A tentative model of technology improvement in ferro- alloys manufacturing process & the business way forward

Содержание

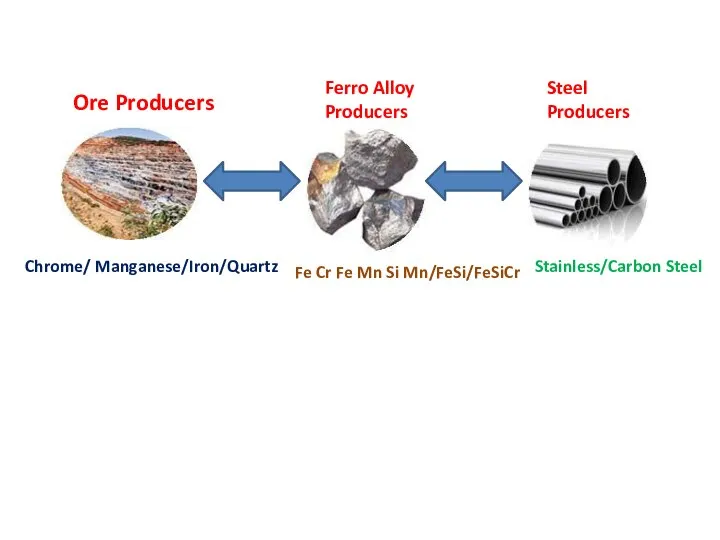

- 2. Chrome/ Manganese/Iron/Quartz Ore Producers Ferro Alloy Producers Steel Producers Fe Cr Fe Mn Si Mn/FeSi/FeSiCr Stainless/Carbon

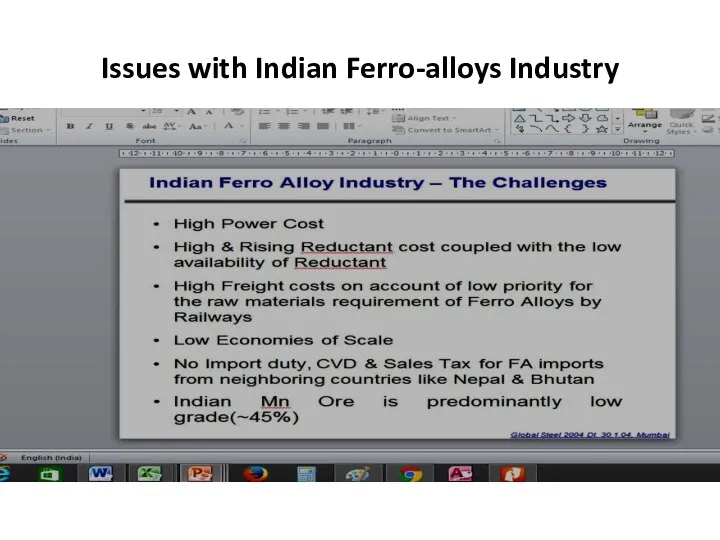

- 3. Issues with Indian Ferro‐alloys Industry

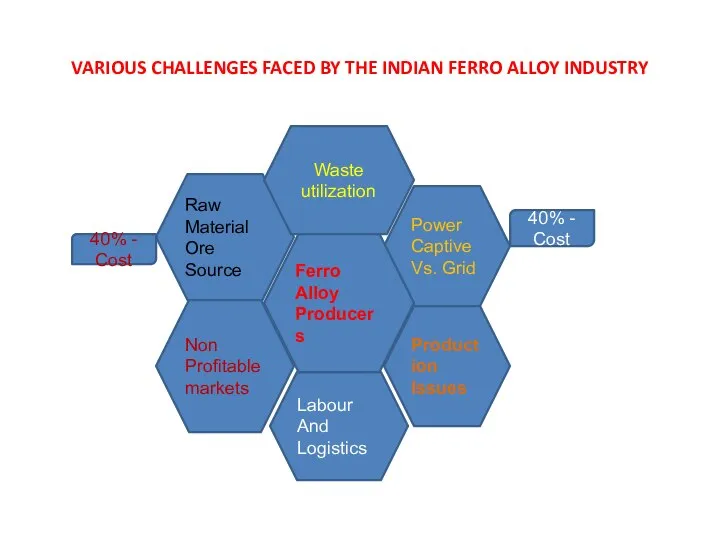

- 4. VARIOUS CHALLENGES FACED BY THE INDIAN FERRO ALLOY INDUSTRY Power Captive Vs. Grid Raw Material Ore

