Содержание

- 2. Basic connverter /transmission theory movie

- 3. TE transmissions Electronic controlled modulation Clutch overlap control Inching control

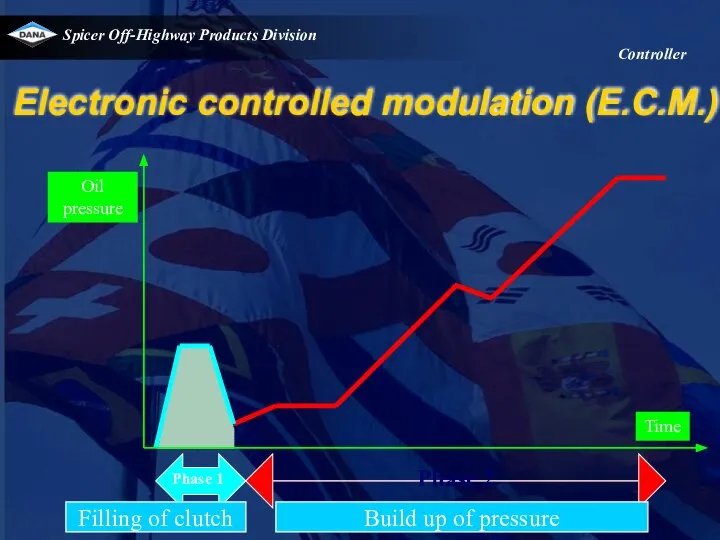

- 4. Electronic controlled modulation (E.C.M.) Controller

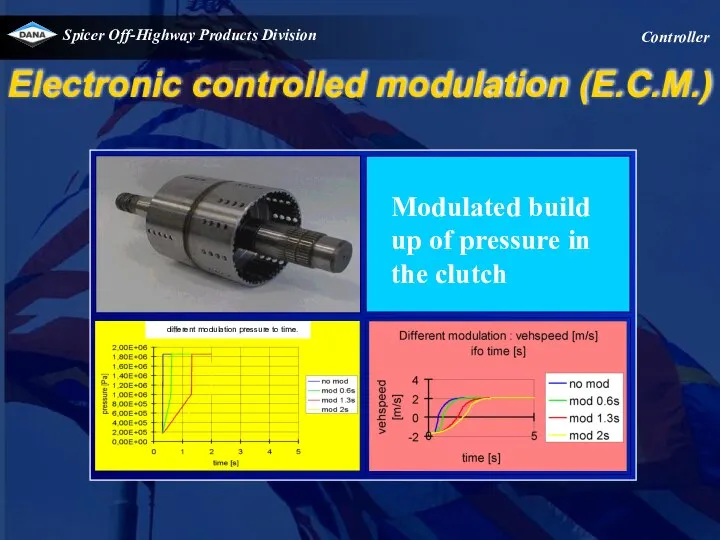

- 5. Modulated build up of pressure in the clutch Electronic controlled modulation (E.C.M.) Controller different modulation pressure

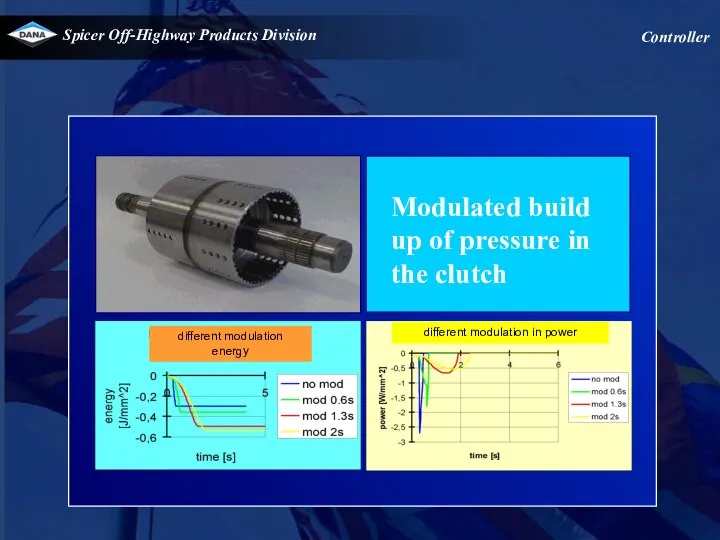

- 6. Modulated build up of pressure in the clutch Controller different modulation energy different modulation in power

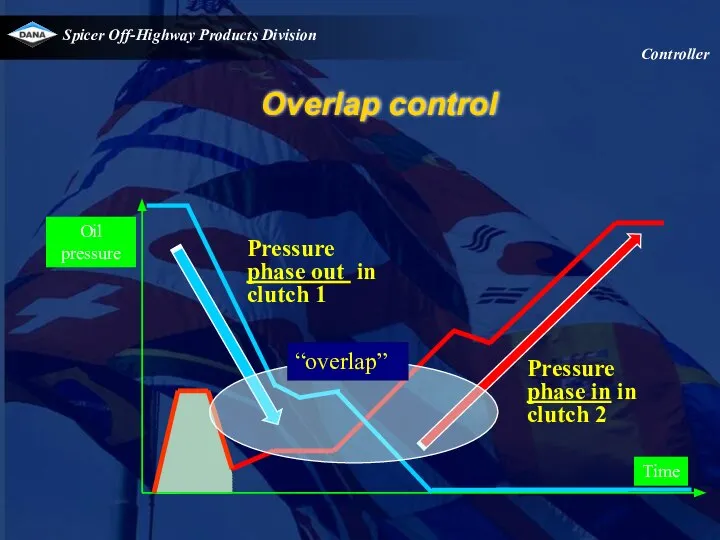

- 7. Overlap control Controller

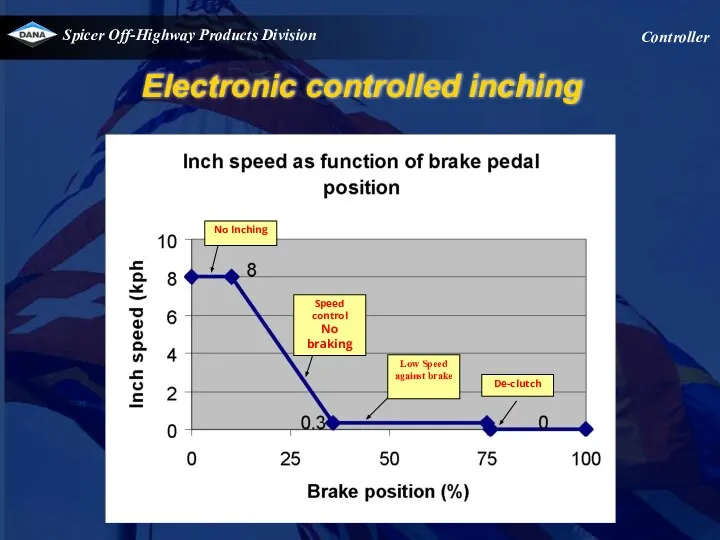

- 8. Electronic controlled inching Controller

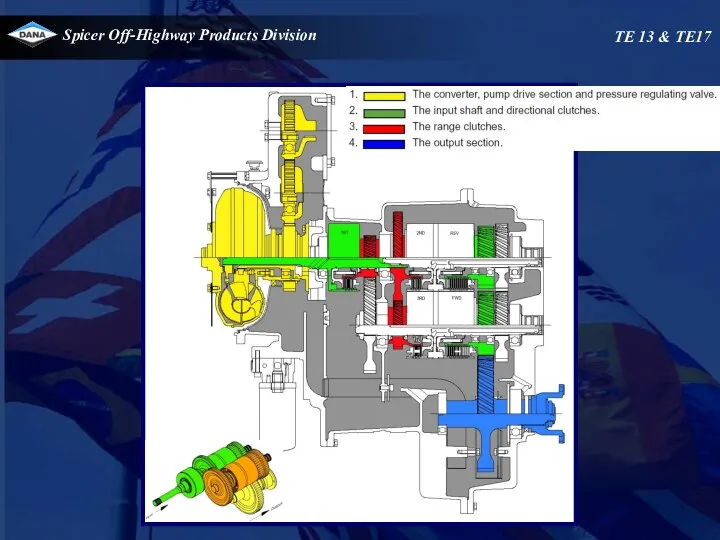

- 9. TE13/17 transmission

- 10. TE 13 & TE17

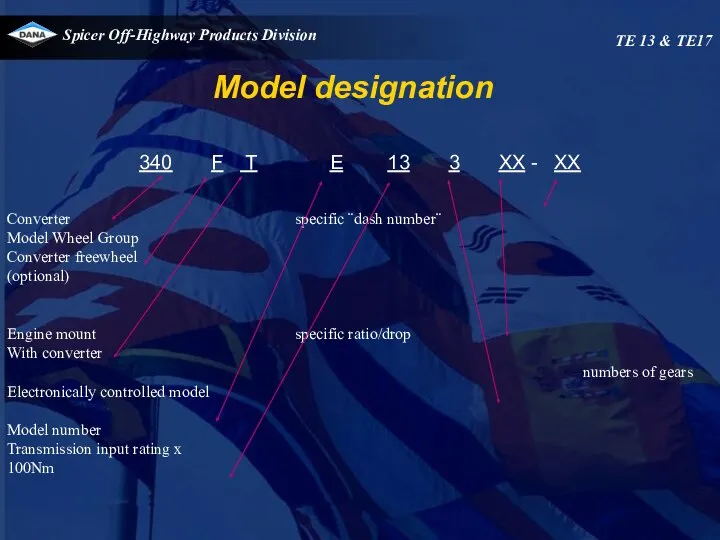

- 11. 340 F T E 13 3 XX - XX Converter specific ¨dash number¨ Model Wheel Group

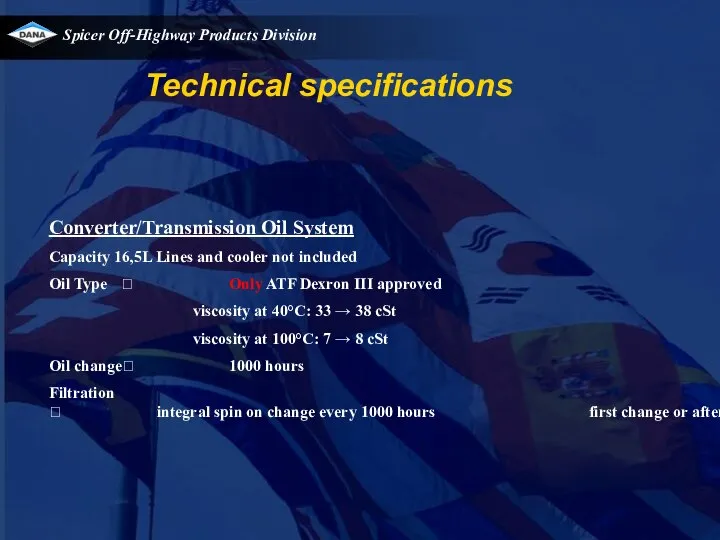

- 12. Converter/Transmission Oil System Capacity 16,5L Lines and cooler not included Oil Type ? Only ATF Dexron

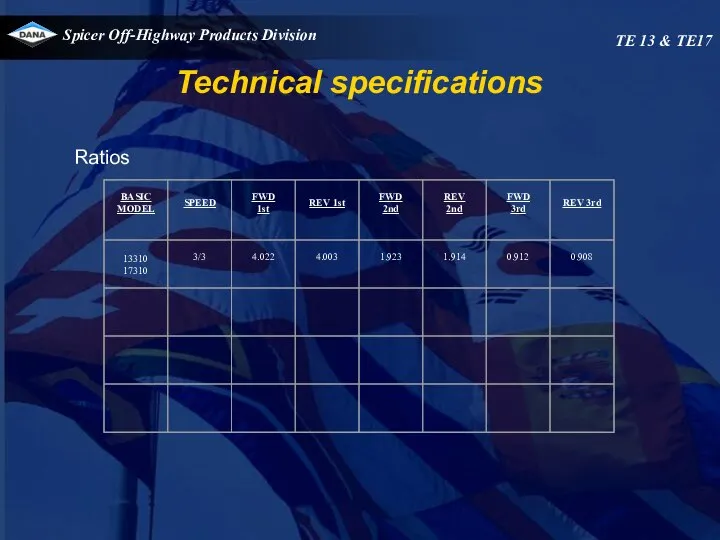

- 13. Ratios Technical specifications TE 13 & TE17

- 14. Temperature specifications Normal operating temperature 70 - 120°C at temperature check port 71 converter out Maximum

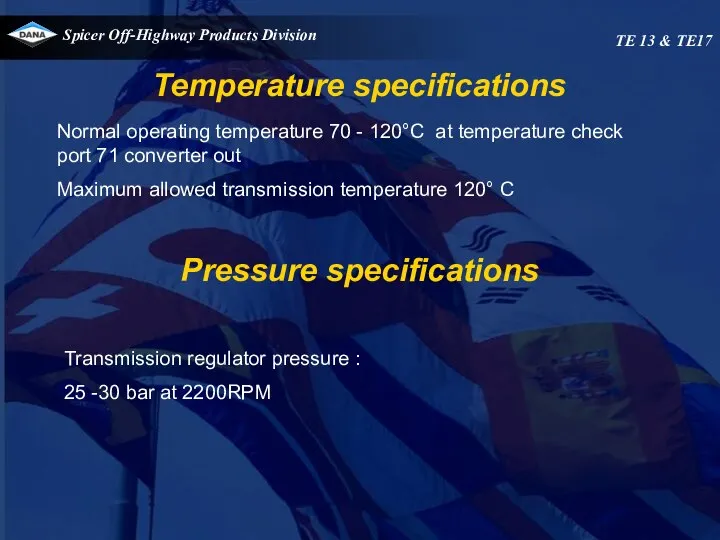

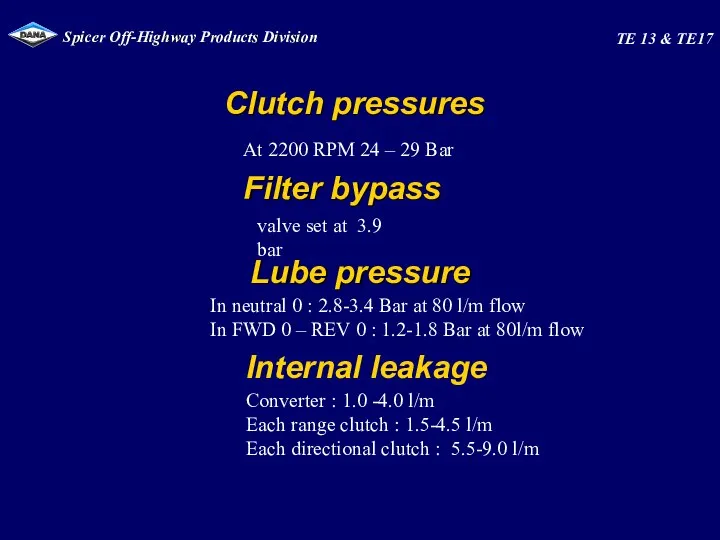

- 15. At 2200 RPM 24 – 29 Bar Converter : 1.0 -4.0 l/m Each range clutch :

- 16. Safety valve cracking pressure 7,5 bar Converter out pressure (to cooler) 3.0 – 3.5 bar. at

- 17. Pump flow At 2200 RPM : 90 to 110 lpm TE 13 & TE17

- 18. Electrical specifications TE 13 & TE17

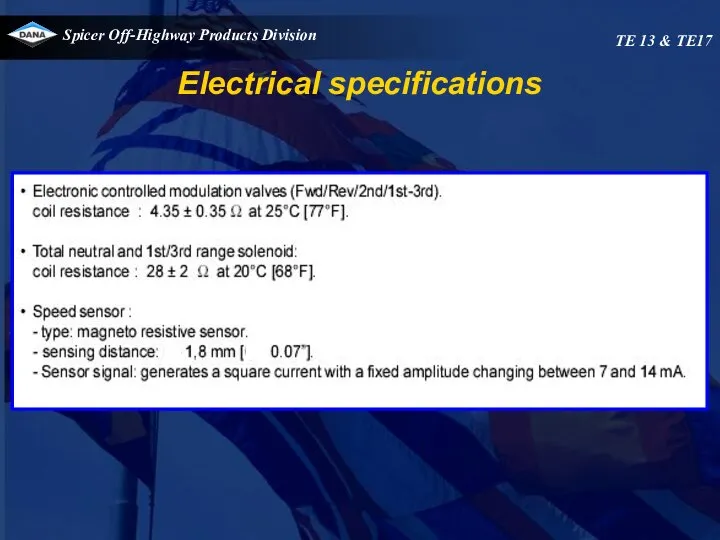

- 19. HYDRAULIC COOLER LINES SPECIFICATIONS. Minimum 19 mm internal diameter for lines and fittings. Suitable for operation

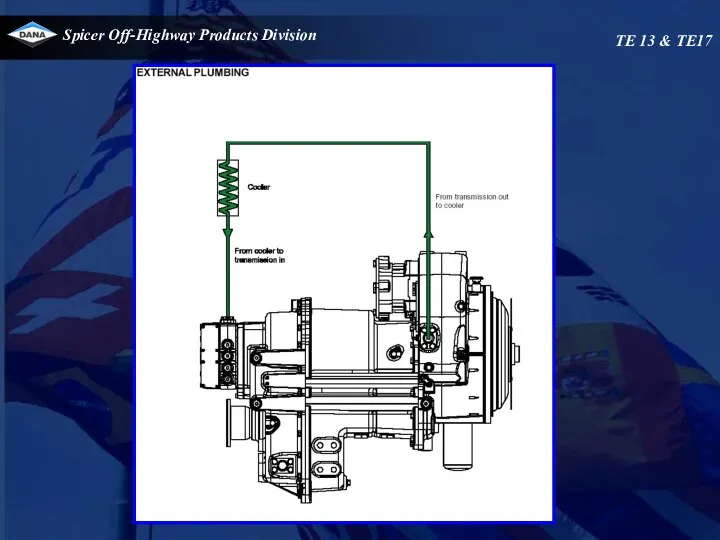

- 20. TE 13 & TE17

- 21. Additional signals Speed sensors Engine speed combined with oil temperature pick up located at pump gear

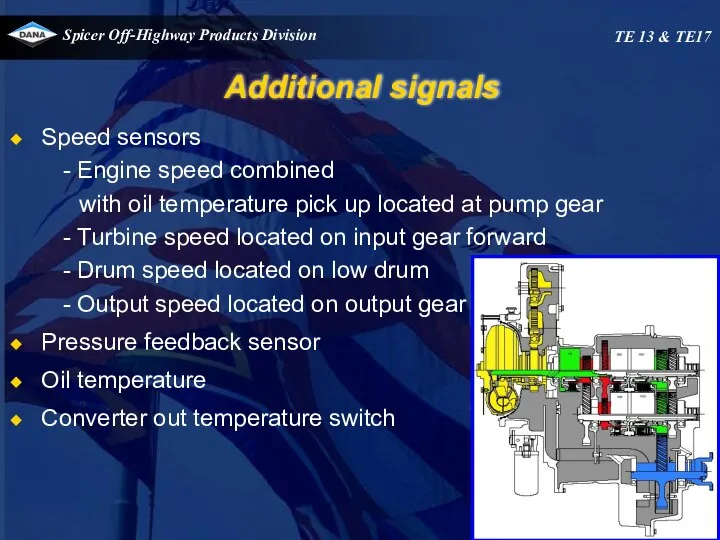

- 22. Wiring schematics TE 13 & TE17 Total neutral

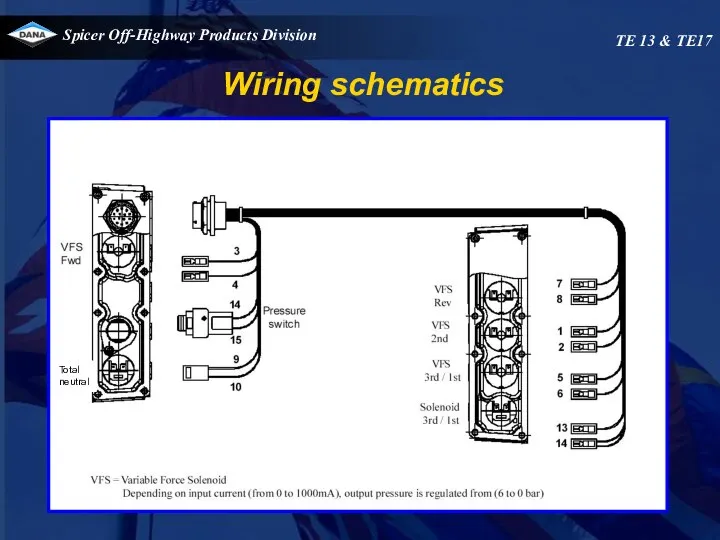

- 23. Wiring schematics TE 13 & TE17

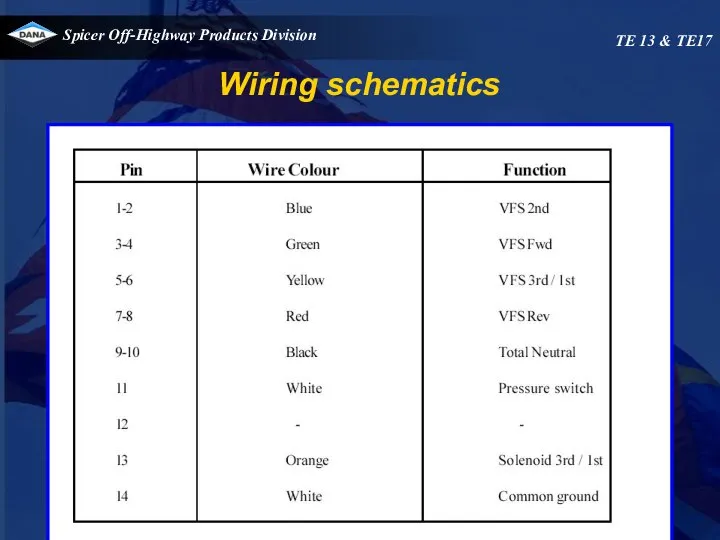

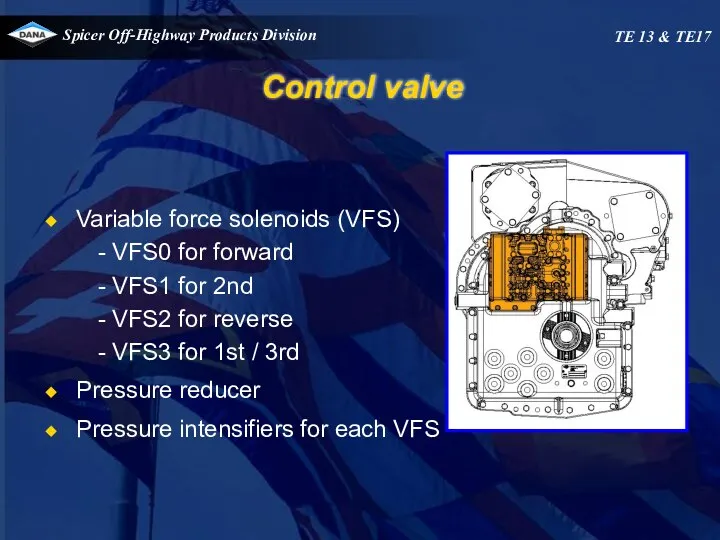

- 24. Control valve Variable force solenoids (VFS) VFS0 for forward VFS1 for 2nd VFS2 for reverse VFS3

