Содержание

- 2. Elements covered HEALTH & SAFETY Training explained Why we need training HASAWA 1974 PUWER 1998 LOLER

- 3. Health & Safety

- 4. Training explained Valid MHE Medical Basic Training Refreshed every 3 years Site Training Refreshed every year

- 5. Why we need training 1. Safe Practice Encourage good practice, develop safe procedures and to provide

- 6. The act is far ranging and covers: Employers Employees The self employed The general public Health

- 7. Health & Safety at Work Act 1974 EMPLOYERS responsibilities (section 2) 2(a) Provide and maintain plant

- 8. Health & Safety at Work Act 1974 EMPLOYEES Responsibilities Section 7(a) Duty to take reasonable care

- 9. Provision and Use of Work Equipment Regulations 1998 These regulations apply to the provision and use

- 10. Lifting Operations and Lifting Equipment Regulations 1998 All lifting equipment should be: Well designed and constructed

- 11. Management of Health & Safety at Work Regulations 1999 Risk assessment L’Oreal carries out a risk

- 12. Accidents and associated risks Accidents don’t just happen They are caused by, among other things: Operator

- 13. The cost of accidents The COST of accidents: Personal injury Social and emotional costs Legal costs

- 14. Personal risk assessment What is the task? Make sure you know exactly what the task involves

- 15. Personal risk assessment Do I know who or what could be harmed? Am I aware of

- 16. Personal protective equipment PPE Types Gloves, goggles, aprons, safety footwear PPE Requirements Check what PPE is

- 17. Alcohol and drugs The law considers a fork lift truck to be a motor vehicle This

- 18. Equipment Introduction

- 19. Understanding the hydraulics The simple definition of hydraulics is: “The power of liquid, under pressure, passed

- 20. Rated capacity plate Rated Capacity Load Centre Distance Year of Manufacture Mass of Truck Without Battery

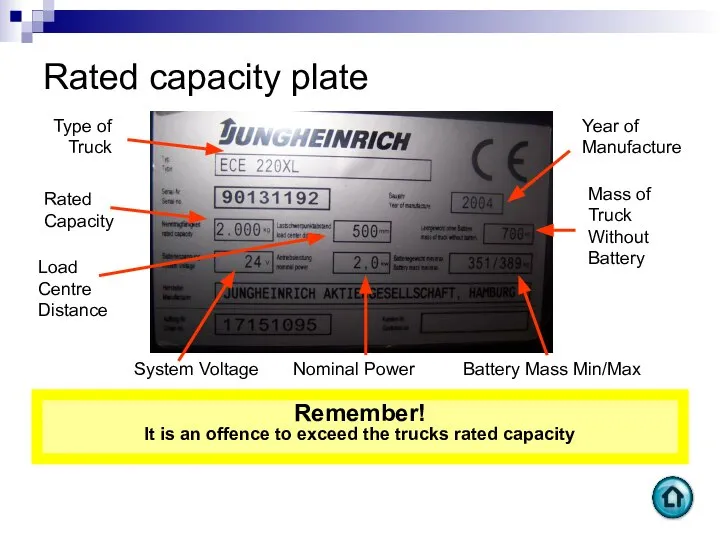

- 21. Load centre plate The load centre is the distance from the vertical face of the forks

- 22. Stability Triangle

- 23. Stability triangle Stability triangle Truck centre of gravity Combined centre of gravity Load centre of gravity

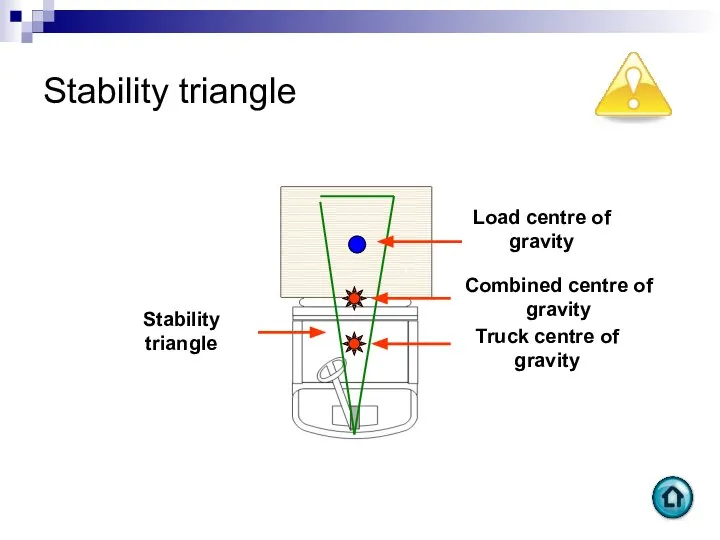

- 24. Lengthwise instability Overloading Causing the truck to tip forward Harsh braking Centre of gravity moving quickly

- 25. Sideways instability Ground conditions If one wheel drops into a pothole Turning at speed Even if

- 26. General Safe Driving Rules

- 27. General safe driving rules Park properly: With key removed or logged out Forks lowered to the

- 28. General safe driving rules Obey all signs and travel direction restrictions Make smooth use of controls

- 29. General safe driving rules Be aware of pedestrians at all times Always park safely Only handle

- 30. General safe driving rules Always look in the direction of travel When turning in reverse, your

- 31. General safe driving rules A moving truck is at its most stable when driven: In a

- 32. General safe driving rules Concentrate – no eating, drinking, smoking, using a mobile phone etc No

- 33. General safe driving rules When approaching a blind corner: Slow down and manoeuvre slowly Be prepared

- 34. Driving on inclines Drive slowly Do not turn, even with an unladen truck Always drive directly

- 35. Ergonomics All MHE are Ergonomically designed for safety & comfort You must ensure all your limbs

- 36. Pallet Types & Load Assessment

- 37. Four-way entry non reversible Pallet types Four-way entry reversible Two-way entry reversible Four-way entry cruciform (shown