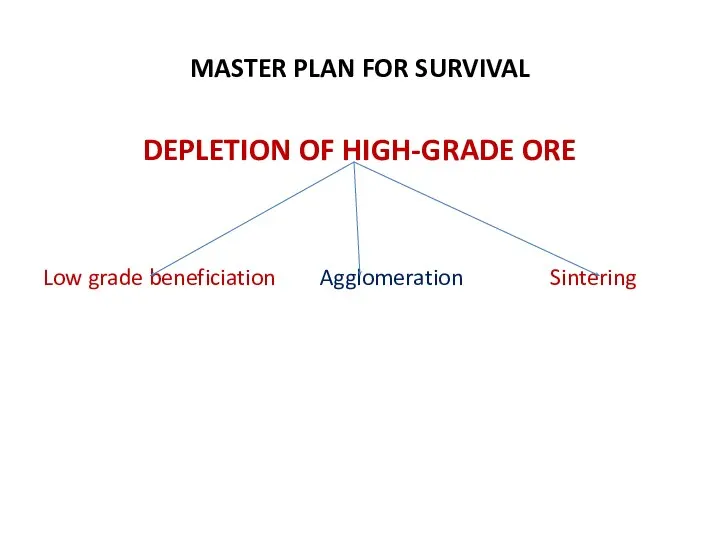

- 5. MASTER PLAN FOR SURVIVAL DEPLETION OF HIGH-GRADE ORE Low grade beneficiation Agglomeration Sintering

- 7. Agglomeration & Productivity Improvement for Manganese alloy Investment in beneficiation & use of agglomerated feed •

- 8. Waste Heat Utilization & Raw material Handling Minimizing heat loss and use waste gases for power

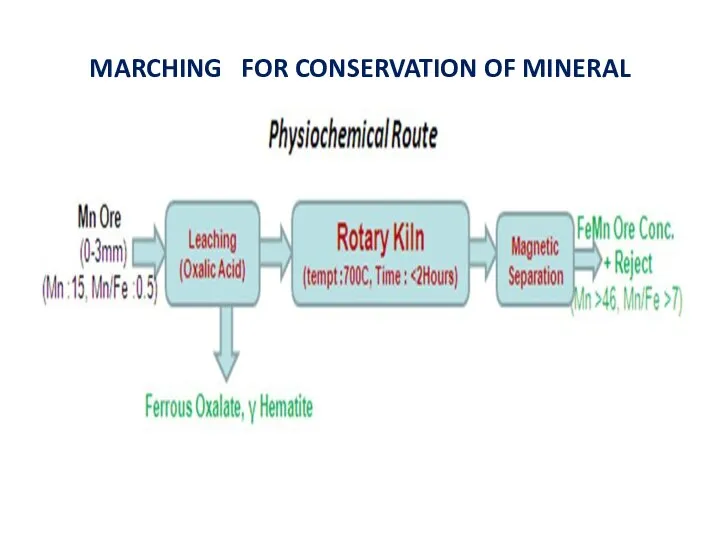

- 9. MARCHING FOR CONSERVATION OF MINERAL

- 10. MARCHING FOR NEW INNOVATION Waste management of Manganese ore MnSO4 for agriculture

- 11. EXPERIMENT OBSERVATIONS FOR MANGANESE ORE SINTERING • Low yield with 100% belt spillage material for sintering.

- 12. Experiment Conclusion Raw material belt spillages can be sintered in combination with high grade Mn ore

