Содержание

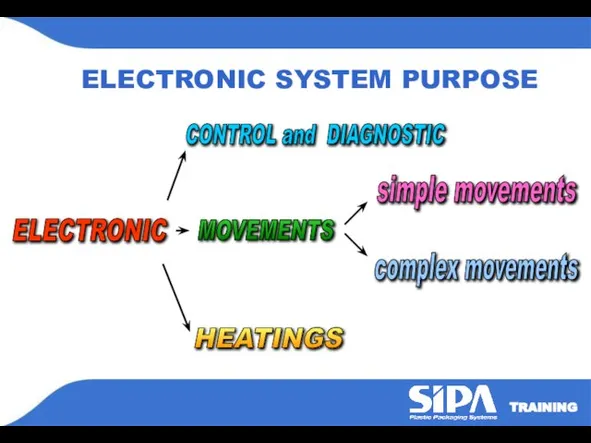

- 2. ELECTRONIC SYSTEM PURPOSE ELECTRONIC HEATINGS MOVEMENTS simple movements complex movements CONTROL and DIAGNOSTIC

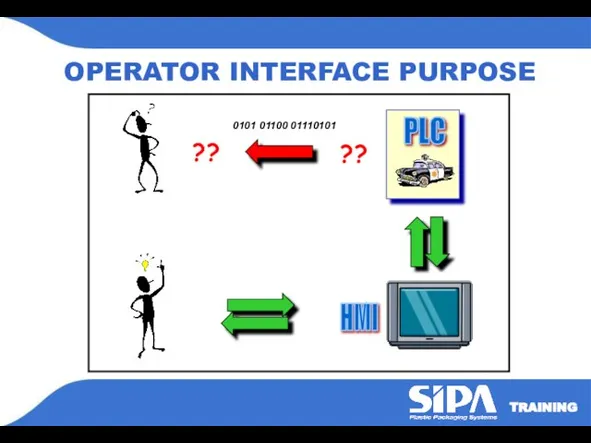

- 3. 0101 01100 01110101 PLC ? HMI ? ? ? OPERATOR INTERFACE PURPOSE

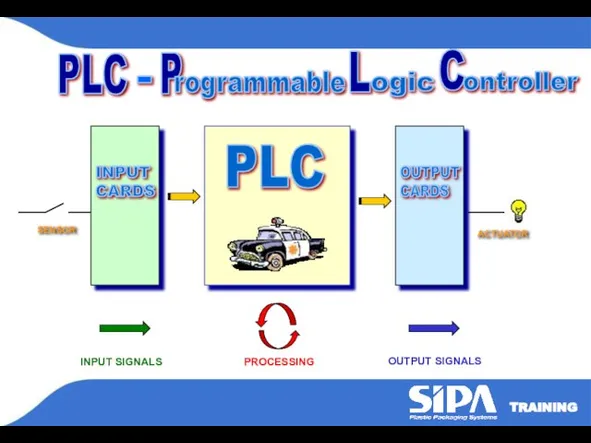

- 4. TRAINING PLC PLC C L P ontroller ogic - PROCESSING INPUT CARDS OUTPUT CARDS INPUT SIGNALS

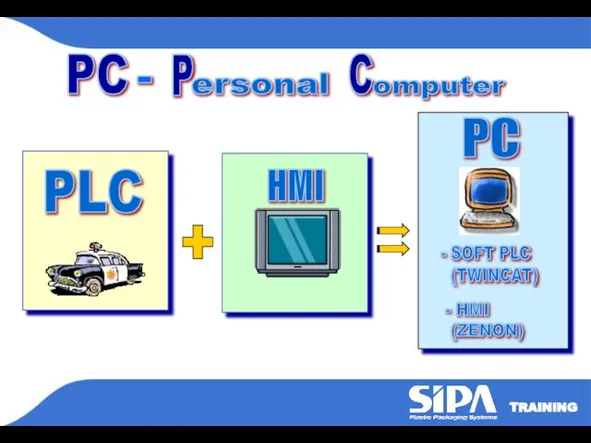

- 5. TRAINING PC PLC C P omputer - ersonal PC - SOFT PLC (TWINCAT) HMI - HMI

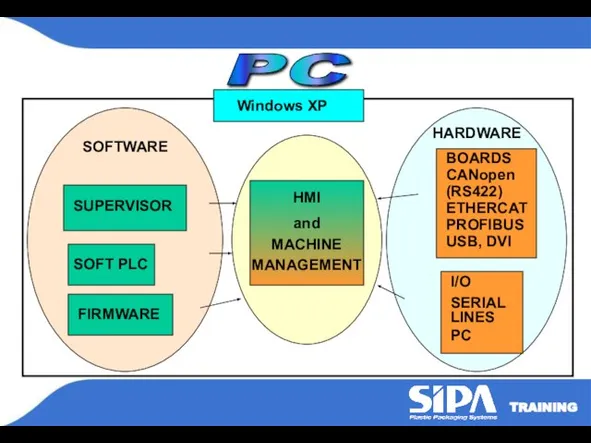