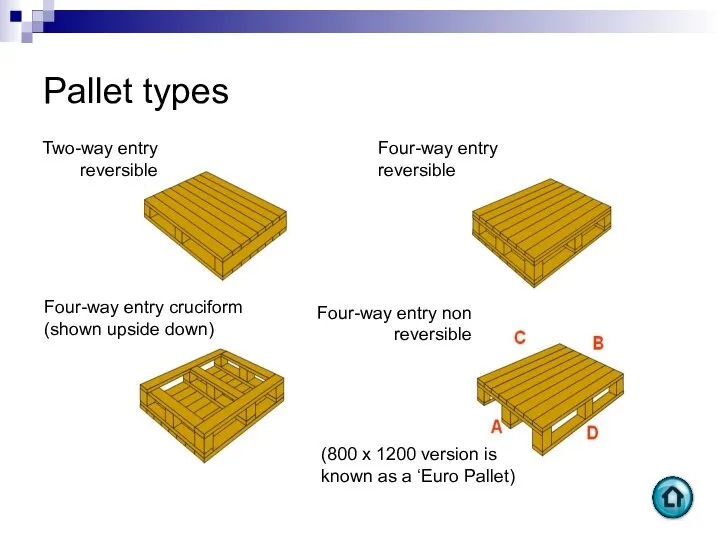

- 38. Pallet types Normally metal so take extra care when handling as metal forks against metal pallet

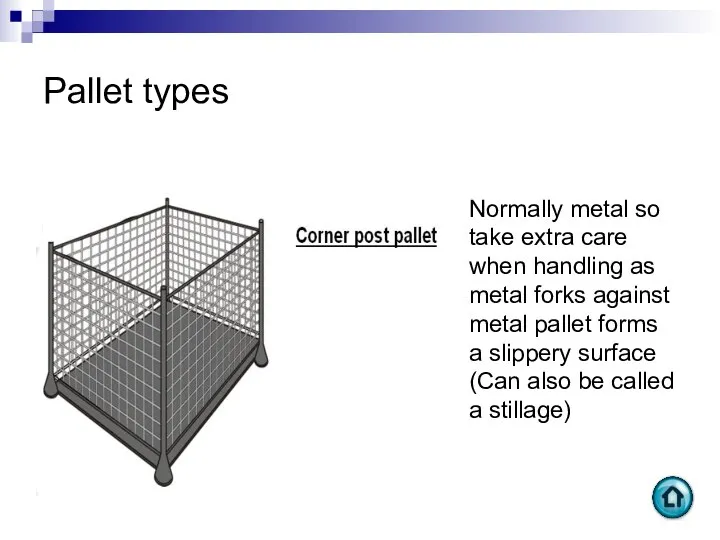

- 39. Pallet and load assessment Make sure the weight falls within the rated capacity of the truck

- 40. Pallet and load assessment Load Centre: Ensure the load centre and weight of the load fall

- 41. Pallet and load assessment Size of the Load: Ensure the load is not too large to

- 42. Battery Care & Charging

- 43. Battery care and charging Batteries are the most expensive single item on truck and often the

- 44. Battery care and charging Electricity Always use the correct charger for the type of truck you

- 45. Battery care and charging Sulphuric acid (burns) Wear appropriate safety equipment, e.g. rubber gloves, goggles, rubber

- 46. Battery care and charging Hydrogen and Oxygen Do not smoke whilst handling or charging the battery

- 47. Pre Use Checks

- 48. Pre use checks Pre-use checks must be carried out each day, or at the start of

- 49. Pre use checks Forks Check for cracks, fractures, excessive wear, deformity and ensure they are equally

- 50. Pre use checks Drive and braking Move the truck backwards and forwards and test both the

- 51. Pre use checks Example of Pre Use Check Sheet

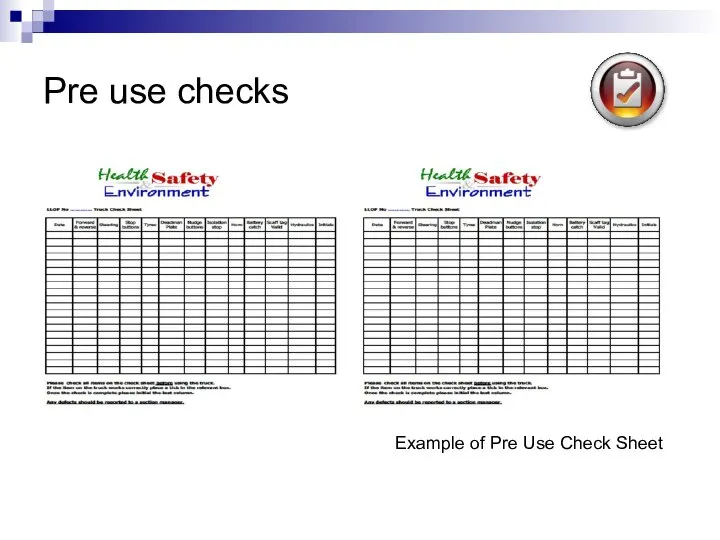

- 52. Use of the manufacturers operating manual The manufacturers operating manual provides important information on the safe

- 53. Any Questions?

- 54. Equipment Specific LLOP EPT STACKER

- 55. Low Level Order Picker (LLOP)