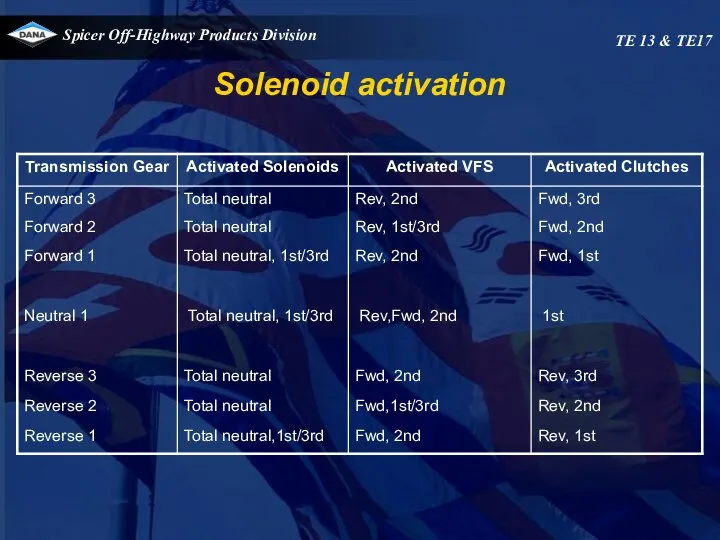

- 25. Solenoid activation TE 13 & TE17

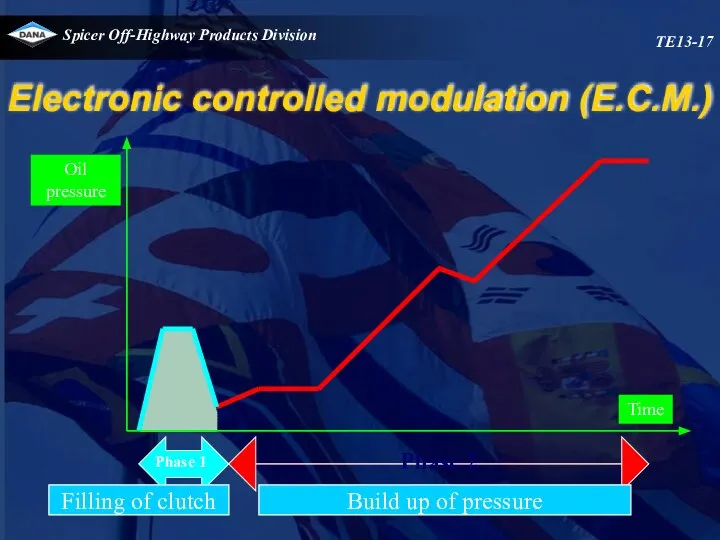

- 26. Electronic controlled modulation (E.C.M.) TE13-17

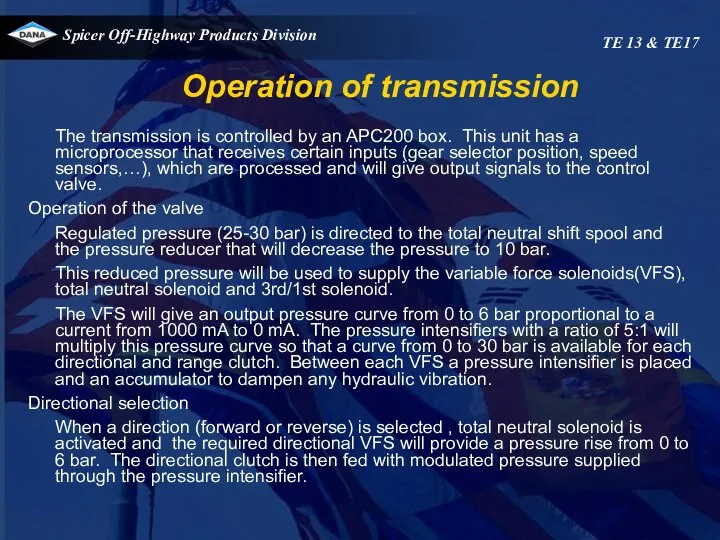

- 27. Operation of transmission TE 13 & TE17 The transmission is controlled by an APC200 box. This

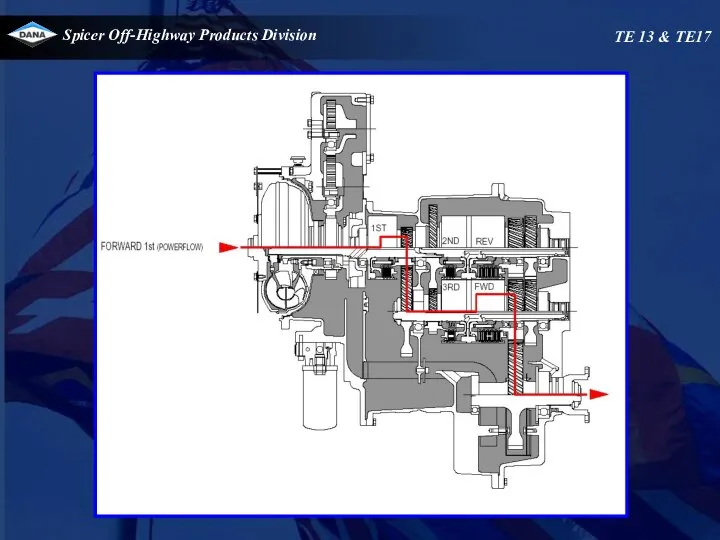

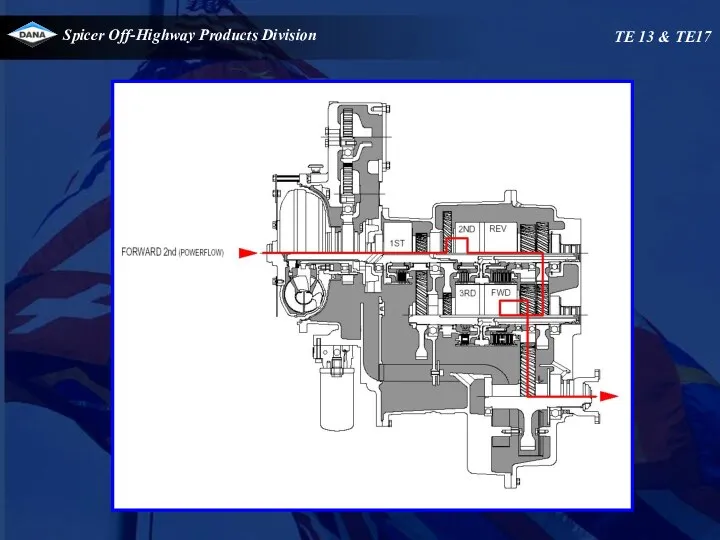

- 28. Operation of transmission TE 13 & TE17 Range selection When 1 st clutch is selected ,

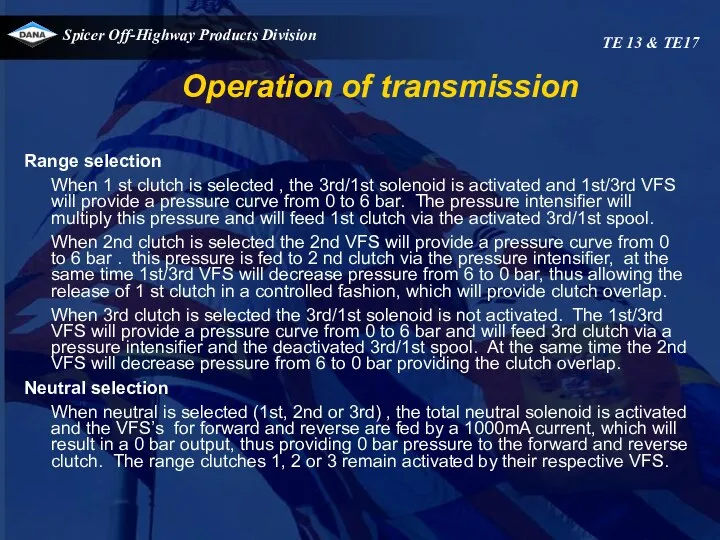

- 29. Operation of transmission TE 13 & TE17 Total neutral selection Total neutral is only selected by

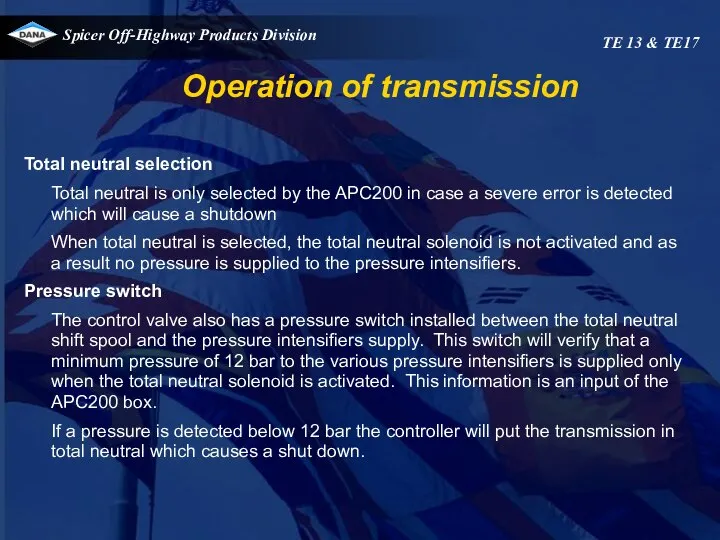

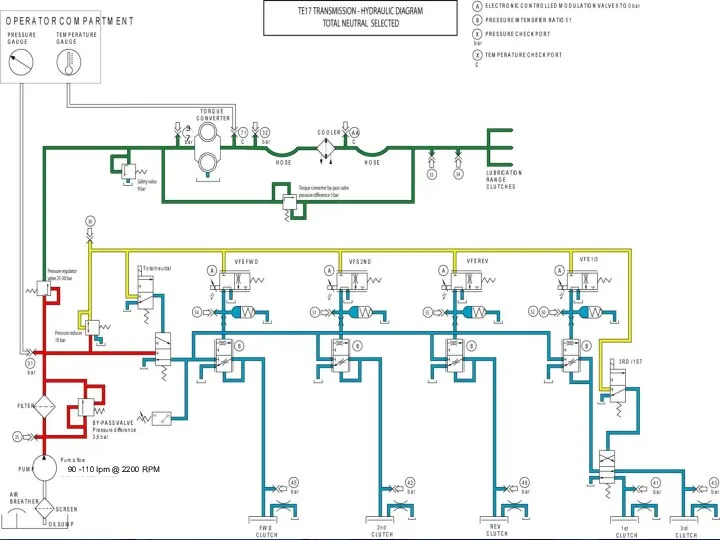

- 30. TE 13 & TE17 37 90 -110 lpm @ 2200 RPM

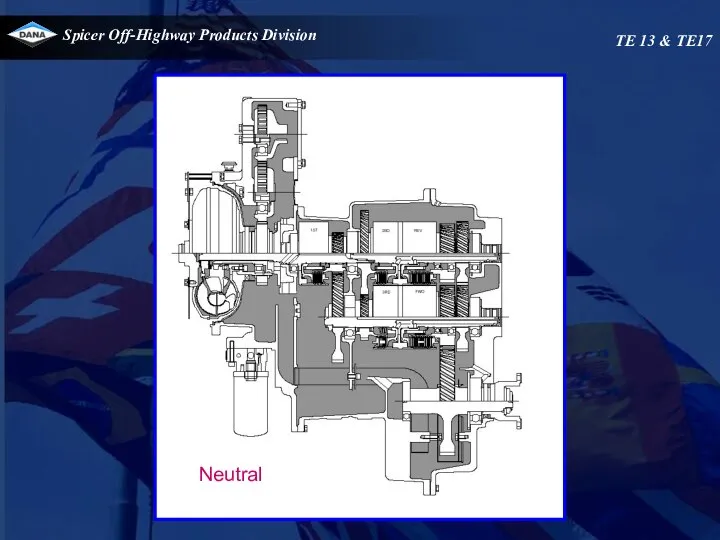

- 31. Neutral TE 13 & TE17

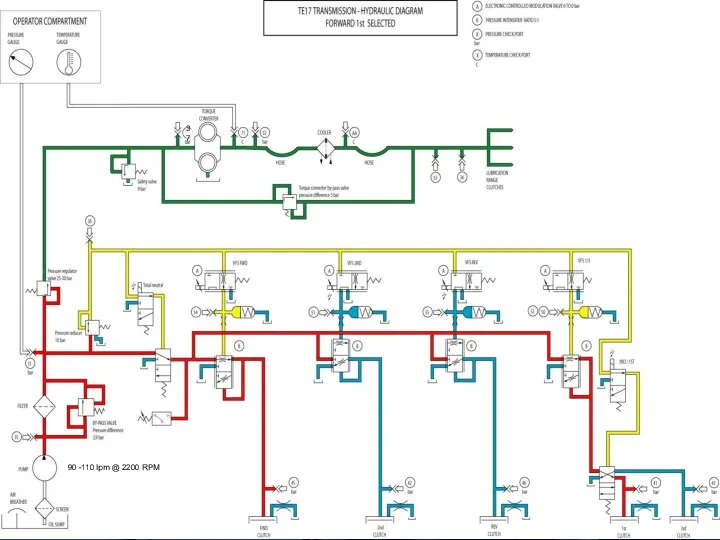

- 32. TE 13 & TE17 90 -110 lpm @ 2200 RPM 37

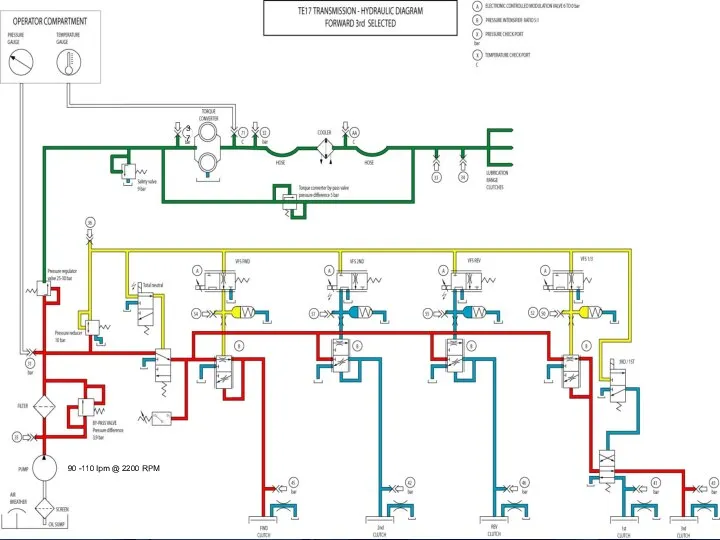

- 33. TE 13 & TE17

- 34. TE 13 & TE17 90 -110 lpm @ 2200 RPM 37

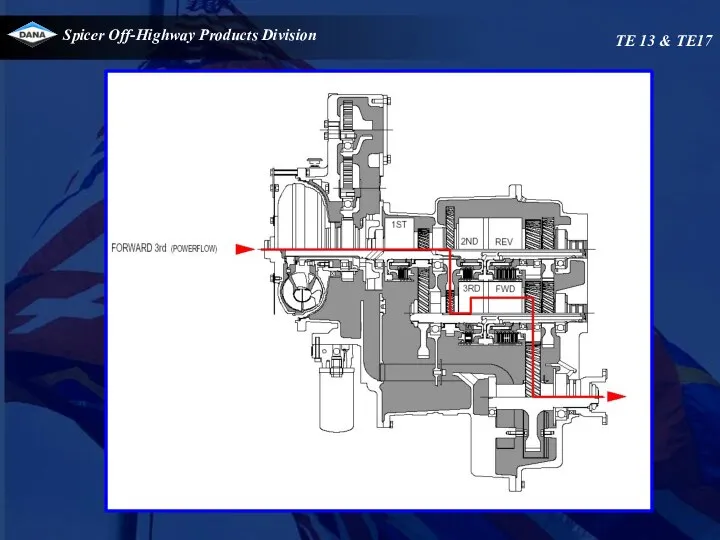

- 35. TE 13 & TE17

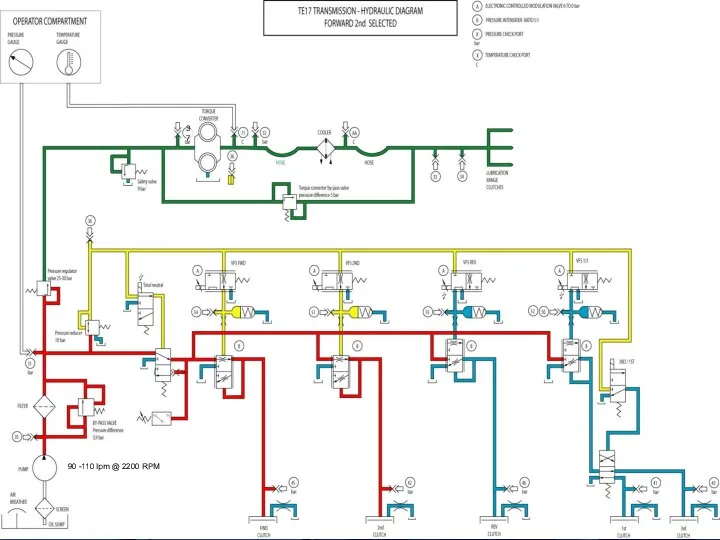

- 36. TE 13 & TE17 90 -110 lpm @ 2200 RPM 37

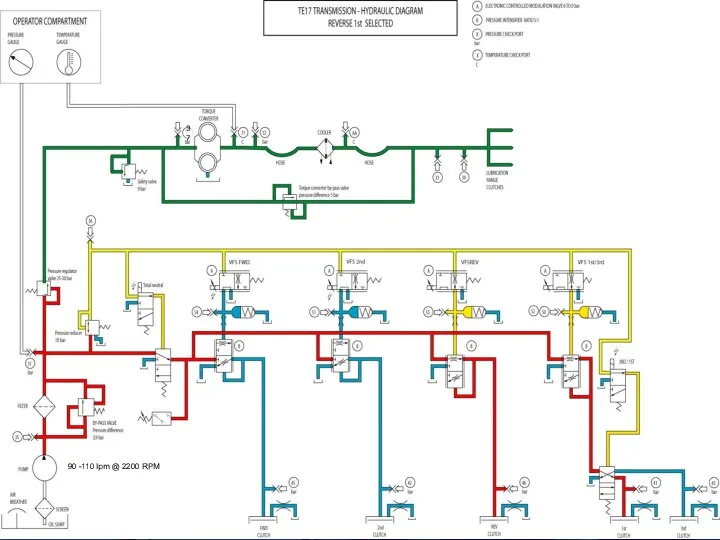

- 37. TE 13 & TE17

- 38. TE 13 & TE17 90 -110 lpm @ 2200 RPM 37

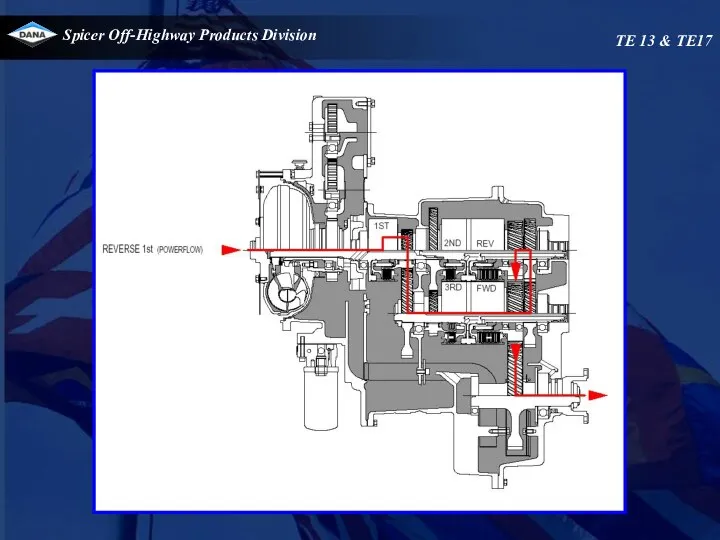

- 39. TE 13 & TE17

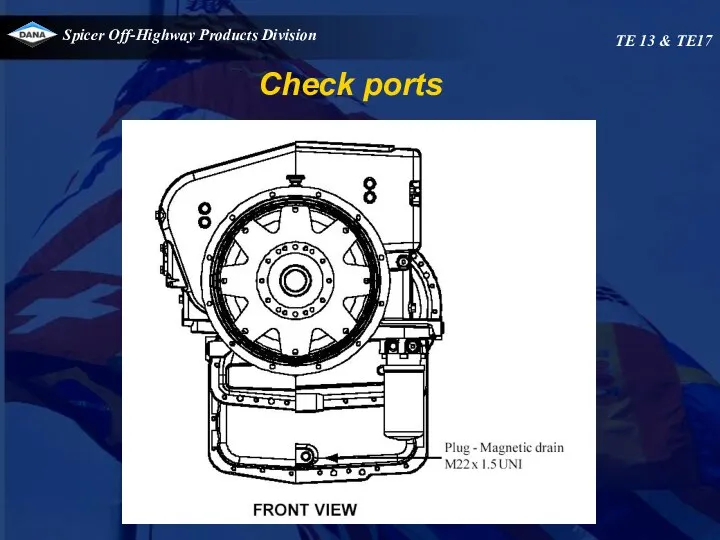

- 40. Check ports TE 13 & TE17

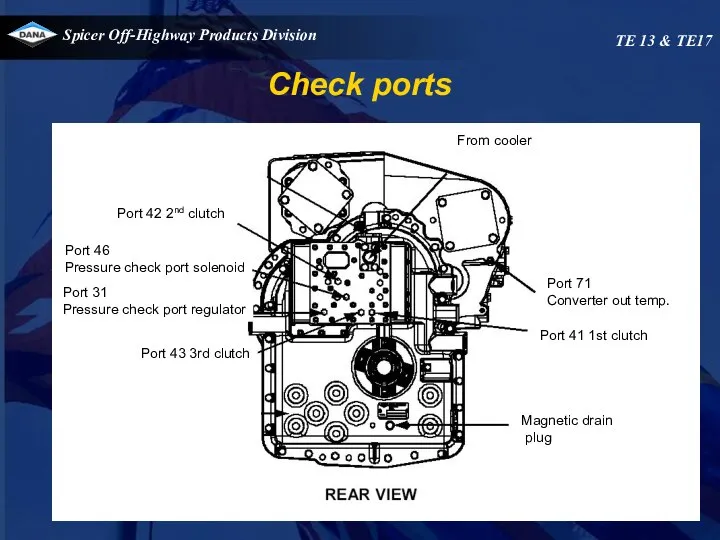

- 41. Check ports TE 13 & TE17 Port 42 2nd clutch Port 46 Pressure check port solenoid

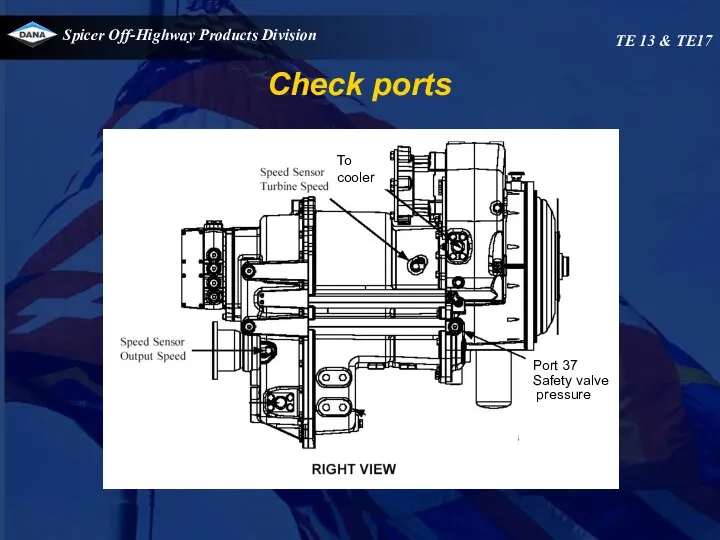

- 42. Check ports TE 13 & TE17 To cooler Port 37 Safety valve pressure Safaty valve mmmpressure

