Содержание

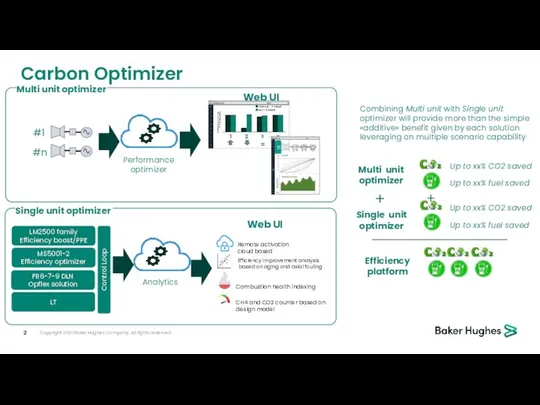

- 2. Copyright 2021 Baker Hughes Company. All rights reserved. Control Loop Carbon Optimizer Web UI LM2500 family

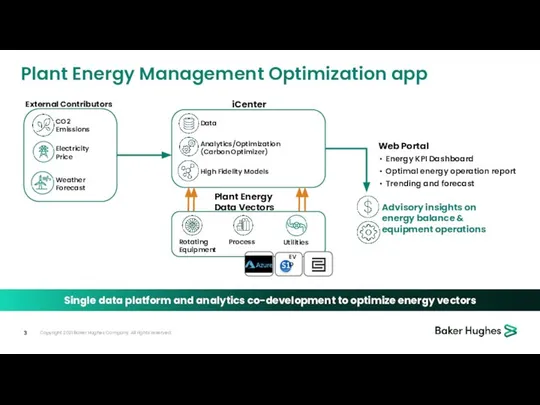

- 3. Copyright 2021 Baker Hughes Company. All rights reserved. Single data platform and analytics co-development to optimize

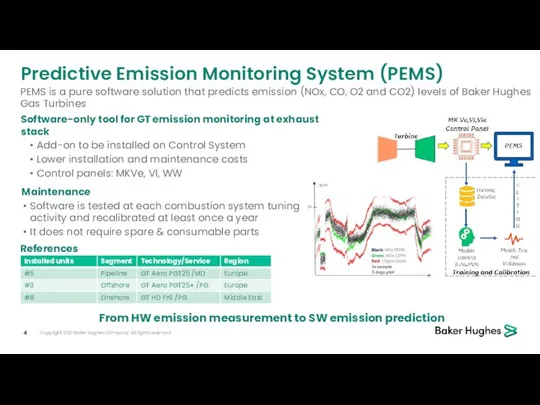

- 4. Copyright 2021 Baker Hughes Company. All rights reserved. From HW emission measurement to SW emission prediction

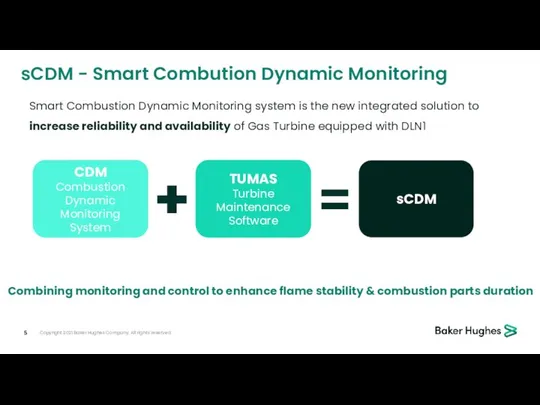

- 5. Copyright 2021 Baker Hughes Company. All rights reserved. Combining monitoring and control to enhance flame stability

- 6. Combustion Dynamic Monitoring & Remote Tuning Copyright 2021 Baker Hughes Company. All rights reserved. Increasing Productivity

- 7. Copyright 2021 Baker Hughes Company. All rights reserved. DLN Tuning Maintenance Software - TUMAS sCDM -

- 8. Copyright 2021 Baker Hughes Company. All rights reserved. Map 2 Winter Map 1 Summer Conventional mapping

- 10. Скачать презентацию

Copyright 2021 Baker Hughes Company. All rights reserved.

Control Loop

Carbon Optimizer

Web

Copyright 2021 Baker Hughes Company. All rights reserved.