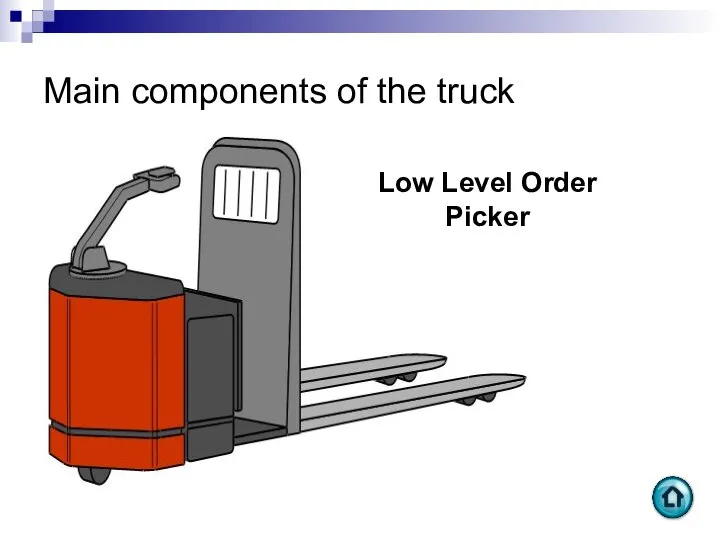

- 56. Main Components: LLOP

- 57. Main components of the truck Low Level Order Picker

- 58. Main components of the truck Battery Compartment

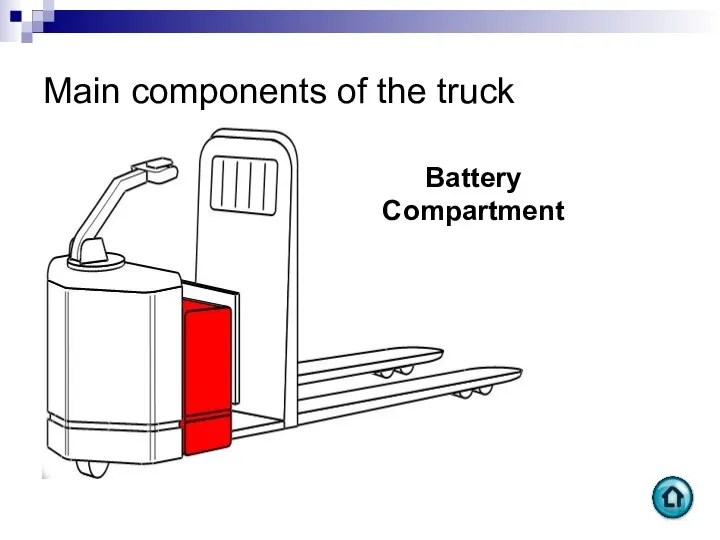

- 59. Main components of the truck Forks Carry the load, which should always be ‘heeled’ for safe

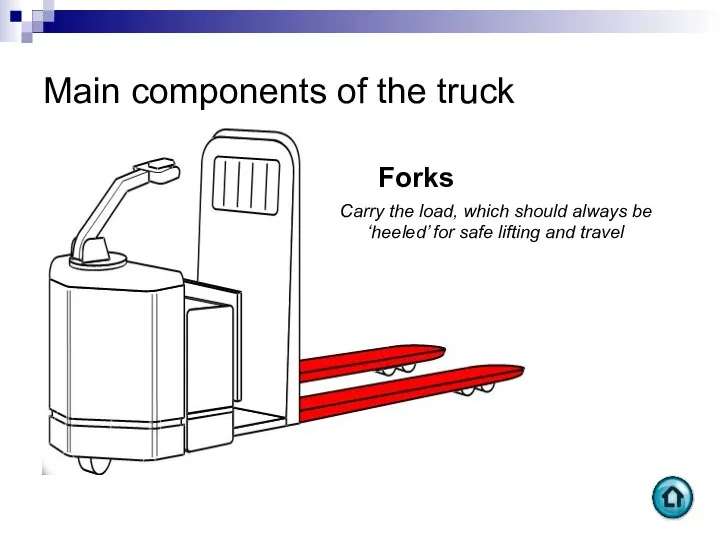

- 60. Main components of the truck Front support rollers Support the front of the forks, always ensure

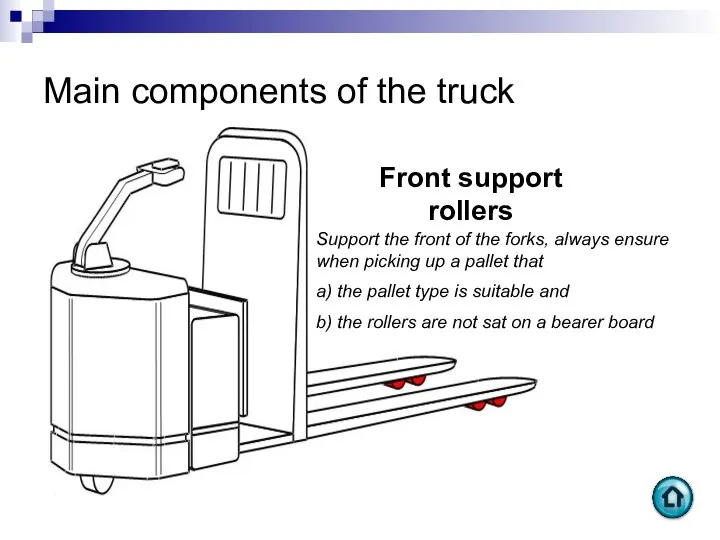

- 61. Main components of the truck Drive Wheel Driven by the batteries to provide movement of the

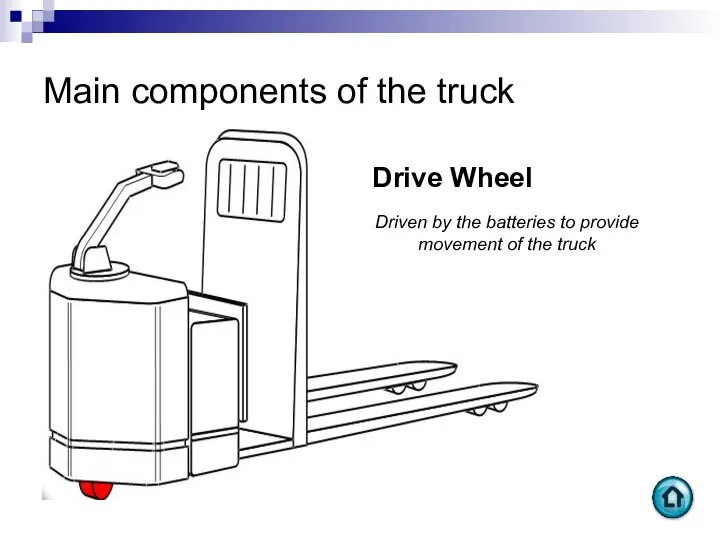

- 62. Main components of the truck Tiller arm and tiller controls Controls steering left to right Houses