- 43. Check ports TE 13 & TE17 Safaty valve pressure Engine

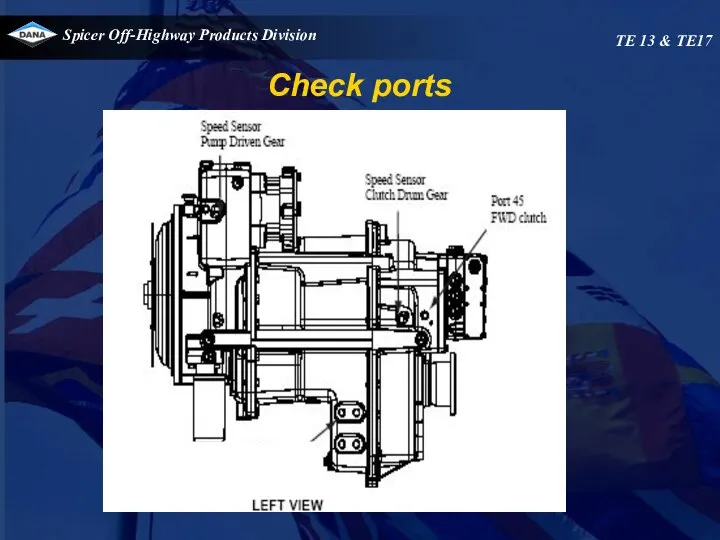

- 44. Check ports TE 13 & TE17 Port 46 Rev. clutch Rev. clutch Pump Pressure Port 35

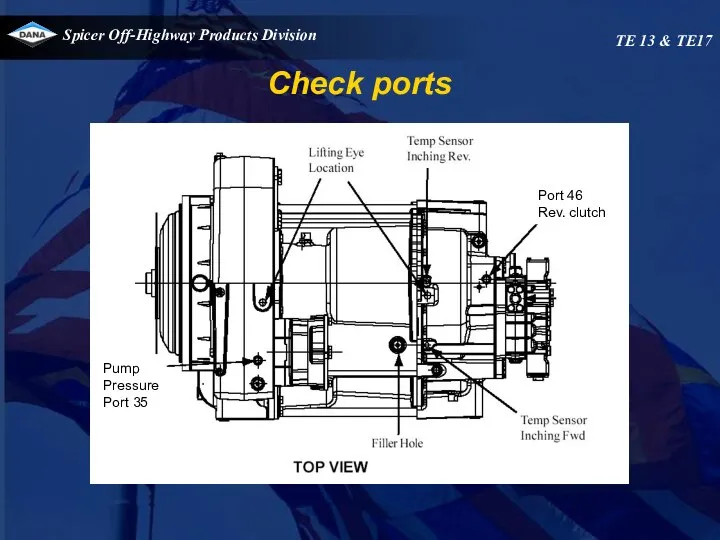

- 45. Check ports TE 13 & TE17 Pressure To cooler Port 32

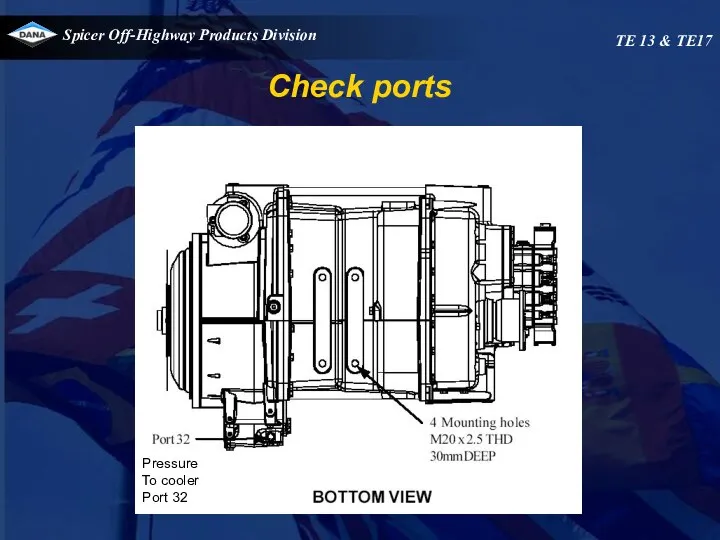

- 46. Check ports Control valve TE 13 & TE17 VFS REV Port 55 VFS 2nd Port 51

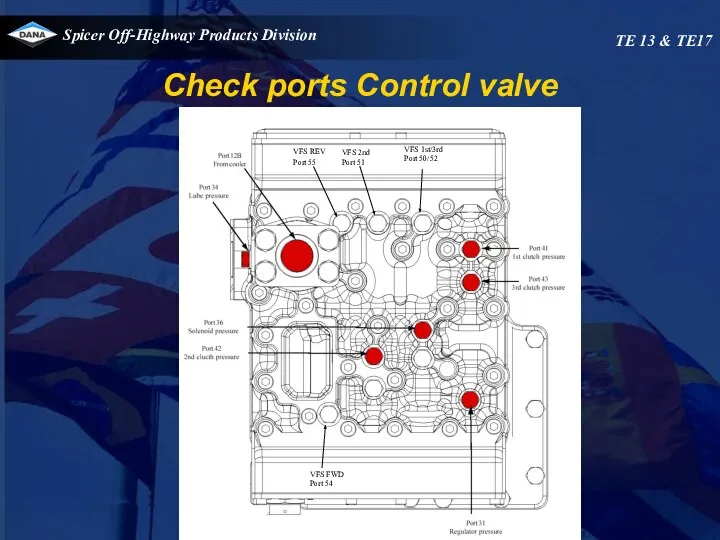

- 47. Control valve installation instruction Removing the valve 1.Make sure that the area around the valve is

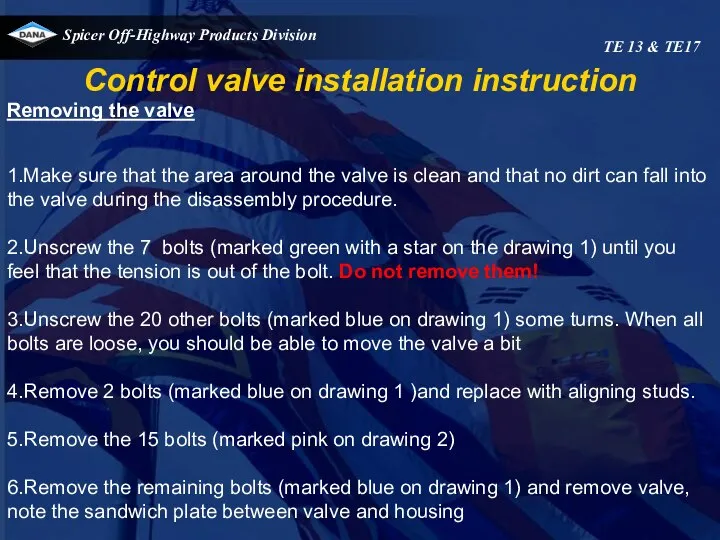

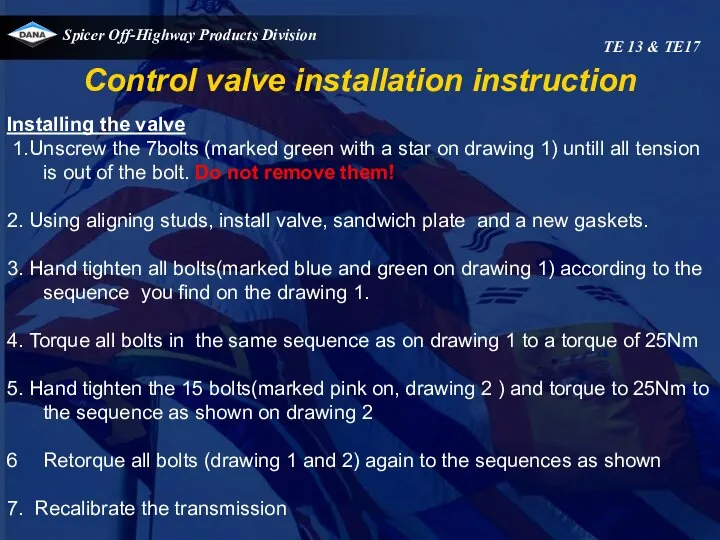

- 48. Control valve installation instruction Installing the valve 1.Unscrew the 7bolts (marked green with a star on

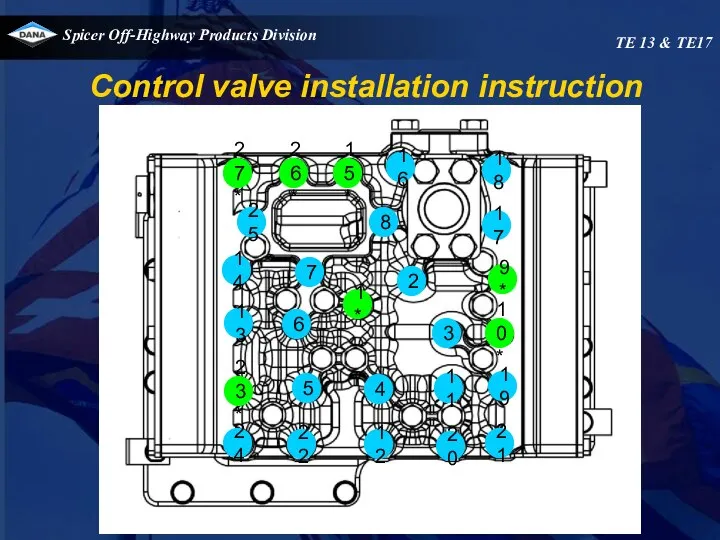

- 49. 27* 26* 15* 16 18 25 24 22 12 20 21 23* 5 4 11 19

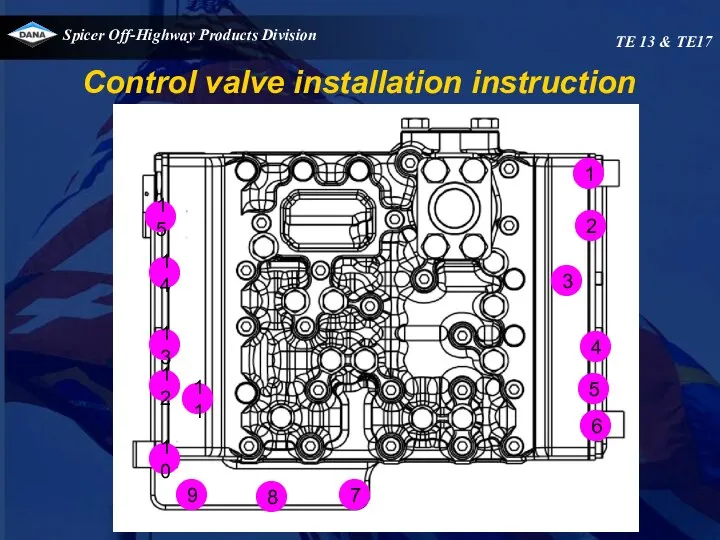

- 50. Control valve installation instruction TE 13 & TE17 15 9 8 7 10 11 12 13

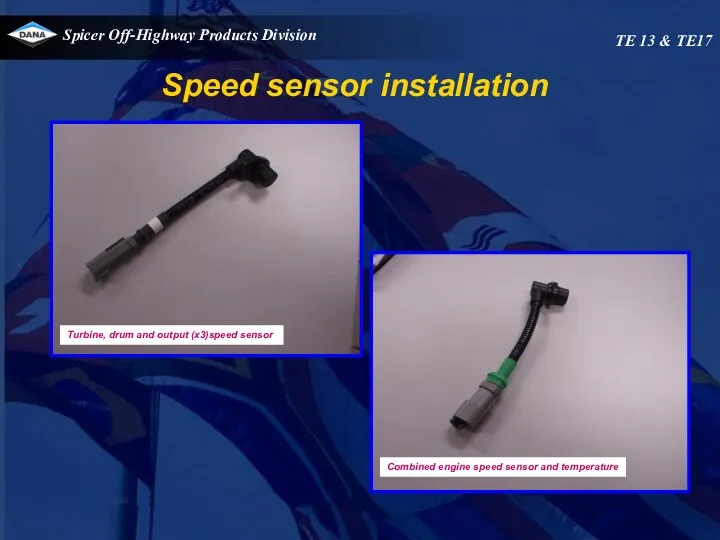

- 51. Speed sensor installation TE 13 & TE17 Combined engine speed sensor and temperature Turbine, drum and

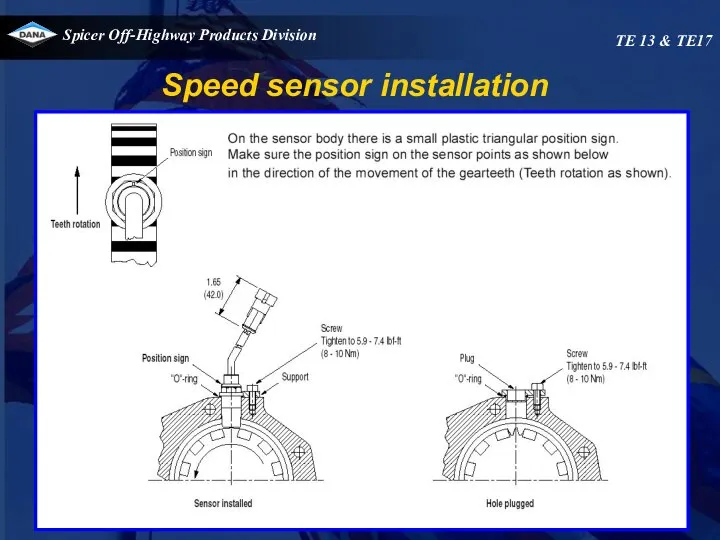

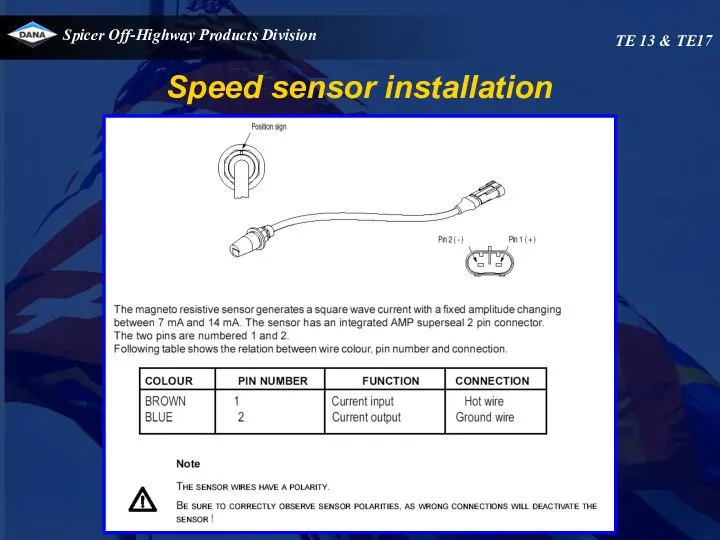

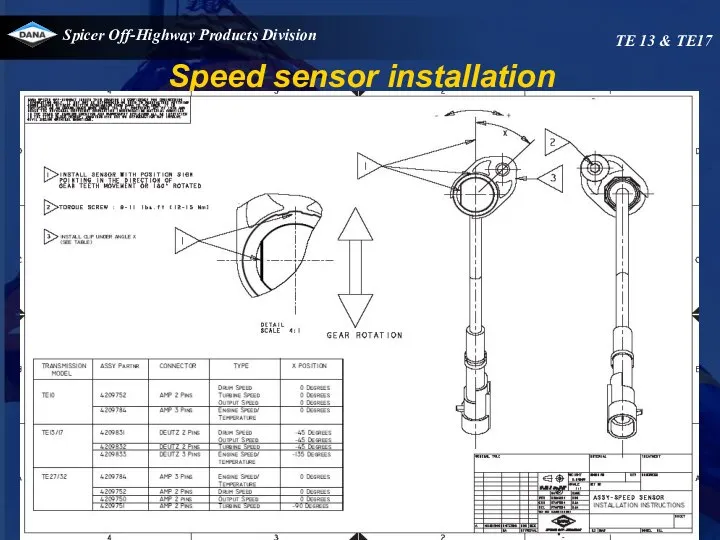

- 52. Speed sensor installation TE 13 & TE17

- 53. Speed sensor installation TE 13 & TE17

- 54. Speed sensor installation TE 13 & TE17

- 55. TE32 transmission

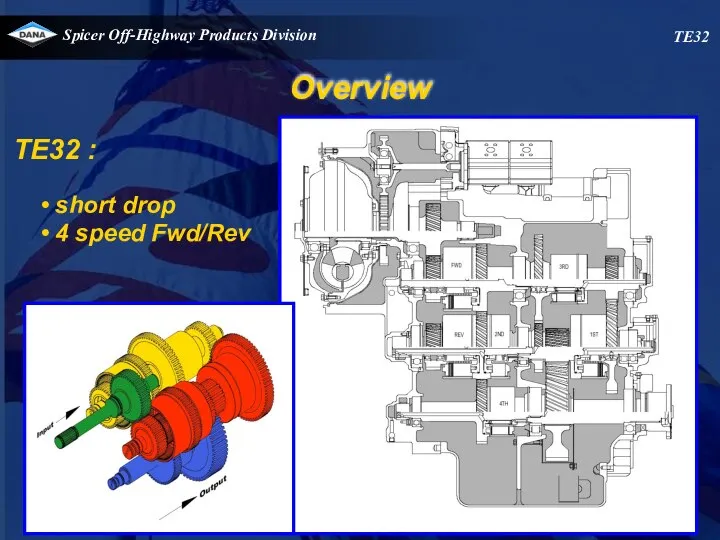

- 56. Overview TE32 TE32 : short drop 4 speed Fwd/Rev

- 57. TE32 Transmission Layout

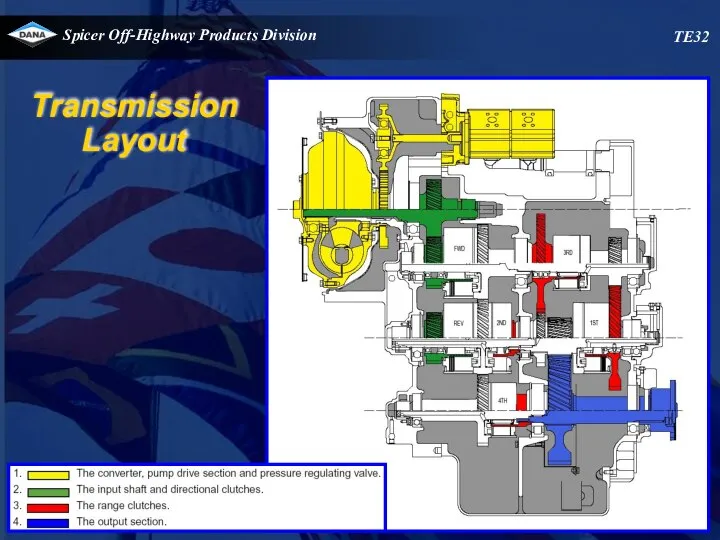

- 58. 1X.X T E 32 4 X X - XX Converter specific ¨dash number¨ Model Wheel Group

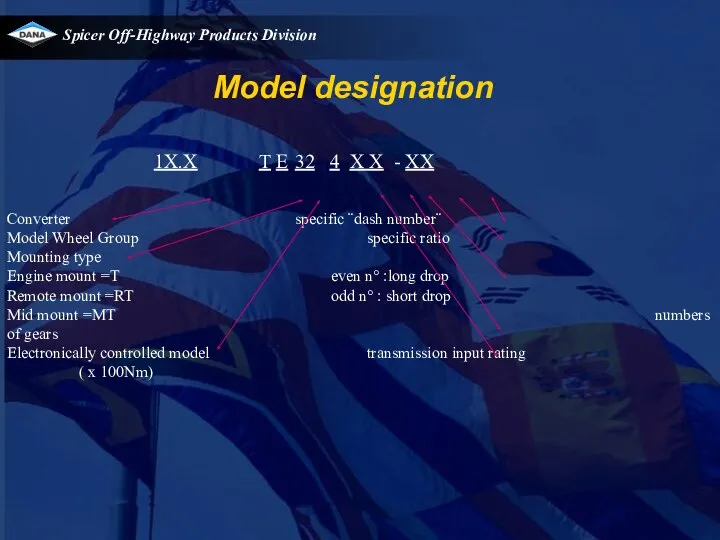

- 59. TE32 Technical specifications Ratio TE32418

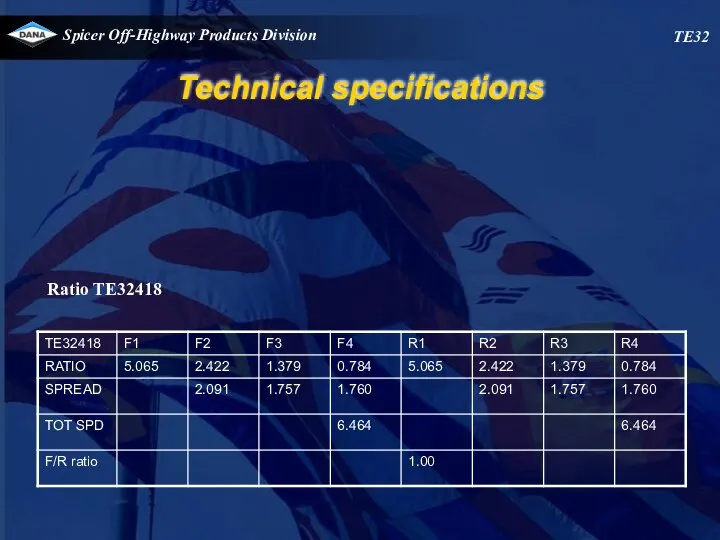

- 60. TE32 Technical specifications Output flange rotation – (transmission forward clutch engaged) Model Output Short Drop Opposite

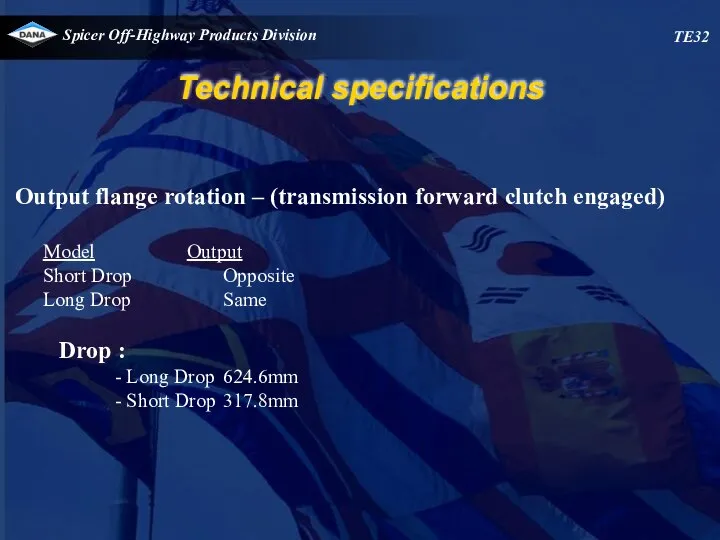

- 61. Speed pick-up : - Engine speed combined with temperature located on pump drive gear Turbine speed

