Содержание

- 2. General Perspective Materials Science in Semiconductor Processing (MSSP) Exact type of the predominant defects dependent on

- 3. In the case of Non-amorphizing Implants {113} rod-like defects; {113} planes elongated along the directions Formation

- 4. Terms Weak Beam Dark Field (WBDF) image High-Resolution TEM (HREM) Bravais lattices: 14 different point lattices

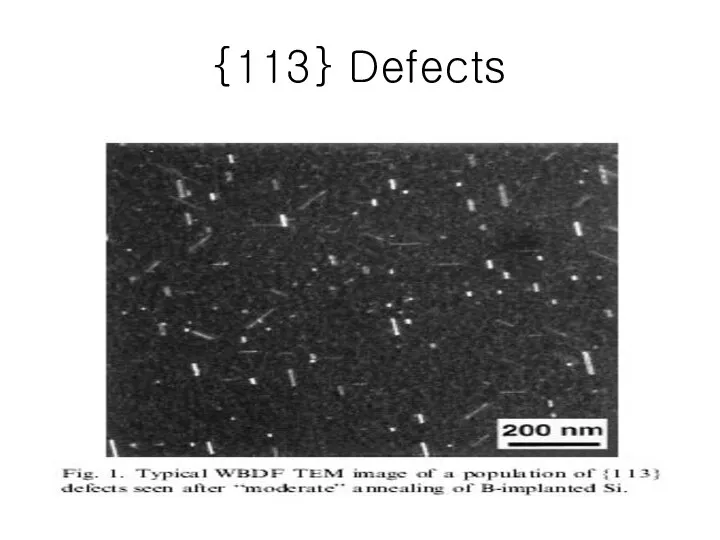

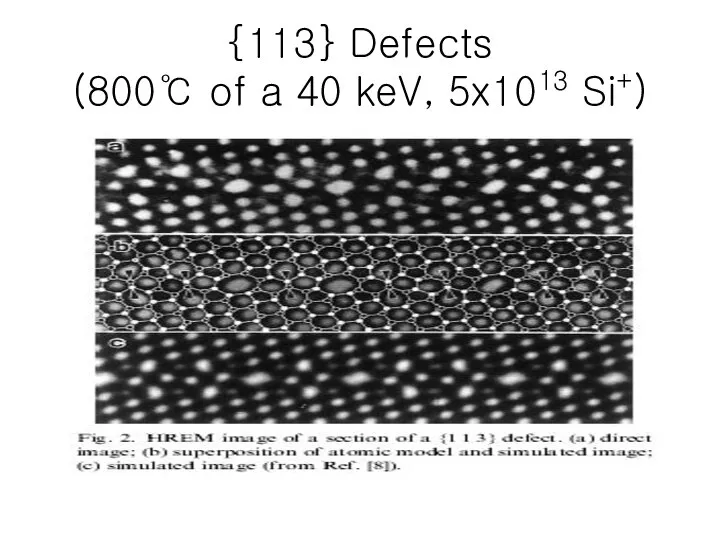

- 5. {113} Defects

- 6. {113} Defects (800℃ of a 40 keV, 5x1013 Si+)