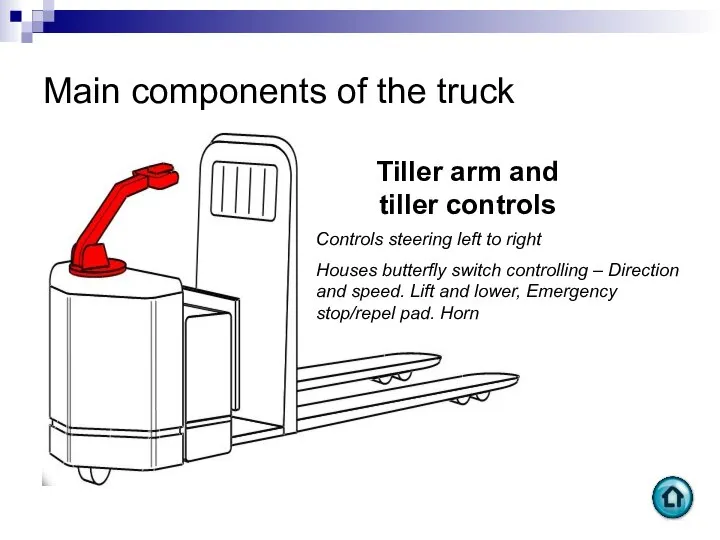

- 63. Main components of the truck Ride on platform Operator position with ‘deadman’ footpad

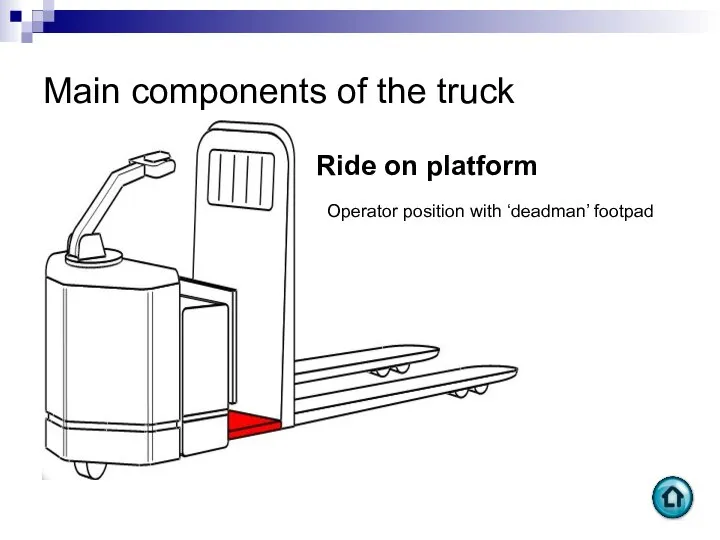

- 64. Main components of the truck Load Guard

- 65. LLOP Safe Driving Rules

- 66. General safe driving rules Stay in control: You must have two hands on the controls whenever

- 67. General safe driving rules Stay in control: Always face the direction you are travelling. Drive forwards

- 68. General safe driving rules Mount / Dismount & Parking: Ensure equipment has come to a complete

- 69. Electric Pedestrian Truck (EPT)

- 70. Main Components: EPT

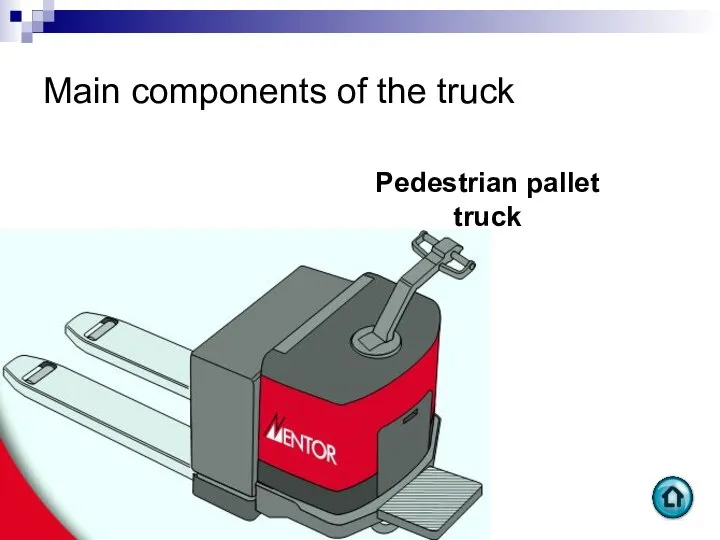

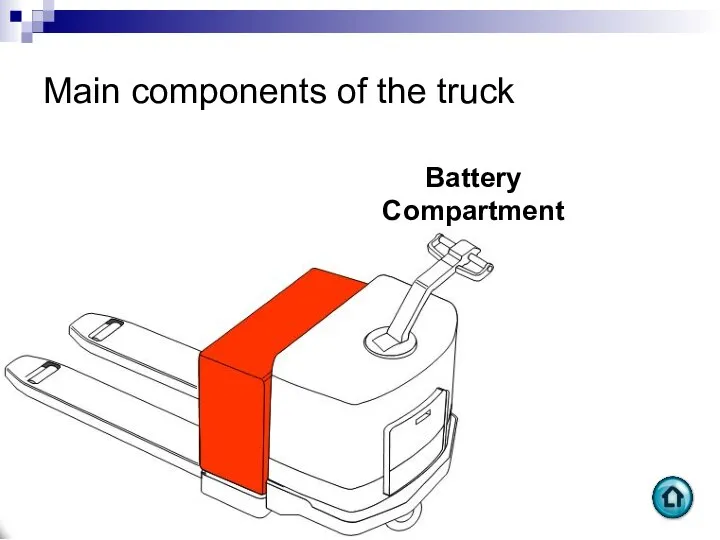

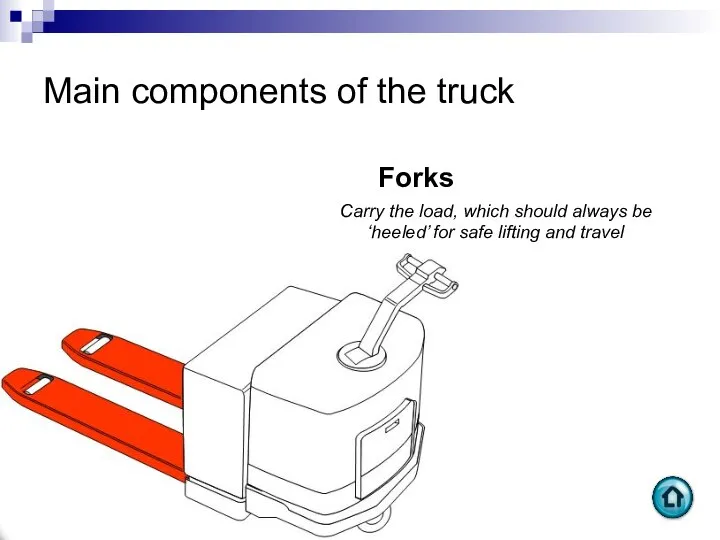

- 71. Main components of the truck Pedestrian pallet truck

- 72. Main components of the truck Battery Compartment

- 73. Main components of the truck Forks Carry the load, which should always be ‘heeled’ for safe