- 6. PC Windows XP SUPERVISOR SOFT PLC SOFTWARE HARDWARE BOARDS CANopen (RS422) ETHERCAT PROFIBUS USB, DVI I/O

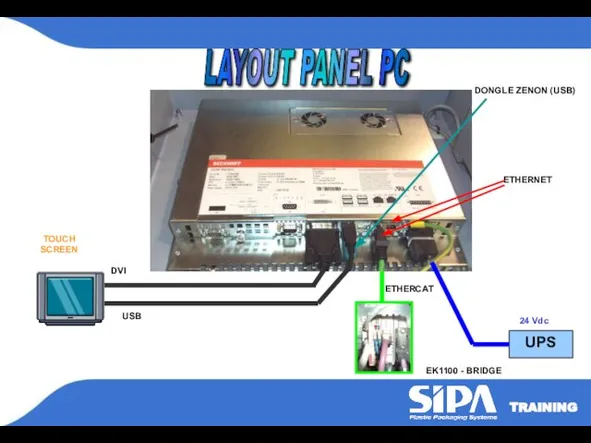

- 7. LAYOUT PANEL PC TOUCH SCREEN DVI USB UPS 24 Vdc DONGLE ZENON (USB) EK1100 - BRIDGE

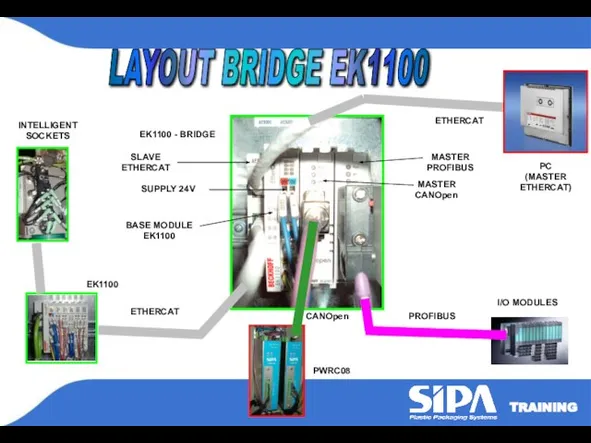

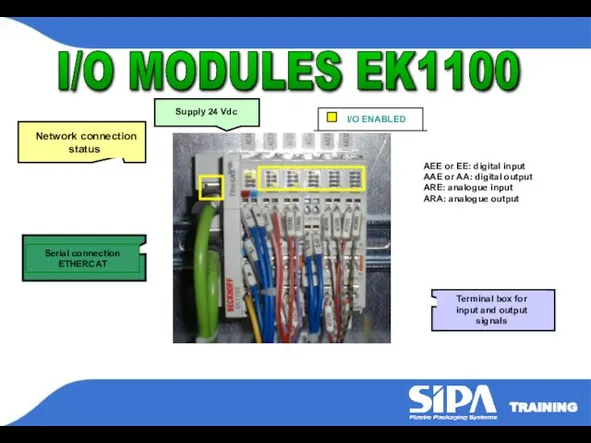

- 8. LAYOUT BRIDGE EK1100 EK1100 - BRIDGE ETHERCAT PC (MASTER ETHERCAT) PROFIBUS CANOpen I/O MODULES ETHERCAT PWRC08

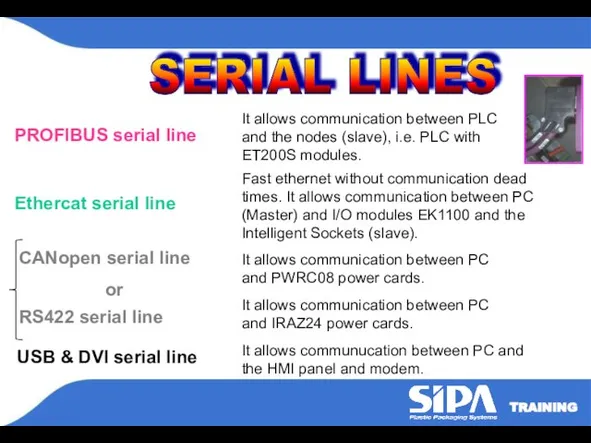

- 9. SERIAL LINES Fast ethernet without communication dead times. It allows communication between PC (Master) and I/O