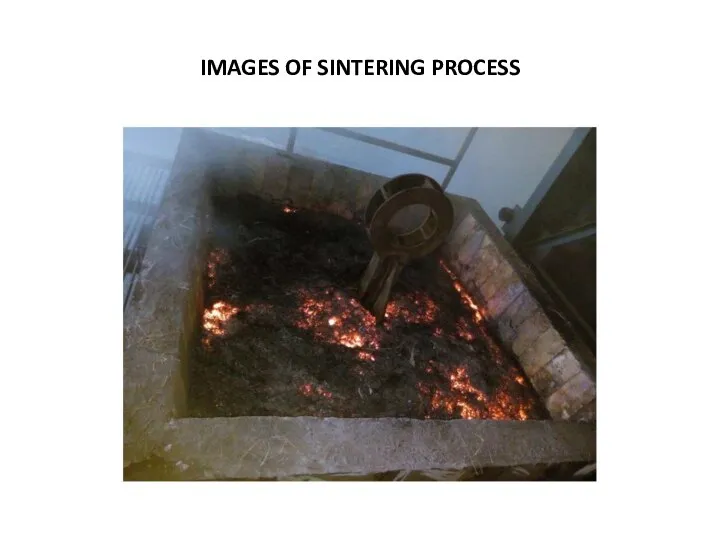

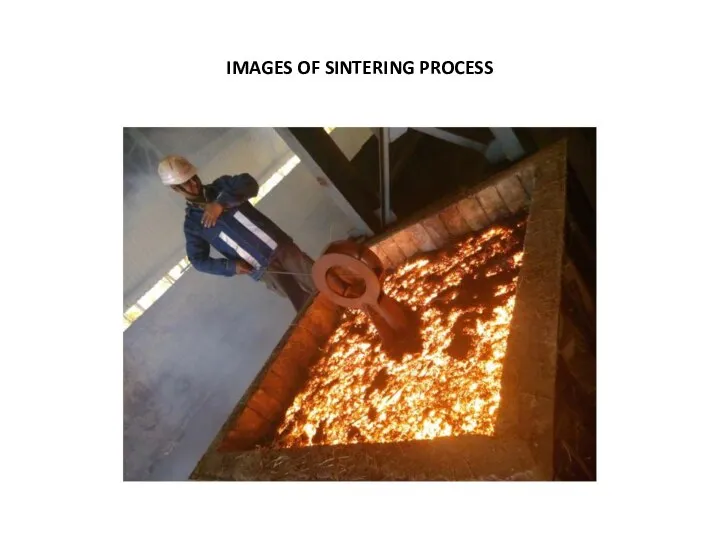

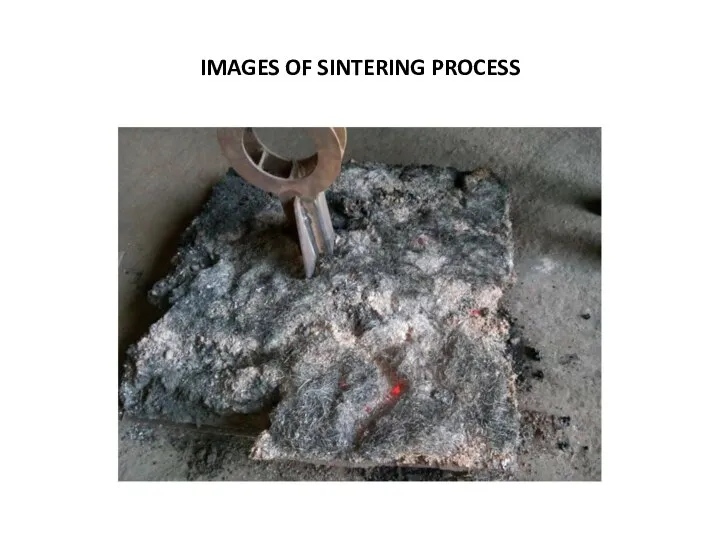

- 13. IMAGES OF SINTERING PROCESS

- 14. IMAGES OF SINTERING PROCESS

- 15. IMAGES OF SINTERING PROCESS

- 16. IMAGES OF SINTERING PROCESS

- 17. IMAGES OF SINTERING PROCESS

- 18. IMAGES OF SINTERING PROCESS

- 19. IMAGES OF SINTERING PROCESS

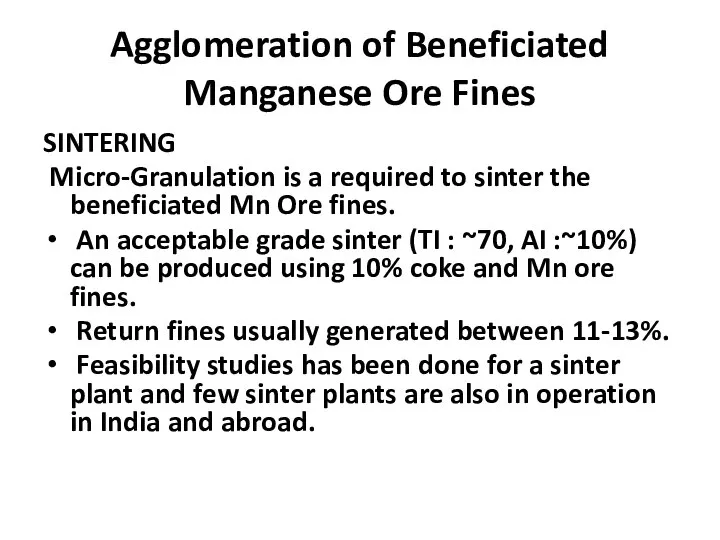

- 20. Agglomeration of Beneficiated Manganese Ore Fines SINTERING Micro‐Granulation is a required to sinter the beneficiated Mn

- 21. BRIQUETING • Mn ore briquettes were produced and trial conducted in different Ferro Alloys Plant. •

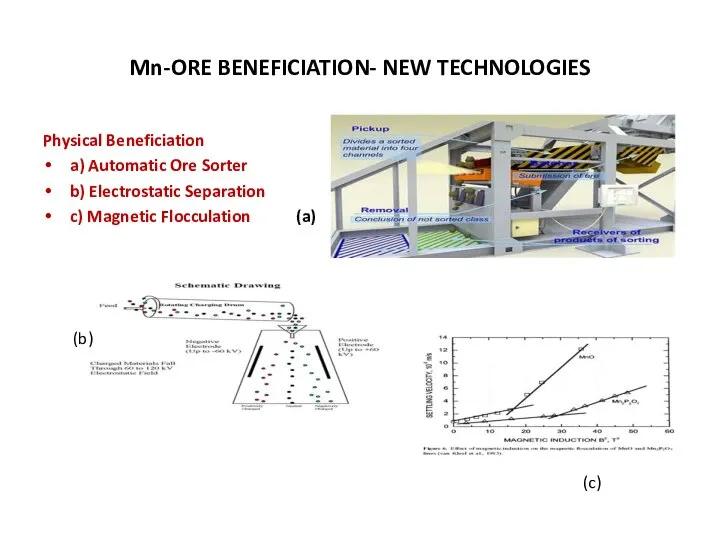

- 22. Mn‐ORE BENEFICIATION‐ NEW TECHNOLOGIES Physical Beneficiation a) Automatic Ore Sorter b) Electrostatic Separation c) Magnetic Flocculation

