Содержание

- 2. Sensors and Transducers (definition) Pr. Nazim Mir-Nasiri Sensors are used for an element which produces a

- 3. Sensors performance terminology and specifications Pr. Nazim Mir-Nasiri Range and span Range defines the limits between

- 4. Sensors performance terminology and specifications Pr. Nazim Mir-Nasiri Accuracy is the extend to which the value

- 5. Sensors performance terminology and specifications Pr. Nazim Mir-Nasiri Sensitivity is relationship indicating how much output you

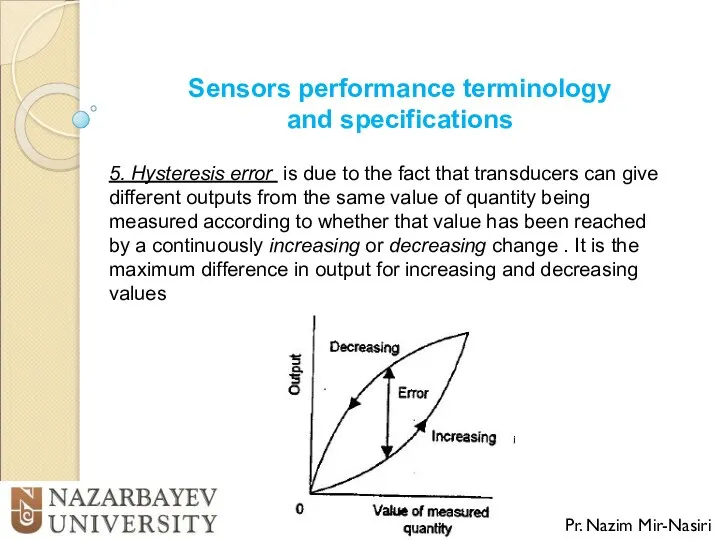

- 6. Sensors performance terminology and specifications Pr. Nazim Mir-Nasiri 5. Hysteresis error is due to the fact

- 7. Sensors performance terminology and specifications Pr. Nazim Mir-Nasiri 6. Non-linearity error is due to the fact

- 8. Sensors performance terminology and specifications Pr. Nazim Mir-Nasiri 6. Non-linearity error a. The error is defined

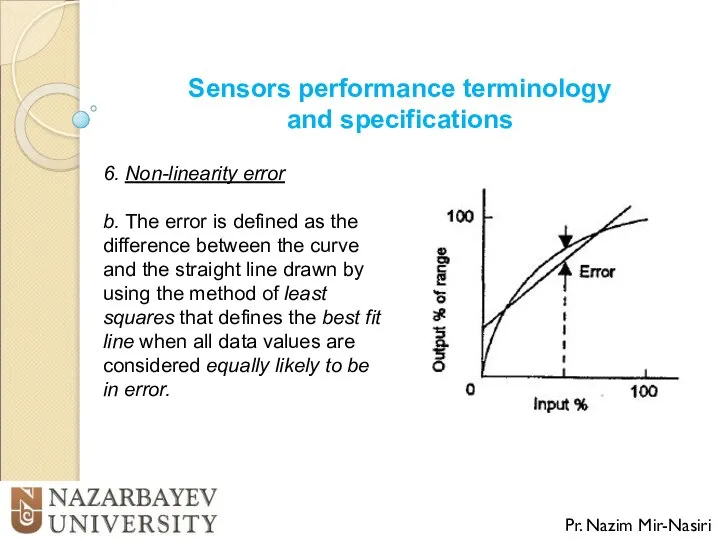

- 9. Sensors performance terminology and specifications Pr. Nazim Mir-Nasiri 6. Non-linearity error b. The error is defined

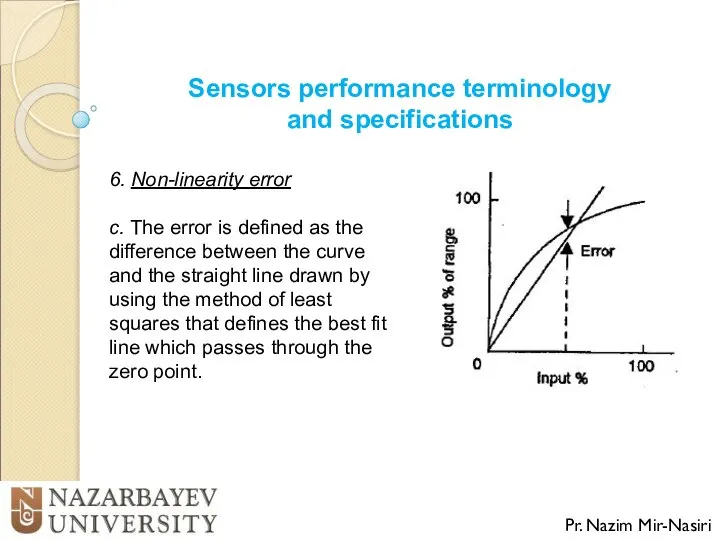

- 10. Sensors performance terminology and specifications Pr. Nazim Mir-Nasiri 6. Non-linearity error c. The error is defined

