Содержание

- 2. Machines Compared JCB 531-70 - 7m Lift Height - 3100kg Lift Capacity - 74kW/100hp JCB Engine

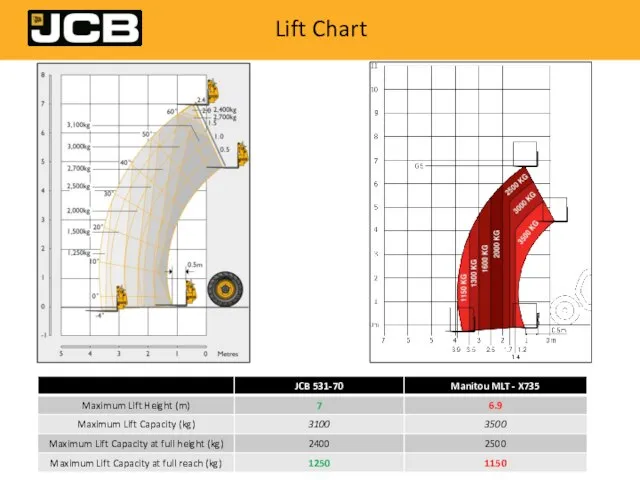

- 3. Lift Chart

- 4. Lift Chart / LMI Higher capacity at reach Separate, A pillar mounted LMI Inferior capacity at

- 5. Boom – Crowd / Dump cylinder Internal - protected Underneath – exposed Exposed HBCV’s

- 6. Boom – Crowd / Dump cylinder Internal - protected Underneath – exposed Exposed HBCV’s

- 7. Boom – QFIT carriage Strong, wide construction that adds rigidity to attachments Over centre locking mechanism

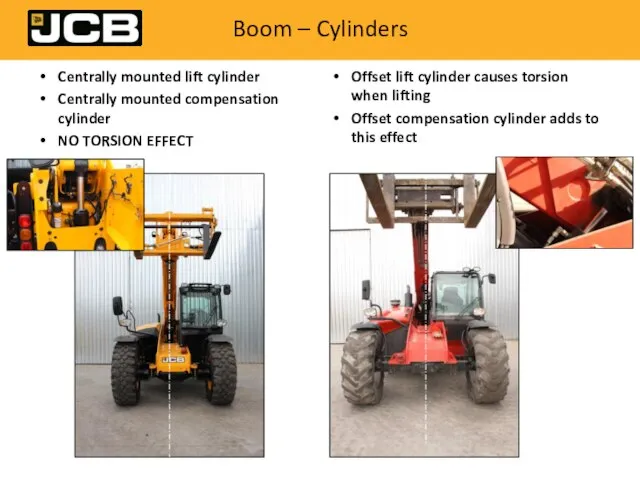

- 8. Boom – Cylinders Centrally mounted lift cylinder Centrally mounted compensation cylinder NO TORSION EFFECT Offset lift

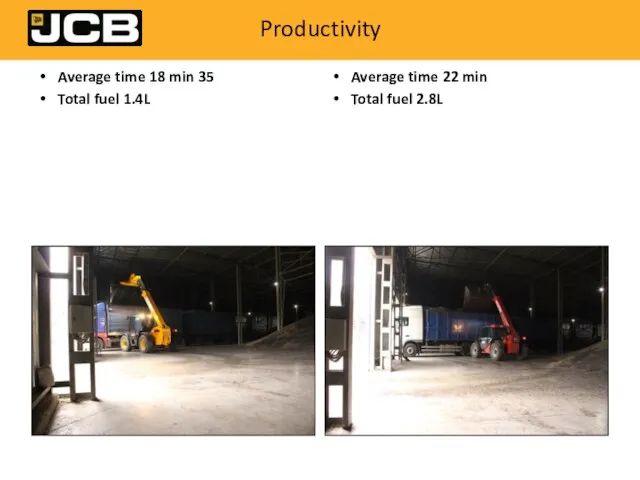

- 9. Productivity Average time 18 min 35 Total fuel 1.4L Average time 22 min Total fuel 2.8L

- 10. Boom – Lubrication Dry wax lubricant – every 500 hours Less chance of debris getting drawn

