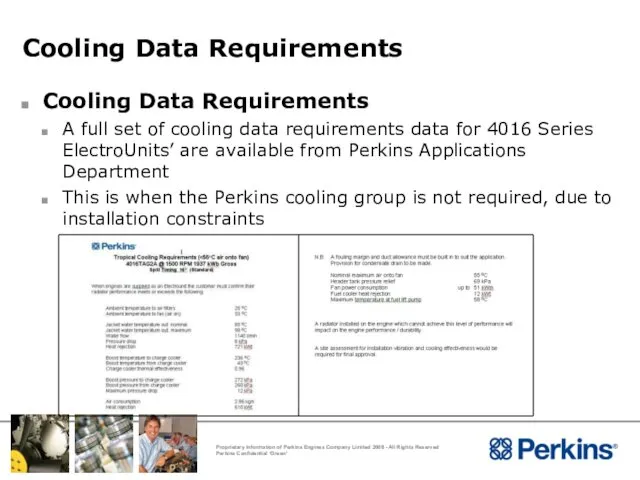

- 209. Cooling Data Requirements Cooling Data Requirements A full set of cooling data requirements data for 4016

- 211. Скачать презентацию

Повышение эффективности взаимодействия транспортных средств и погрузочно-разгрузочных машин и механизмов на примере ООО ПЭК

Повышение эффективности взаимодействия транспортных средств и погрузочно-разгрузочных машин и механизмов на примере ООО ПЭК Простейший ремонт сантехнического оборудования

Простейший ремонт сантехнического оборудования Технология ремонта унитаза

Технология ремонта унитаза Sidorenko_Alina_Sergiyivna

Sidorenko_Alina_Sergiyivna Картошечка с грибочками

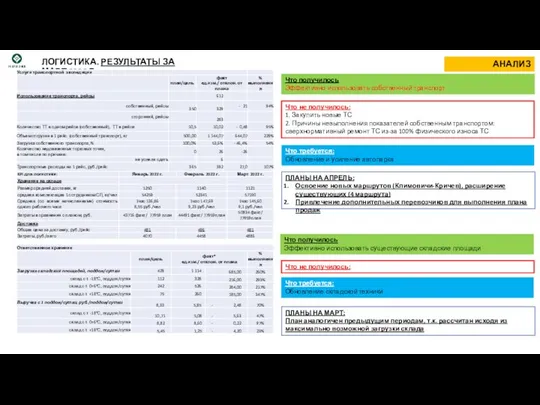

Картошечка с грибочками Логистика. Результаты за март 2022 г

Логистика. Результаты за март 2022 г Bumper ads in UAC The Value & Power of 6 Seconds

Bumper ads in UAC The Value & Power of 6 Seconds Материнская плата

Материнская плата M5Lesson5

M5Lesson5 ЦНППМ: внутренние и внешние ресурсы эффективной деятельности (Чаcть 1)

ЦНППМ: внутренние и внешние ресурсы эффективной деятельности (Чаcть 1) Общие понятия о лесозаготовительном производстве. Лекция 1. Основные понятия о лесозаготовительных предприятиях

Общие понятия о лесозаготовительном производстве. Лекция 1. Основные понятия о лесозаготовительных предприятиях Санитарный и противоэпидемиологический контроль

Санитарный и противоэпидемиологический контроль Бег как средство укрепления здоровья

Бег как средство укрепления здоровья Ознакомление с окружающим миром - Деревья и кусты

Ознакомление с окружающим миром - Деревья и кусты День Святого Валентина

День Святого Валентина Основы религиозных культур и светской этики

Основы религиозных культур и светской этики 20160308_prezentatsiya1

20160308_prezentatsiya1 Наша семья

Наша семья Направления повышения эффективности деятельности ООО ГБЦ

Направления повышения эффективности деятельности ООО ГБЦ Модернизация шлифовального станка

Модернизация шлифовального станка Профессия Лесопатолог

Профессия Лесопатолог Фазовые равновесия с участием фаялитных шлаков в процессах кислородно-факельной плавки

Фазовые равновесия с участием фаялитных шлаков в процессах кислородно-факельной плавки Декоративно-прикладное искусство моей семьи

Декоративно-прикладное искусство моей семьи Реконструкция игры властилин замка

Реконструкция игры властилин замка Шаблон презентации исследования

Шаблон презентации исследования Безопасность автоматизированных систем в финансовобанковской сфере

Безопасность автоматизированных систем в финансовобанковской сфере Благотворительная просветительская акция. Рождество приходит к каждому

Благотворительная просветительская акция. Рождество приходит к каждому 20111108_zagadki_o_lete_chast_4

20111108_zagadki_o_lete_chast_4