- 11. Sensors performance terminology and specifications Pr. Nazim Mir-Nasiri 7. Repeatability/reproducibility of a transducer are used to

- 12. Sensors performance terminology and specifications Pr. Nazim Mir-Nasiri 8. Stability of a transducer is its ability

- 13. Sensors performance terminology and specifications Pr. Nazim Mir-Nasiri 9. Dead band/time of a transducer is the

- 14. Sensors performance terminology and specifications Pr. Nazim Mir-Nasiri 10. Resolution. When the input varies continuously over

- 15. Sensors performance terminology and specifications Pr. Nazim Mir-Nasiri 11. Output impedance When a sensor giving an

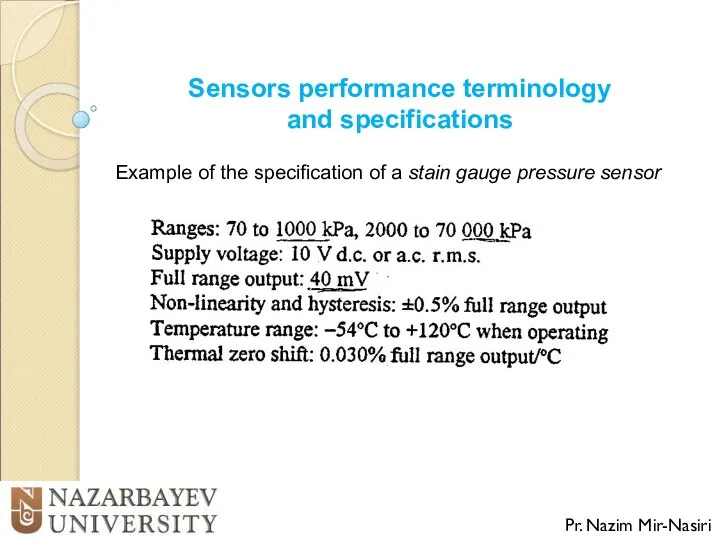

- 16. Sensors performance terminology and specifications Pr. Nazim Mir-Nasiri Example of the specification of a stain gauge

- 17. Static and Dynamic Characteristics of Sensors Pr. Nazim Mir-Nasiri The static characteristics are the values given

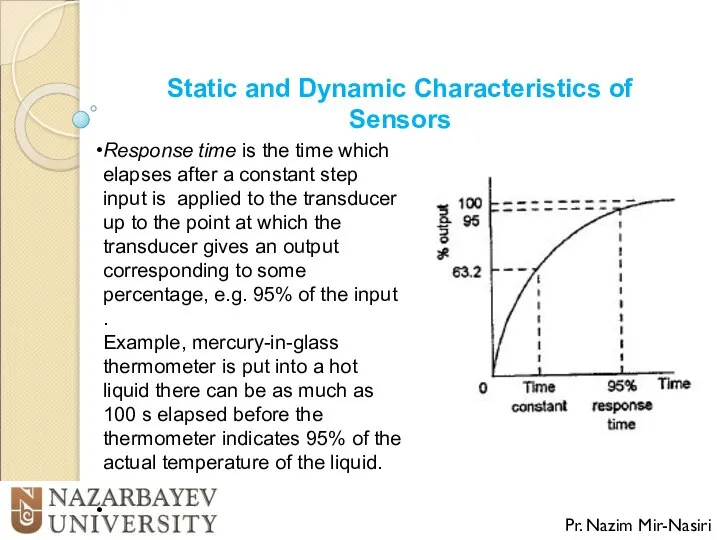

- 18. Static and Dynamic Characteristics of Sensors Pr. Nazim Mir-Nasiri Response time is the time which elapses

- 19. Static and Dynamic Characteristics of Sensors Pr. Nazim Mir-Nasiri Time constant is the 63.2% response time.

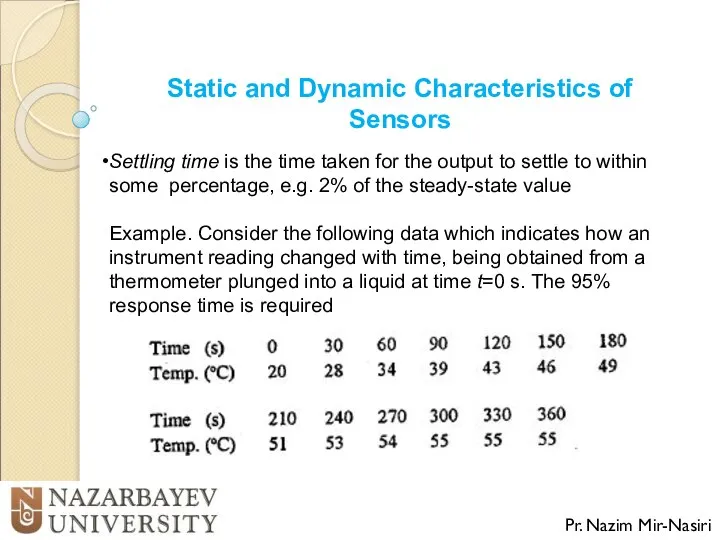

- 20. Static and Dynamic Characteristics of Sensors Pr. Nazim Mir-Nasiri Settling time is the time taken for