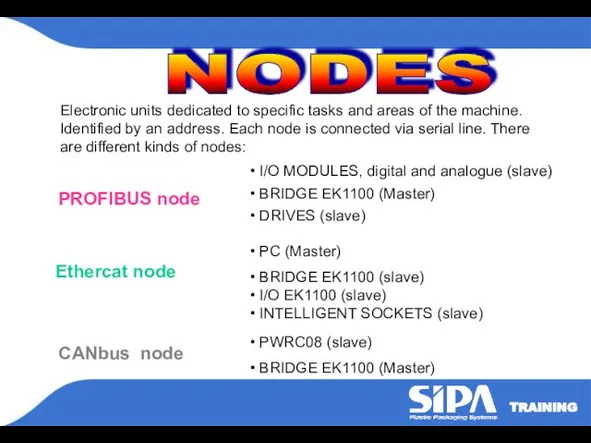

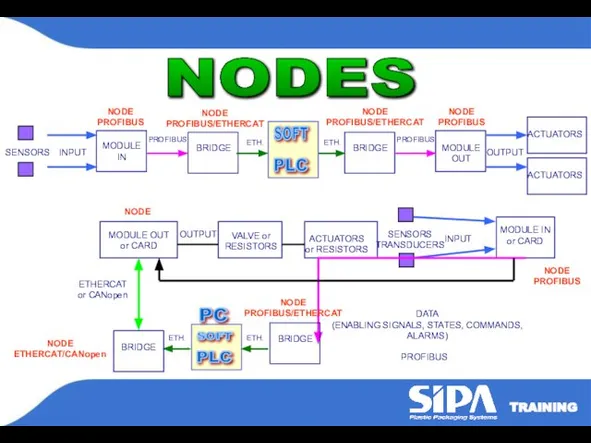

- 10. NODES Electronic units dedicated to specific tasks and areas of the machine. Identified by an address.

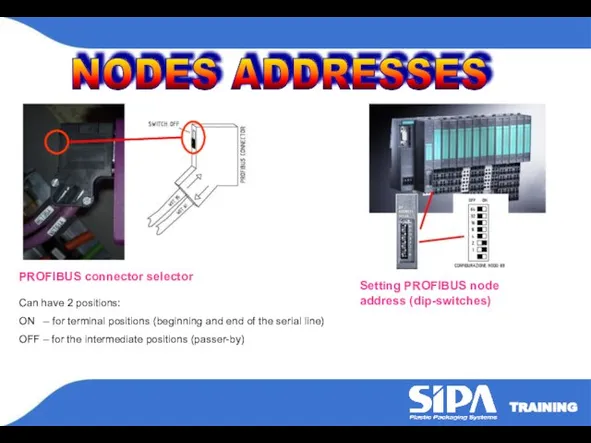

- 11. NODES ADDRESSES PROFIBUS connector selector Can have 2 positions: ON – for terminal positions (beginning and

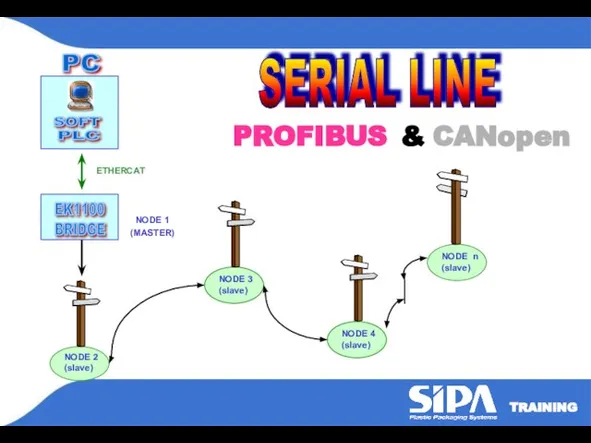

- 12. NODE 3 (slave) NODE 2 (slave) NODE n (slave) NODE 4 (slave) SERIAL LINE PROFIBUS &

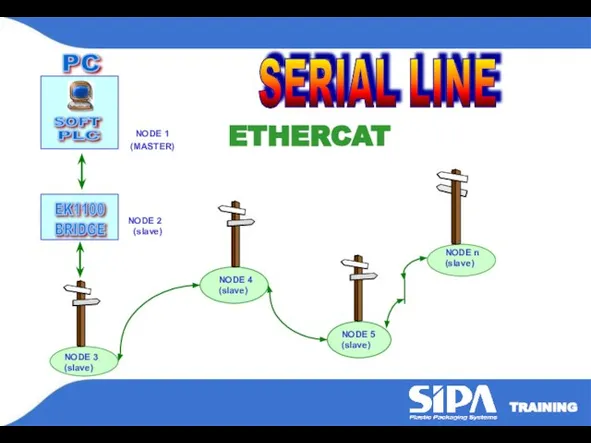

- 13. NODE 3 (slave) NODE 2 (slave) NODE n (slave) NODE 4 (slave) SERIAL LINE PLC PC