- 74. Main components of the truck Front support rollers Support the front of the forks, always ensure

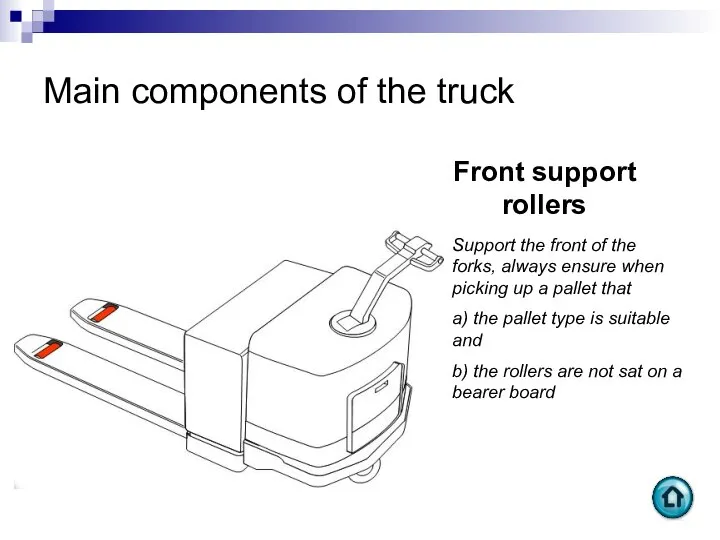

- 75. Main components of the truck Drive Wheel Driven by the batteries to provide movement of the

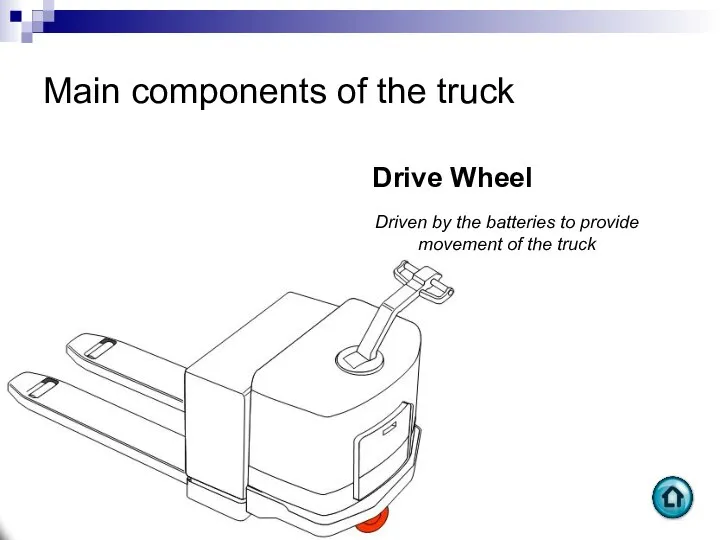

- 76. Main components of the truck Tiller arm and Tiller controls Controls steering and applies brakes by

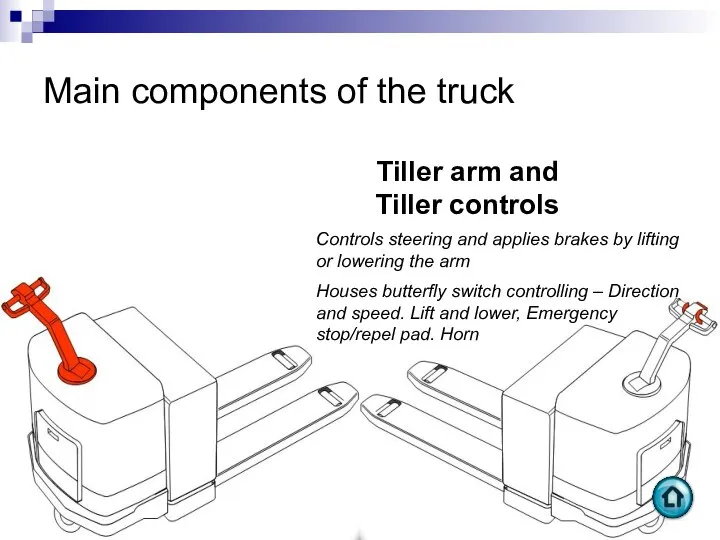

- 77. Main components of the truck Ride on platform Operator position with ‘dead man’ footpad

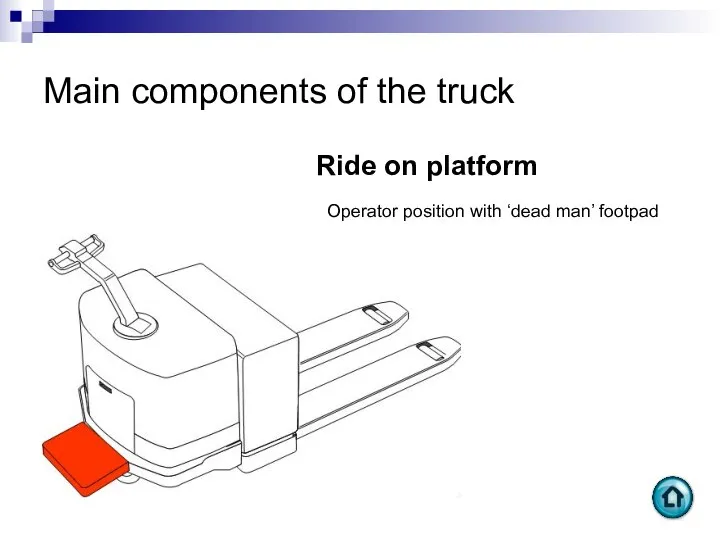

- 78. General safe driving rules Stay in control: Keep both hands on the steering controls at all