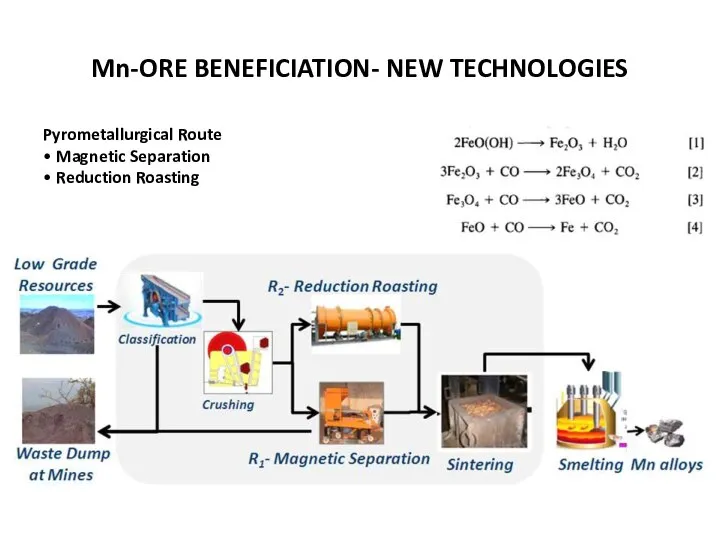

- 23. Mn‐ORE BENEFICIATION‐ NEW TECHNOLOGIES Pyrometallurgical Route • Magnetic Separation • Reduction Roasting

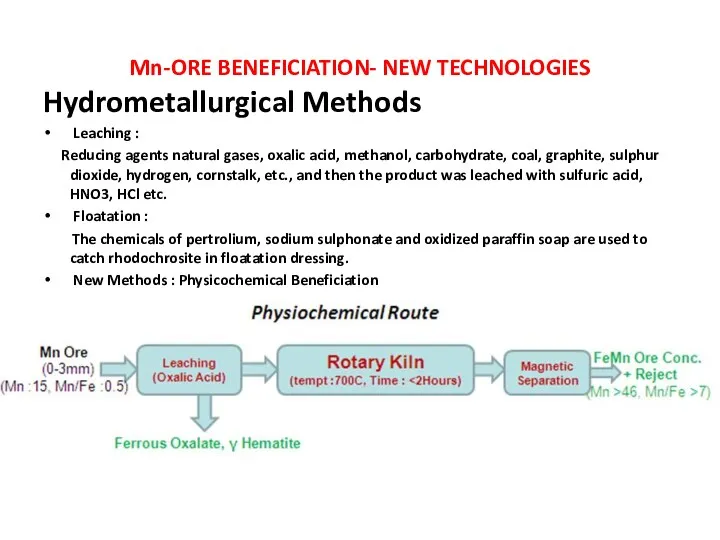

- 24. Mn‐ORE BENEFICIATION‐ NEW TECHNOLOGIES Hydrometallurgical Methods Leaching : Reducing agents natural gases, oxalic acid, methanol, carbohydrate,