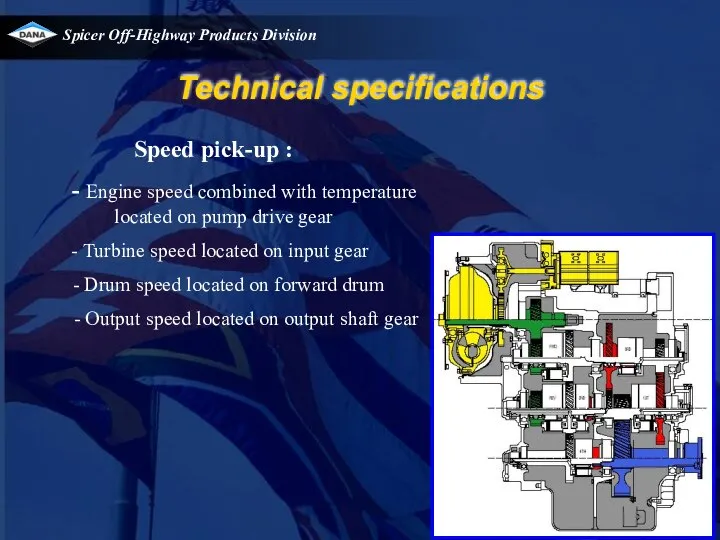

- 62. TE32 Technical specifications Converter/Transmission Oil System Capacity (Approximate: measured at 600 RPM input speed and oil

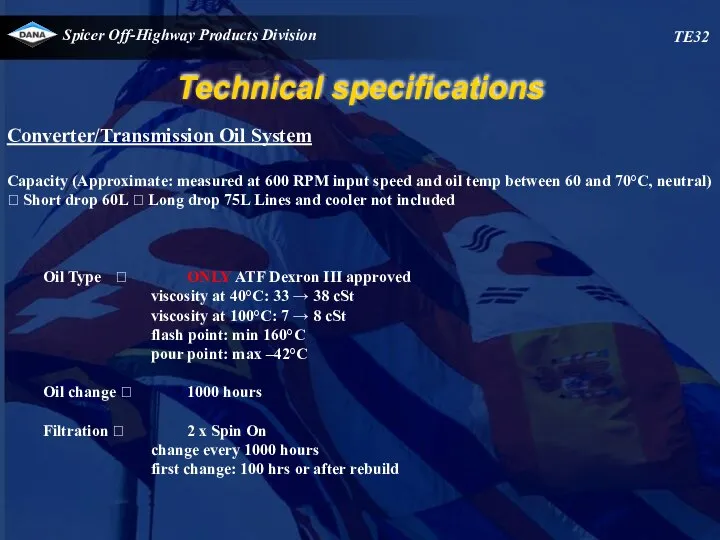

- 63. Normal operating temperature 70 - 120°C at temperature check port converter out Maximum allowed transmission temperature

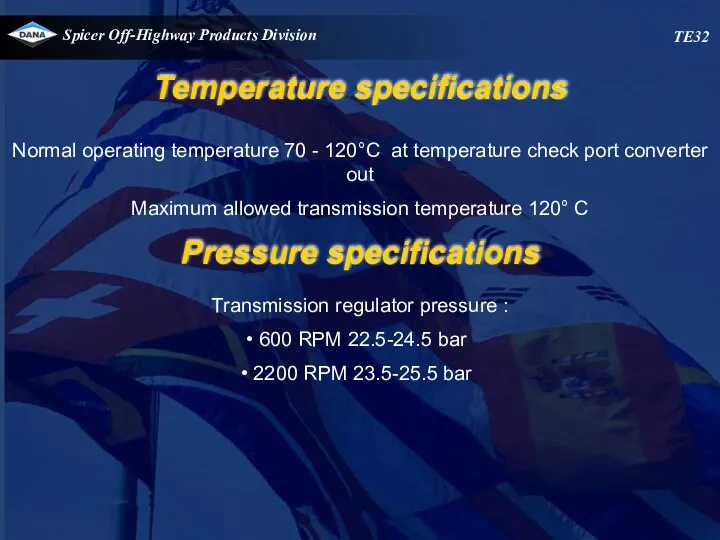

- 64. At 1800 RPM 20.5 - 24.5 bar Fwd/Rev max 4 l/min 1st max 9.2 l/min 2nd/3rd/4th

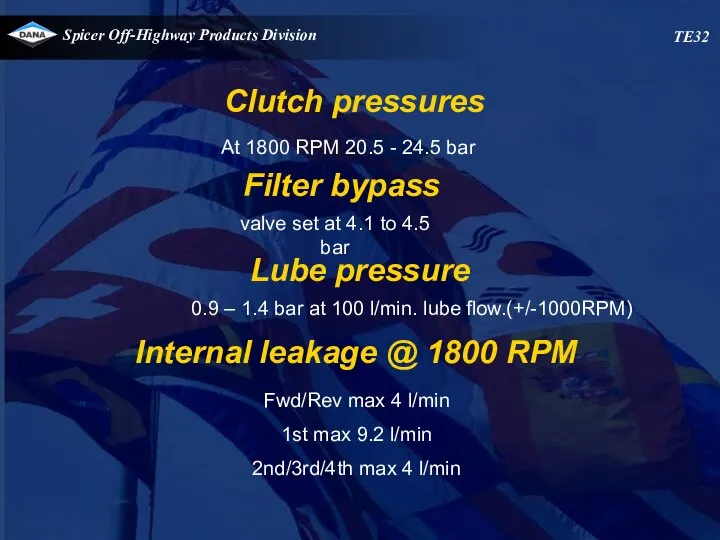

- 65. Savety valve cracking pressure 8.8-9.6 bar Converter out pressure (to cooler) 5 bar min. at 2000

- 66. Variable force solenoids(VFS) VFS 2nd/4th - VFS 1st/3rd - VFS Fwd -VFS Rev Coil resistance 4.35

- 67. Speed sensors Type Magneto resistive sensor. Sensing distance up to 1.8 mm Sensor signal generates a

- 68. HYDRAULIC COOLER LINES SPECIFICATIONS. Minimum 32 mm internal diameter for lines and fittings. Suitable for operation

- 69. TE32

- 70. Additional signals Speed sensors Engine speed combined with oil temperature pick up located at pump gear

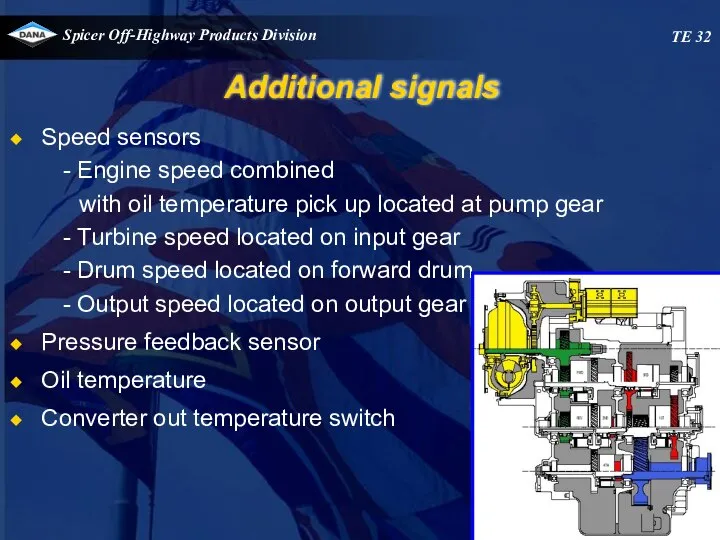

- 71. Wiring schematics TE 32

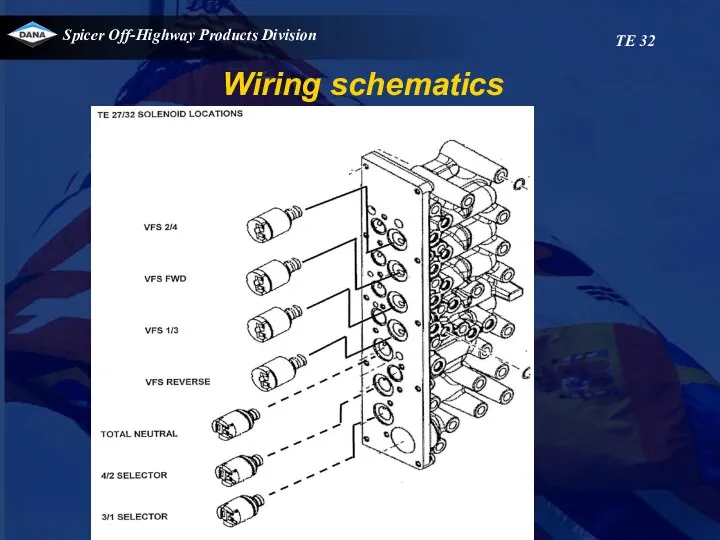

- 72. Wiring schematics TE 32

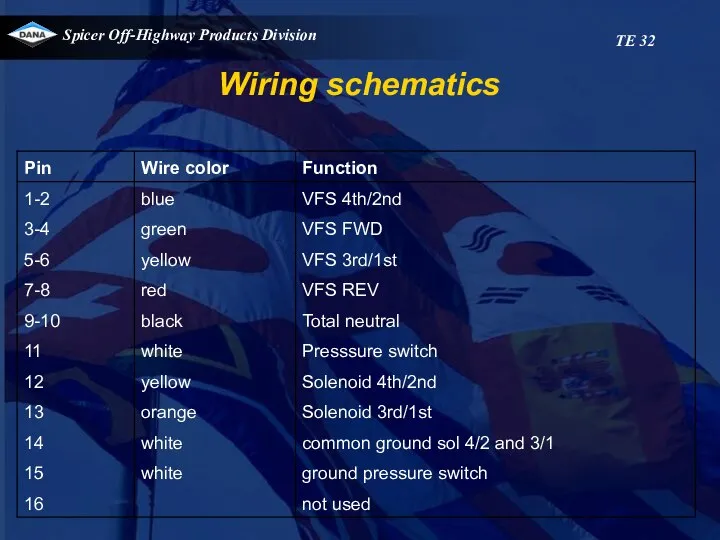

- 73. TE32 Solenoids activated Transmission gear Forward 4 Forward 3 Forward 2 Forward 1 Neutral 4 Neutral

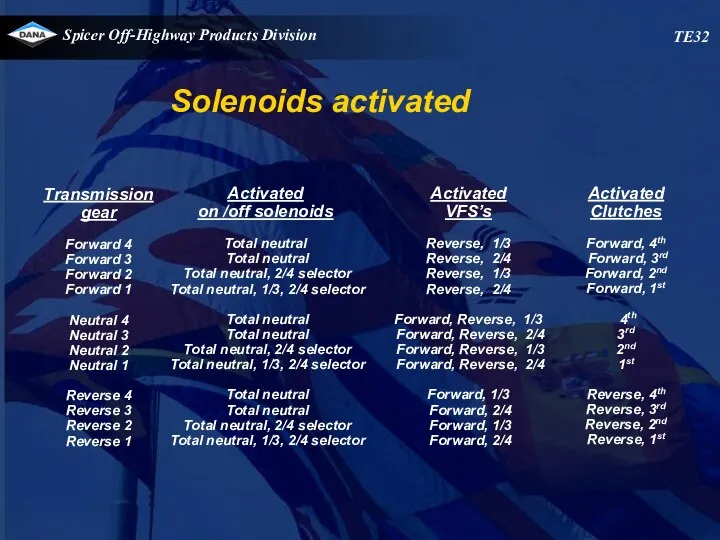

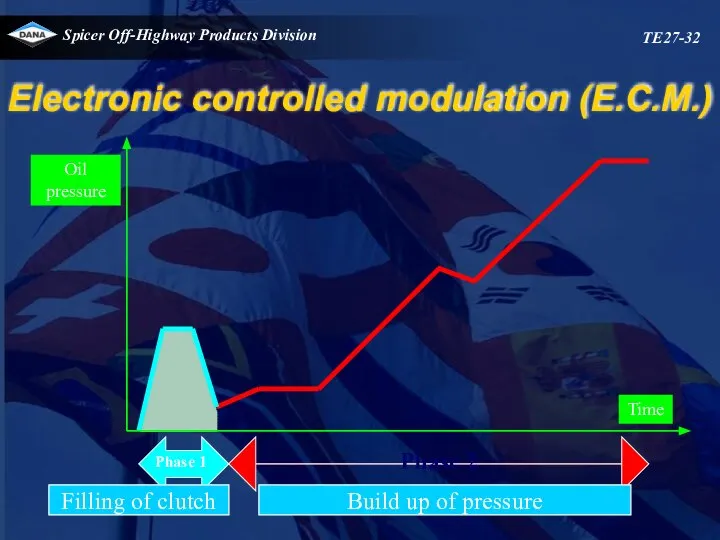

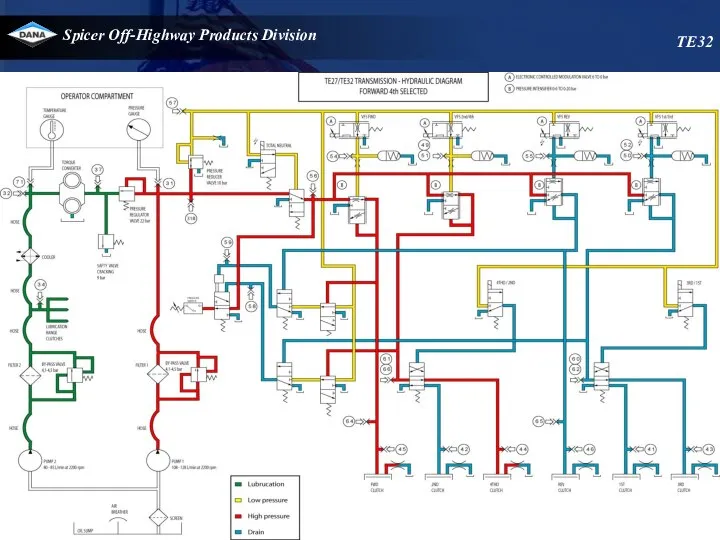

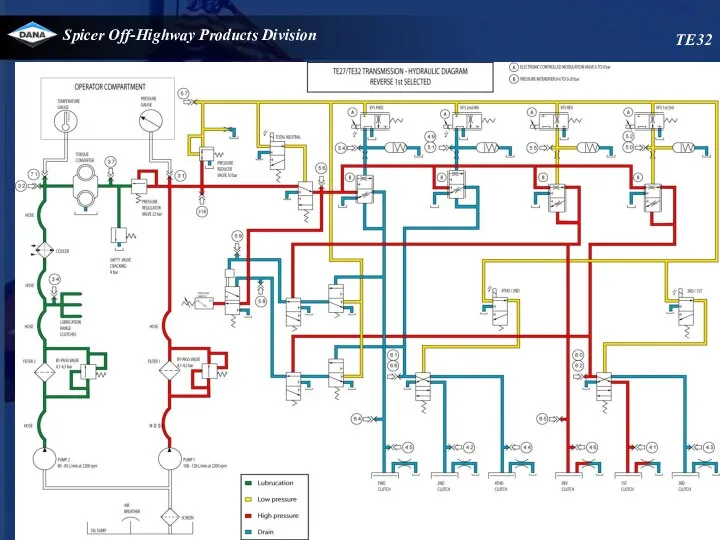

- 74. Electronic controlled modulation (E.C.M.) TE27-32

- 75. Operation of transmission TE32 The transmission is controlled by an APC200 box. This unit has a

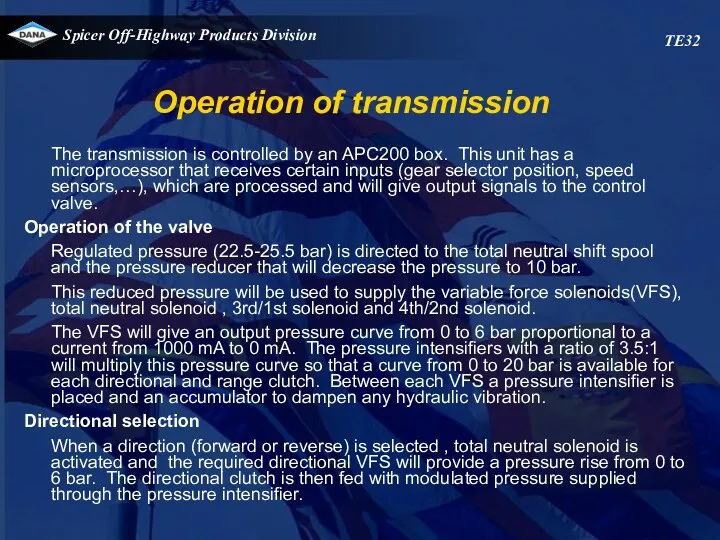

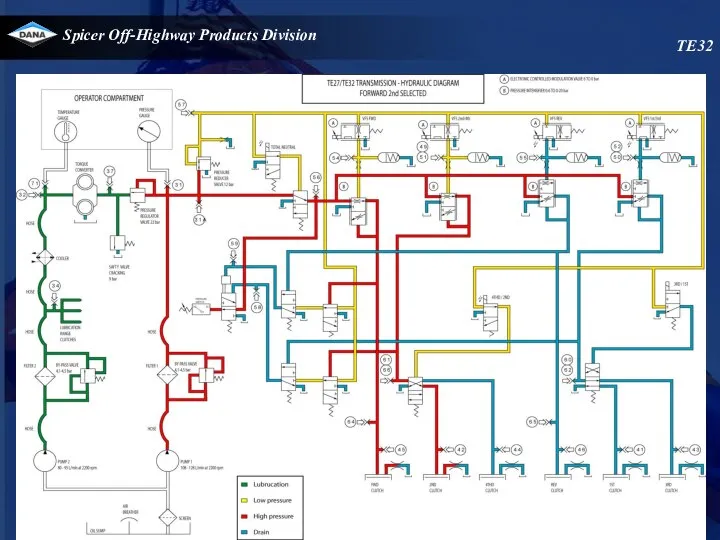

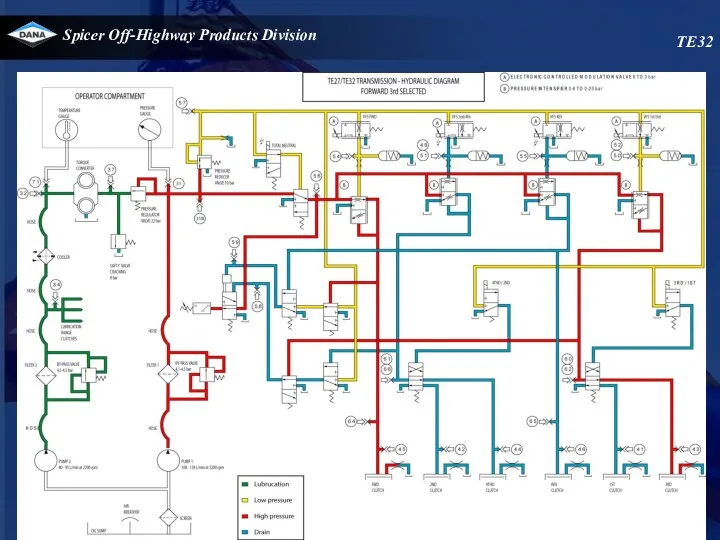

- 76. Operation of transmission TE32 Range selection When 1 st clutch is selected , the 3rd/1st and

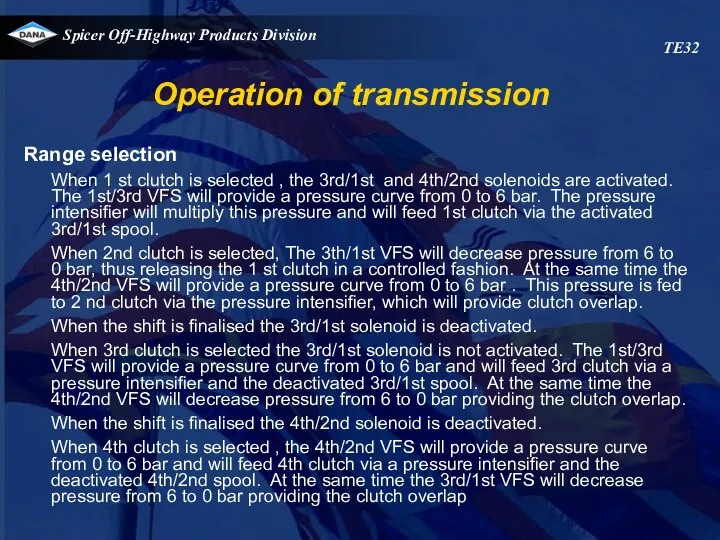

- 77. Operation of transmission TE32 Neutral selection When neutral is selected (1st, 2nd, 3rd or 4th) ,

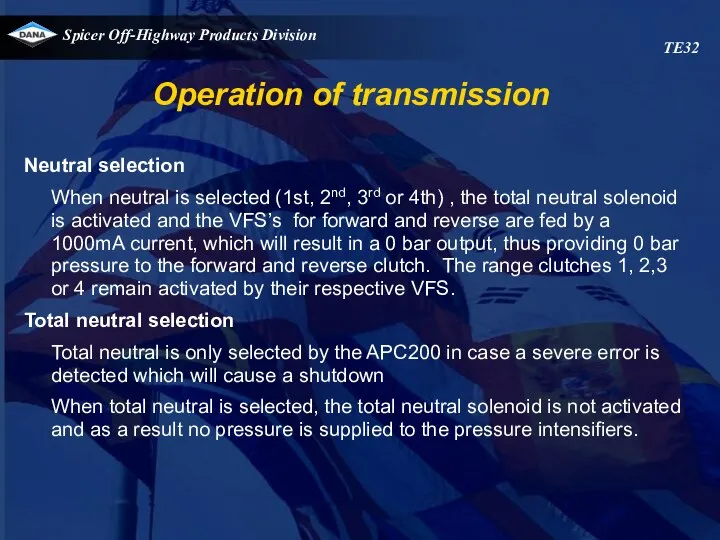

- 78. Operation of transmission TE32 Pressure switch The control valve also has a pressure switch installed between

