Содержание

- 2. FM850 FM850 Participant: John Do Johny Does Joe Did Joey Dun

- 3. FM850 FM850 TAKE CONTROL OF YOUR MACHINE

- 4. FM850 Overview Introduction Technical construction Operation Programming Water flow circuit diagram Commissioning Product adjustment Troubleshooting Cleaning

- 5. FM850 Positioning/target groups As with its predecessor the Spectra Foam Master, the FM850 serves as a

- 6. Introduction Dimensions FM850 800 mm 300 mm 300 mm 712 mm 70-180 mm 520 mm 200

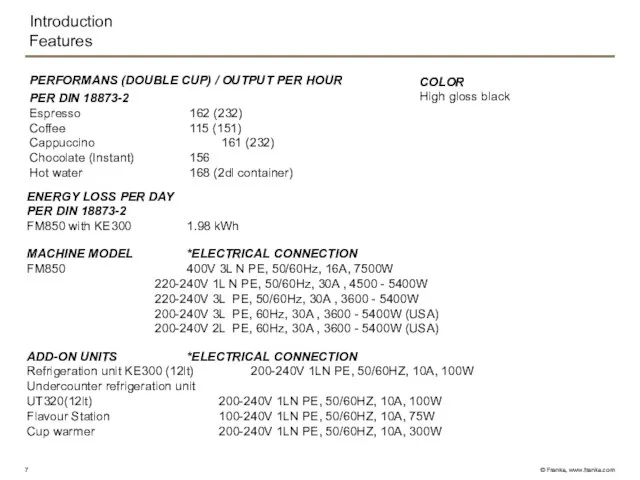

- 7. Introduction Features PERFORMANS (DOUBLE CUP) / OUTPUT PER HOUR PER DIN 18873-2 Espresso 162 (232) Coffee

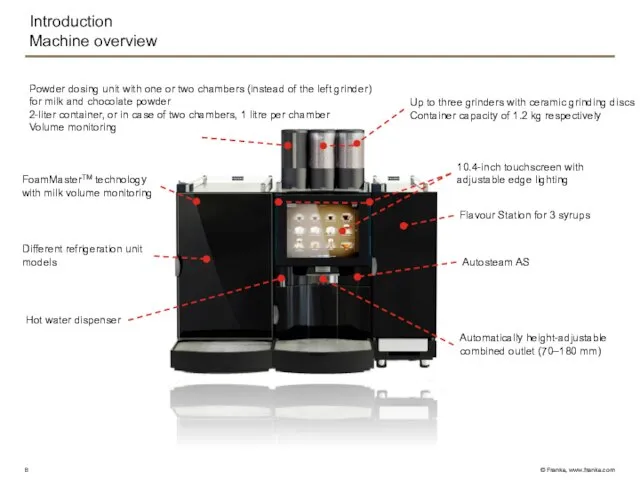

- 8. Introduction Machine overview Powder dosing unit with one or two chambers (instead of the left grinder)

- 9. Introduction Available version and options BASIC MODEL FM850 with one grinder hot water dispenser Black Line

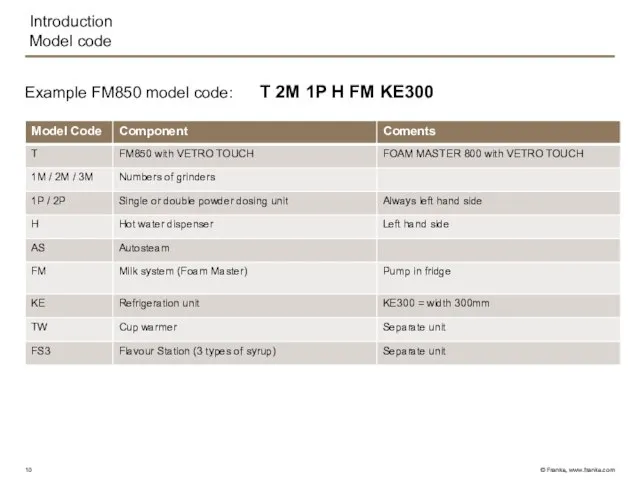

- 10. Introduction Model code Example FM850 model code: T 2M 1P H FM KE300

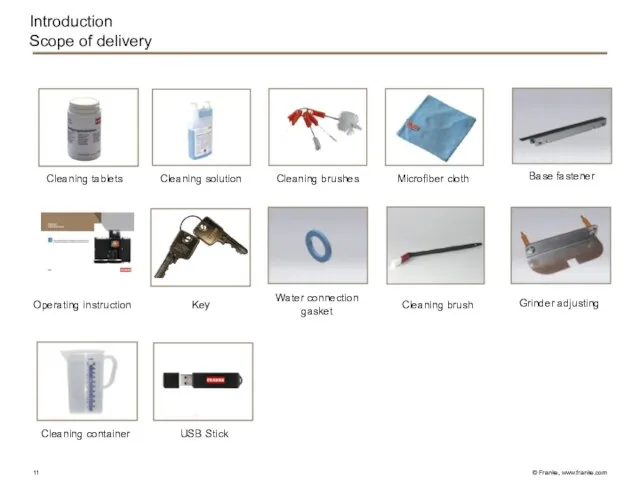

- 11. Introduction Scope of delivery Base fastener Grinder adjusting Water connection gasket Cleaning brush Key Operating instruction

- 12. Introduction Hygiene Short milk tubes between refrigerator and coffee machine Milk pumps in the refrigerator Improved