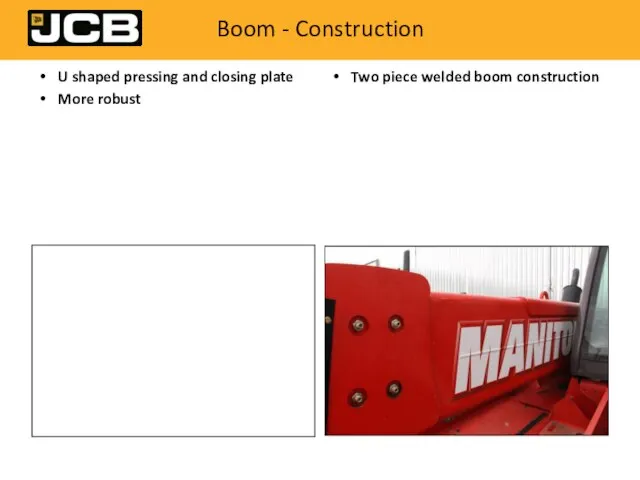

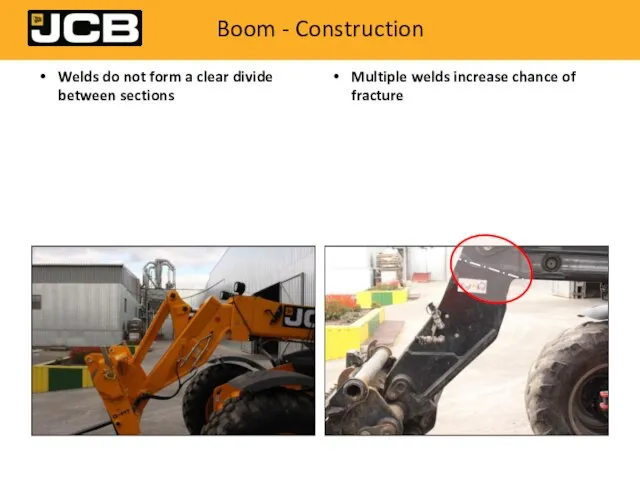

- 11. Boom - Construction U shaped pressing and closing plate More robust Two piece welded boom construction

- 12. Boom - Construction Welds do not form a clear divide between sections Multiple welds increase chance

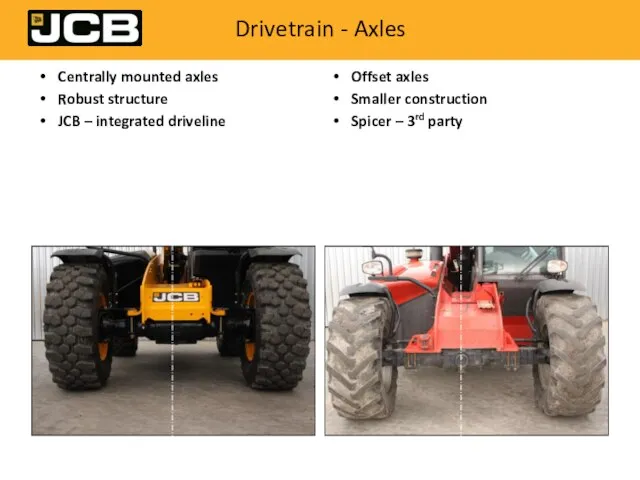

- 13. Drivetrain - Axles Centrally mounted axles Robust structure JCB – integrated driveline Offset axles Smaller construction

- 14. Drivetrain – Steering joints JCB Manufactured axle steering system pivoted at the hub with pivot pin

- 15. Drivetrain - Engine JCB – fully integrated driveline Mounted to the chassis – the pod is

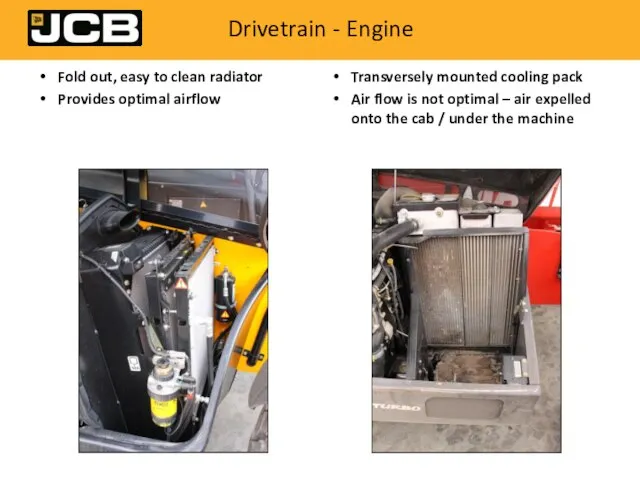

- 16. Drivetrain - Engine Fold out, easy to clean radiator Provides optimal airflow Transversely mounted cooling pack