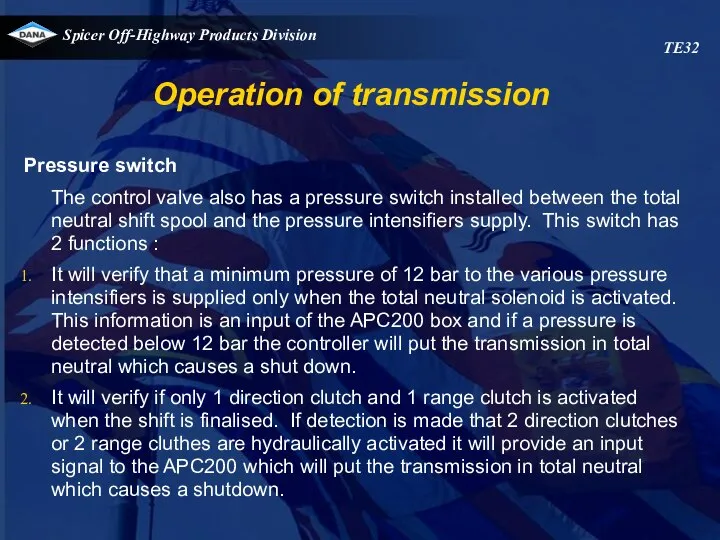

- 79. TE32 VFS 1/3 VFS 2/4

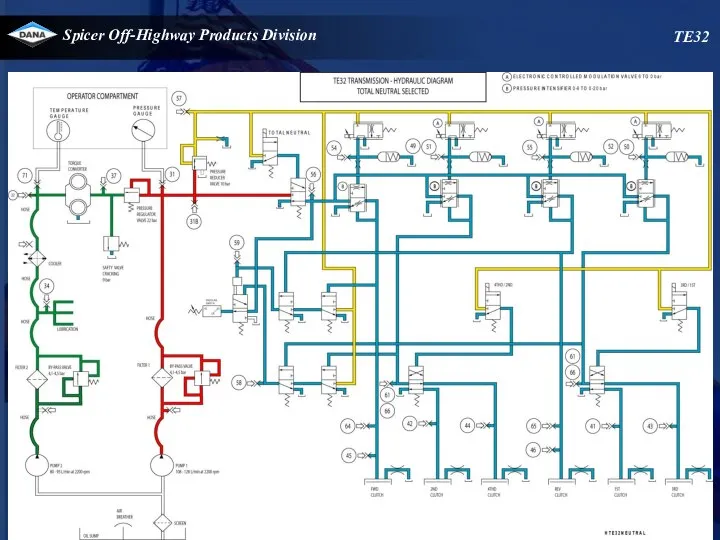

- 80. TE32 Total neutral

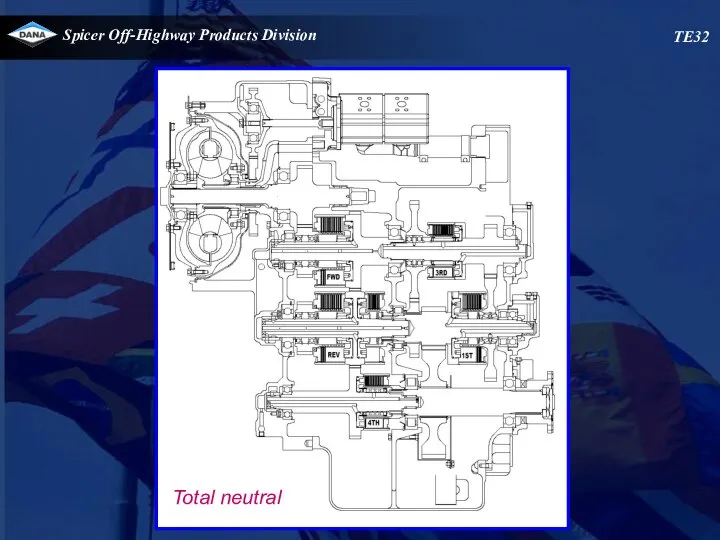

- 81. TE32 VFS 1/3 VFS 2/4

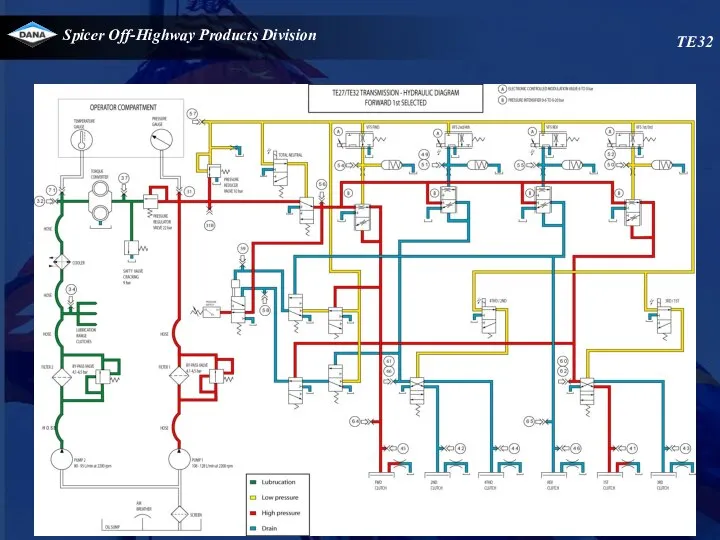

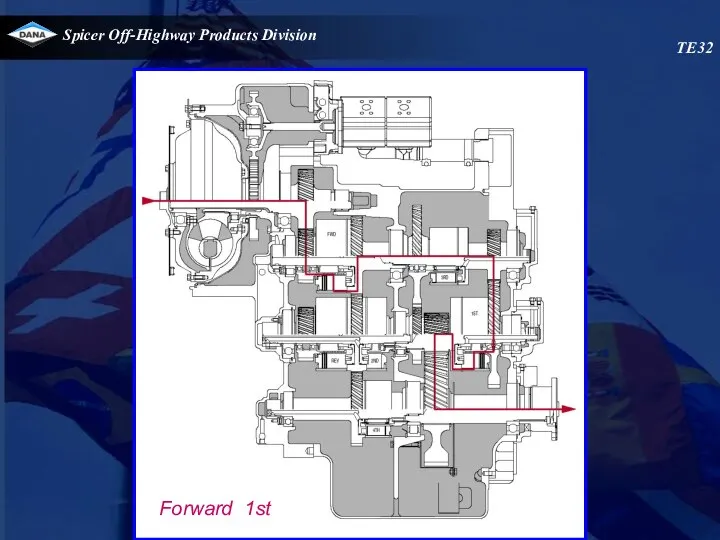

- 82. TE32 Forward 1st

- 83. TE32 VFS 1/3 VFS 2/4

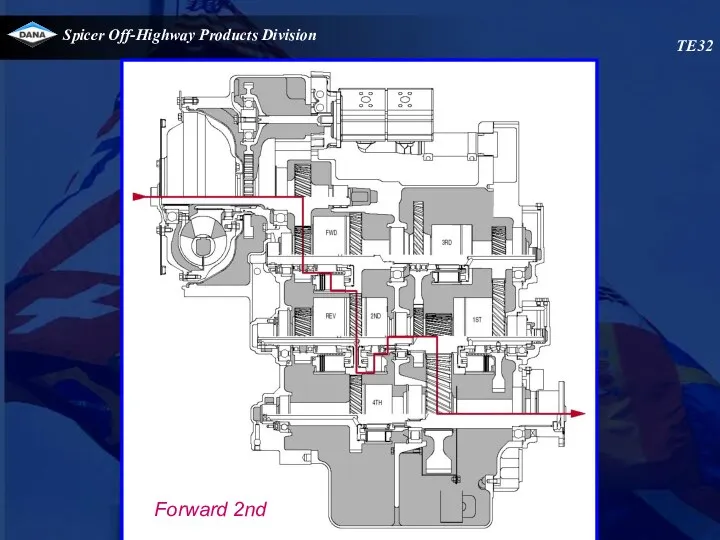

- 84. TE32 Forward 2nd

- 85. TE32 VFS 1/3 VFS 2/4

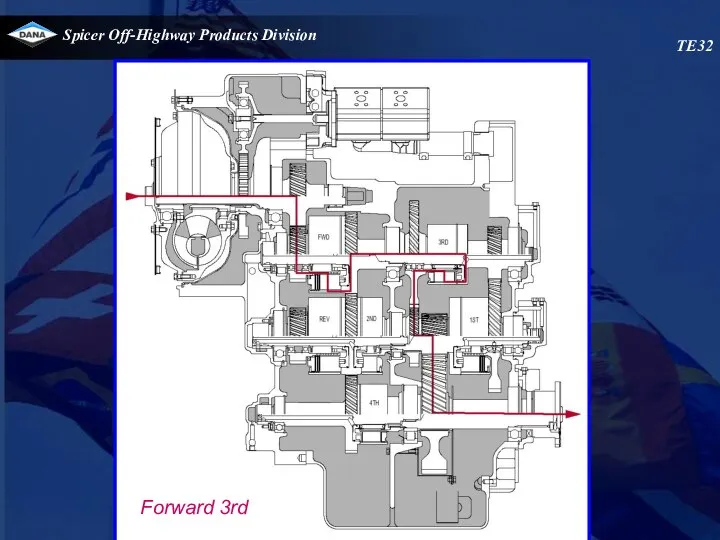

- 86. TE32 Forward 3rd

- 87. TE32 VFS 1/3 VFS 2/4

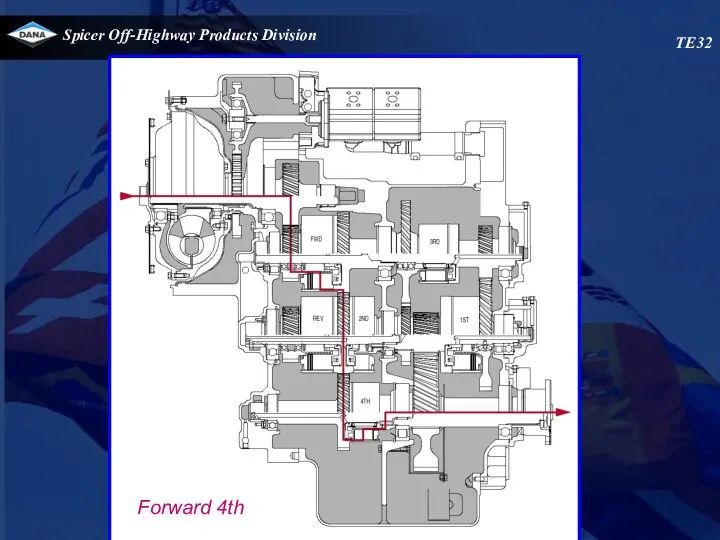

- 88. TE32 Forward 4th

- 89. TE32 VFS 1/3 VFS 2/4

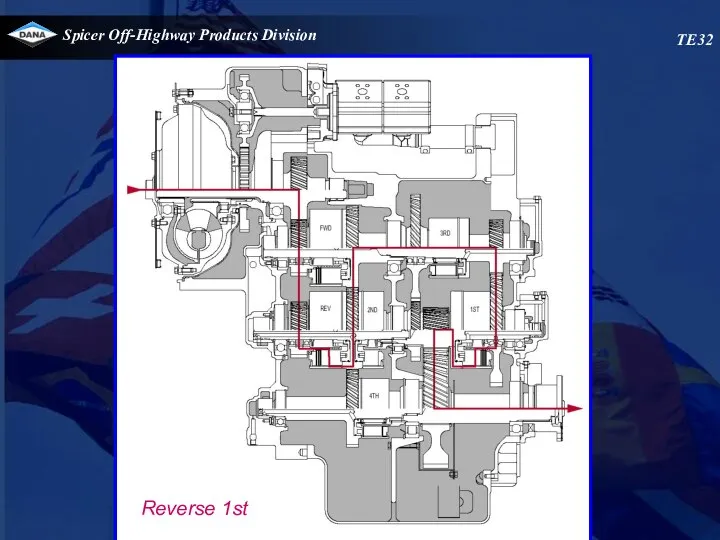

- 90. TE32 Reverse 1st

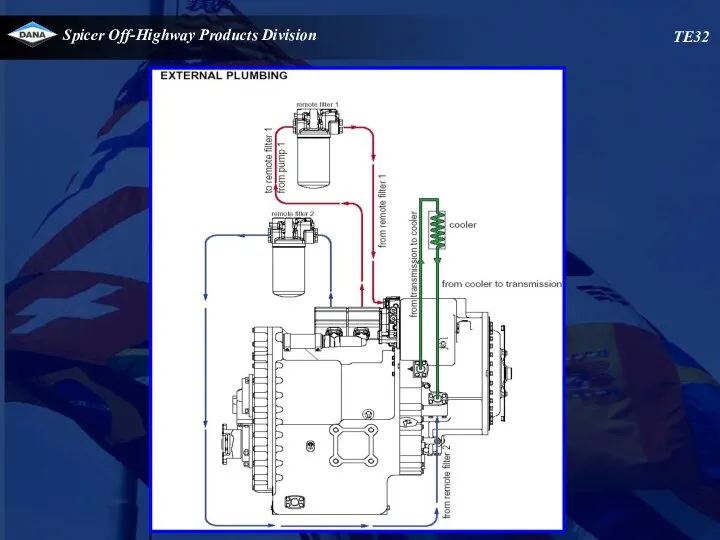

- 91. Connections - top view To remote filter from pump 2 To remote filter from pump 1

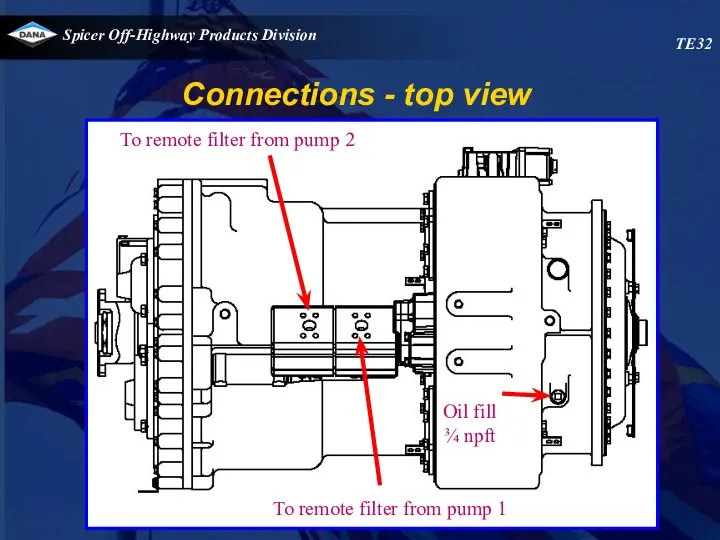

- 92. Pressure check 1st clutch port 41 Oil level check port 1/4 NPT Checkports - left view

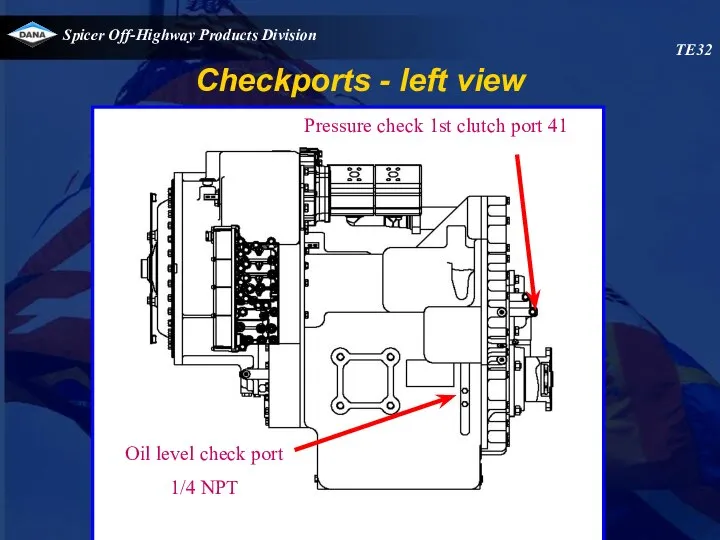

- 93. Checkports - right view TE32 Reg. Pressure port 31 Converter In Pres port 37 To cooler

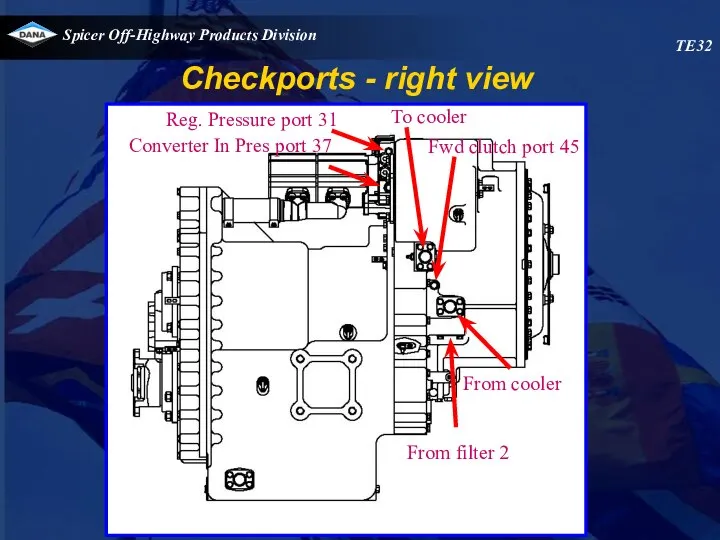

- 94. Checkports - front view TE32 2nd clutch port 42 Rev clutch port 46 4th clutch port

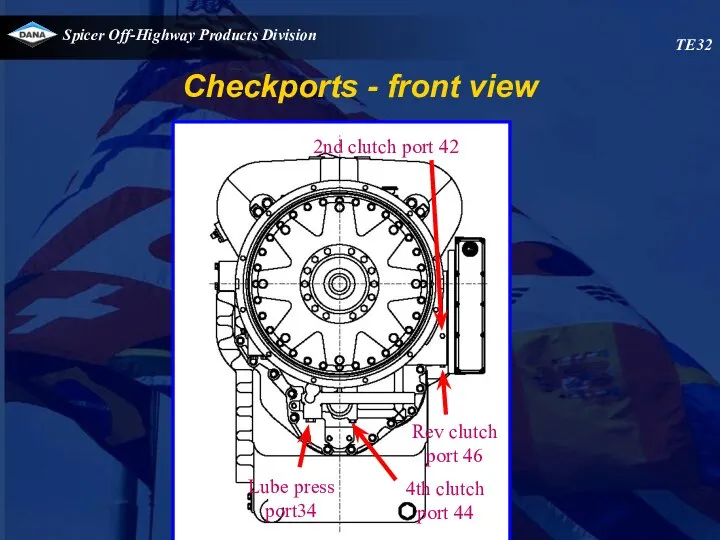

- 95. Checkports - rear view TE32 From filter 1 Conv out press port 32 Temp switch Converter

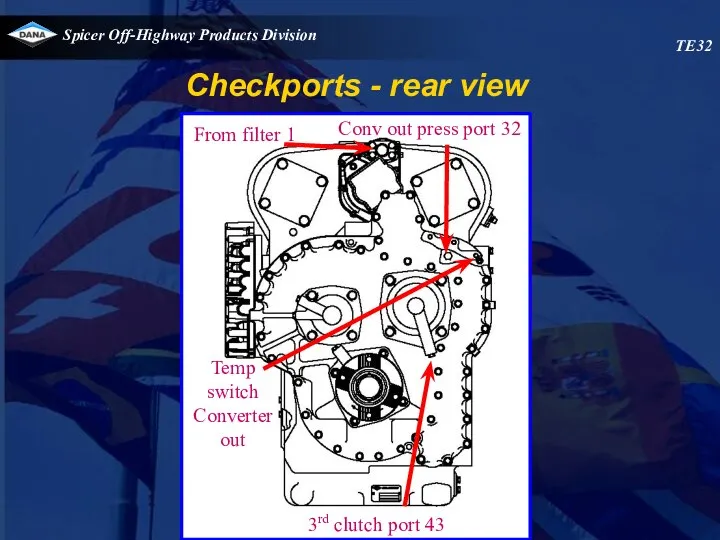

- 96. Speed sensor location TE32 Engine speed & transmission temperature sensor Drum speed sensor Output speed sensor

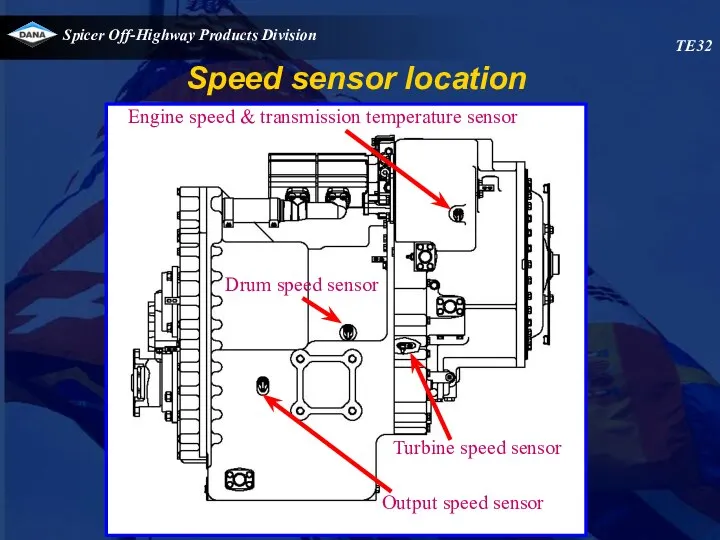

- 97. Checkports control valve 66/61 49/51 F 54 59 58 31b 57 65 55 56 50/52 60/62

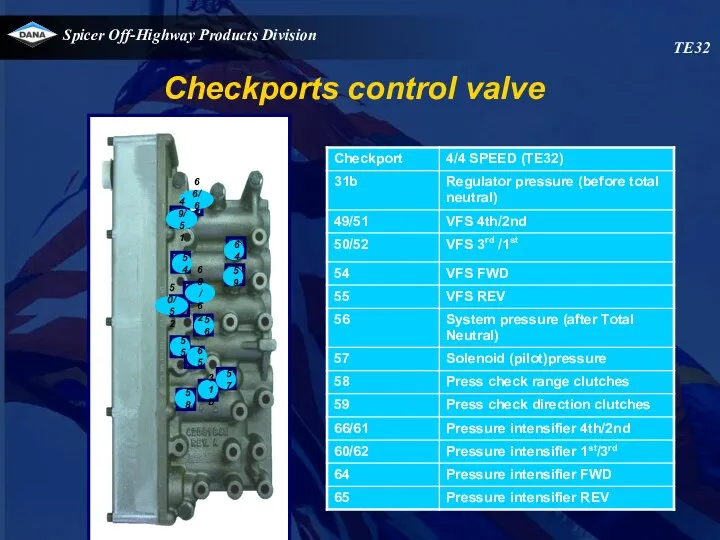

- 98. Control valve replacement Removing the valve 1.Make sure that the area around the valve is clean

- 99. TE32 20 18 19 17 15 3 7 11 13 16 14 2 5 10 12

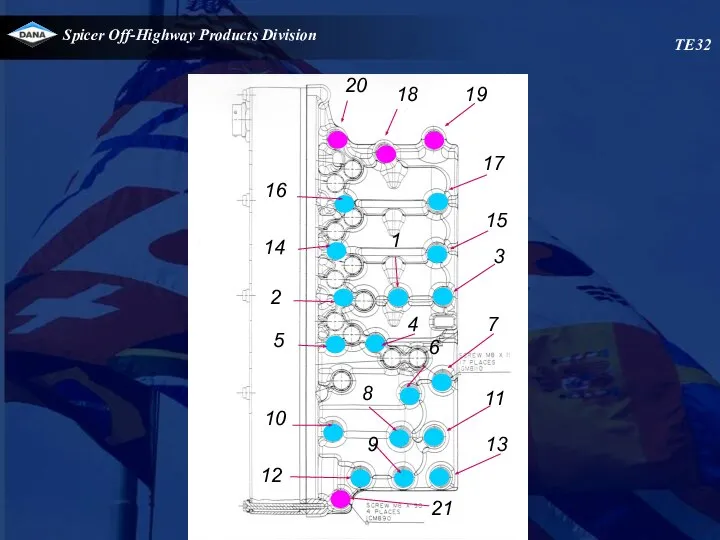

- 100. TE 32 Speed sensor installation

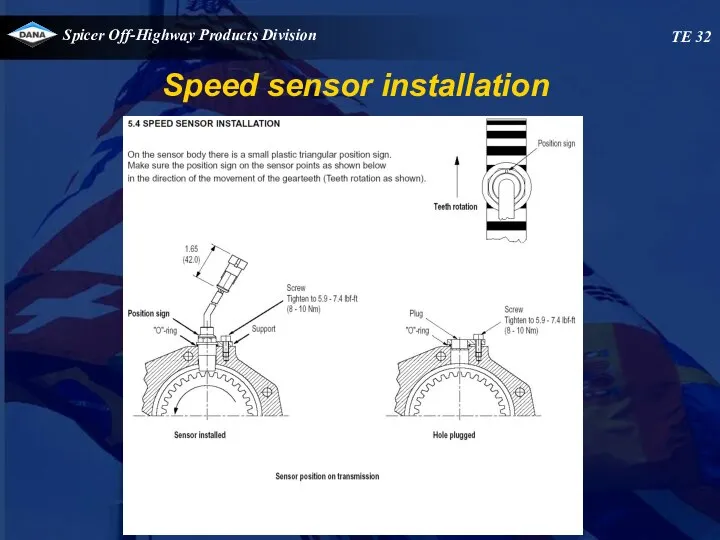

- 101. TE 32 Speed sensor installation

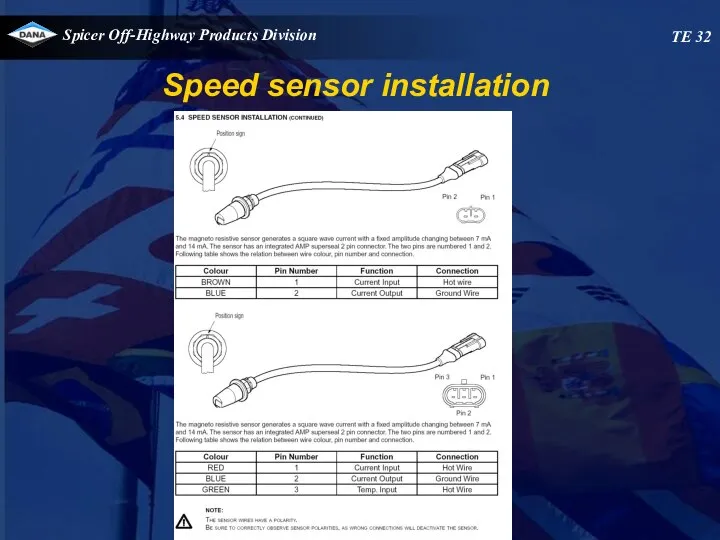

- 102. TE 32 Speed sensor installation

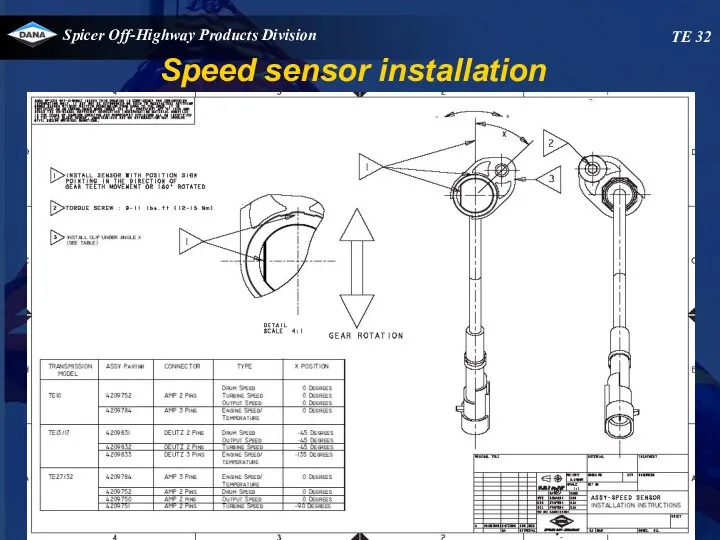

- 103. APC200 CONTROLLER

- 104. Overview Link with the transmission APC200 APC200 display modes APC200 diagnostics System calibration