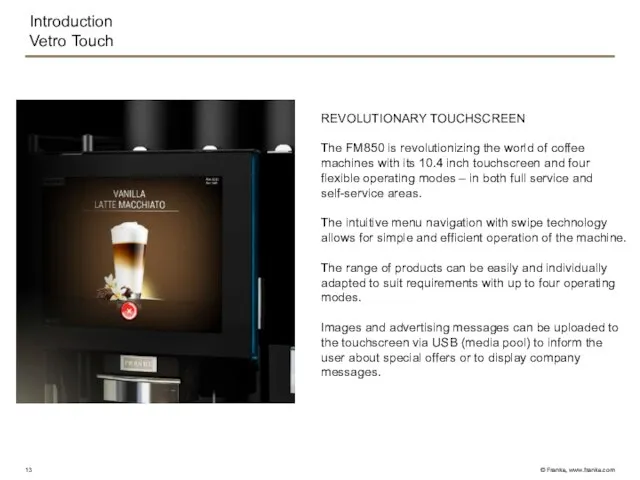

- 13. Introduction Vetro Touch REVOLUTIONARY TOUCHSCREEN The FM850 is revolutionizing the world of coffee machines with its

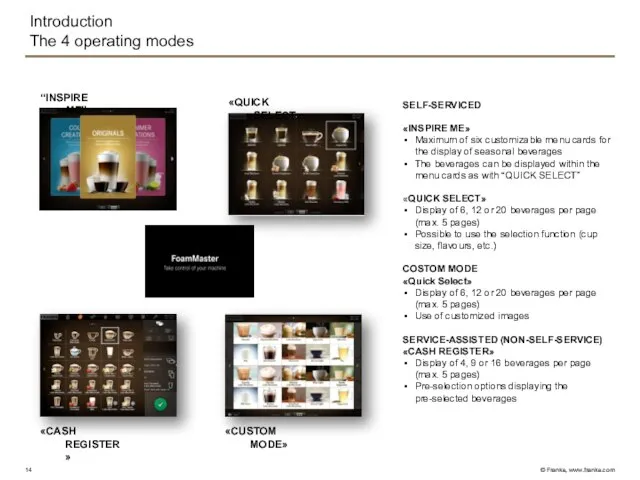

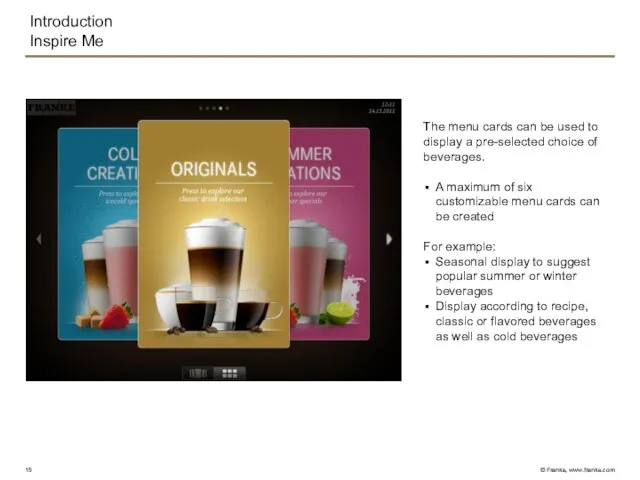

- 14. Introduction The 4 operating modes SELF-SERVICED «INSPIRE ME» Maximum of six customizable menu cards for the

- 15. Introduction Inspire Me The menu cards can be used to display a pre-selected choice of beverages.

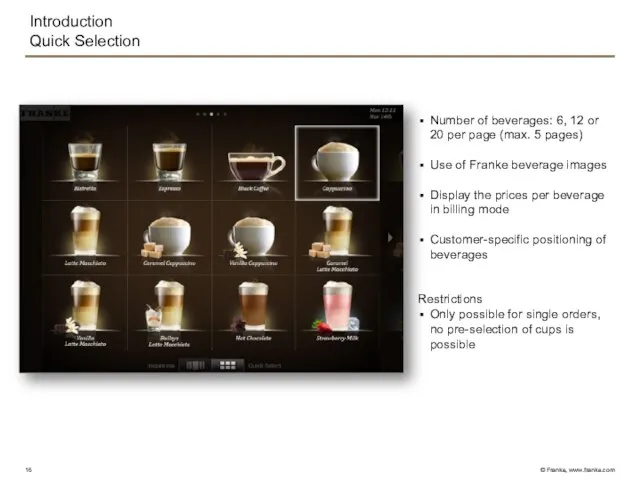

- 16. Introduction Quick Selection Number of beverages: 6, 12 or 20 per page (max. 5 pages) Use

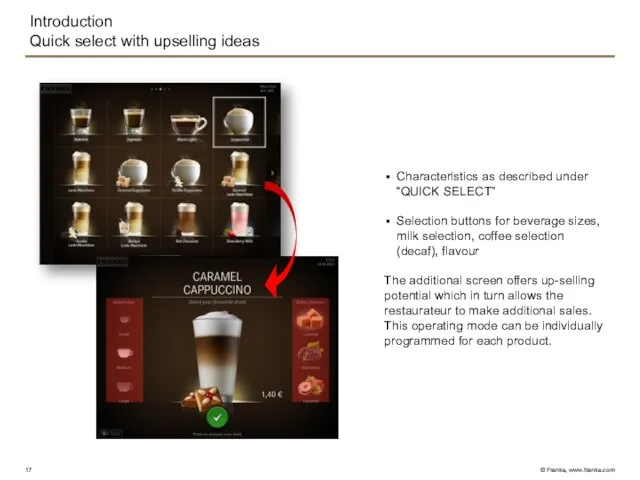

- 17. Introduction Quick select with upselling ideas Characteristics as described under “QUICK SELECT” Selection buttons for beverage