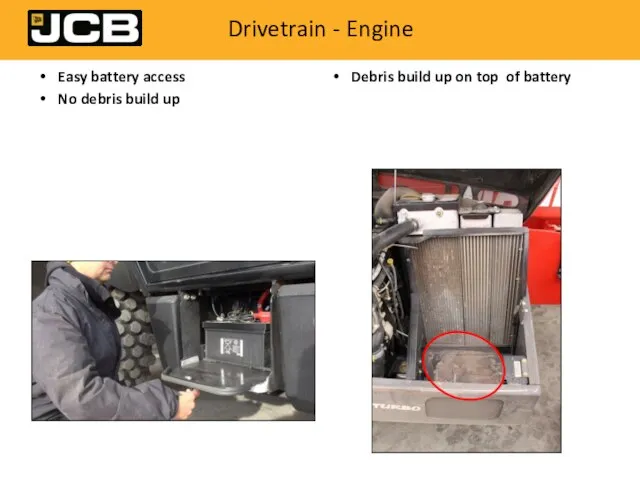

- 17. Drivetrain - Engine Easy battery access No debris build up Debris build up on top of

- 18. Drivetrain - Engine Fan utilised for dust extraction from the air filter Pre filter dust bowl

- 19. Drivetrain - Engine True hydraulically driven reverse fan Operated on-demand Fan reverses by variable vanes operated

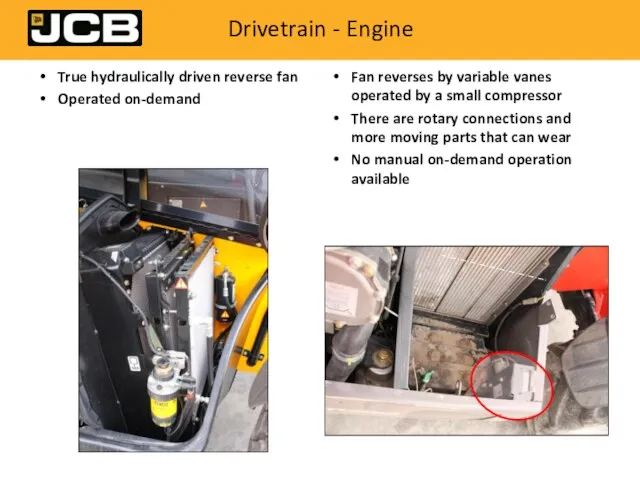

- 20. Structures - Fenders Fenders cover full width of the wheel Narrow fenders

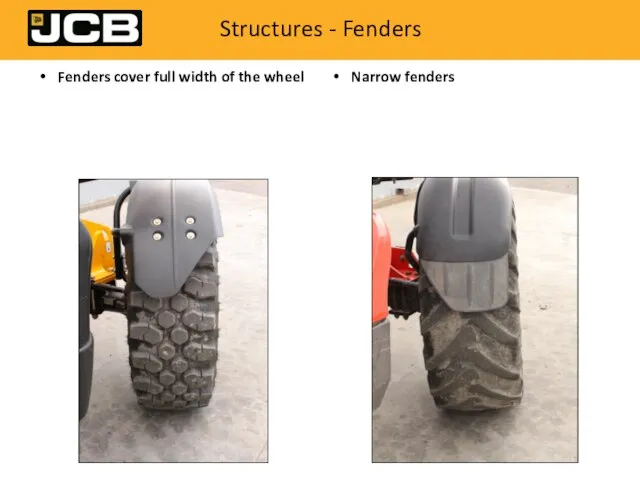

- 21. Structure – Rear lights Adjustable rear lights as standard Reduced damage potential Increased protection to lighting

- 22. Structure – rear hitch mirror Single, compact and robust support Brackets fixed to thin sheet metal

- 23. Service – Fill points Ground level fill Head height fill is more difficult

- 24. Service Grouped daily checks Transmission dipstick under the boom, required to remove cover

- 25. Service Transmission filter ?? hours Easy grouped service access Transmission filter ?? hours Panel removal for