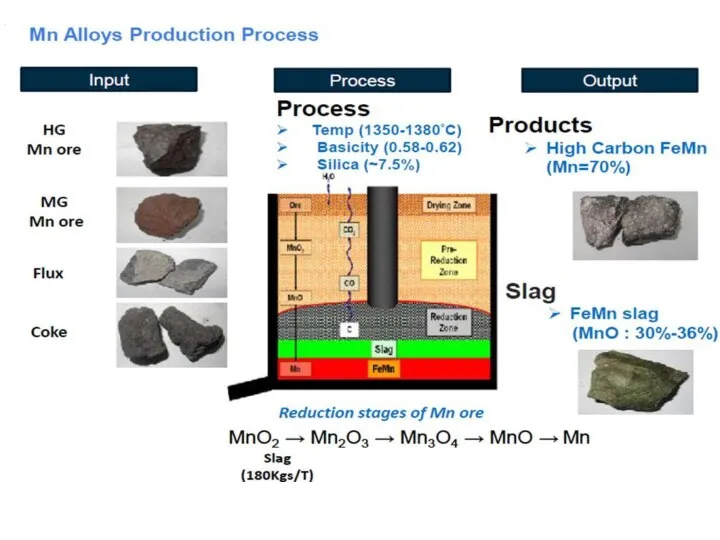

- 26. PROCEDURES AT FERRO MANGANESE PLANT

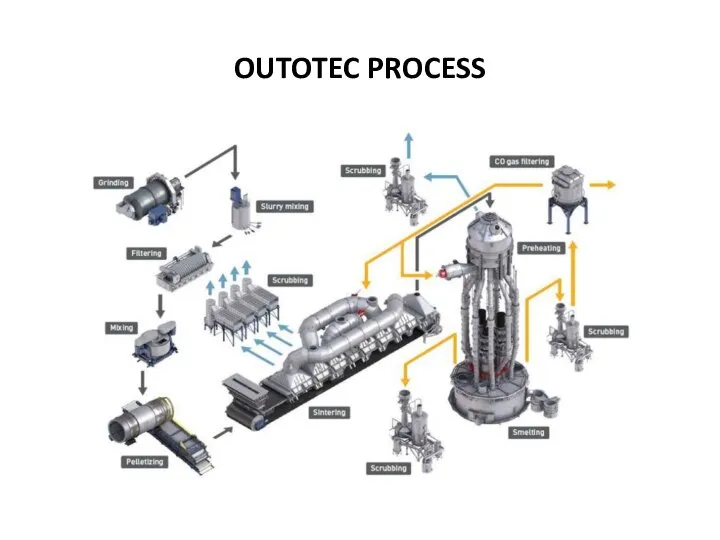

- 27. OUTOTEC PROCESS

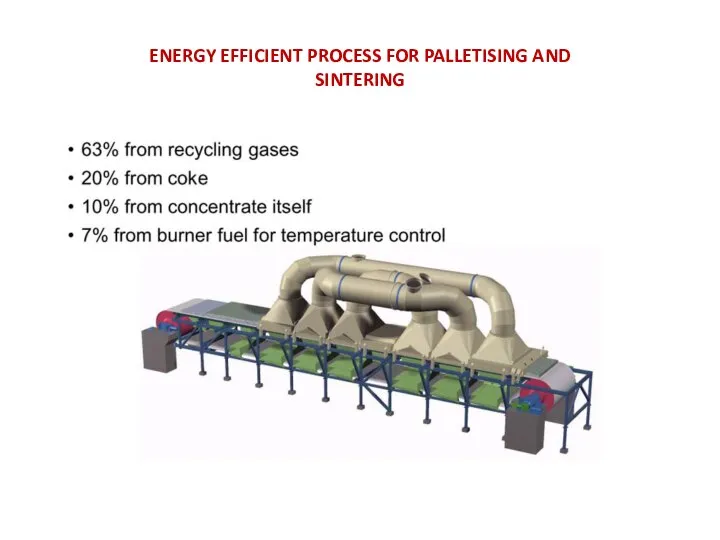

- 28. ENERGY EFFICIENT PROCESS FOR PALLETISING AND SINTERING

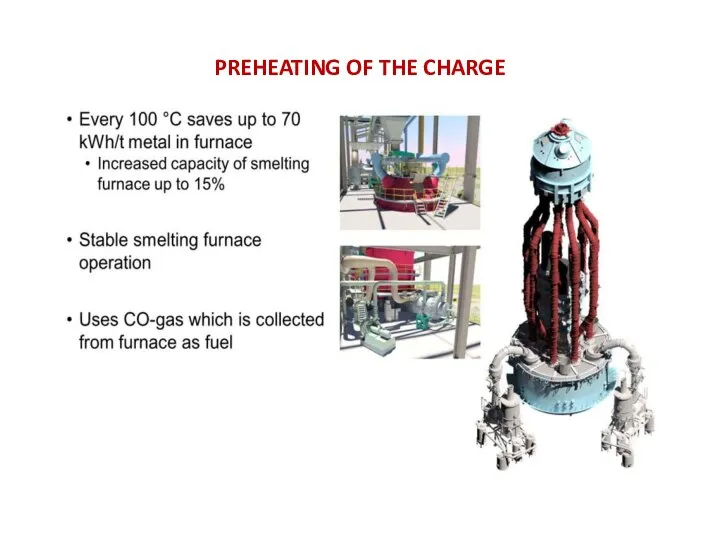

- 29. PREHEATING OF THE CHARGE

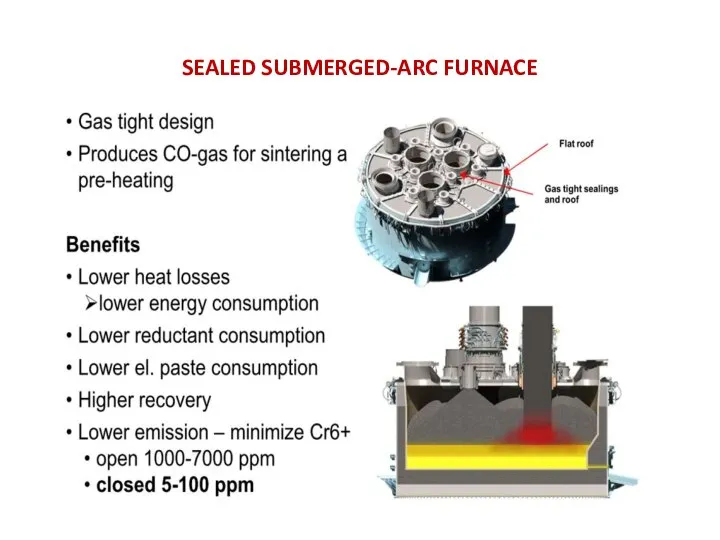

- 30. SEALED SUBMERGED-ARC FURNACE

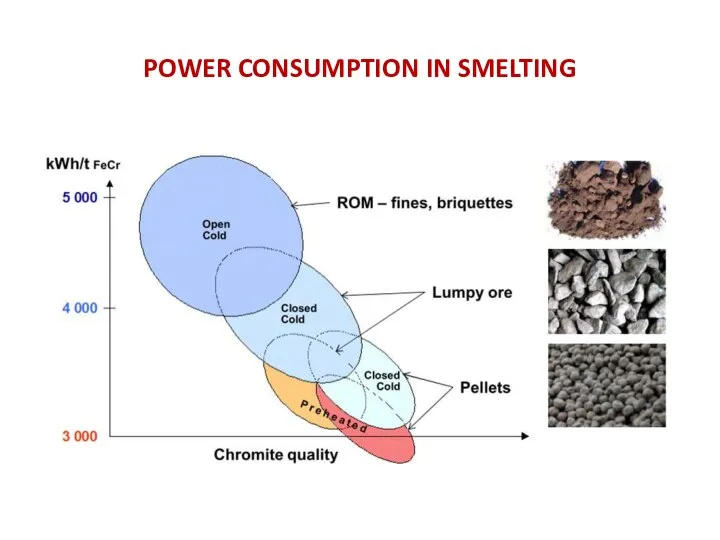

- 31. POWER CONSUMPTION IN SMELTING

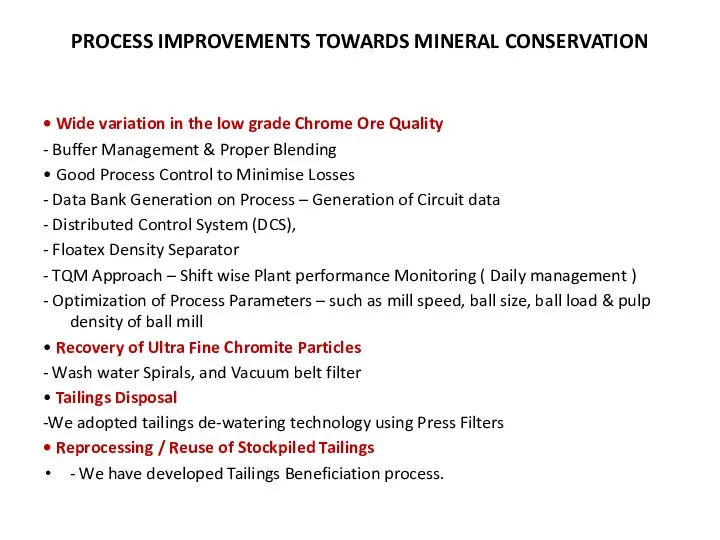

- 32. PROCESS IMPROVEMENTS TOWARDS MINERAL CONSERVATION • Wide variation in the low grade Chrome Ore Quality -

- 33. IMPROVEMENT JOURNEY IN BENEFICIATION OF CHROME ORE FOR BETTER MINERAL CONSERVATION OBJECTIVES Economic Use of Mineral

- 34. BRIQUETTING OF CHROMITES ORE In developing a technology for briquetting of chrome ores, it is important

- 35. LAYOUT MODIFICATION OF BRIQUETTE PLANT Briquette plant should be set of at back site of furnace

- 36. Briquette stacking design should be taken in such a concrete platform that each lot having conical

- 37. CHUTE TUBE FILLING PATTERN Alternate chute tube should be filled with charge always which will give

- 38. DESIGN OF POLLUTION PLANT Furnace generated flue gas through chimney ducting to pollution plant-bag filters-pollution stack

- 39. FURNACE OPERATIONAL POINT OF VIEW Required charge level in furnace hearth. Required electrode length as per

- 40. Increased heat efficiency by suitable selection of current and voltage ranges with proper electrode tip positioning(0.7-0.75

- 41. Proper permeability of charge material should be there to effectively utilize CO gas for reduction. For

- 42. If the Cr2O3 content in the ore is too high , some of the chromium oxide

- 43. Feed consists of temporarily bound fines with higher specific surface are which in turn leads to

- 44. Basicity of the slag should be maintained within the range 1.1-1.2 to have the easy separation

- 45. Hot alloy tapping should be taken with short runner with 2-nos CI- circular pan placing in