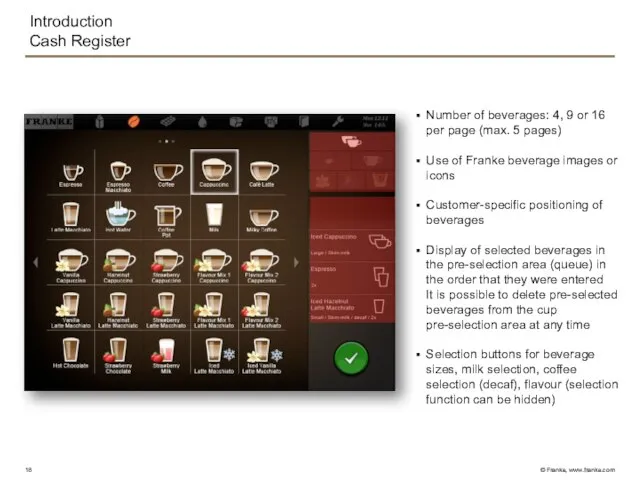

- 18. Introduction Cash Register Number of beverages: 4, 9 or 16 per page (max. 5 pages) Use

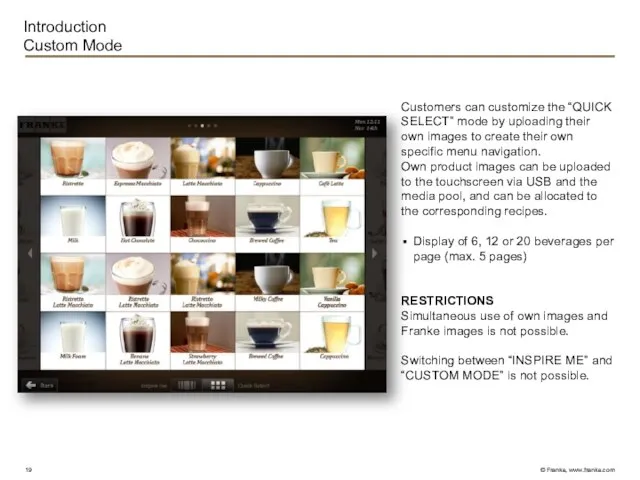

- 19. Customers can customize the “QUICK SELECT” mode by uploading their own images to create their own

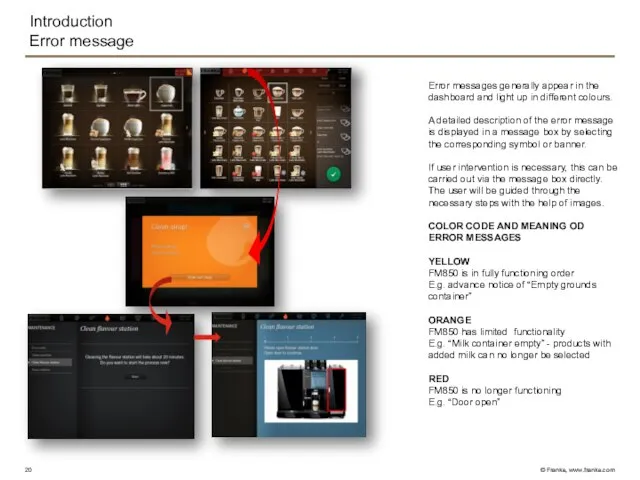

- 20. Error messages generally appear in the dashboard and light up in different colours. A detailed description

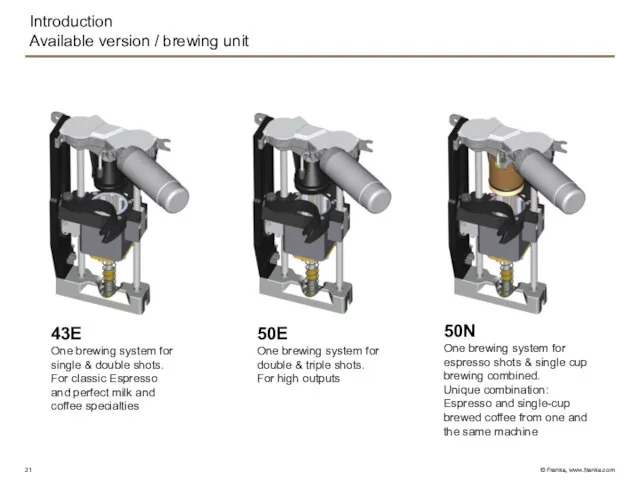

- 21. 43E One brewing system for single & double shots. For classic Espresso and perfect milk and

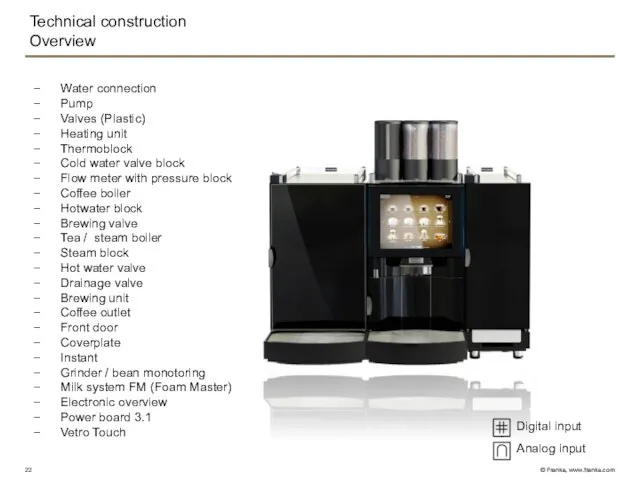

- 22. Technical construction Overview Water connection Pump Valves (Plastic) Heating unit Thermoblock Cold water valve block Flow