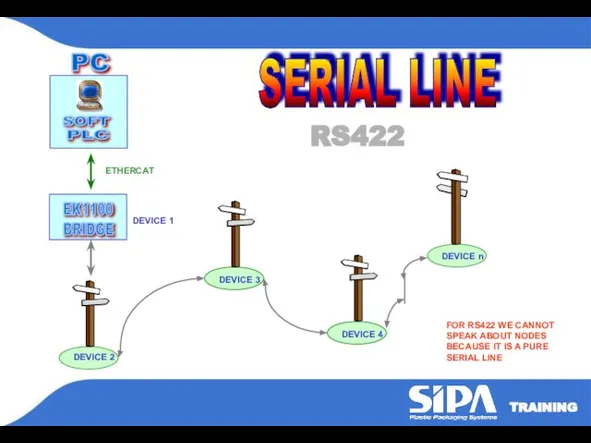

- 14. DEVICE 2 DEVICE 1 DEVICE n DEVICE 3 SERIAL LINE RS422 PLC PC SOFT EK1100 BRIDGE

- 15. NODES SENSORS MODULE IN INPUT MODULE OUT OUTPUT ACTUATORS ACTUATORS PROFIBUS PROFIBUS MODULE OUT or CARD

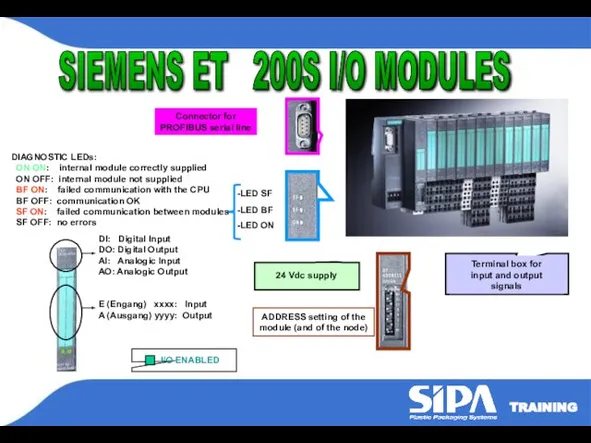

- 16. SIEMENS ET 200S I/O MODULES -LED SF -LED BF -LED ON ADDRESS setting of the module

- 17. AEE or EE: digital input AAE or AA: digital output ARE: analogue input ARA: analogue output

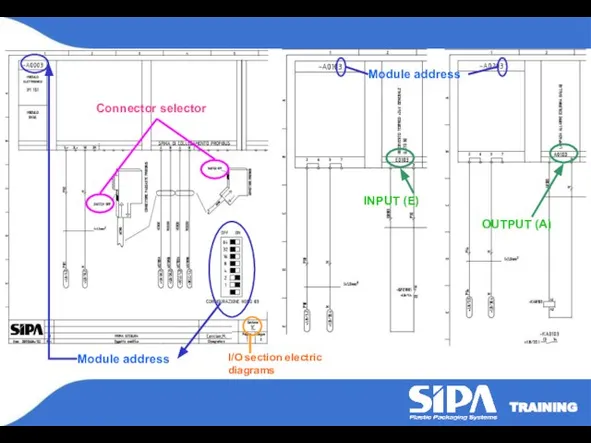

- 18. Connector selector Module address I/O section electric diagrams Module address INPUT (E) OUTPUT (A)

- 19. SIMPLE with ON/OFF VALVE and ON/OFF SENSOR COMPLEX with DRIVE and TRANSDUCER (linear or rotary) KIND