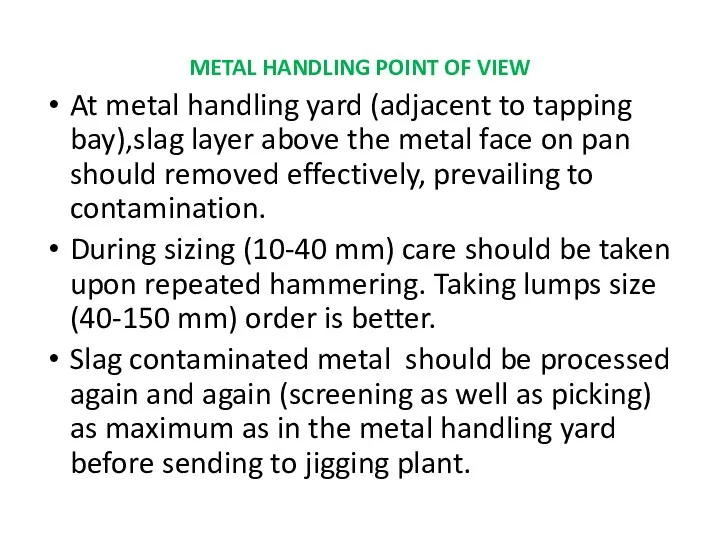

- 46. METAL HANDLING POINT OF VIEW At metal handling yard (adjacent to tapping bay),slag layer above the

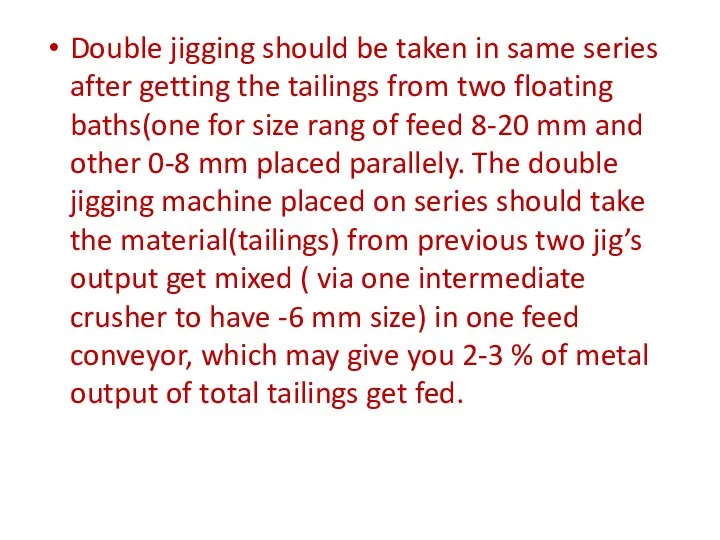

- 47. Double jigging should be taken in same series after getting the tailings from two floating baths(one

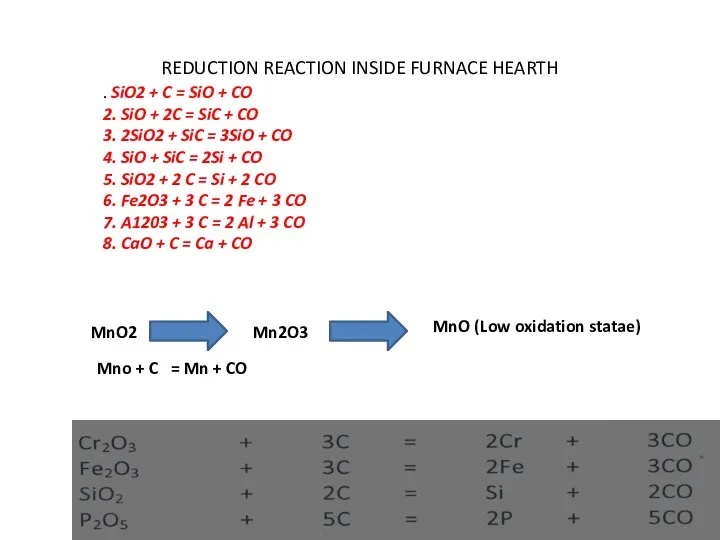

- 48. REDUCTION REACTION INSIDE FURNACE HEARTH MnO2 Mn2O3 MnO (Low oxidation statae) Mno + C = Mn

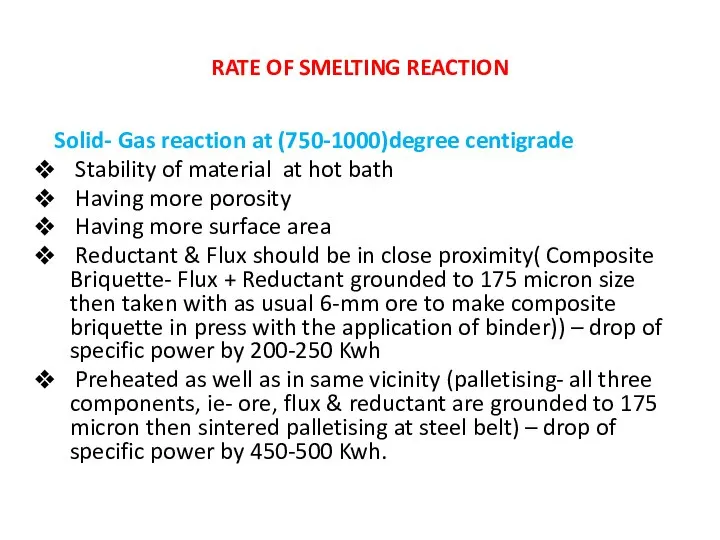

- 49. RATE OF SMELTING REACTION Solid- Gas reaction at (750-1000)degree centigrade Stability of material at hot bath