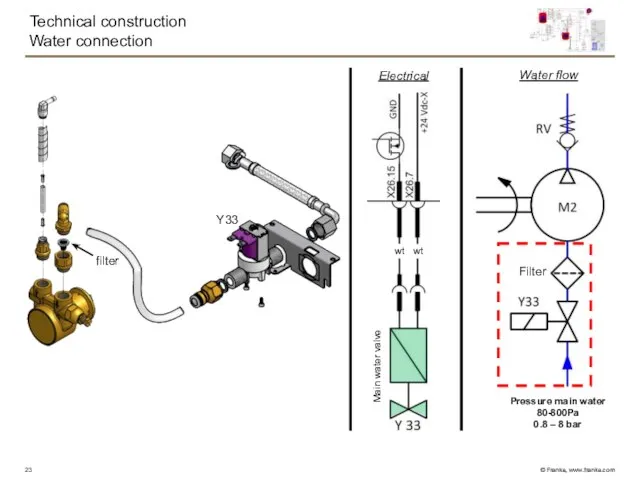

- 23. Technical construction Water connection Water flow Y33 Filter filter Pressure main water 80-800Pa 0.8 – 8

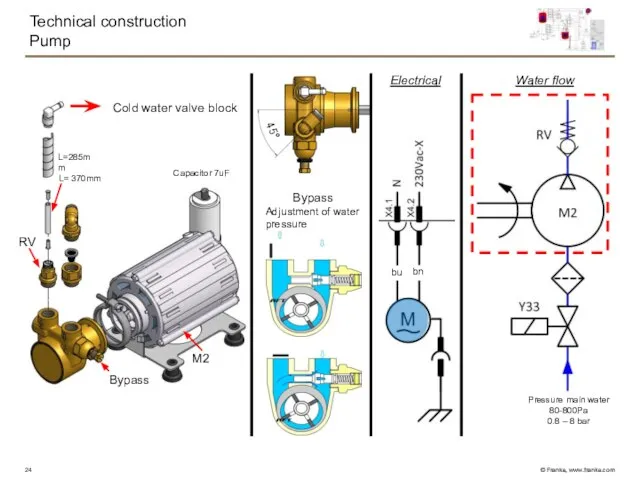

- 24. Technical construction Pump Water flow RV M2 Cold water valve block Bypass Bypass Adjustment of water

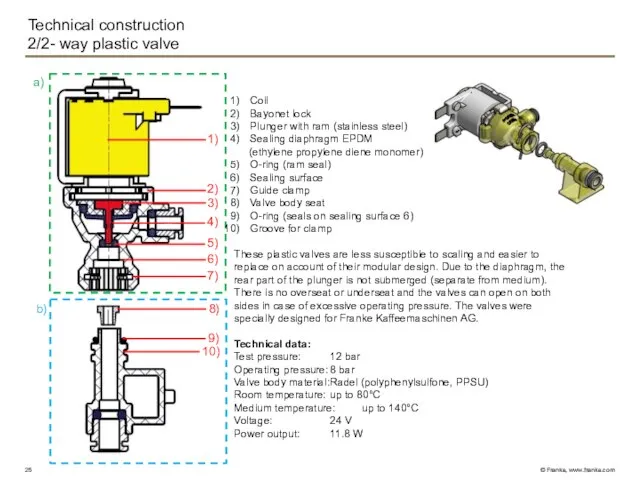

- 25. Technical construction 2/2- way plastic valve 1) 2) 3) 4) 6) 5) 7) 9) 10) a)

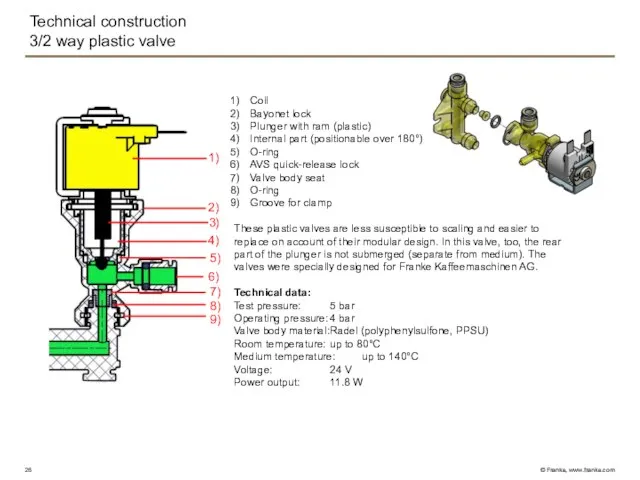

- 26. Technical construction 3/2 way plastic valve 1) 2) 3) 4) 6) 5) 7) 8) 9) Coil