Control Loop

Carbon Optimizer

Web

LM2500 family

Efficiency boost/PPE

MS5001-2

Efficiency optimizer

LT

FR6-7-9 DLN

Opflex solution

Remote activation

cloud based

Efficiency improvement analysis

based on aging and axial fouling

Combustion health indexing

CH4 and CO2 counter based on design model

...

#1

#n

Performance

optimizer

Web UI

Analytics

Multi unit optimizer

Single unit optimizer

Multi unit optimizer

Single unit optimizer

Efficiency platform

+

+

Combining Multi unit with Single unit optimizer will provide more than the simple «additive» benefit given by each solution leveraging on multiple scenario capability

Up to xx% CO2 saved

Up to xx% fuel saved

Up to xx% CO2 saved

Up to xx% fuel saved

Copyright 2021 Baker Hughes Company. All rights reserved.

Single data platform and

Copyright 2021 Baker Hughes Company. All rights reserved.

Single data platform and

External Contributors

Plant Energy

Data Vectors

iCenter

CO2 Emissions

Electricity

Price

Weather Forecast

Web Portal

Energy KPI Dashboard

Optimal energy operation report

Trending and forecast

Rotating Equipment

Process

Utilities

Data

Analytics/Optimization

(Carbon Optimizer)

High Fidelity Models

Advisory insights on energy balance & equipment operations

Plant Energy Management Optimization app

Copyright 2021 Baker Hughes Company. All rights reserved.

From HW emission measurement

Copyright 2021 Baker Hughes Company. All rights reserved.

From HW emission measurement

Software-only tool for GT emission monitoring at exhaust stack

Add-on to be installed on Control System

Lower installation and maintenance costs

Control panels: MKVe, VI, WW

Maintenance

Software is tested at each combustion system tuning activity and recalibrated at least once a year

It does not require spare & consumable parts

PEMS is a pure software solution that predicts emission (NOx, CO, O2 and CO2) levels of Baker Hughes Gas Turbines

References

Predictive Emission Monitoring System (PEMS)

Copyright 2021 Baker Hughes Company. All rights reserved.

Combining monitoring and control

Copyright 2021 Baker Hughes Company. All rights reserved.

Combining monitoring and control

Smart Combustion Dynamic Monitoring system is the new integrated solution to increase reliability and availability of Gas Turbine equipped with DLN1

CDM

Combustion Dynamic Monitoring System

TUMAS

Turbine Maintenance Software

sCDM

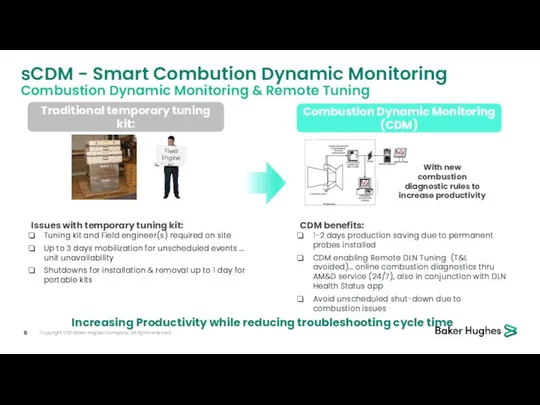

sCDM - Smart Combution Dynamic Monitoring

Combustion Dynamic Monitoring & Remote Tuning

Copyright 2021 Baker Hughes Company. All

Combustion Dynamic Monitoring & Remote Tuning

Copyright 2021 Baker Hughes Company. All

Increasing Productivity while reducing troubleshooting cycle time

Traditional temporary tuning kit:

Combustion Dynamic Monitoring (CDM)

Issues with temporary tuning kit:

Tuning kit and Field engineer(s) required on site

Up to 3 days mobilization for unscheduled events … unit unavailability

Shutdowns for installation & removal up to 1 day for portable kits

CDM benefits:

1-2 days production saving due to permanent probes installed

CDM enabling Remote DLN Tuning (T&L avoided)… online combustion diagnostics thru AM&D service (24/7), also in conjunction with DLN Health Status app

Avoid unscheduled shut-down due to combustion issues

Field Engineer

With new combustion diagnostic rules to increase productivity

sCDM - Smart Combution Dynamic Monitoring

Copyright 2021 Baker Hughes Company. All rights reserved.