- 50. CONCLUSION Maximum portion of the income of Ferro-alloy manufacturers is taken away by electricity. Hence the

- 52. Скачать презентацию

ЕСТЕСТВОЗНАНИЕ И НКН НКН – целостная система взглядов и представлений на общие свойства и закономерности природы, выраженная в

ЕСТЕСТВОЗНАНИЕ И НКН НКН – целостная система взглядов и представлений на общие свойства и закономерности природы, выраженная в  Агротуризм. Многофункциональный проект. ООО «Ясень»

Агротуризм. Многофункциональный проект. ООО «Ясень» ММА. What is UFC

ММА. What is UFC Актуальные конференции

Актуальные конференции Я люблю спорт

Я люблю спорт Летняя практика. Часть 4. Массивы

Летняя практика. Часть 4. Массивы Платформа «Центр управления M2M»

Платформа «Центр управления M2M» Презентация Маркетинговые исследования

Презентация Маркетинговые исследования Силурийский период 443 млн.л.н. – 416 млн.л.н.

Силурийский период 443 млн.л.н. – 416 млн.л.н. Монолитные ребристые перекрытия

Монолитные ребристые перекрытия Тема 9. Бюджетная система

Тема 9. Бюджетная система Droga Krzyżowa z Janem Pawłem II

Droga Krzyżowa z Janem Pawłem II Методология и методы педагогических исследований

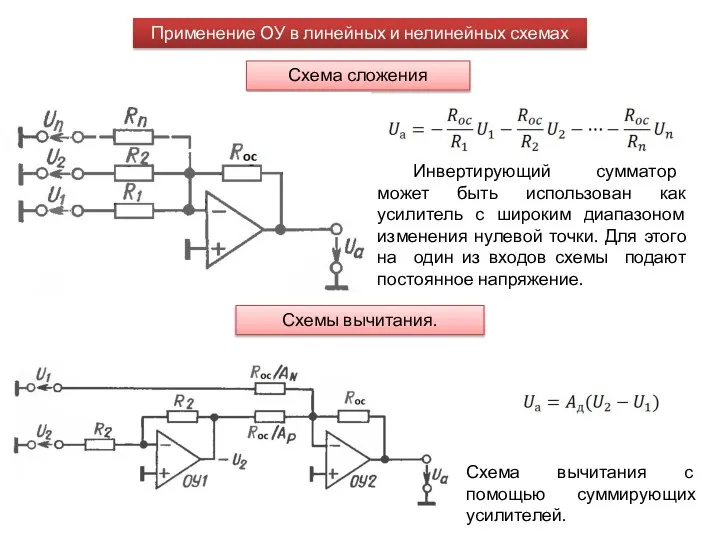

Методология и методы педагогических исследований Применение ОУ в линейных и нелинейных схемах. СА1 лекция 7

Применение ОУ в линейных и нелинейных схемах. СА1 лекция 7 Формы и типы государств. Лекция № 3

Формы и типы государств. Лекция № 3 Программа «БОНУС-ЭКСПРЕС» Предложение для потенциальных потребителей

Программа «БОНУС-ЭКСПРЕС» Предложение для потенциальных потребителей Административная, военная, церковная, налоговая реформы Петра Великого

Административная, военная, церковная, налоговая реформы Петра Великого Народы Норвегии

Народы Норвегии  Политический режим

Политический режим Сети центров общения «Надежда». Новый формат сотрудничества на условиях франчайзинга

Сети центров общения «Надежда». Новый формат сотрудничества на условиях франчайзинга Церковь и государство в XVI веке

Церковь и государство в XVI веке Generic Collections Java Core

Generic Collections Java Core Правовое положение учреждений Никитенко Екатерина Медянкин Павел

Правовое положение учреждений Никитенко Екатерина Медянкин Павел  Лингвистическая экспертиза

Лингвистическая экспертиза Глюконеогенез

Глюконеогенез Развитие программирования. Платформа .NET (C#, Лекция 1)

Развитие программирования. Платформа .NET (C#, Лекция 1) Необходимость обучения плаванию в рамках занятий физической культурой

Необходимость обучения плаванию в рамках занятий физической культурой Несие алуға қажетті құжаттар

Несие алуға қажетті құжаттар