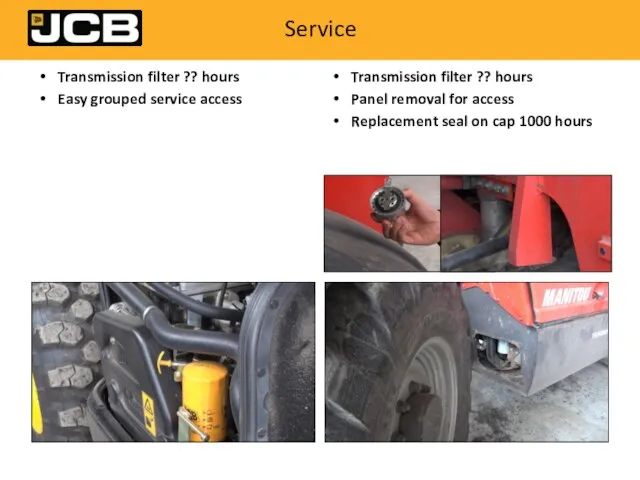

- 26. Service Hinged rear access cover Simple operation to access Dedicated ‘T’ bar locking system to increase

- 27. Service Hydraulic tank in the rear Fill point at ground level Hydraulic tank under cab radiates

- 28. Service Livelink fuel level warning as standard 3rd party level gauge No livelink fuel guard

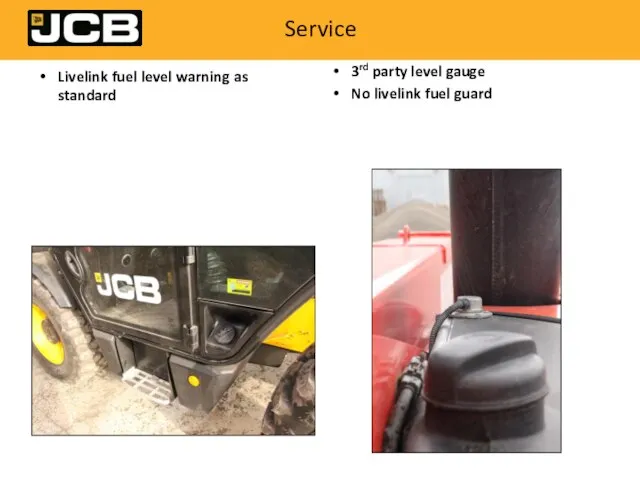

- 29. Service Handbrake lever mechanism covered Exposed handbrake mechanism

- 30. Cab Ergonomic single lever control JSM not ergonomic position for operator

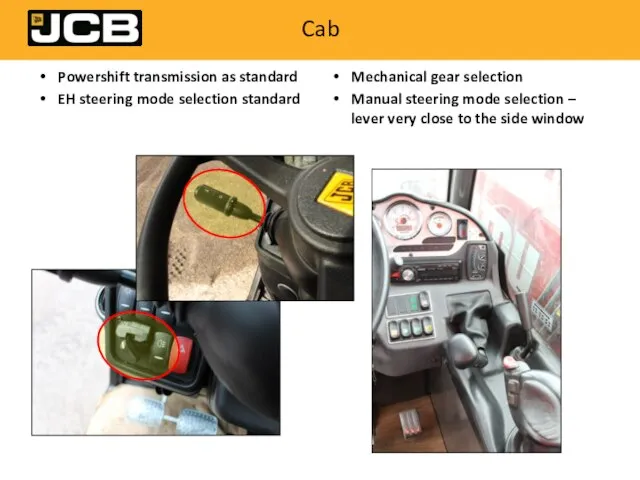

- 31. Cab Powershift transmission as standard EH steering mode selection standard Mechanical gear selection Manual steering mode

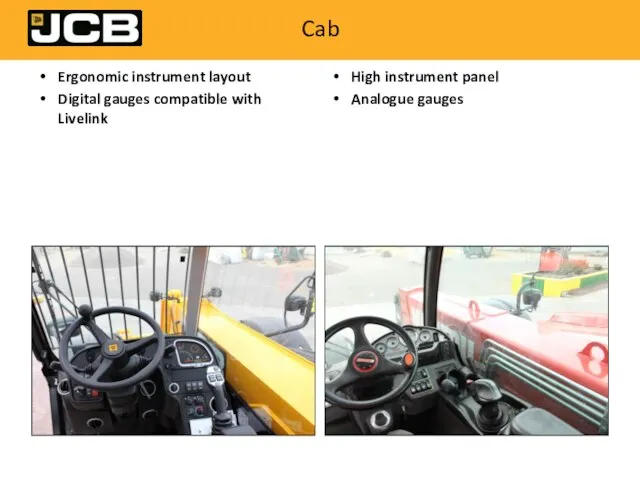

- 32. Cab Ergonomic instrument layout Digital gauges compatible with Livelink High instrument panel Analogue gauges