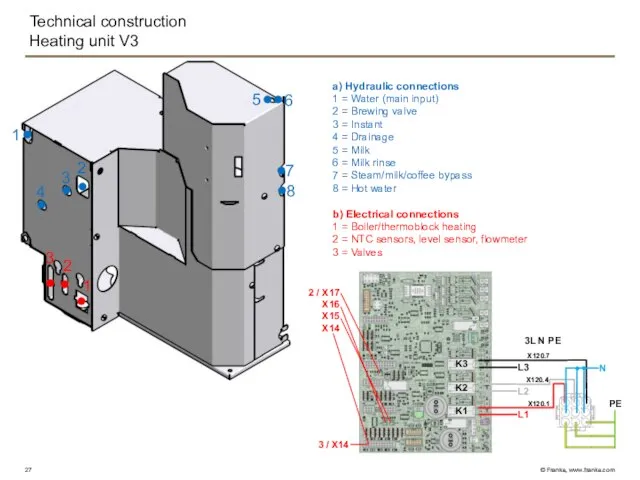

- 27. Technical construction Heating unit V3 2 3 4 1 2 3 6 5 1 7 8

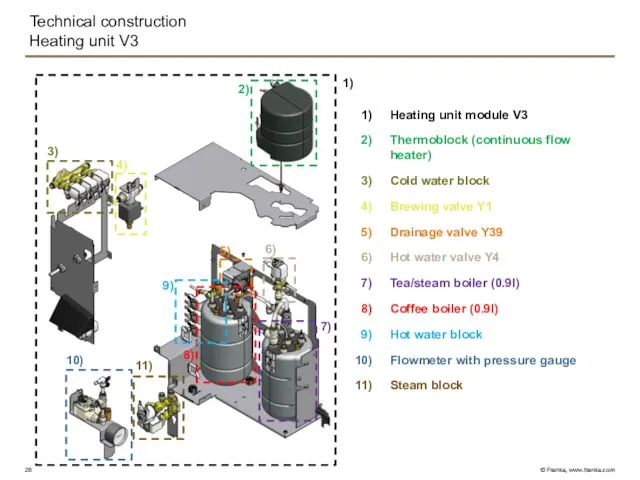

- 28. Technical construction Heating unit V3 1) 2) 3) 4) 5) 6) 7) 8) 9) 10) 11)

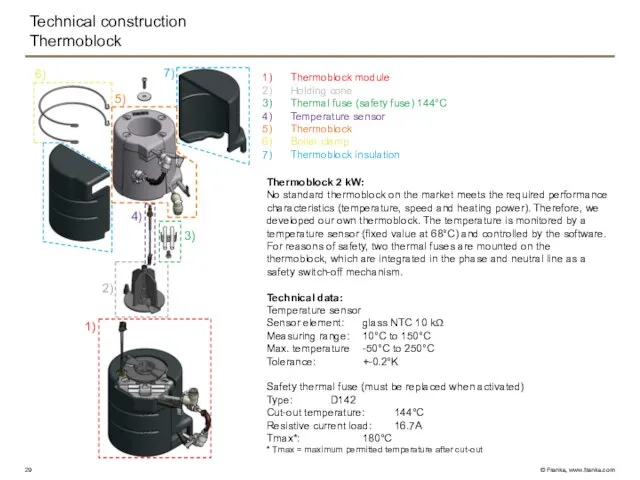

- 29. Technical construction Thermoblock 7) 6) 5) 4) 3) 2) 1) Thermoblock module Holding cone Thermal fuse

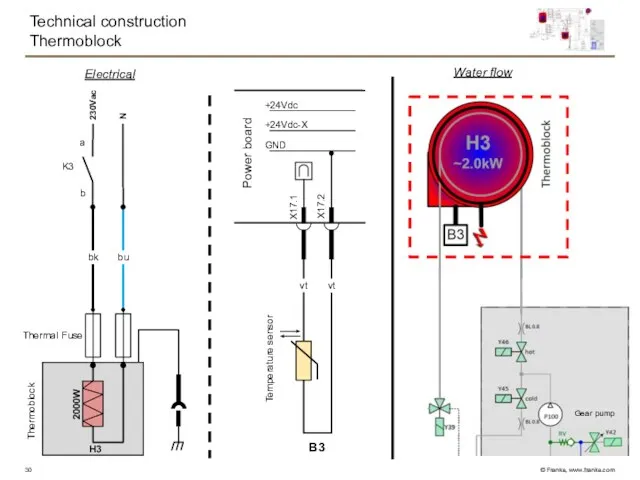

- 30. Technical construction Thermoblock Water flow Electrical 230Vac N bk H3 bu K3 b a Thermal Fuse

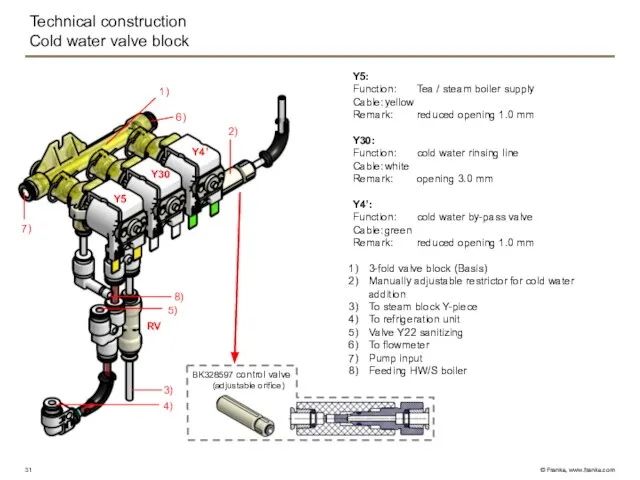

- 31. Technical construction Cold water valve block Y30 Y4’ Y5 RV 1) 2) 3) 4) 8) 6)