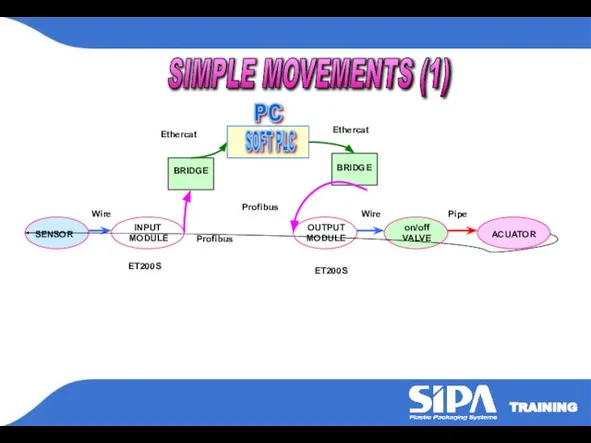

- 20. SENSOR INPUT MODULE OUTPUT MODULE on/off VALVE ACUATOR Wire Wire Pipe SIMPLE MOVEMENTS (1) SOFT PLC

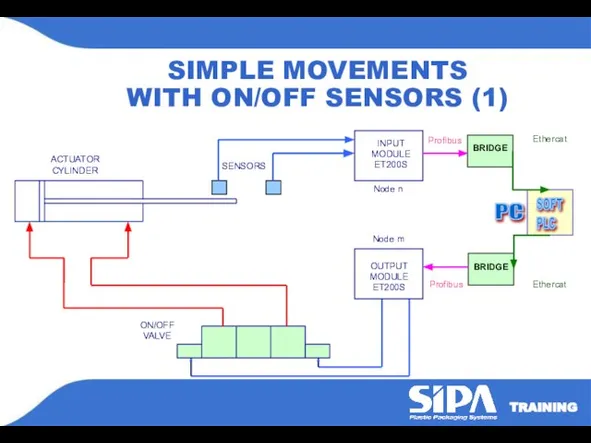

- 21. SENSOR INPUT MODULE OUTPUT MODULE on/off VALVE ACUATOR Wire Wire Pipe SIMPLE MOVEMENTS (2) SOFT PLC

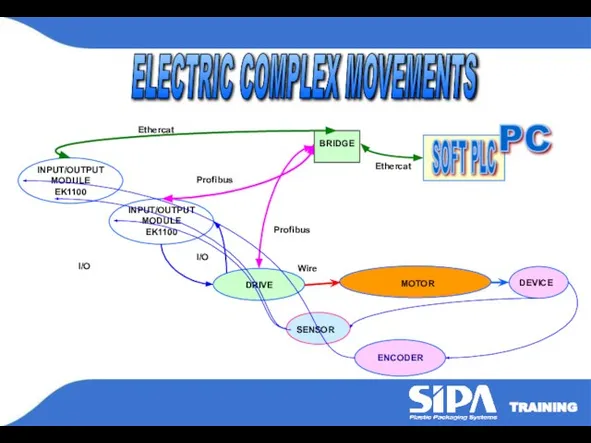

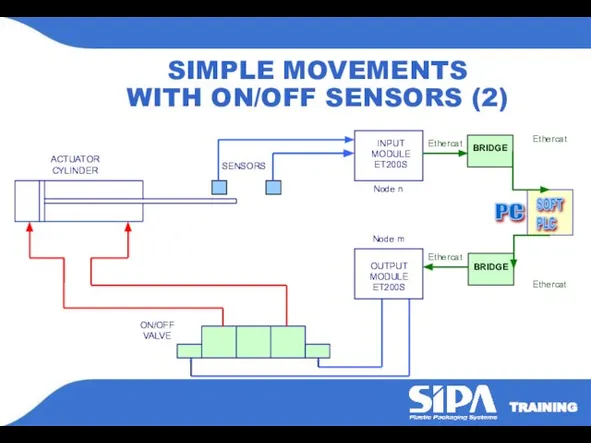

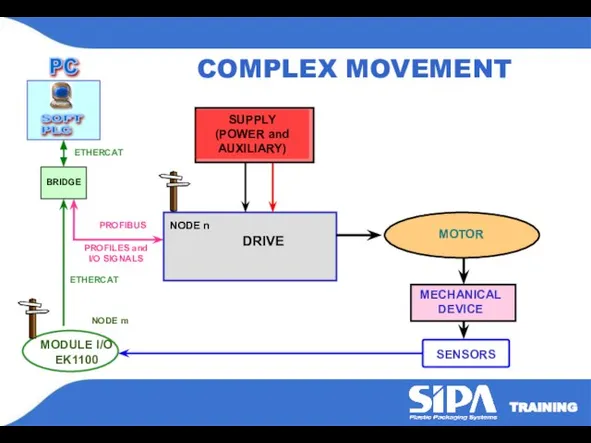

- 22. SOFT PLC MOTOR DEVICE INPUT/OUTPUT MODULE EK1100 DRIVE Profibus Ethercat Wire PC I/O BRIDGE Profibus INPUT/OUTPUT

- 23. SENSORS SIMPLE MOVEMENTS WITH ON/OFF SENSORS (1) ACTUATOR CYLINDER ON/OFF VALVE INPUT MODULE ET200S OUTPUT MODULE

- 24. SENSORS SIMPLE MOVEMENTS WITH ON/OFF SENSORS (2) ACTUATOR CYLINDER ON/OFF VALVE INPUT MODULE ET200S OUTPUT MODULE

- 25. NODE m MECHANICAL DEVICE MOTOR SENSORS MODULE I/O EK1100 PROFIBUS DRIVE NODE n PROFILES and I/O

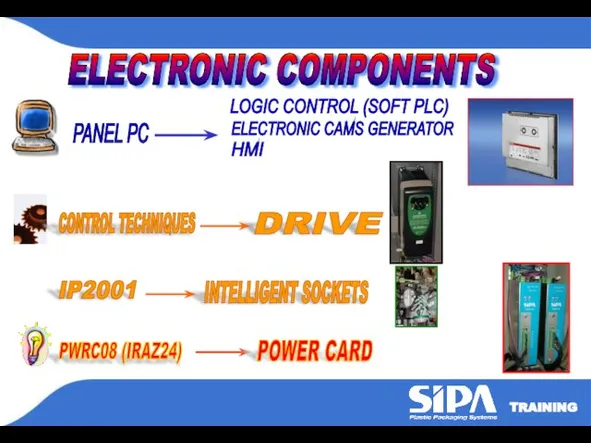

- 26. ELECTRONIC COMPONENTS PANEL PC PWRC08 (IRAZ24) DRIVE CONTROL TECHNIQUES ELECTRONIC CAMS GENERATOR HMI INTELLIGENT SOCKETS IP2001

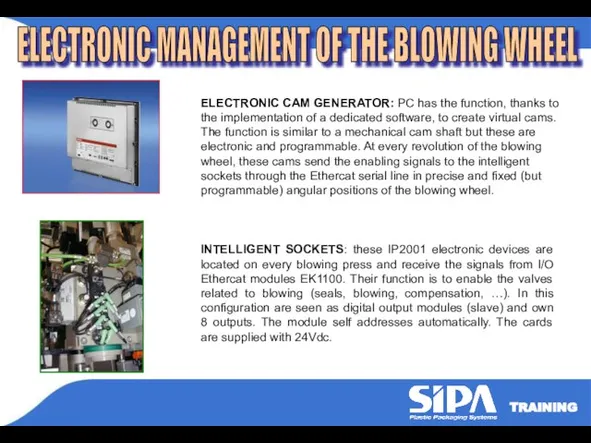

- 27. ELECTRONIC CAM GENERATOR: PC has the function, thanks to the implementation of a dedicated software, to

- 28. ABSOLUTE ENCODER: electromechanical device that converts the angular position of its rotating axis in electric numeric