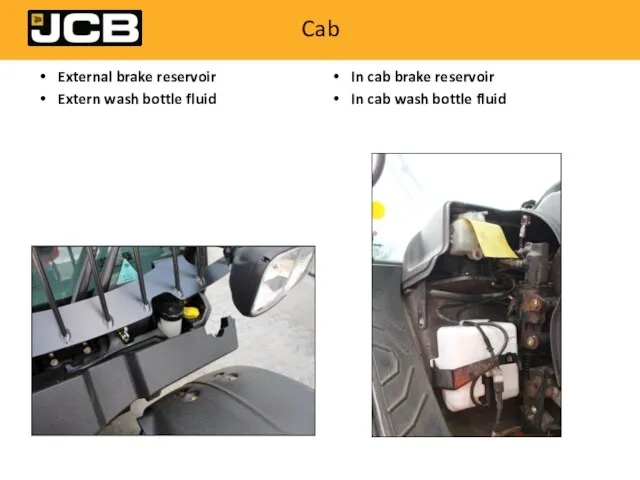

- 33. Cab External brake reservoir Extern wash bottle fluid In cab brake reservoir In cab wash bottle

- 34. Cab - Visibility Unrivalled visibility Exhaust and air pre filter reduce visibility

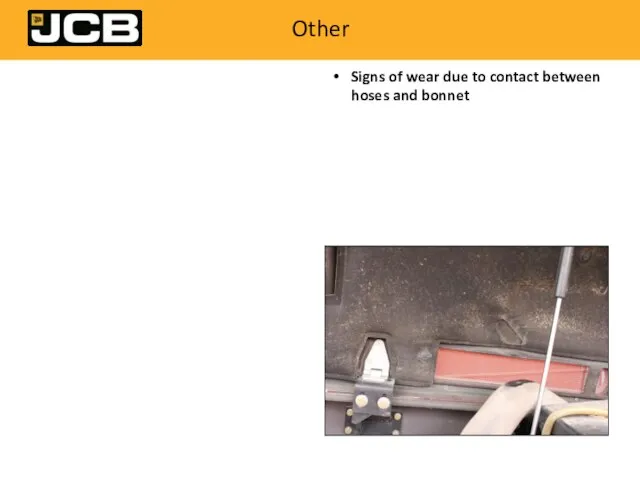

- 35. Other Signs of wear due to contact between hoses and bonnet

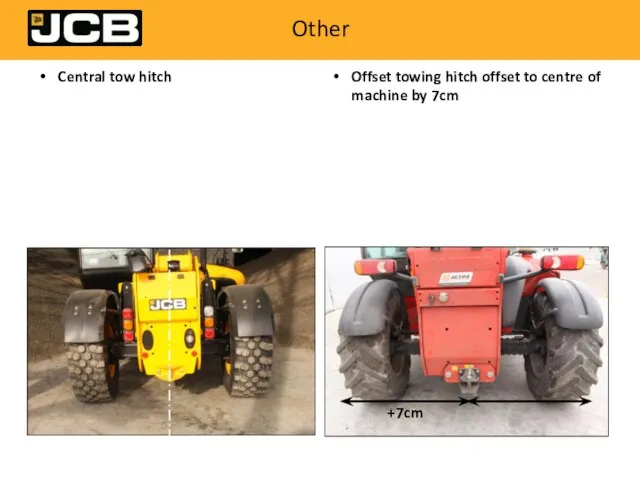

- 36. Other Central tow hitch Offset towing hitch offset to centre of machine by 7cm +7cm

- 37. Other Work lights spread across full cab – better coverage Roof mounted work lights are on