- 105. Transmission Input signals Speed sensors Engine speed Turbine speed Drum speed Output speed Pressure feedback switch

- 106. Control valve Proportional solenoids (VFS = “Variable Force Solenoid”) VFS0 for forward VFS1 for 2nd/4th (if

- 107. APC 200 Device for shifting Spicer Off Highway Products ECM powershift transmissions (TE transmissions) ECM ->

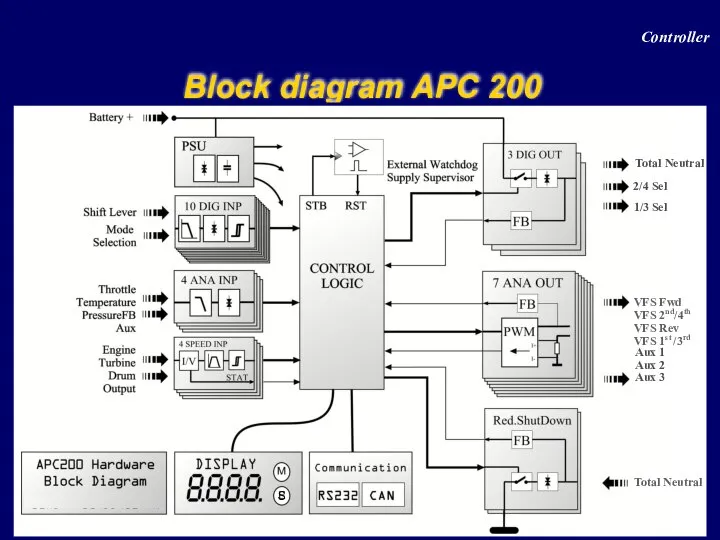

- 108. Block diagram APC 200 Controller

- 109. Block diagram APC 200 : inputs Controller 10 digital inputs 6 (7) analogue inputs Ani0 Pressure

- 110. Block diagram APC 200 : outputs (1/3) Controller 4 digital outputs Do0 RSP Drive Solenoid +

- 111. Block diagram APC 200 : outputs (2/3) Controller Do0 and Do3 : RSP Drive Solenoid =

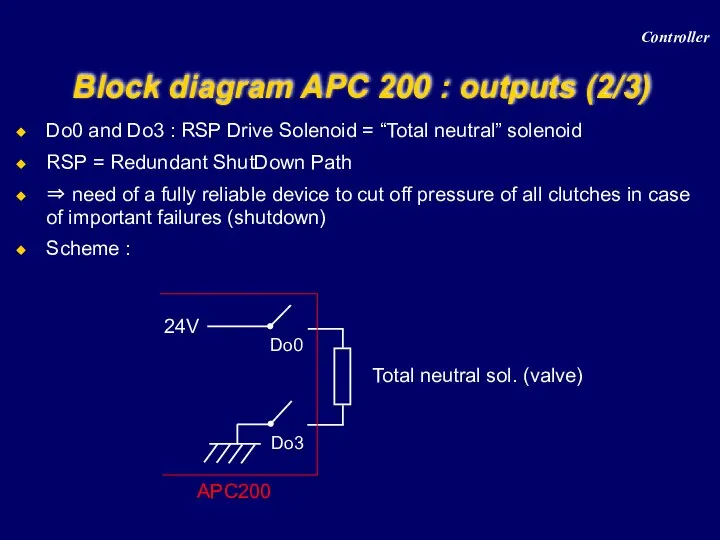

- 112. Block diagram APC 200 : outputs (3/3) Controller 7 analogue outputs Closed loop current regulation for

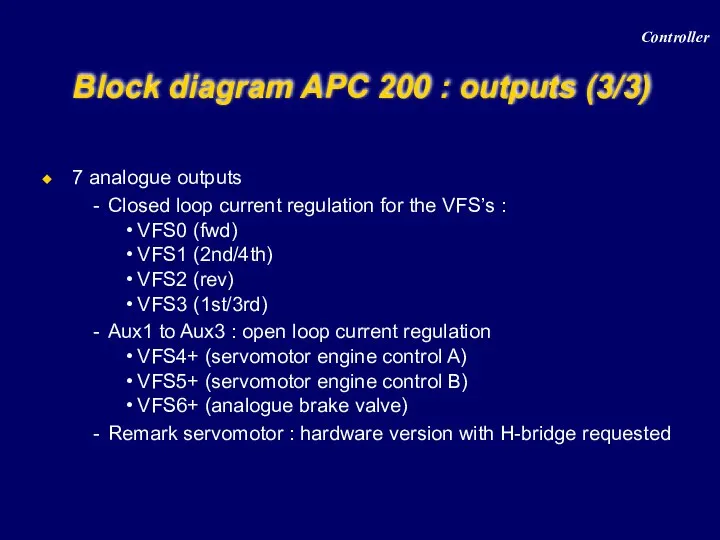

- 113. Block diagram APC 200 : example Controller

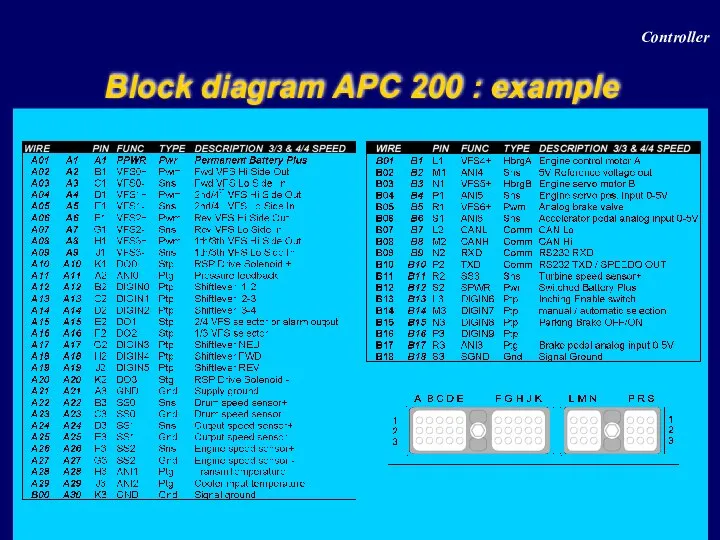

- 114. PSU = Power Supply Unit Version : 12V or 24V Two power lines PPWR : permanent

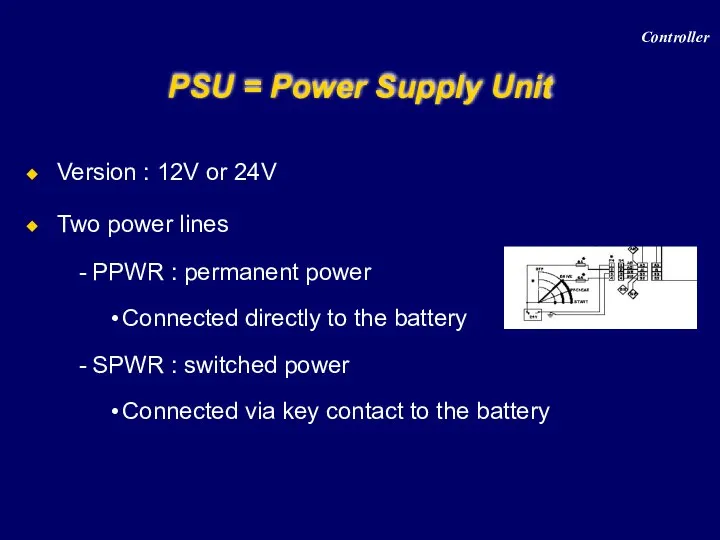

- 115. Bootstrap and reset circuit Bootstrap: Special mode, controller wants to receive serial data, to program the

- 116. Functions Manual / automatic shifting Electronic modulation Overlap control Electronic inching Start 1st / 2nd Limit

- 117. Functions on wiring diagram Controller

- 118. Communication CAN 2.0 B Communicate with different controllers and PC RS 232 To flash a new

- 119. Parameter setting 1 approved drive-line = 1 APT-file Approved drive-line = Specific type of vehicle +

- 120. Display 4 red 7-segment LED digits 3 status LED lamps D -> yellow, test modes E

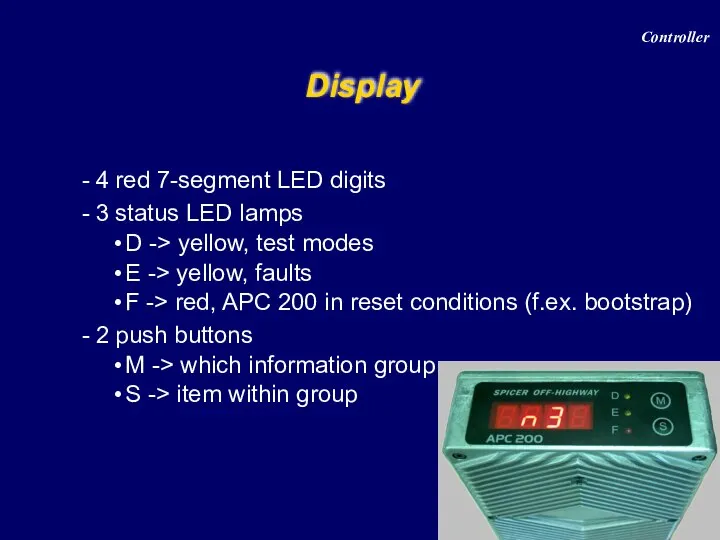

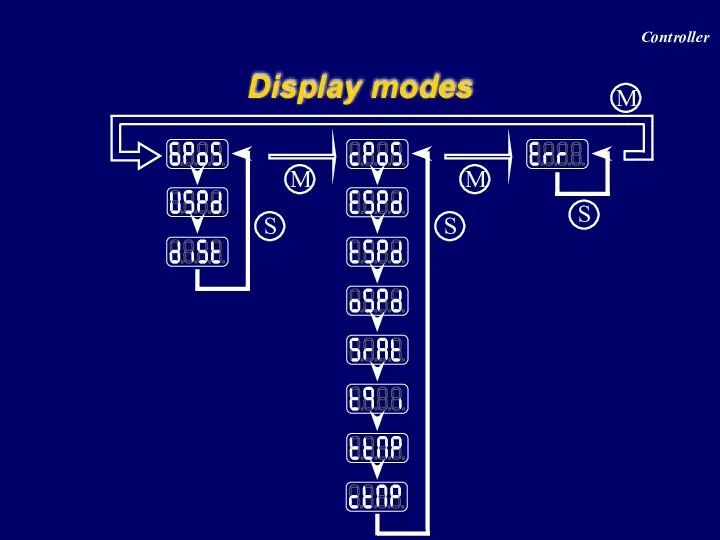

- 121. Display modes Controller

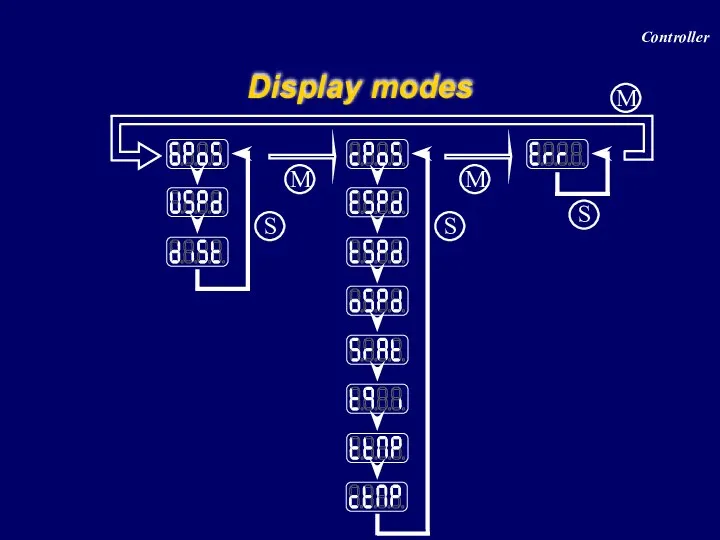

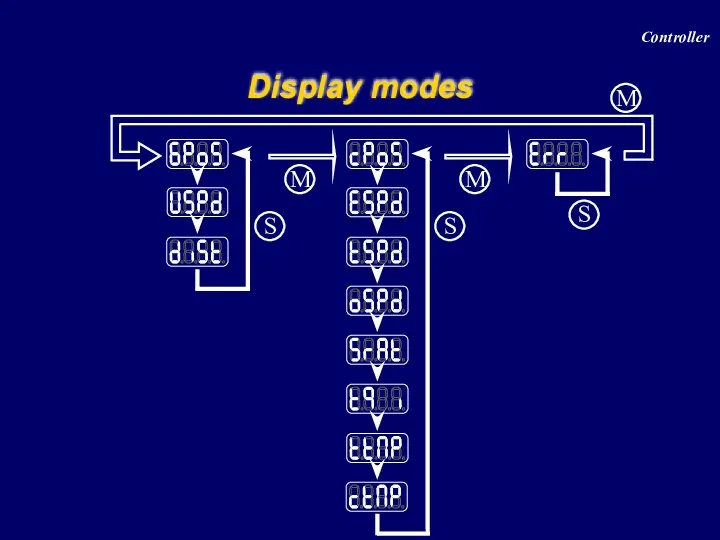

- 122. “GPOS” display Reflects the actually engaged transmission direction and range Display modes Controller

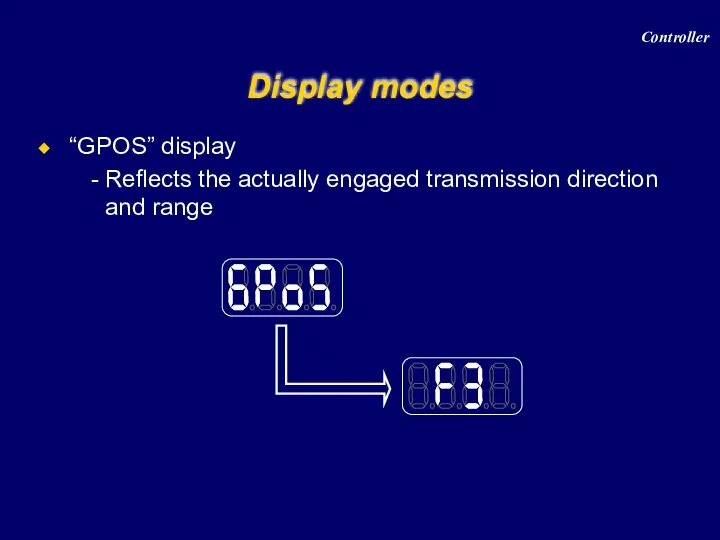

- 123. Display modes “VSPD” display Shows the vehicle speed in km/h or MPH, with a resolution of

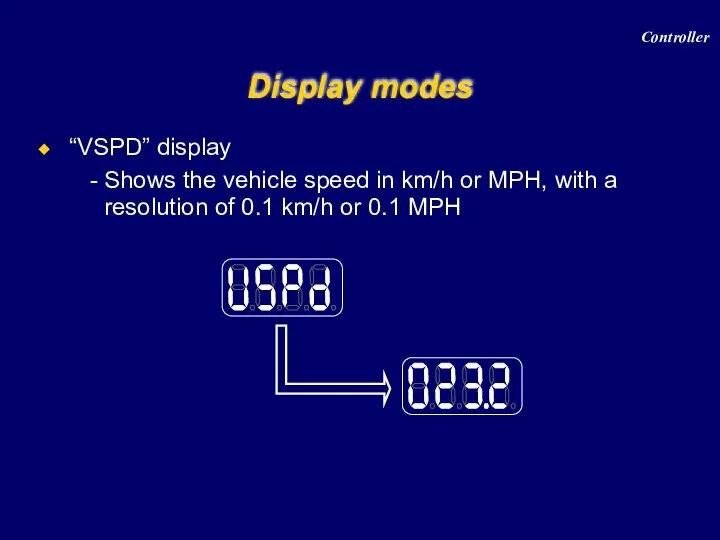

- 124. “dist” display Shows the distance travelled in km or miles, with a resolution of 0.1 km

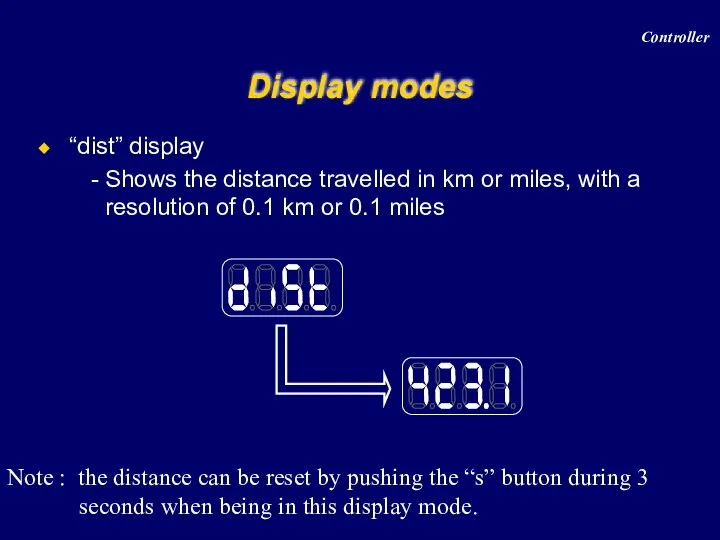

- 125. Display modes Controller

- 126. “CPOS” display Reflects the actually shiftlever position Display modes Controller

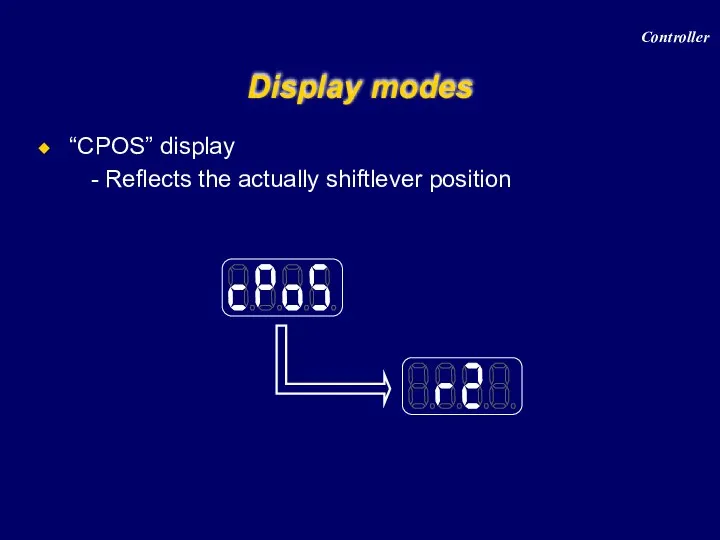

- 127. “Espd” display Shows the measured engine speed in RPM Display modes Controller

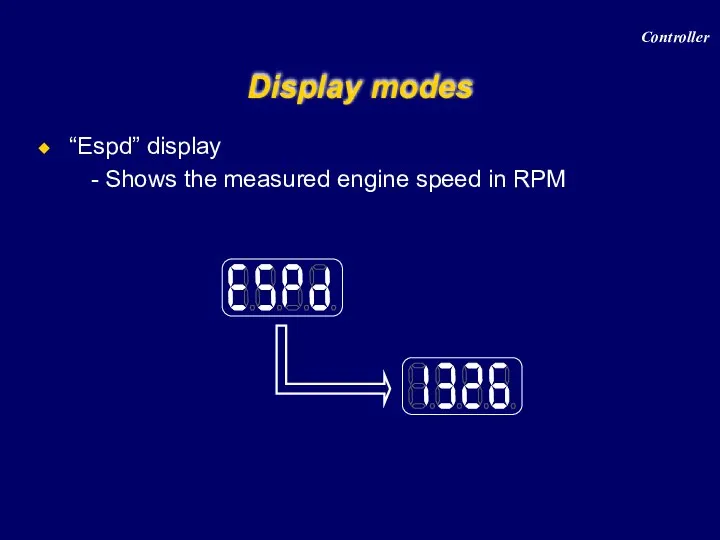

- 128. “Tspd” display Shows the measured turbine speed in RPM Display modes Controller

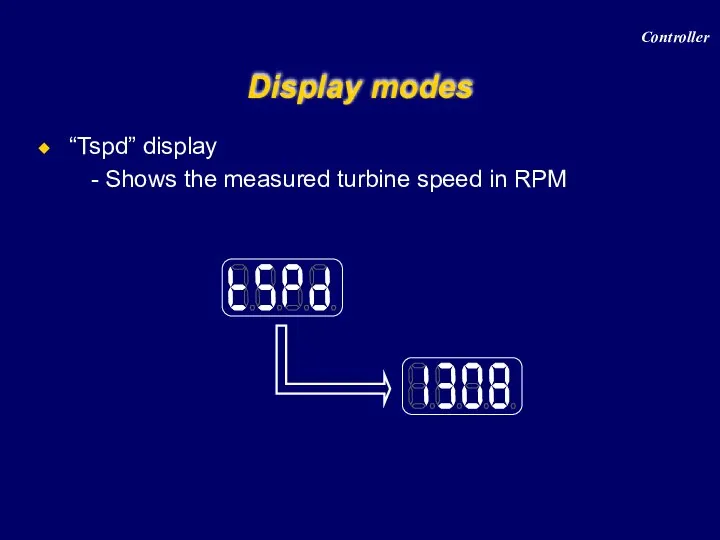

- 129. “Ospd” display Shows the measured output speed in RPM Display modes Controller