- 79. General safe driving rules Stay in control: Always face the direction you are travelling. You may

- 80. General safe driving rules Stay in control: Trafford Park Only specially adapted Red Pyroban EPT’s are

- 81. General safe driving rules Mount & Dismount: Ensure equipment has come to a complete stop before

- 82. Vehicle loading and unloading Precautions to be taken whilst loading/unloading over dock leveller… Bend knees to

- 83. Vehicle loading and unloading (general rules) As a lift truck driver you should liaise with the

- 84. Pedestrian Stacker Truck

- 85. Main Components: Stacker Truck

- 86. Main components of the truck Pedestrian stacker truck

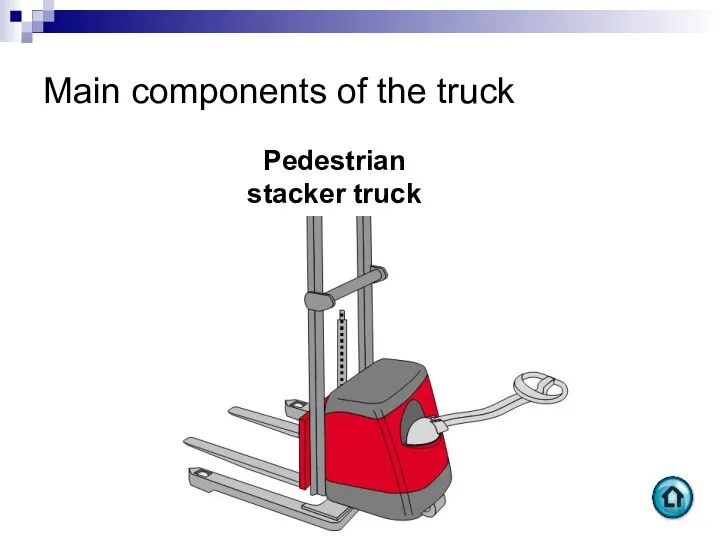

- 87. Main components of the truck Battery Compartment

- 88. Main components of the truck Forks Carry the load, which should always be ‘heeled’ for safe