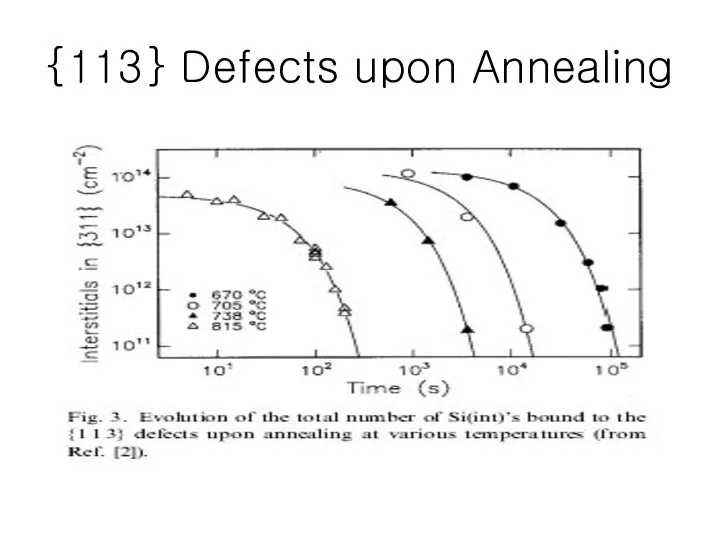

- 7. {113} Defects upon Annealing

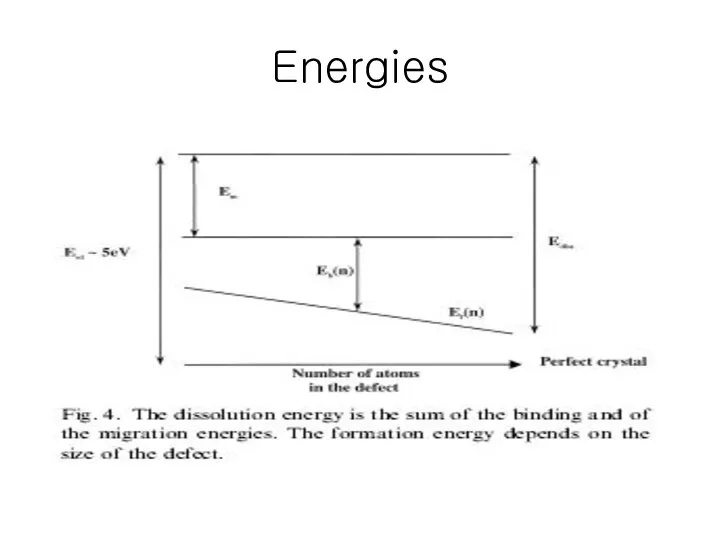

- 8. Energies

- 9. Energies Formation energy of a defect: energy incease due to the incorporation of an extra Si

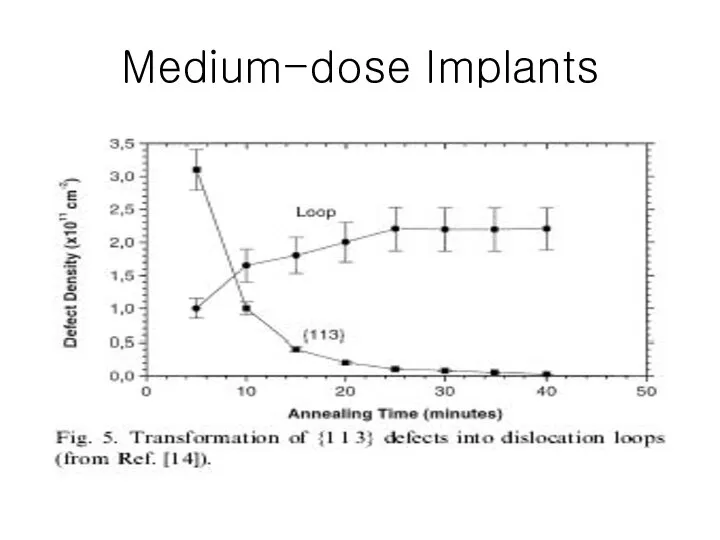

- 10. In the case of Medium-dose Implants 100 keV Si+–implanted Si at 800 ℃ {113} and dislocation

- 11. Medium-dose Implants

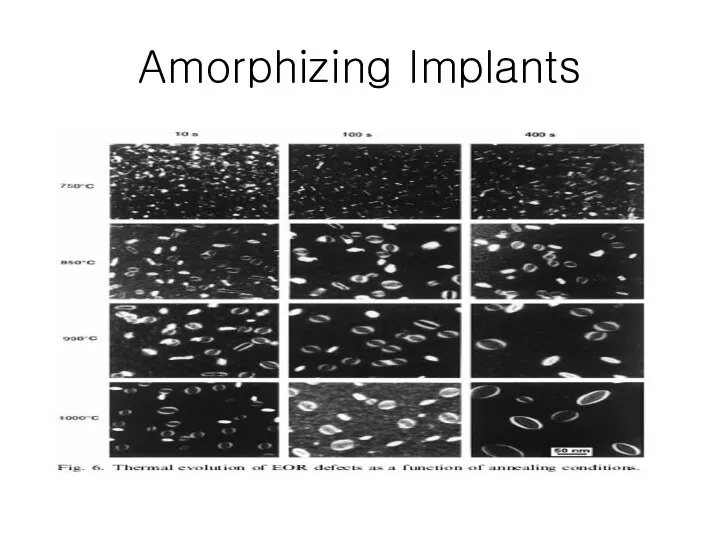

- 12. In the case of Amorphizing Implants Oswald ripening process; formation energy decreases as its size increases

