Содержание

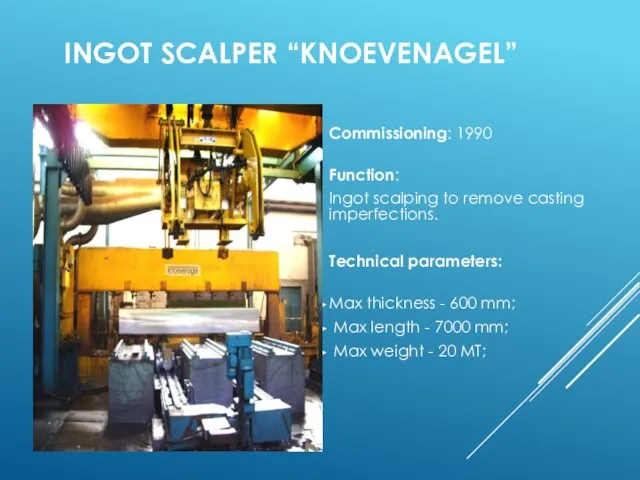

- 2. INGOT SCALPER “KNOEVENAGEL” Commissioning: 1990 Function: Ingot scalping to remove casting imperfections. Technical parameters: Max thickness

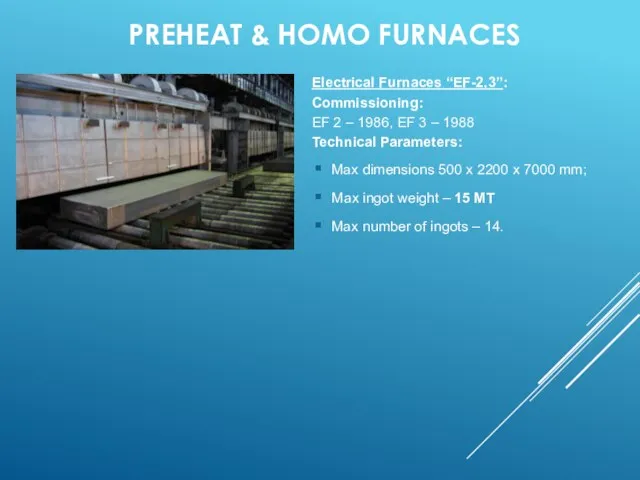

- 3. Electrical Furnaces “EF-2,3”: Commissioning: EF 2 – 1986, EF 3 – 1988 Technical Parameters: Max dimensions

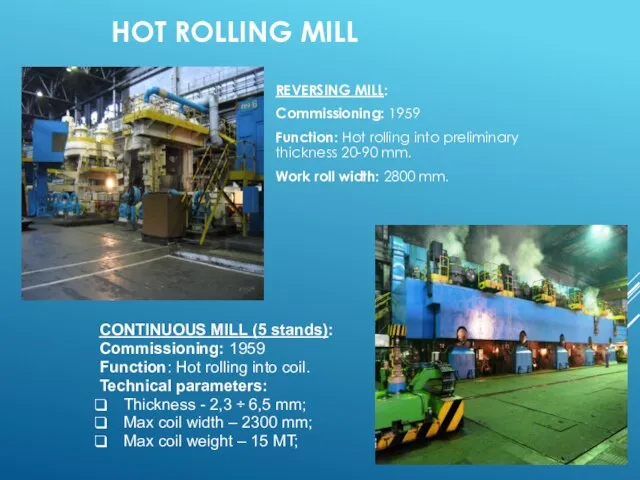

- 4. HOT ROLLING MILL REVERSING MILL: Commissioning: 1959 Function: Hot rolling into preliminary thickness 20-90 mm. Work

- 6. Скачать презентацию

Презентация Microsoft PowerPoint

Презентация Microsoft PowerPoint Презентация Microsoft Office PowerPoint (21)

Презентация Microsoft Office PowerPoint (21) 20151031_proekt_alleya

20151031_proekt_alleya Электромагнитные реле автомобилей

Электромагнитные реле автомобилей Урок №1 Экономическая и социальная география России. Введение

Урок №1 Экономическая и социальная география России. Введение Квиз Взрыв мозга

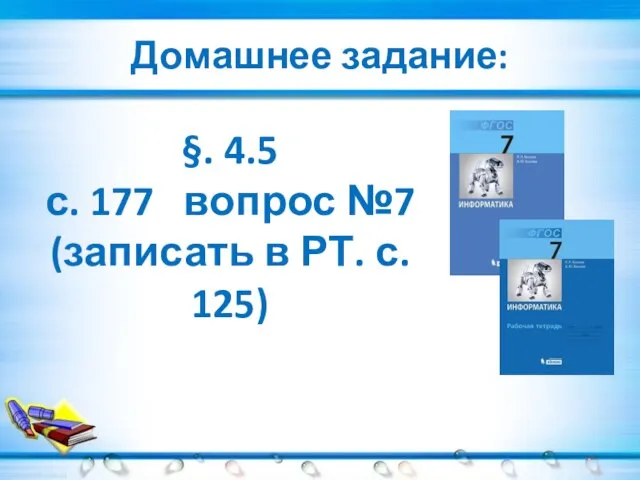

Квиз Взрыв мозга Ур. 27 Распознавание текста и системы компьютерного перевода

Ур. 27 Распознавание текста и системы компьютерного перевода Воплощение Христа в работах художников

Воплощение Христа в работах художников Конструирование конической юбки

Конструирование конической юбки Минеральные вяжущие материалы и изделия

Минеральные вяжущие материалы и изделия Отношение к труду

Отношение к труду Буратіно. Вироби з дерева, різьба по дереву та меблеві вироби

Буратіно. Вироби з дерева, різьба по дереву та меблеві вироби Мой папа - механизатор

Мой папа - механизатор к выпускному

к выпускному Правила технической эксплуатации железных дорог Российской Федерации

Правила технической эксплуатации железных дорог Российской Федерации офср

офср WHAT DO WE KNOW ABOUT EGE IN ENGLISH

WHAT DO WE KNOW ABOUT EGE IN ENGLISH Жилая застройка

Жилая застройка Насосы: Погружные дренажные/Фекальные

Насосы: Погружные дренажные/Фекальные 20150616_prezentatsiya_na_temu_zhizn_i_tvorchestvo_emilya_zolya

20150616_prezentatsiya_na_temu_zhizn_i_tvorchestvo_emilya_zolya Здравствуй, Лето! Мероприятия, приуроченные к дню защиты детей

Здравствуй, Лето! Мероприятия, приуроченные к дню защиты детей С днем Учителя !

С днем Учителя ! 20160116_desyatichnye_drobi

20160116_desyatichnye_drobi Настольная игра по роману Д. Дефо Робинзон Крузо

Настольная игра по роману Д. Дефо Робинзон Крузо Строительные материалы. Часть 1

Строительные материалы. Часть 1 20151210_arhitekturnyy_oblik_drevney_rusi

20151210_arhitekturnyy_oblik_drevney_rusi Визитная карточка

Визитная карточка Еврокоды

Еврокоды