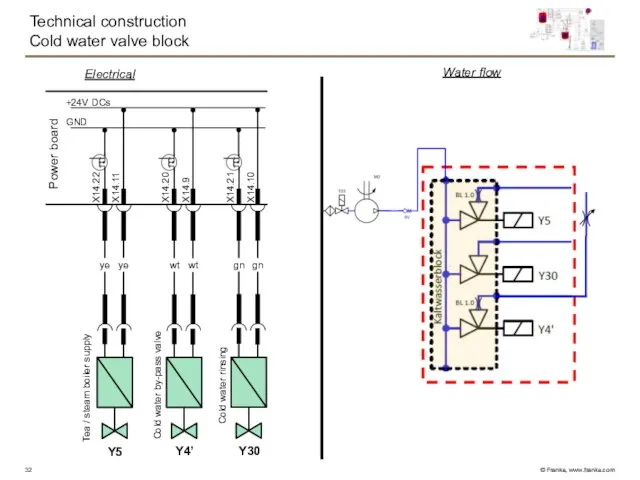

- 32. Technical construction Cold water valve block GND +24V DCs Power board X14.22 X14.11 X14.20 X14.9 X14.21

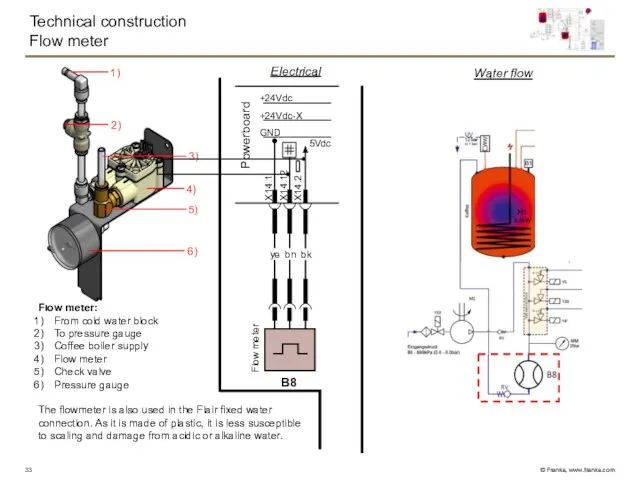

- 33. Flow meter: From cold water block To pressure gauge Coffee boiler supply Flow meter Check valve

- 34. Technical construction Coffee boiler, 2.5kW (0.9l) Safety valve12 bar (Spectra) NTC temperature sensor Coffee boiler supply

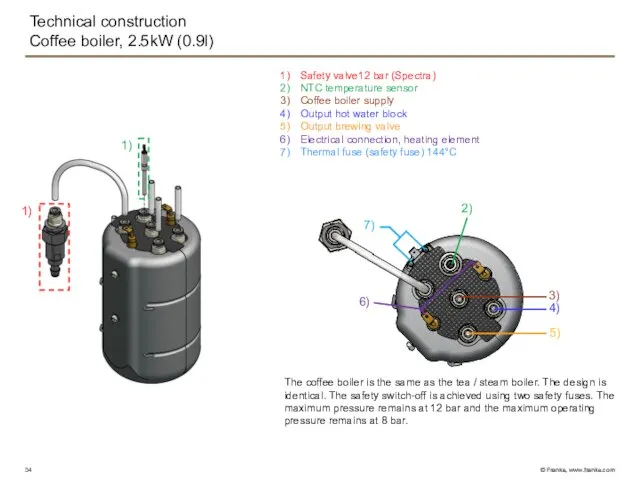

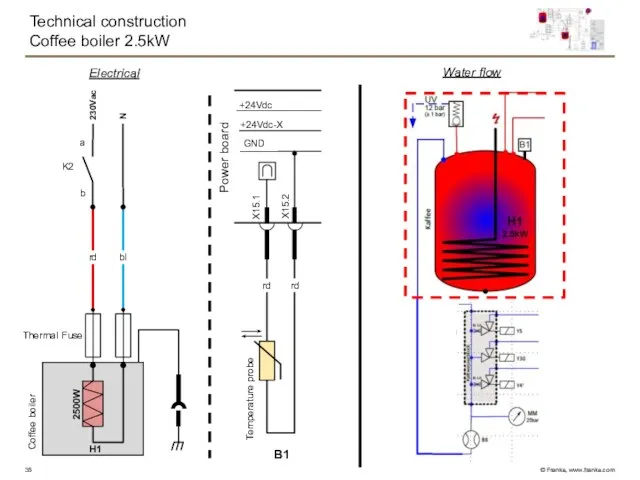

- 35. Technical construction Coffee boiler 2.5kW Water flow Electrical N rd H1 bl K2 b a Thermal

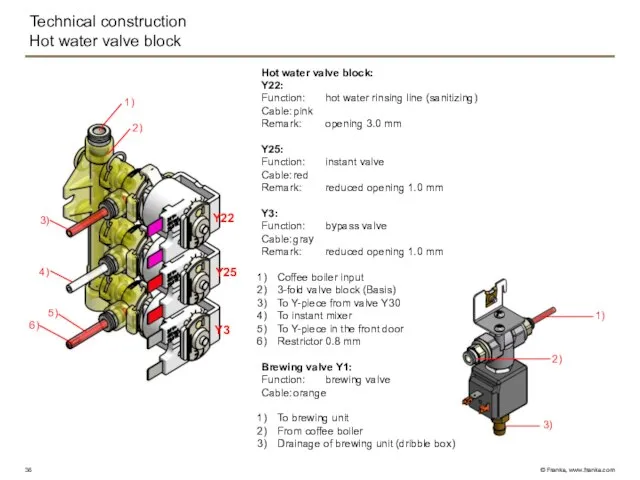

- 36. Technical construction Hot water valve block Hot water valve block: Y22: Function: hot water rinsing line