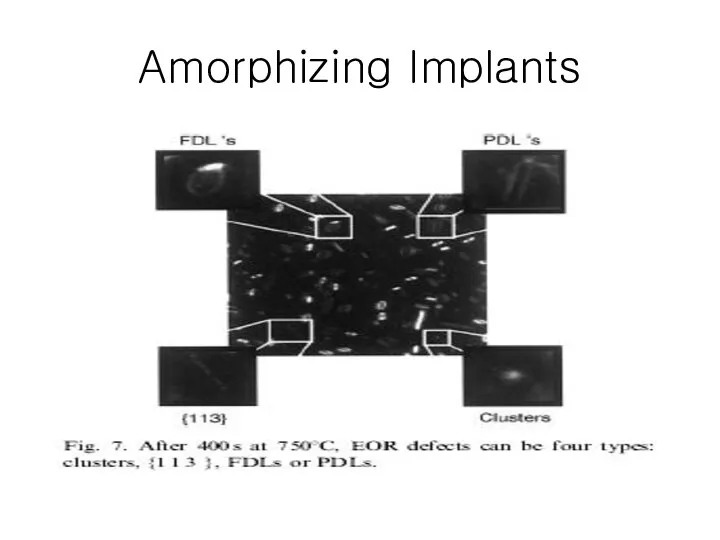

- 13. Amorphizing Implants Formation energy of PDLs higher than FDLs For low-budget thermal annealings, clusters and {113}