DLN Tuning Maintenance Software

Copyright 2021 Baker Hughes Company. All rights reserved.

DLN Tuning Maintenance Software

sCDM - Smart Combution Dynamic Monitoring

What it is

Software designed to preserve the tuning of the DLN1 system with a focus on combustion dynamics.

How does it work

Adjust combustion parameters without affecting load to optimize combustion chamber dynamics in Premix

Test run on a regular time basis and when dynamics vary

Value proposition

Keep low acoustic dynamics in PMX steady state

Enhance flame stability

Reduce undesired transition from PMX to ELL

Enhance combustion parts life duration

Applicability

MS5001P/PA, MS5002C/D MS6001B, MS7001EA, MS9001E

Control panels: MKVI, MKVIe

Requirements

CDM installed

Dedicated tuning activity after installation (3 days)

Copyright 2021 Baker Hughes Company. All rights reserved.

Map 2

Winter

Map 1

Summer

Conventional mapping

Automated

Copyright 2021 Baker Hughes Company. All rights reserved.

Map 2

Winter

Map 1

Summer

Conventional mapping

Automated

Map 2

Winter

Map 1

Summer

Map 2

Winter

Map 1

Summer

3yr vision

Map during 1 start up

Map after engine swap

3yr vision

Dry Low Emission (DLE) combustion system automapping

Auto Tuning

Техническое обслуживание и ремонт тормозной системы автомобиля Renault Logan

Техническое обслуживание и ремонт тормозной системы автомобиля Renault Logan Принести эту нетронутую красоту людям… Дорога добра Егора Полушкина

Принести эту нетронутую красоту людям… Дорога добра Егора Полушкина Город Набережные Челны

Город Набережные Челны Основы организации перевозок на железнодорожном транспорте. Понятие о транспорте. Продукция транспорта

Основы организации перевозок на железнодорожном транспорте. Понятие о транспорте. Продукция транспорта 20160405_delovaya_igra_vybory_politicheskaya_partiya_nasha_russia

20160405_delovaya_igra_vybory_politicheskaya_partiya_nasha_russia Почему самолеты летают? Основные части самолета

Почему самолеты летают? Основные части самолета Лужение и пайка проводов

Лужение и пайка проводов Будет в НБ 30.03-05.04

Будет в НБ 30.03-05.04 20160504_sredstva_individualnoy_zashchity

20160504_sredstva_individualnoy_zashchity Отечественный воспитательный идеал в историко- педагогическом прочтении

Отечественный воспитательный идеал в историко- педагогическом прочтении Unsere Generation

Unsere Generation Модель организации внеурочной деятельности в начальной школе, направленная на формирование мотивационной сферы обучающихся

Модель организации внеурочной деятельности в начальной школе, направленная на формирование мотивационной сферы обучающихся мурченко (1)

мурченко (1) У тебя есть борода , я скажу тебе да

У тебя есть борода , я скажу тебе да Испытание и контроль качества электрооборудования расчетной линии в схеме электроснабжения цеха нефтяного оборудования

Испытание и контроль качества электрооборудования расчетной линии в схеме электроснабжения цеха нефтяного оборудования О конкурсе научно-технологических проектов

О конкурсе научно-технологических проектов Интерфейсы семейства “Стык С2”

Интерфейсы семейства “Стык С2” Тепловая схема турбоустановки ТЭЦ МЭИ

Тепловая схема турбоустановки ТЭЦ МЭИ Технология водостойких, огнестойких ДСтП

Технология водостойких, огнестойких ДСтП Огнетушители. Сроки и цена

Огнетушители. Сроки и цена 20120104_arhiv_zip_-_winrar_7

20120104_arhiv_zip_-_winrar_7 4

4 Пчеловодство Удмуртской республики

Пчеловодство Удмуртской республики Употребление 才就

Употребление 才就 Технология изготовления валов

Технология изготовления валов Средства аскетической борьбы

Средства аскетической борьбы Методы анализа стабильных изотопов

Методы анализа стабильных изотопов Правила застройки и землепользования г. Ангарска

Правила застройки и землепользования г. Ангарска