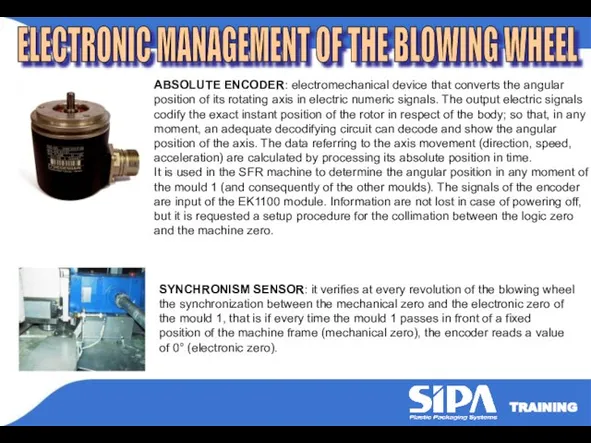

- 29. MOULD 1 0° φ ε β β = actual angle of the mould 1 read by

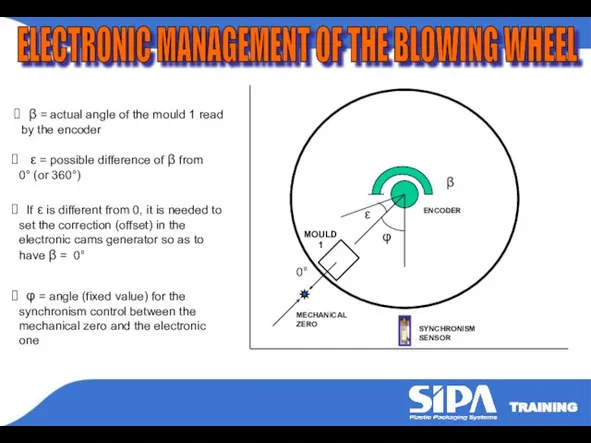

- 30. ELECTRONIC MANAGEMENT OF THE BLOWING WHEEL + + ELECTRONIC CAM ENABLING FROM PLC OUTPUT ENCODER CAM

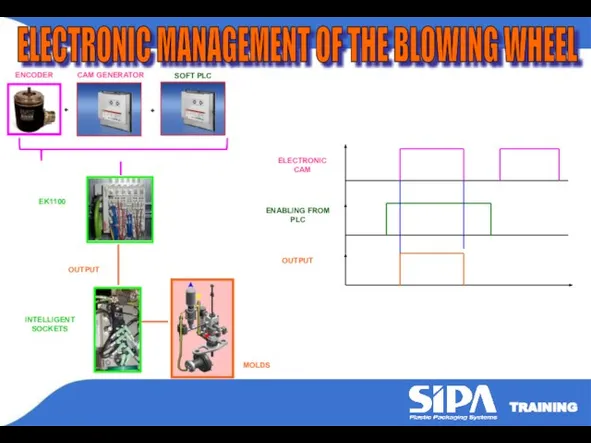

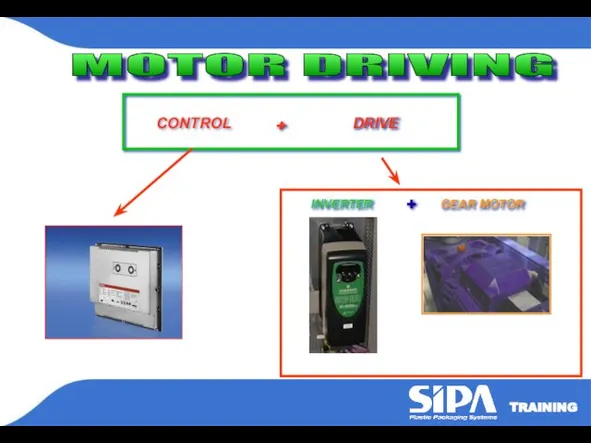

- 31. CONTROL MOTOR DRIVING + DRIVE INVERTER GEAR MOTOR +

- 32. SYNCHRONISM SENSOR I/O SIGNALS MOULDS VALVES BLOWING WHEEL GEAR MOTOR I/O SIGNALS INTELLIGENT SOCKET ABSOLUTE ENCODER

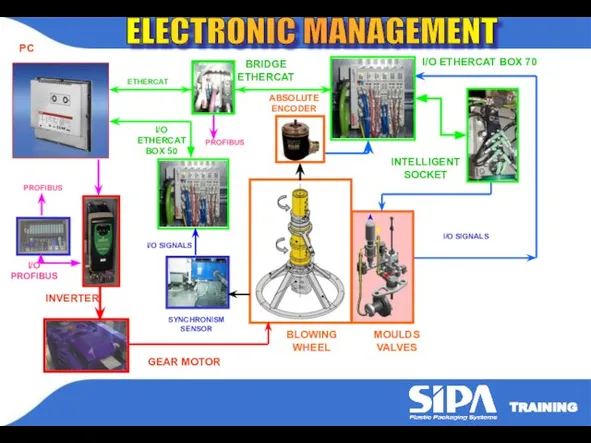

- 33. Power output Address setting PWRC08 I/O SIGNALS PC CARD SUPPLY (230Vac) SINGLE PHASE VOLTAGE DROK: yellow