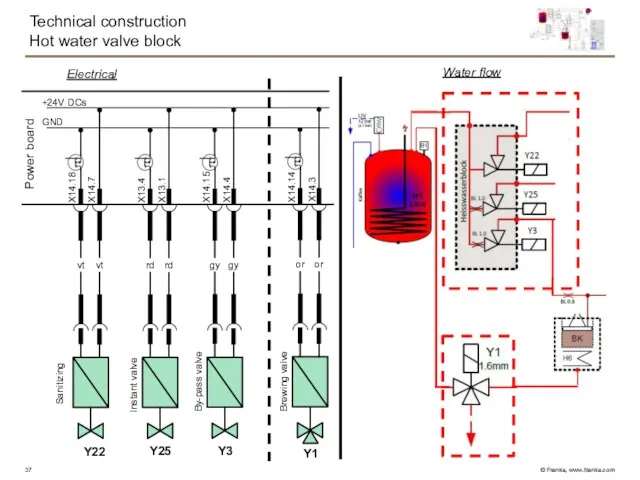

- 37. Technical construction Hot water valve block GND +24V DCs Power board X14.18 X14.7 X13.4 X13.1 X14.15

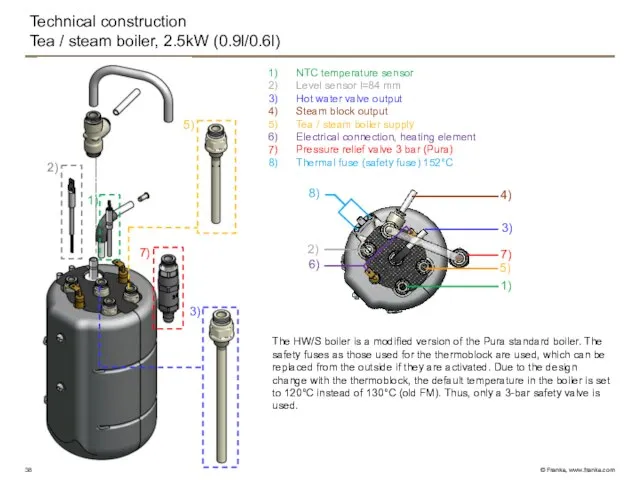

- 38. Technical construction Tea / steam boiler, 2.5kW (0.9l/0.6l) NTC temperature sensor Level sensor l=84 mm Hot

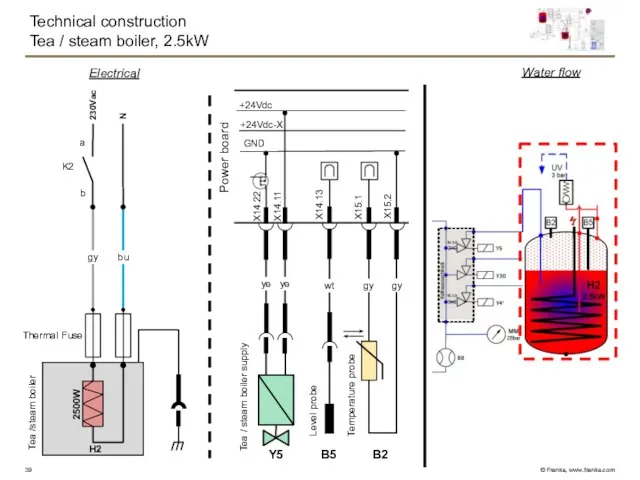

- 39. Technical construction Tea / steam boiler, 2.5kW Water flow Electrical N gy H2 bu K2 b

- 40. Technical construction Steam valve block Y6: Function: Autosteam (3/2-way valve) Cable: brown Marking: white, opening 3.0

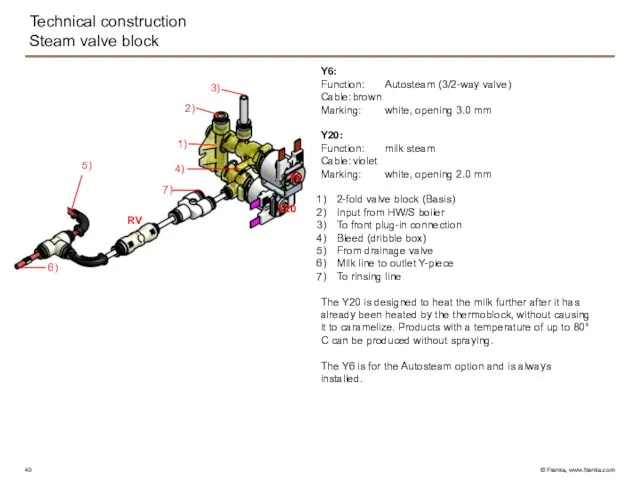

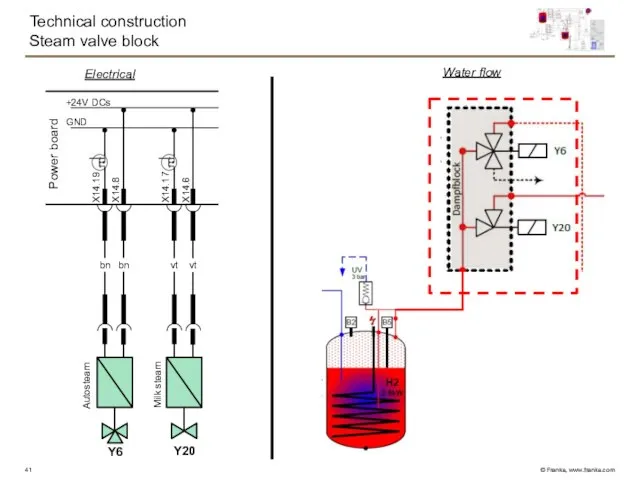

- 41. Technical construction Steam valve block GND +24V DCs Power board X14.19 X14.8 X14.17 X14.6 bn bn