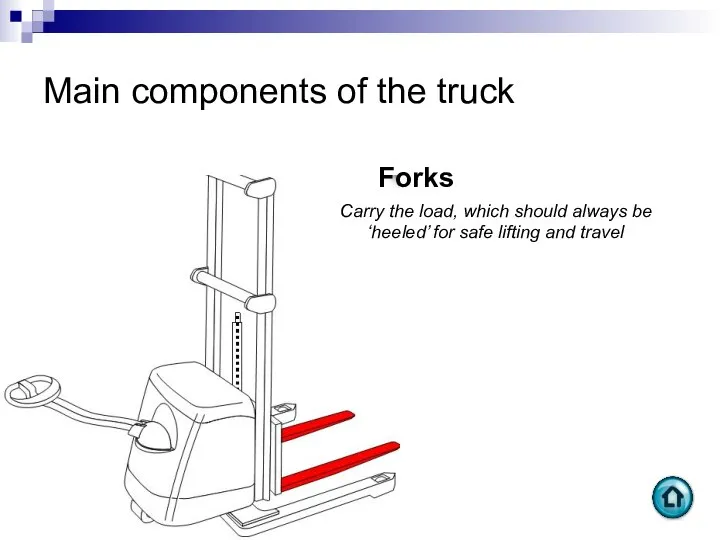

- 89. Main components of the truck Carriage Plate

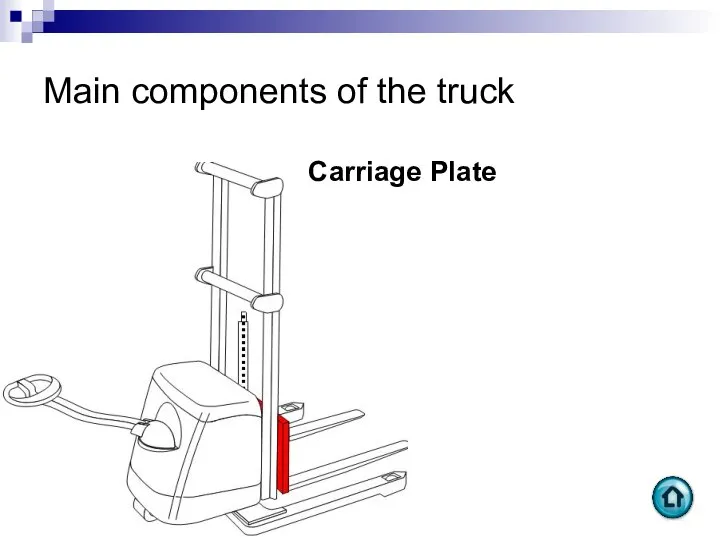

- 90. Main components of the truck Mast/s

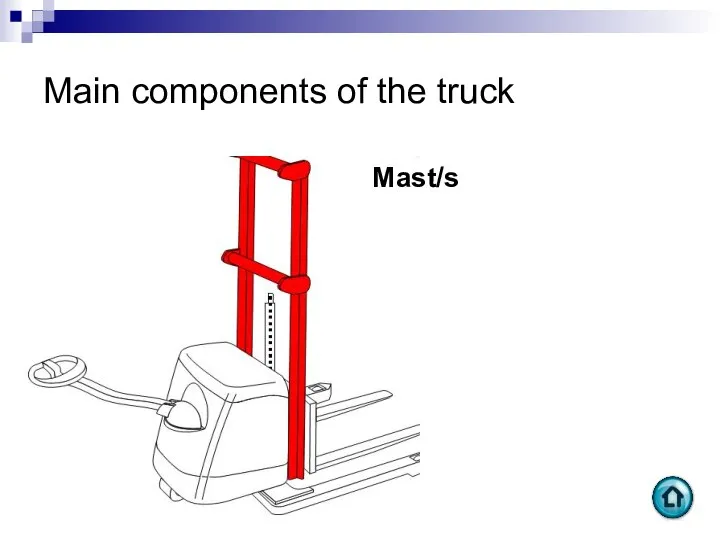

- 91. Main components of the truck Load chain/s

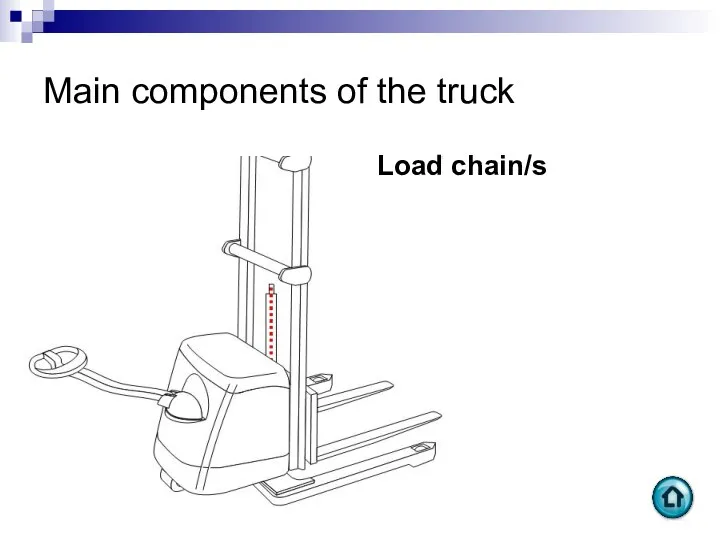

- 92. Main components of the truck Hoist cylinder rams

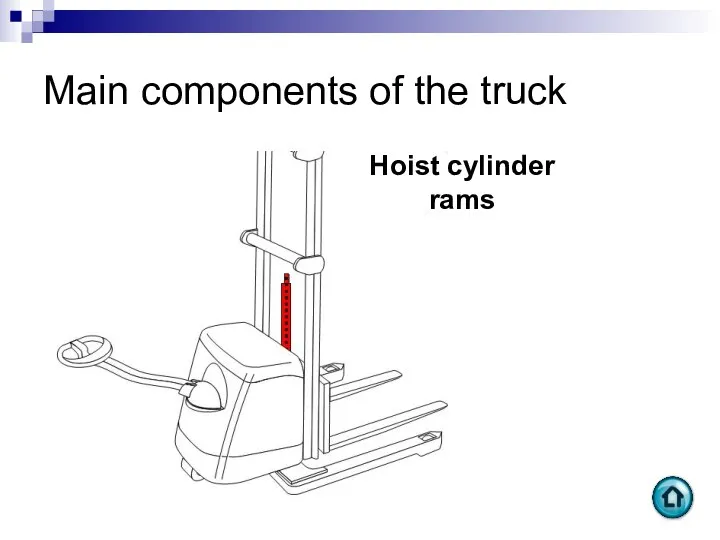

- 93. Main components of the truck Tilt cylinder rams

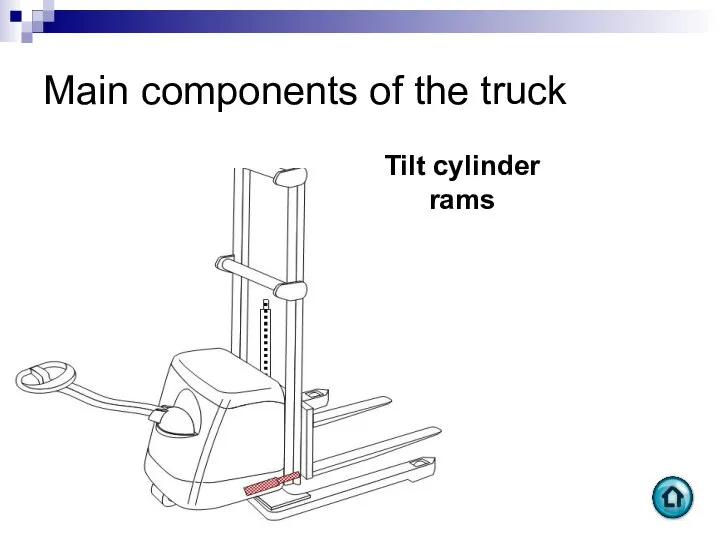

- 94. Main components of the truck Drive & steering wheel

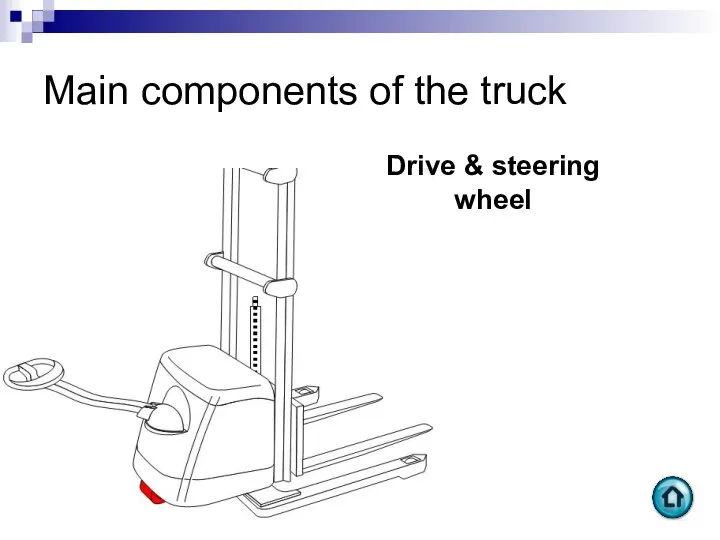

- 95. Main components of the truck Load bearing wheels

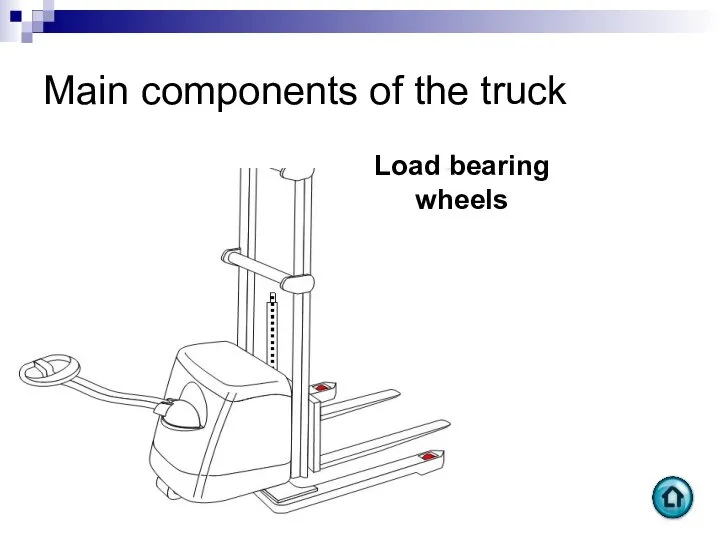

- 96. Main components of the truck Tiller arm & controls

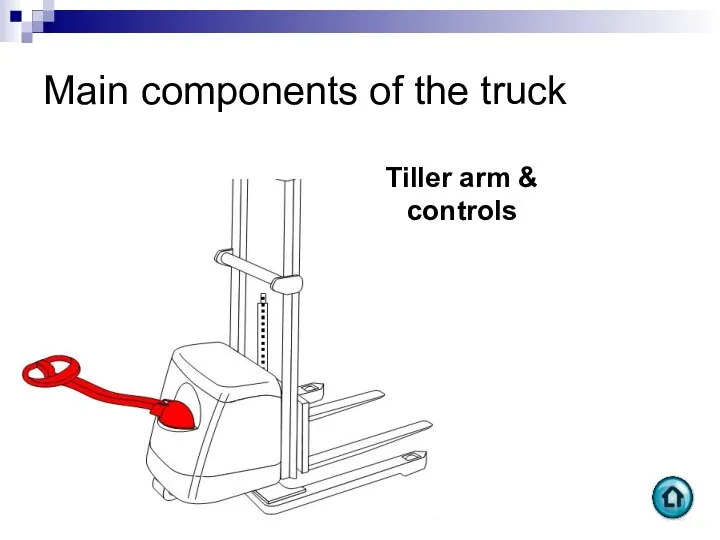

- 97. Main components of the truck Ride on platform

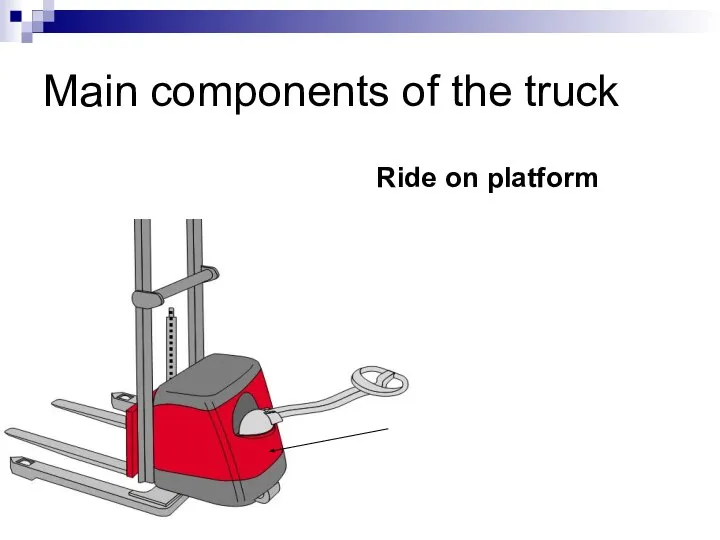

- 98. General safe driving rules Stay in control: Keep both hands on the steering controls at all

- 99. General safe driving rules Stay in control: Always face the direction you are travelling. You may

- 101. Скачать презентацию

Сільське господарство України. Рослинництво

Сільське господарство України. Рослинництво Свойства топлив Механические примеси и вода в бензине

Свойства топлив Механические примеси и вода в бензине Звук и буква Х

Звук и буква Х 10 интересных фактов о порте Южный

10 интересных фактов о порте Южный покупка гуггла

покупка гуггла ф.г.лорка

ф.г.лорка Lexicography. Types of dictionaries

Lexicography. Types of dictionaries Лекция №3. Этика делового общения. Основные функции общения