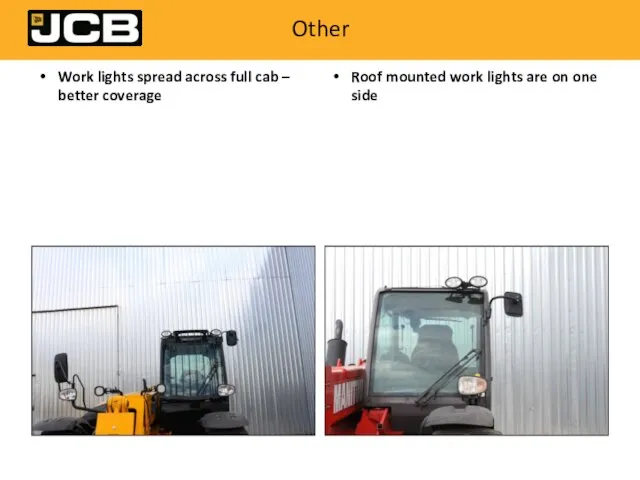

- 39. Скачать презентацию

In Harmony with the World

In Harmony with the World Предложения по внедрению новой стандартной окраски для подвижного состава МУП КТТУ

Предложения по внедрению новой стандартной окраски для подвижного состава МУП КТТУ 20140913_novaya_papka

20140913_novaya_papka 20140203_novye_zhanry_v_poezii

20140203_novye_zhanry_v_poezii Луценко В.Д. презентация 10 б

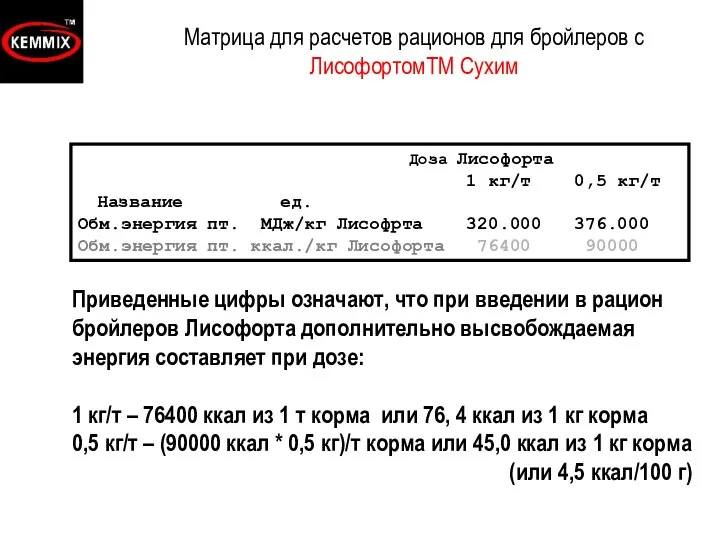

Луценко В.Д. презентация 10 б Матрица для расчетов рационов для бройлеров, Лисофорт ТМ

Матрица для расчетов рационов для бройлеров, Лисофорт ТМ Вопросы для размышления

Вопросы для размышления ТЗ интерфейсы

ТЗ интерфейсы кино-ребус

кино-ребус Супружеские взаимоотношения

Супружеские взаимоотношения Структура АТСК 100/2000. Назначение и характеристика основных элементов. Алгоритм работы станции.,

Структура АТСК 100/2000. Назначение и характеристика основных элементов. Алгоритм работы станции., 20130713_vershiny_kitayskoy_kultury

20130713_vershiny_kitayskoy_kultury Мировые религии

Мировые религии Аттестационная работа Милюсин В С

Аттестационная работа Милюсин В С Стеклянные строительные материалы и изделия

Стеклянные строительные материалы и изделия Хиро́му Арака́ва (Hiromu Arakawa)

Хиро́му Арака́ва (Hiromu Arakawa) С Днём Матери

С Днём Матери Интеллект, сознание, информация

Интеллект, сознание, информация Портфолио. Васенина Мария Николаевна

Портфолио. Васенина Мария Николаевна Зона арктических пустынь

Зона арктических пустынь Современное Мировое хозяйство

Современное Мировое хозяйство Ремонт квартир

Ремонт квартир Проект. Окружающий мир

Проект. Окружающий мир ВАЗОНЫ 2022 (1)

ВАЗОНЫ 2022 (1) Основные темы и герои Библии

Основные темы и герои Библии Промыслы и ремесла Ивановской области

Промыслы и ремесла Ивановской области RCS Presentation

RCS Presentation Индивидуальность – плохо или хорошо?

Индивидуальность – плохо или хорошо?