- 14. Amorphizing Implants

- 15. Amorphizing Implants

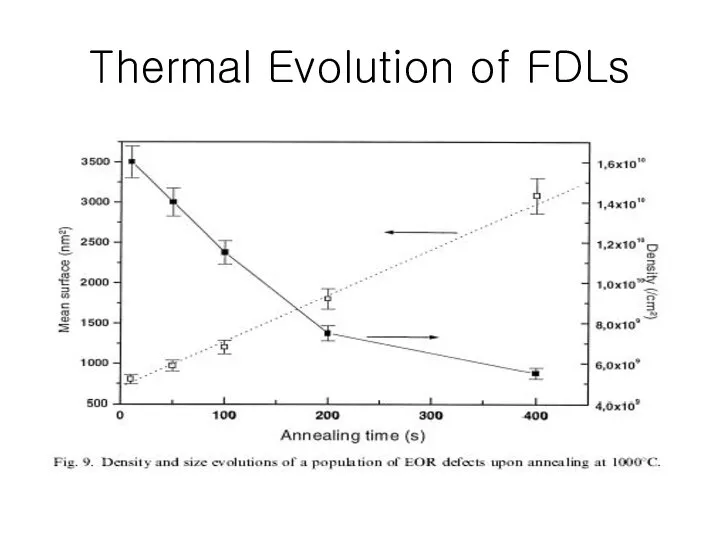

- 16. Thermal Evolution of FDLs

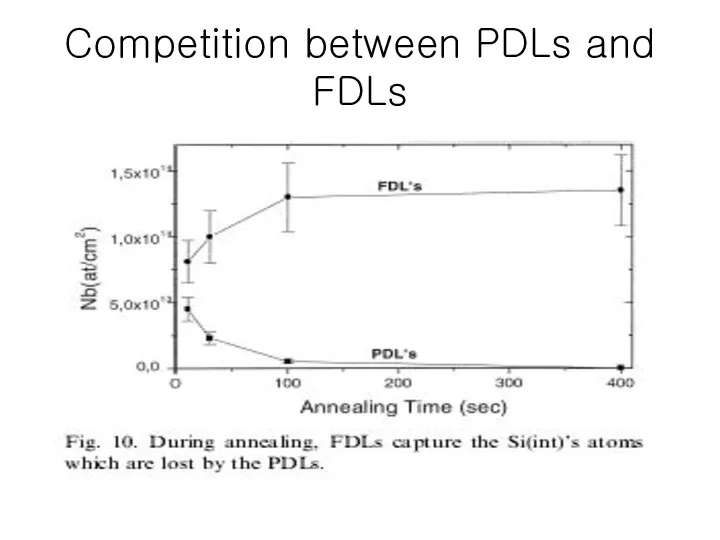

- 17. Competition between PDLs and FDLs

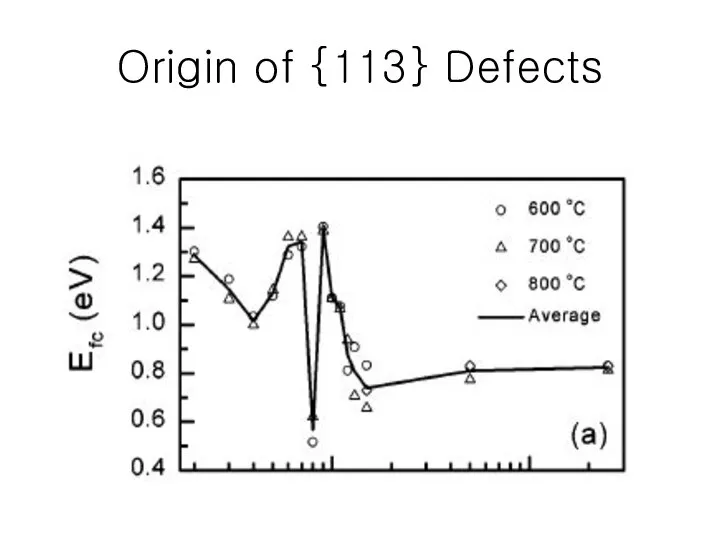

- 18. Origin of {113} Defects

- 19. Defect Evolution Di-interstitials {113} defects PDLs and FDLs FDLs Surface effect as a sink

- 20. Defect Evolution Driving force for the growth of a given type of defects is due to

- 22. Скачать презентацию

Электростатика. Электродинамика

Электростатика. Электродинамика Локальные системы молниезащиты объектов электроэнергетики

Локальные системы молниезащиты объектов электроэнергетики Квантово-полевая картина мира

Квантово-полевая картина мира Ренгенофлуоресцентный анализ

Ренгенофлуоресцентный анализ Биофизика, как наука. История и методология биофизики. Кинетика биологических процессов. Термодинамика биологических процессов

Биофизика, как наука. История и методология биофизики. Кинетика биологических процессов. Термодинамика биологических процессов Релейный регулятор для движения по границе черного и белого

Релейный регулятор для движения по границе черного и белого Космические скорости

Космические скорости Строение тел. Агрегатные состояния вещества и фазовые переходы. Законы термодинамики

Строение тел. Агрегатные состояния вещества и фазовые переходы. Законы термодинамики Модели распространения радиоволн, методы предсказания напряжённости поля и потерь распространения, применяемые МСЭ-R Модели расп

Модели распространения радиоволн, методы предсказания напряжённости поля и потерь распространения, применяемые МСЭ-R Модели расп Постоянный электрический ток. Характеристики электрической цепи. Действие электрического тока и правила техники безопасности

Постоянный электрический ток. Характеристики электрической цепи. Действие электрического тока и правила техники безопасности Современные проблемы физики наноструктурных материалов. Механические свойства и механизмы деформации наноматериалов

Современные проблемы физики наноструктурных материалов. Механические свойства и механизмы деформации наноматериалов Закон Ома для участка цепи

Закон Ома для участка цепи Источники звука. Характеристики звука.

Источники звука. Характеристики звука. Звуковые волны. Урок физики в 9 классе

Звуковые волны. Урок физики в 9 классе Теория электромагнитного поля

Теория электромагнитного поля Элементы машиноведения. Устройство бытовой швейной машины

Элементы машиноведения. Устройство бытовой швейной машины Источники света. Распространение света

Источники света. Распространение света Типовые гидродинамические модели ТОУ

Типовые гидродинамические модели ТОУ Фазированные антенные решетки и их назначение

Фазированные антенные решетки и их назначение Гидродинамика. Уравнение Бернулли. Подъемная сила. Течение вязкой жидкости. Формула Стокса. Обтекание тел

Гидродинамика. Уравнение Бернулли. Подъемная сила. Течение вязкой жидкости. Формула Стокса. Обтекание тел Шкала Р.А. Реомюра

Шкала Р.А. Реомюра Podstawowe pojęcia z zakresu RADIOMETRII

Podstawowe pojęcia z zakresu RADIOMETRII Основные понятия кинематики. Тест №1. 9 класс

Основные понятия кинематики. Тест №1. 9 класс Турбина, первичный двигатель с вращательным движением рабочего органа

Турбина, первичный двигатель с вращательным движением рабочего органа Частота. Маятник

Частота. Маятник Вывод формул веществ по массовым долям элементов

Вывод формул веществ по массовым долям элементов Новое состояние материи – кварк-глюонная плазма

Новое состояние материи – кварк-глюонная плазма Двигатель внутреннего сгорания

Двигатель внутреннего сгорания