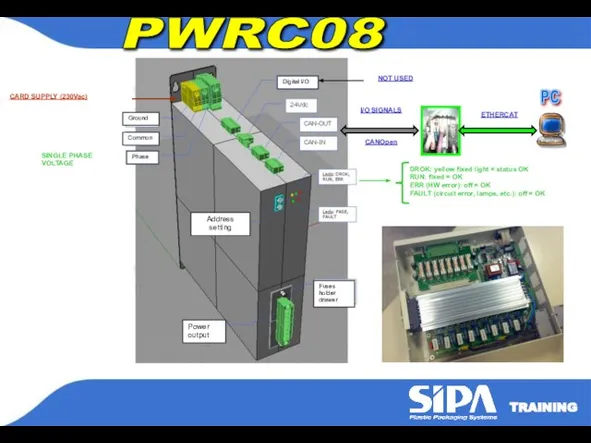

- 34. IRAZ24 CARD I/O SIGNALS I/O MODULES X1 CPU STOPPAGE WATCHDOG ADDRESS SETTING X4 IRAZ 24 WD

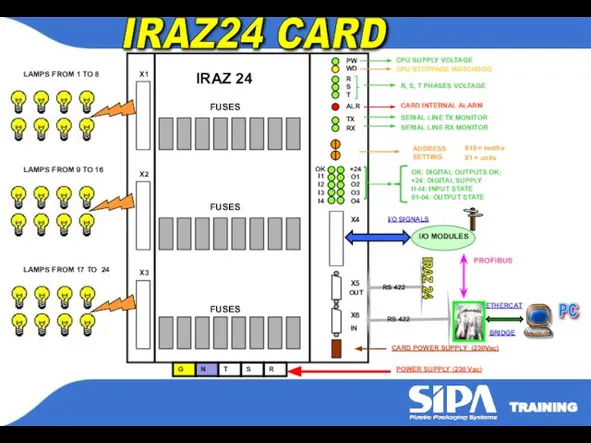

- 35. HEATINGS MANAGEMENT - PWRC08 PREFORM TEMPERATURE CONTROL OVEN AIR TEMPERATURE CONTROL PT100 LAMPS PWRC08 ANALOGUE MODULE

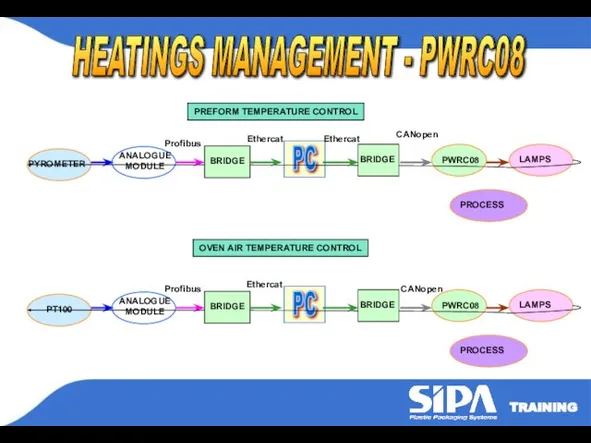

- 36. HEATINGS MANAGEMENT - IRAZ24 PREFORM TEMPERATURE CONTROL OVEN AIR TEMPERATURE CONTROL PT100 LAMPS IRAZ24 ANALOGUE MODULE

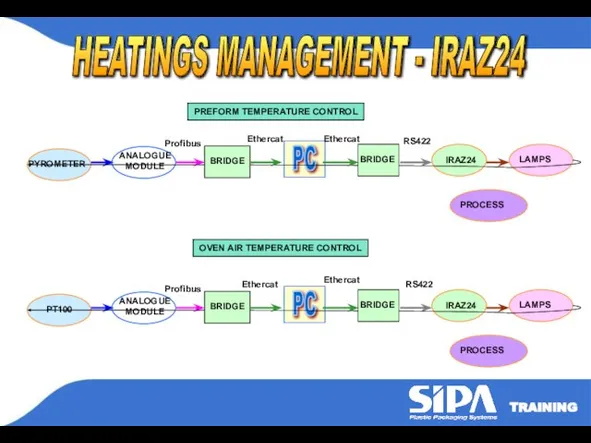

- 37. HEATINGS MANAGEMENT - PWRC08 PWRC08 Output X1 PC CANopen Lamps CANopen BRIDGE Ethercat PWRC08 CANopen 8

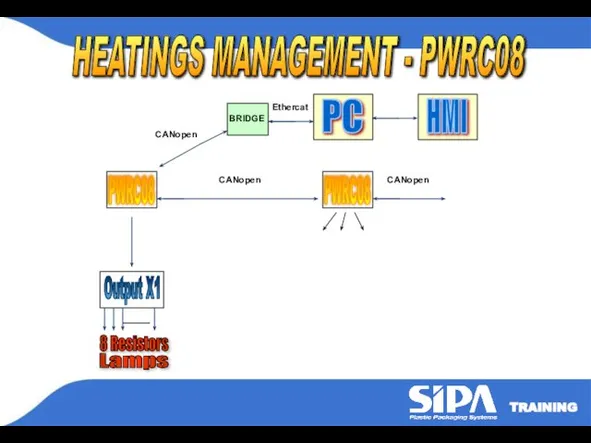

- 39. Скачать презентацию

Практика 1 тема

Практика 1 тема Об итогах реализации мероприятий по догазификации УР на 2021г. в разрезе муниципальных образований и планах на 2022 год