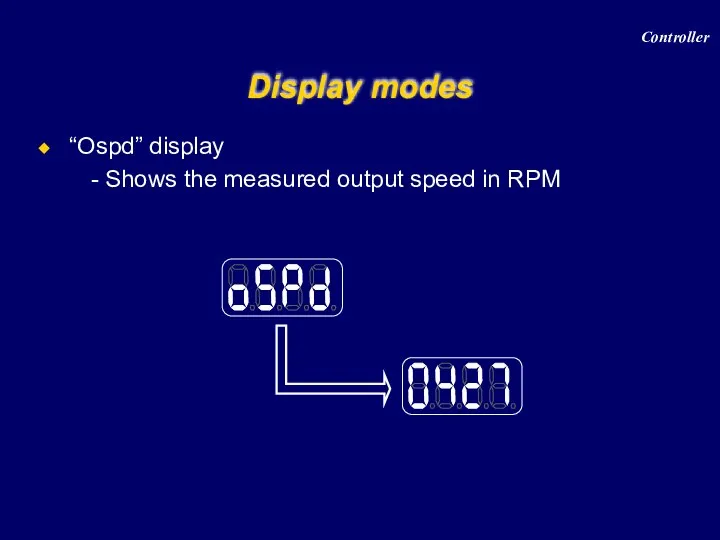

- 130. “Srat” display Reflects the current speed ration ( Tspd / Espd ), which is an important

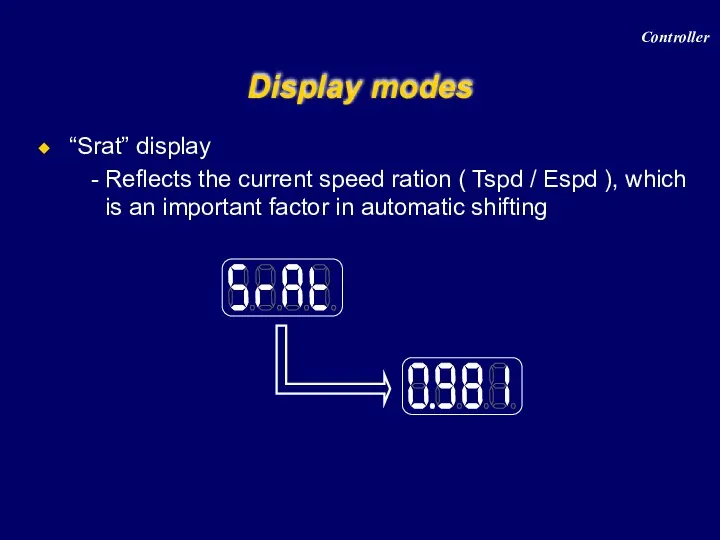

- 131. “TQ I” display Reflects the measured torque (turbine torque) at the transmission input side in Nm

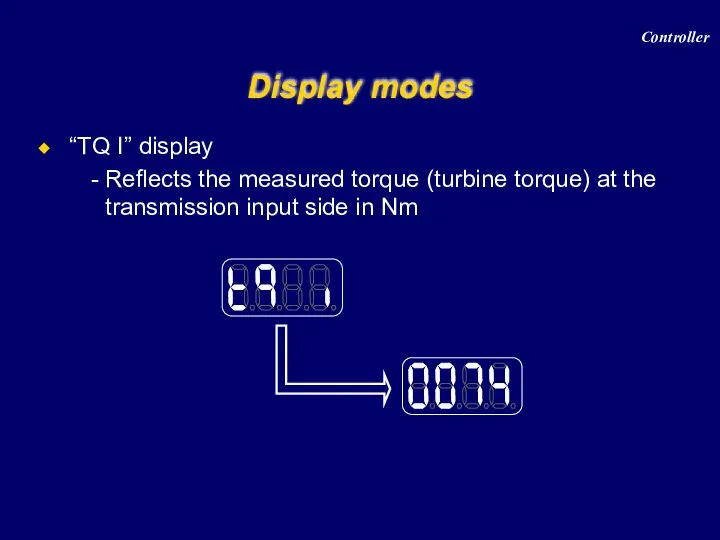

- 132. “Ttmp” display Shows the transmission sump temperature in °C Display modes Controller

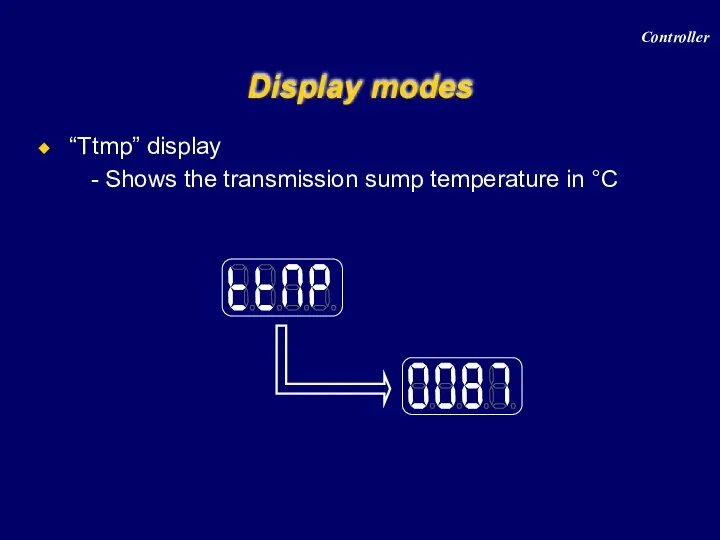

- 133. “Ctmp” display Shows the Converter out temperature in °C Display modes Note : due that the

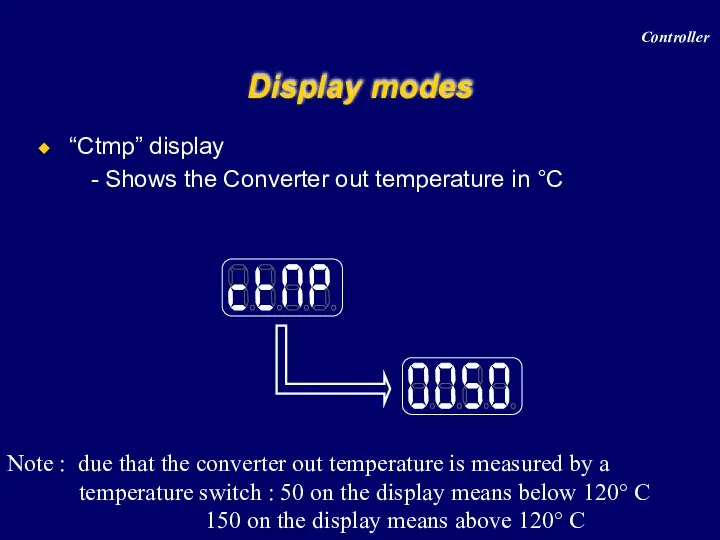

- 134. Display modes Controller

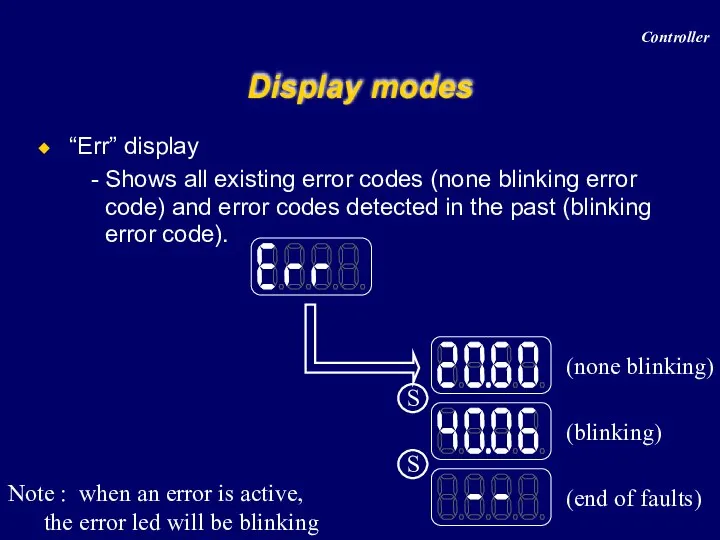

- 135. “Err” display Shows all existing error codes (none blinking error code) and error codes detected in

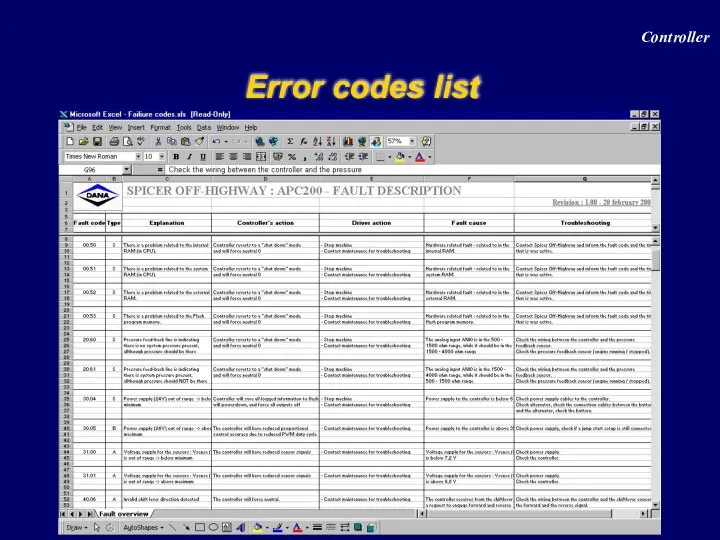

- 136. Error codes list Controller

- 137. Diagnostics Controller

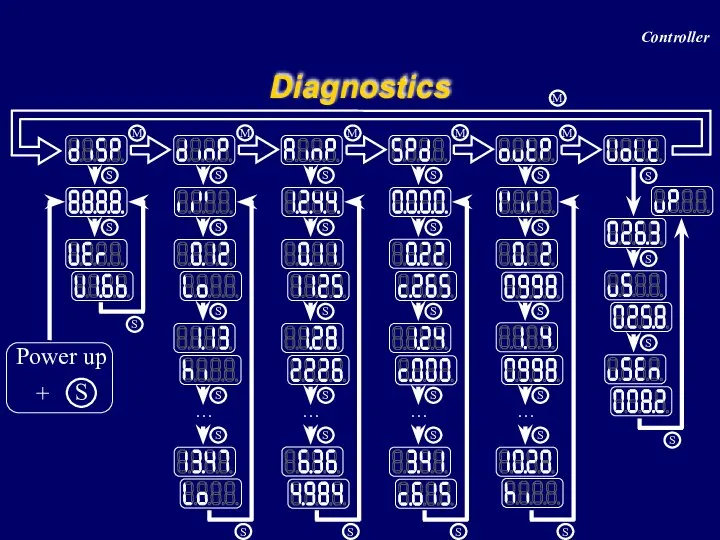

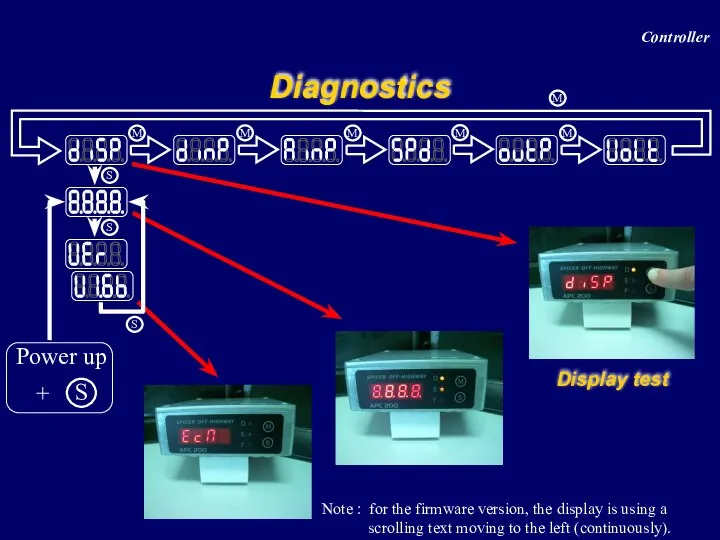

- 138. Diagnostics Note : for the firmware version, the display is using a scrolling text moving to

- 139. Diagnostics Digital input test Digital input reference 0 1 2 3 4 5 8 9 6

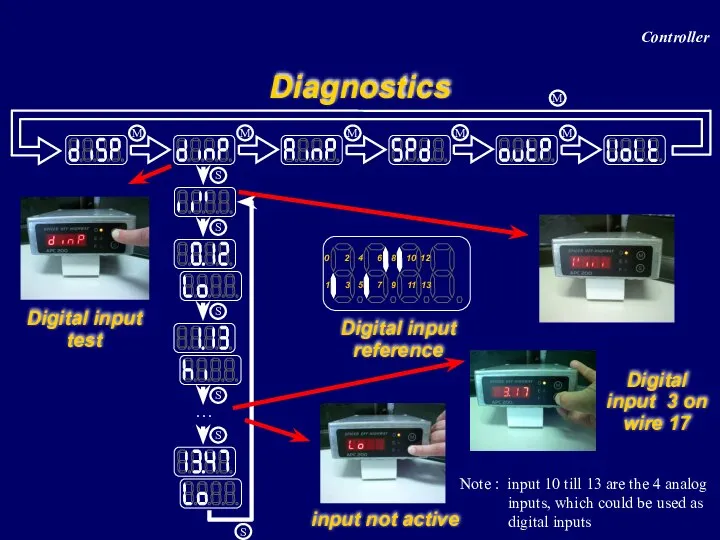

- 140. Diagnostics Analog input test 1st value (kΩ or V) of the 1st 4 analog inputs No

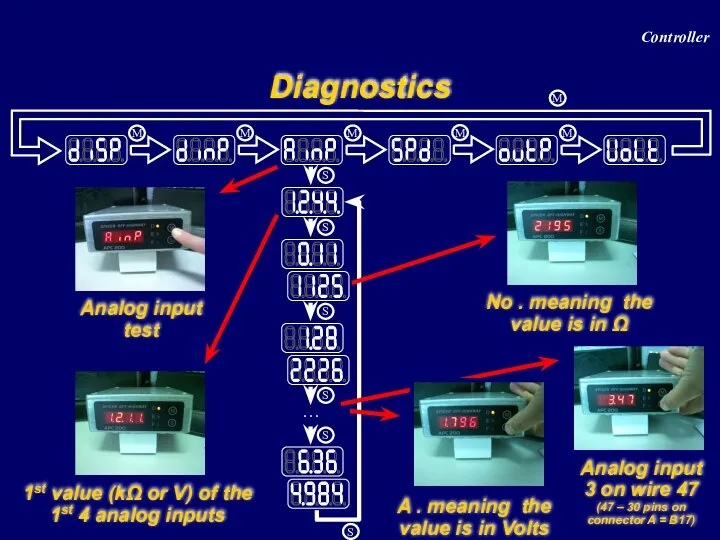

- 141. Diagnostics Speed sensor test C informs the sensor is a current sensor, value is expressed in

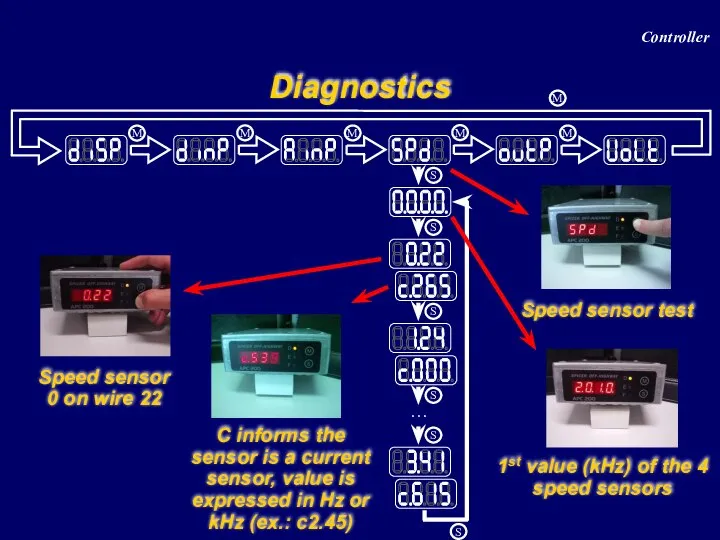

- 142. Diagnostics Output test Analog output Current of 997 mA Analog output 3 on wire 8 Note

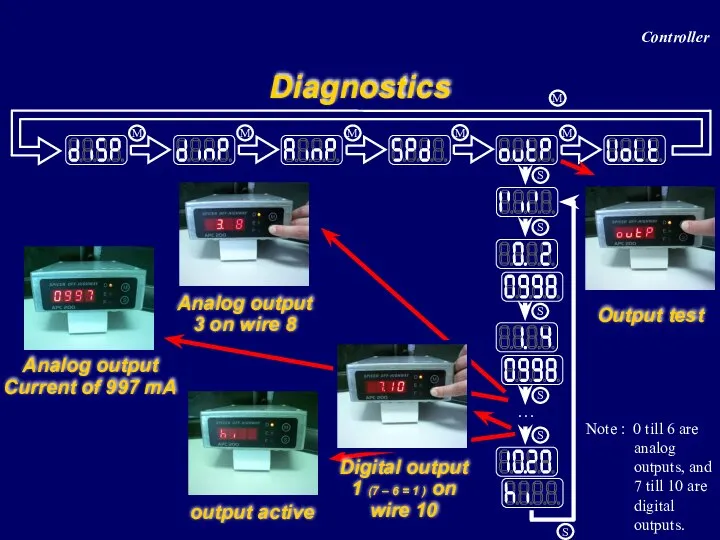

- 143. Diagnostics Voltage test Voltage switched power Voltage sensor power supply 22.7 volt 8.1 volt Controller

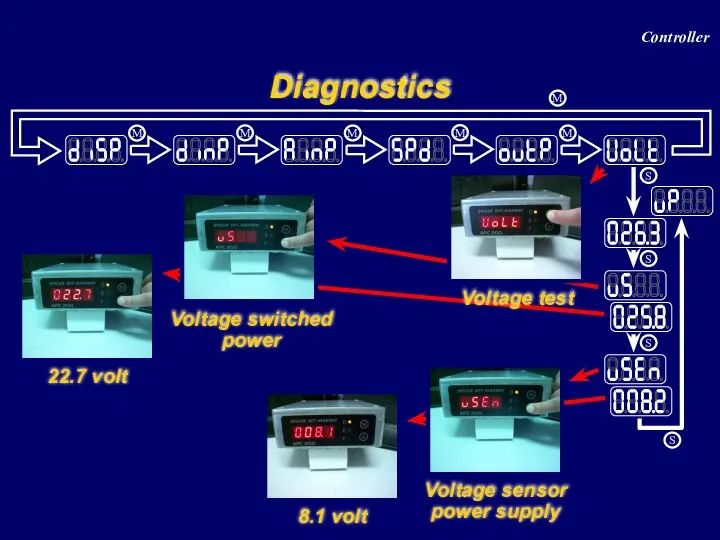

- 144. Calibration APC200-Transmission Menu structure overview Transmission calibration (clutch filling) Heat mode Calibration of the analogue inputs

- 145. Menu structure overview

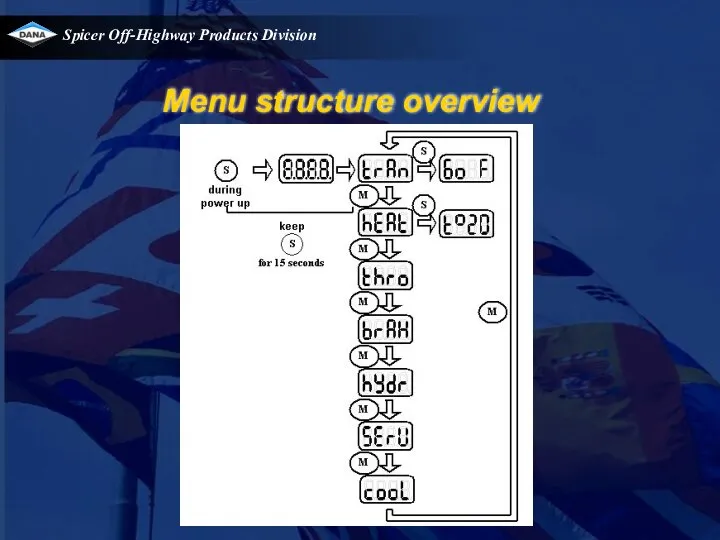

- 146. Transmission calibration (clutch filling) Introduction What? Is determining volume of oil that is needed to fill

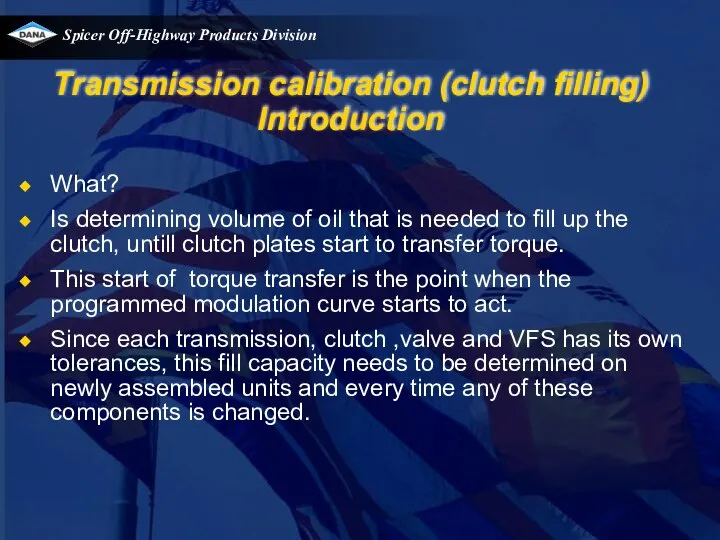

- 147. Transmission calibration (clutch filling) Introduction How ? Direction (FWD/REV)clutches are calibrated by fully activating 2nd range

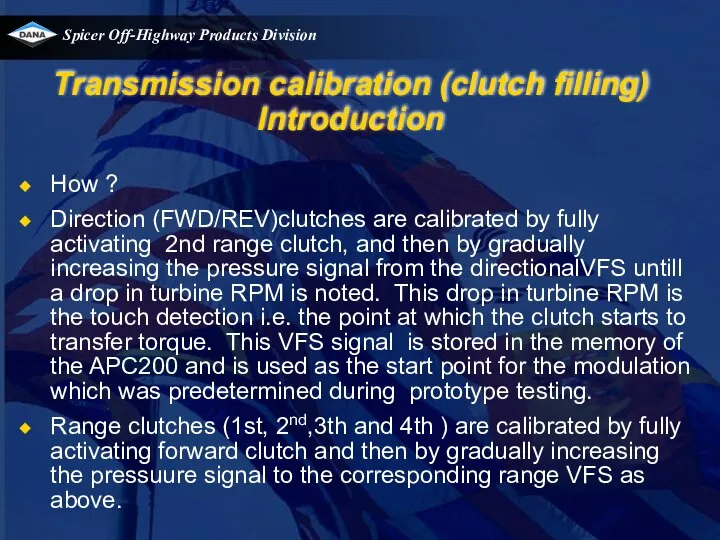

- 148. Transmission calibration (clutch filling) Introduction A transmission calibration has to be performed : when the vehicle