Лекция №3. Этика делового общения. Основные функции общения Cui trebuie să ne închinăm?

Cui trebuie să ne închinăm? 20151201_hram_neporochnogo_zachatiya_presvyatoy_devy_marii

20151201_hram_neporochnogo_zachatiya_presvyatoy_devy_marii Хранение подвижного состава автомобильного транспорта

Хранение подвижного состава автомобильного транспорта Соціальний пакет

Соціальний пакет Специфические свойства аглопорита

Специфические свойства аглопорита День святых жён - мироносиц

День святых жён - мироносиц Робот бабочка

Робот бабочка Звери и птицы весной

Звери и птицы весной Система технічного регулювання при виробництві та обігу фіточаїв

Система технічного регулювання при виробництві та обігу фіточаїв Твердотельная электроника. Семинар №7. Расчет характеристик МОПТ в рамках идеальной модели

Твердотельная электроника. Семинар №7. Расчет характеристик МОПТ в рамках идеальной модели Год Российской науки

Год Российской науки Петр Просто Великий

Петр Просто Великий Монтажные и обмоточные провода

Монтажные и обмоточные провода Миниатюрные ландшафтные композиции из тропических растений

Миниатюрные ландшафтные композиции из тропических растений ФФЯ собрание с 1 курсом

ФФЯ собрание с 1 курсом Автопаркинг на 500 автомобилей

Автопаркинг на 500 автомобилей 5 - Г класс- Звезды. Фотоальбом

5 - Г класс- Звезды. Фотоальбом аграм дисгр

аграм дисгр 20140625_pril_0

20140625_pril_0 Interview Questions-Basics of Electronics and Communication Engg

Interview Questions-Basics of Electronics and Communication Engg