- 21. Static and Dynamic Characteristics of Sensors Pr. Nazim Mir-Nasiri Example. Fig. shows the graph of how

- 23. Скачать презентацию

Презентация по физике "«Источники электрического тока»" - скачать

Презентация по физике "«Источники электрического тока»" - скачать  Закон сохранения механической энергии. Механические колебания

Закон сохранения механической энергии. Механические колебания Система Интернет-олимпиад СПбГУ Тренировка 10 класс

Система Интернет-олимпиад СПбГУ Тренировка 10 класс Автоматика. Типовые звенья САУ и их свойства

Автоматика. Типовые звенья САУ и их свойства Создание транспортно-энергетического модуля на основе ядерной энергодвигательной установки мегаваттного класса

Создание транспортно-энергетического модуля на основе ядерной энергодвигательной установки мегаваттного класса Физические взрывы

Физические взрывы Обобщающий урок по теме «Давление твердых тел, жидкостей и газов.» 7класс учитель Васильева М.В. 2009 год

Обобщающий урок по теме «Давление твердых тел, жидкостей и газов.» 7класс учитель Васильева М.В. 2009 год Экспериментальные доказательства существования спина и магнитного момента электрона

Экспериментальные доказательства существования спина и магнитного момента электрона Сообщающиеся сосуды

Сообщающиеся сосуды Основы молекулярной физики Раздел Молекулярно-кинетическая теория идеальных газов

Основы молекулярной физики Раздел Молекулярно-кинетическая теория идеальных газов  Презентация по физике "Основные характеристики звёзд" - скачать

Презентация по физике "Основные характеристики звёзд" - скачать  Ионизирующее излучение

Ионизирующее излучение Пара сил. (Лекция 3)

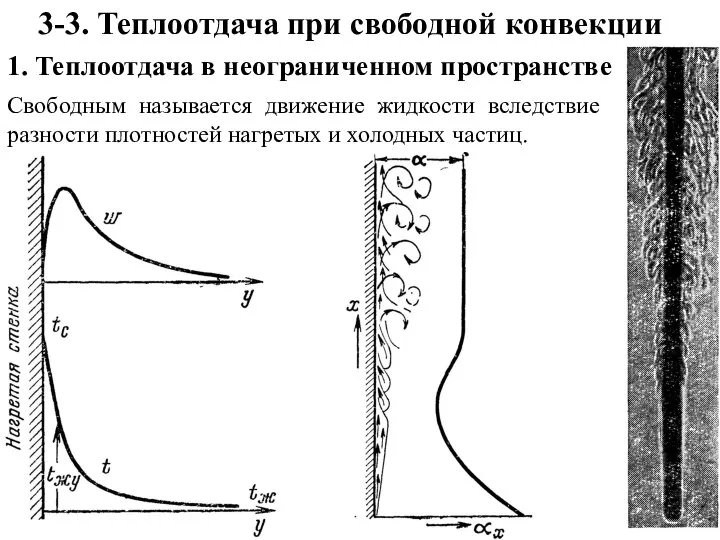

Пара сил. (Лекция 3) Теплоотдача при свободной конвекции. Теплоотдача в неограниченном пространстве

Теплоотдача при свободной конвекции. Теплоотдача в неограниченном пространстве Д/з

Д/з Газодинамический расчет пограничного слоя на плоской пластине, обтекаемой потоком вязкого газа

Газодинамический расчет пограничного слоя на плоской пластине, обтекаемой потоком вязкого газа Работа (7 класс)

Работа (7 класс) Графическое представление тепловых процессов Т.И. Звягина, 2012 г. ГБОУ СОШ № 644 г. Санкт-Петербург

Графическое представление тепловых процессов Т.И. Звягина, 2012 г. ГБОУ СОШ № 644 г. Санкт-Петербург Барометр - анероид Вавилова В.Н. МБОУ СОШ №8 г. Ельца

Барометр - анероид Вавилова В.Н. МБОУ СОШ №8 г. Ельца Сила Ампера. Движение заряженных частиц в магнитном поле. Задачи

Сила Ампера. Движение заряженных частиц в магнитном поле. Задачи Проект “Дизельный двигатель”

Проект “Дизельный двигатель” Расчет сопротивления проводников

Расчет сопротивления проводников Презентация по физике "Реактивное движение физика" - скачать

Презентация по физике "Реактивное движение физика" - скачать  Приборы для измерения давления

Приборы для измерения давления Сложный теплообмен и теплопередача

Сложный теплообмен и теплопередача Основы молекулярной физики и термодинамики

Основы молекулярной физики и термодинамики Энергия и движение. Источники энергии

Энергия и движение. Источники энергии Нанотехнологии. Технологии в современном мире

Нанотехнологии. Технологии в современном мире