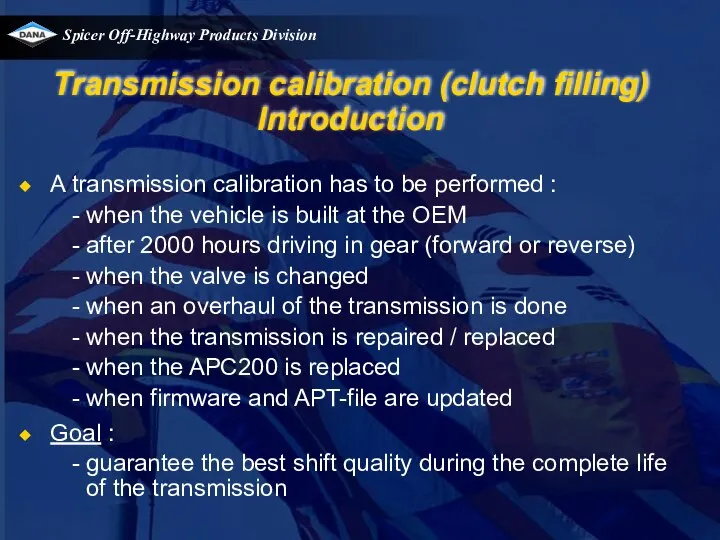

- 149. Transmission calibration (clutch filling) How ? (1/3) Enter the calibration menu by pressing the S-button on

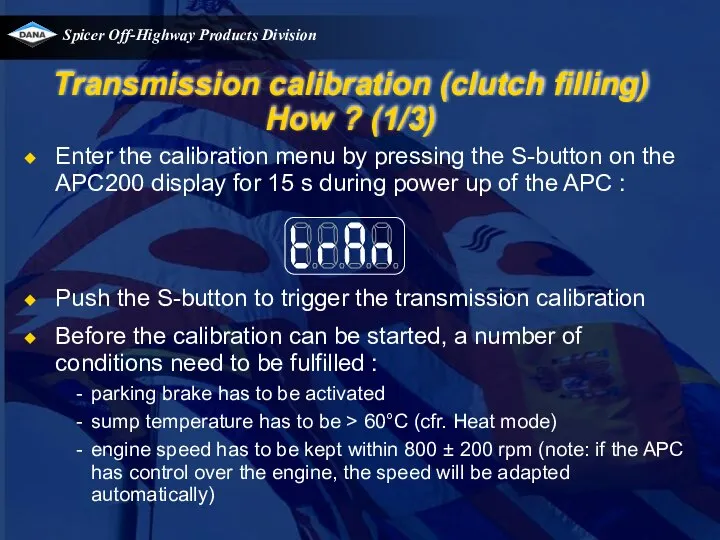

- 150. Transmission calibration (clutch filling) How ? (2/3) If all these conditions are met, the APC will

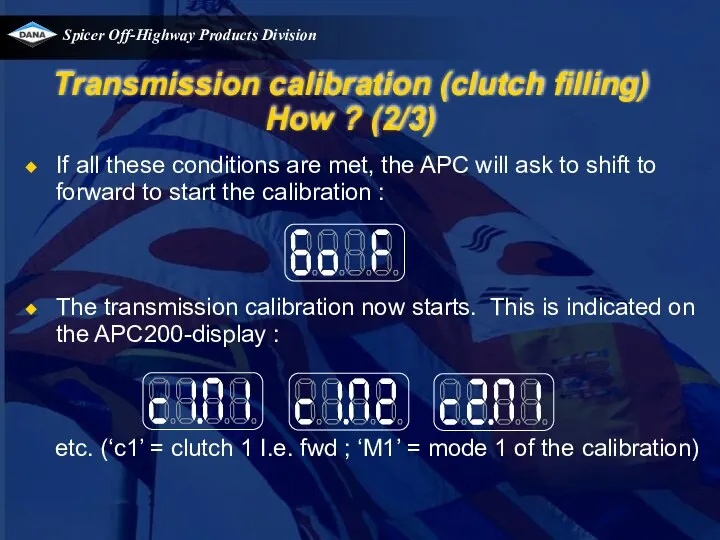

- 151. Transmission calibration (clutch filling) How ? (3/3) When all clutches have been calibrated, the APC200 displays

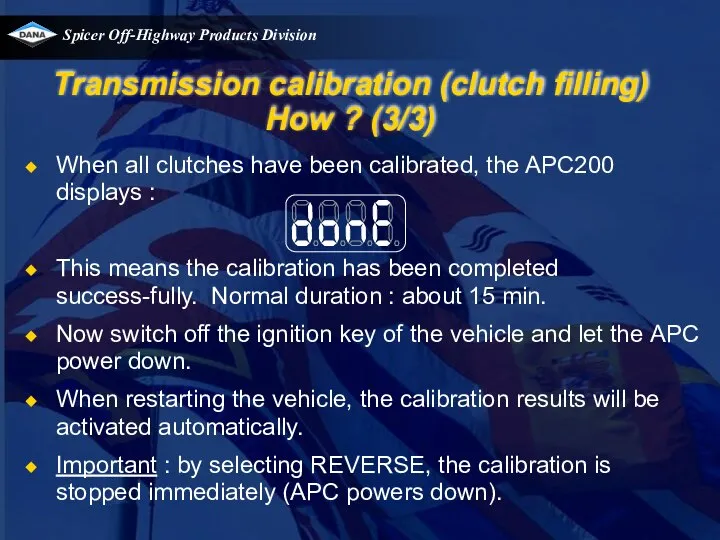

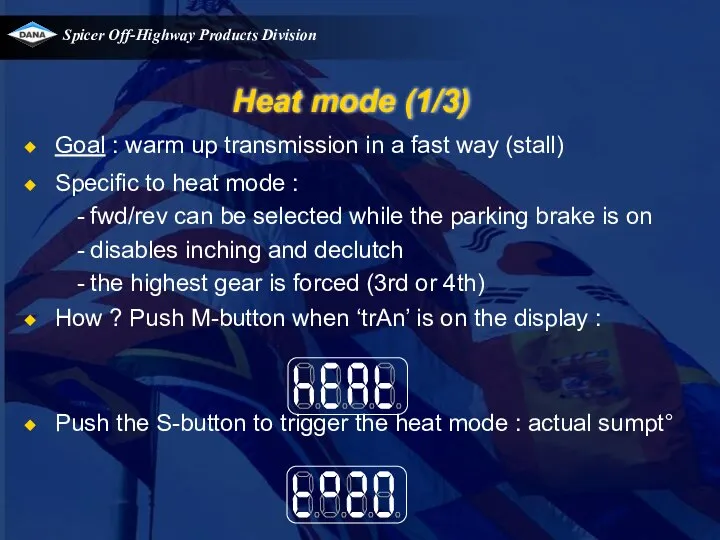

- 152. Heat mode (1/3) Goal : warm up transmission in a fast way (stall) Specific to heat

- 153. Heat mode (2/3) Perform the following scheme to warm up the transmission : When the sumpt°

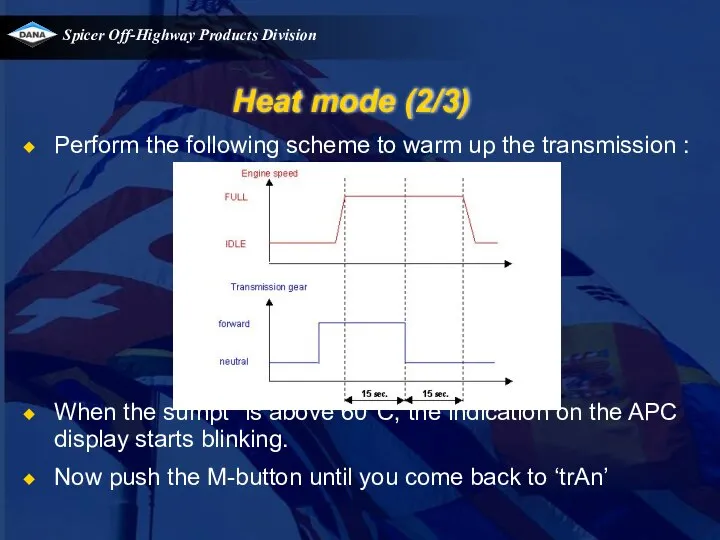

- 154. Heat mode (3/3) Note : When the converter out temperature would exceed 120°C, the engine speed

- 155. Other messages during calibration (1/5) 1. Calibration condition messages

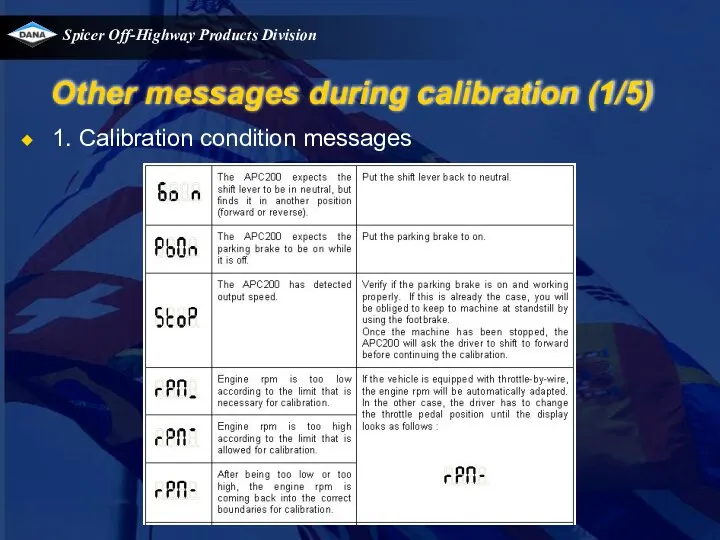

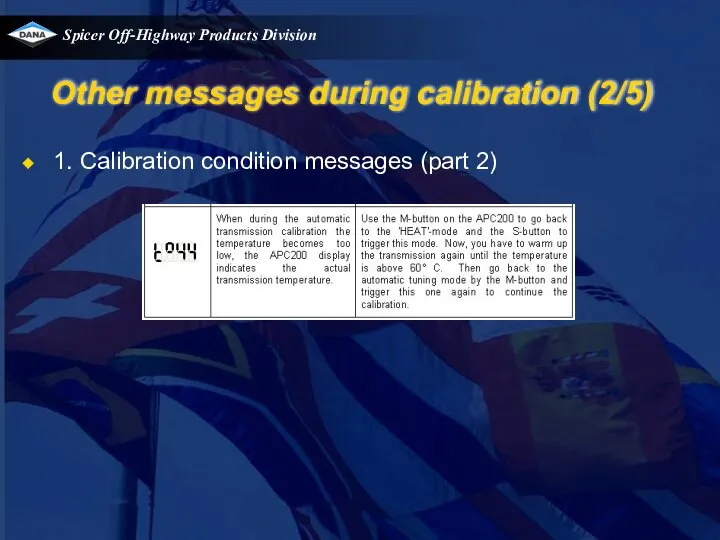

- 156. Other messages during calibration (2/5) 1. Calibration condition messages (part 2)

- 157. Other messages during calibration (3/5) 2. Calibration error messages E1.25 : during calibration, early touch detect.

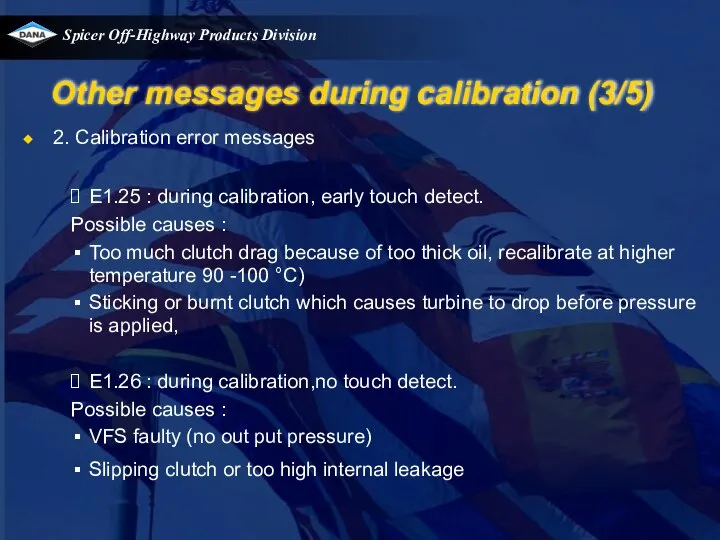

- 158. Other messages during calibration (4/5) 2. Calibration error messages continued E1.10 : during calibration, shift inhibit.

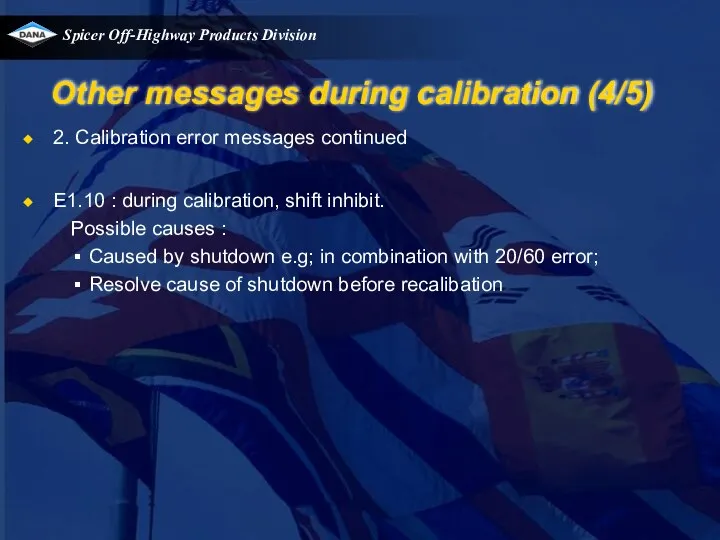

- 159. Other messages during calibration (5/5) 2. Calibration error messages continued E2.14 : calibration failed ,fill time

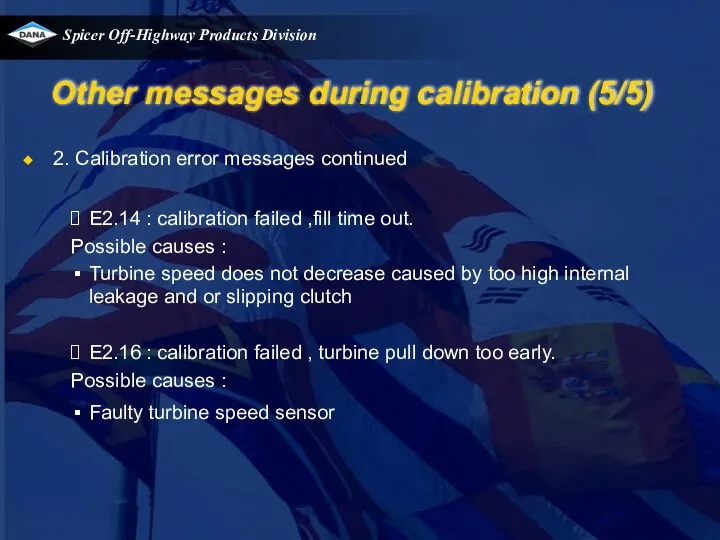

- 160. Calibration of analogue imputs Example : brake pedal (1/4) Enter the calibration menu by pressing the

- 161. Calibration of analogue imputs Example : brake pedal (2/4) Then, the APC asks for the mid

- 162. Calibration of analogue imputs Example : brake pedal (3/4) Finally, the APC asks for the full

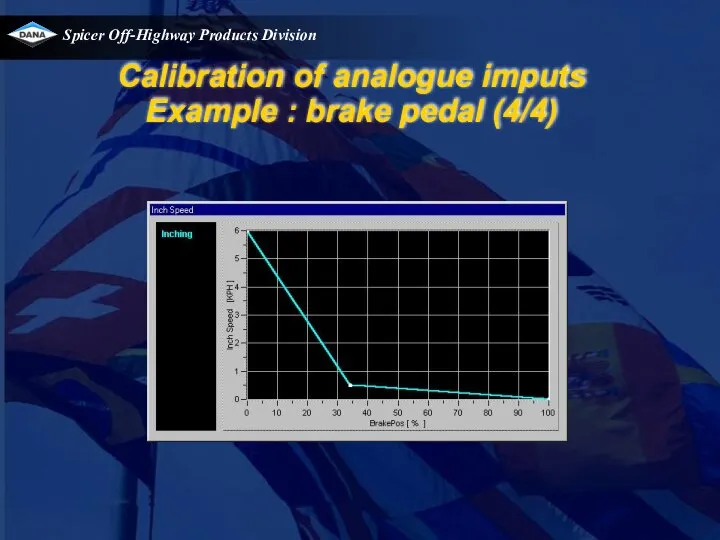

- 163. Calibration of analogue imputs Example : brake pedal (4/4)

- 164. TE transmission field experience TE13/17 field campaign Speed sensor changes Case studies

- 165. TE transmission field experience TE13/17 field campaign Clutch end plate snapring jumps out of groove, causing

- 166. TE transmission field experience Speed sensor changes. Cracked speedsensor housing causes potting material to swell which

- 167. TE transmission field experience Case studies 1. Vehicle stops error 00.50 action 1 : Change APC

- 168. TE transmission field experience Case studies 2. Vehicle has a delay when downshifting, no error codes

- 169. TE transmission field experience Case studies 3. Tel call : machine sometimes shows 20.60error code action

- 170. TE transmission field experience Case studies 4. Tel call : unit shocks when 4th is selected

- 171. TE transmission field experience Case studies 5. Tel call : failure code 20/61 with engine not

- 172. TE transmission field experience Case studies 6. Tel call : error code 42/04 (speed ratio (Turbine/Output)

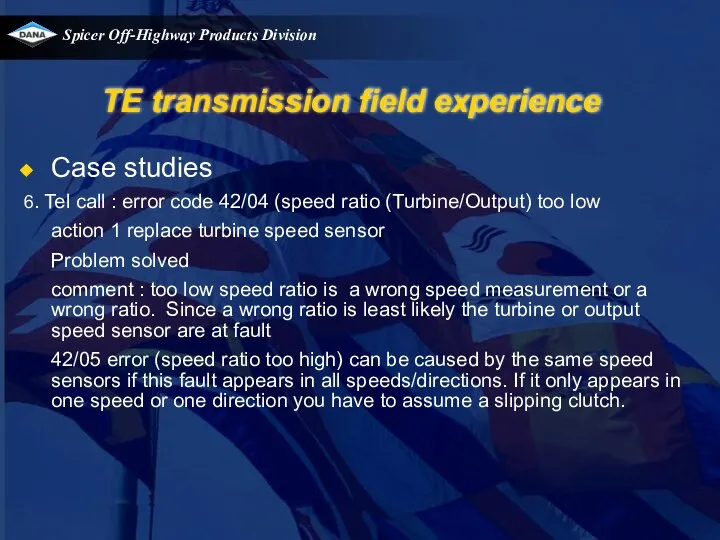

- 174. Скачать презентацию

МКТ и термодинамика

МКТ и термодинамика Бүкіл әлемдік тартылыс күші

Бүкіл әлемдік тартылыс күші Магнітне поле

Магнітне поле Момент силы относительно центра (точки)

Момент силы относительно центра (точки) Основы радиационной дозиметрии

Основы радиационной дозиметрии  Электромагнитные волны

Электромагнитные волны Блоки. Золотое правило механики

Блоки. Золотое правило механики Перспективы использования наномолекулярных материалов в строительстве

Перспективы использования наномолекулярных материалов в строительстве Барометрическая формула. Распределение Больцмана

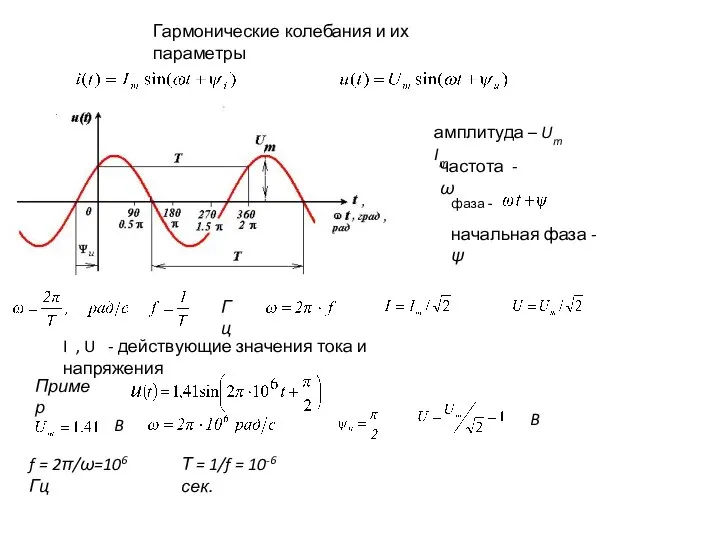

Барометрическая формула. Распределение Больцмана Гармонические колебания и их параметры

Гармонические колебания и их параметры Интерференция света

Интерференция света Презентация по физике Транспорт будущего

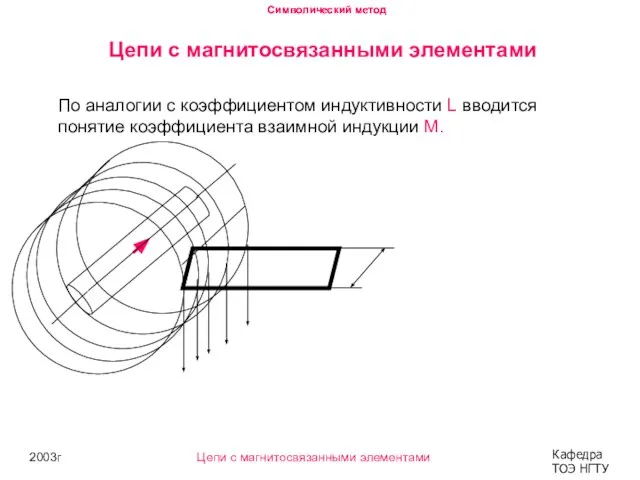

Презентация по физике Транспорт будущего  Символический метод. Цепи с магнитосвязанными элементами

Символический метод. Цепи с магнитосвязанными элементами Презентация на тему: «Теория фотоэффекта»

Презентация на тему: «Теория фотоэффекта» Процессы переноса

Процессы переноса Ультразвук и инфразвук

Ультразвук и инфразвук Биоэлектрлік құбылыстар. Биопотенциалдар табиғаты туралы қазіргі кездегі көзқарас

Биоэлектрлік құбылыстар. Биопотенциалдар табиғаты туралы қазіргі кездегі көзқарас Презентация Голография

Презентация Голография  Зависимость силы тока от напряжения. Сопротивление проводника

Зависимость силы тока от напряжения. Сопротивление проводника Кинематика материальной точки. (Тема 1)

Кинематика материальной точки. (Тема 1) Диагностика и ремонт ТНВД двигателя автомобиля Киа Рио в автосервисе ООО КАРС

Диагностика и ремонт ТНВД двигателя автомобиля Киа Рио в автосервисе ООО КАРС Энергия мысли. Сила мысли

Энергия мысли. Сила мысли Тайна сокровищ Ощущение тайны - наиболее прекрасное из доступных нам переживаний. Именно это чувство стоит у колыбели настоящ

Тайна сокровищ Ощущение тайны - наиболее прекрасное из доступных нам переживаний. Именно это чувство стоит у колыбели настоящ Основні закономірності термодинаміки. Термостатика та термодинаміка. Лекція 1

Основні закономірності термодинаміки. Термостатика та термодинаміка. Лекція 1 Единая физическая картина мира. 11 класс

Единая физическая картина мира. 11 класс Электротехнические материалы

Электротехнические материалы Анализ сигналов

Анализ сигналов Аттестационная работа. Образовательная программа элективного курса. Математические методы в физике

Аттестационная работа. Образовательная программа элективного курса. Математические методы в физике