Об итогах реализации мероприятий по догазификации УР на 2021г. в разрезе муниципальных образований и планах на 2022 год Асинхронный режимы

Асинхронный режимы 21 февраля – Международный день родного языка! Сегодня мы поговорим о языке, как о средстве общения

21 февраля – Международный день родного языка! Сегодня мы поговорим о языке, как о средстве общения Анализ работы механизированного фонда нефтяных скважин на хохряковском месторождении

Анализ работы механизированного фонда нефтяных скважин на хохряковском месторождении ухтомский

ухтомский Маркетинг EKF_ NEW 2022 (v3)

Маркетинг EKF_ NEW 2022 (v3) Родительское собрание. Итоги 3 четверти

Родительское собрание. Итоги 3 четверти Издательство Русское слово

Издательство Русское слово 20130310_slaydy_k_uroku_po_proizvedeniyu_m.prishvina_kladovaya_solnca

20130310_slaydy_k_uroku_po_proizvedeniyu_m.prishvina_kladovaya_solnca Красота труда

Красота труда Число 7. Цифра 7

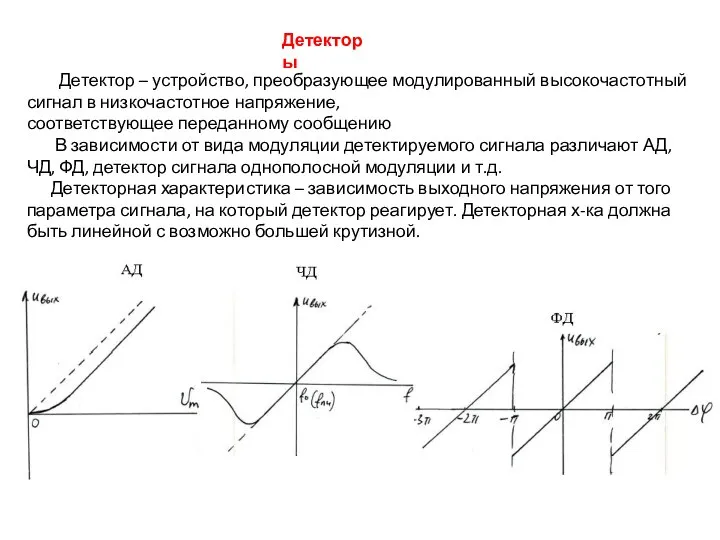

Число 7. Цифра 7 Детекторы. Детекторная характеристика

Детекторы. Детекторная характеристика Сочинение по серии картинок

Сочинение по серии картинок Концепция умные дома и города

Концепция умные дома и города Моя профессия-мое будущее

Моя профессия-мое будущее Животноводство

Животноводство 01.22Пут нат 12.30-14.00.Жив. и чел

01.22Пут нат 12.30-14.00.Жив. и чел Зависимость успеваемости по предметам разных циклов от функциональной асимметрии мозга

Зависимость успеваемости по предметам разных циклов от функциональной асимметрии мозга Микрометры и их применение. Измерительные инструменты

Микрометры и их применение. Измерительные инструменты Удивительный транспорт

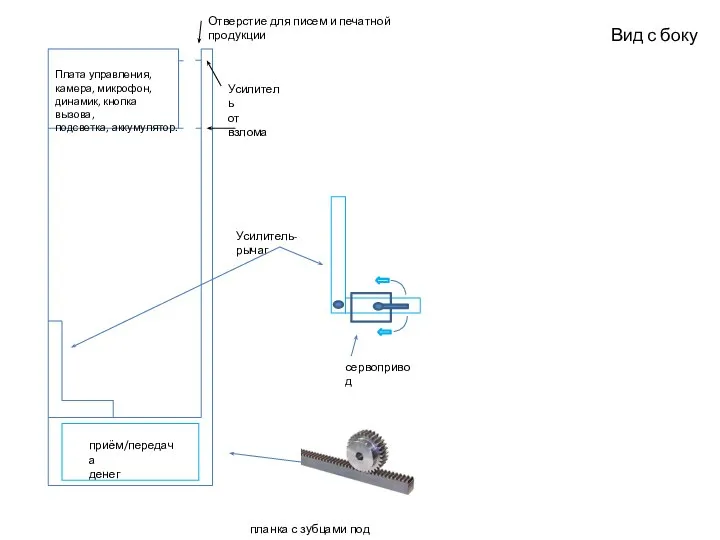

Удивительный транспорт Схема

Схема Судова практика визнання недійсними результатів торгів через незаконні дії організаторів

Судова практика визнання недійсними результатів торгів через незаконні дії організаторів Волшебница зима

Волшебница зима 6 кл Біологія - наука про життя

6 кл Біологія - наука про життя Законы физики служат людям. Архимед (287 – 212 г.г. до нашей эры)

Законы физики служат людям. Архимед (287 – 212 г.г. до нашей эры) Классификация и функциональное назначение гаражного оборудования. (Тема 1)

Классификация и функциональное назначение гаражного оборудования. (Тема 1) Почему первым прорастает корень

Почему первым прорастает корень