- 42. Technical construction Hot water valve 1) 2) 3) 4) Y4: Function: hot water/tea Cable: blue Remark:

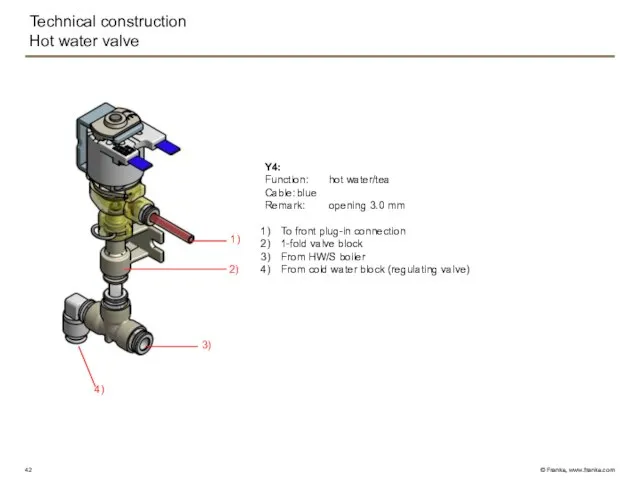

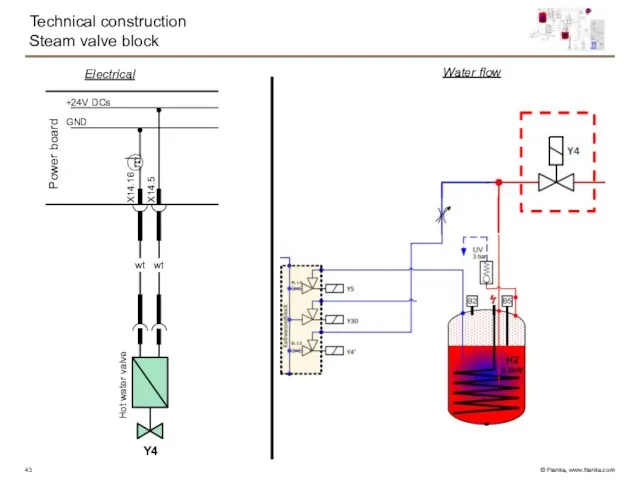

- 43. Technical construction Steam valve block GND +24V DCs Power board X14.16 X14.5 wt wt Y4 Water

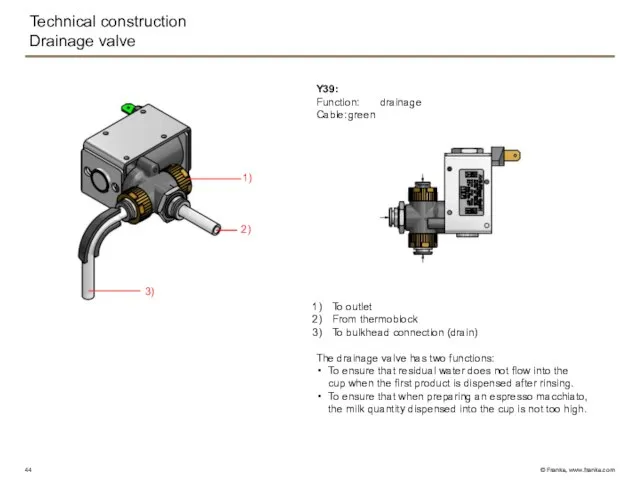

- 44. Technical construction Drainage valve Y39: Function: drainage Cable: green To outlet From thermoblock To bulkhead connection

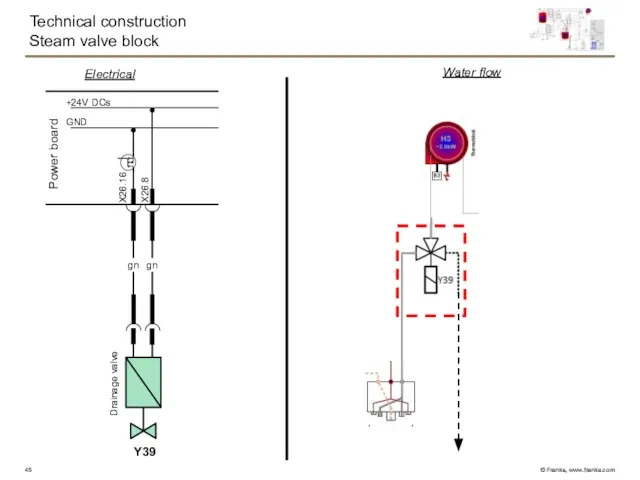

- 45. Technical construction Steam valve block GND +24V DCs Power board X26.16 X26.8 gn gn Y39 Water

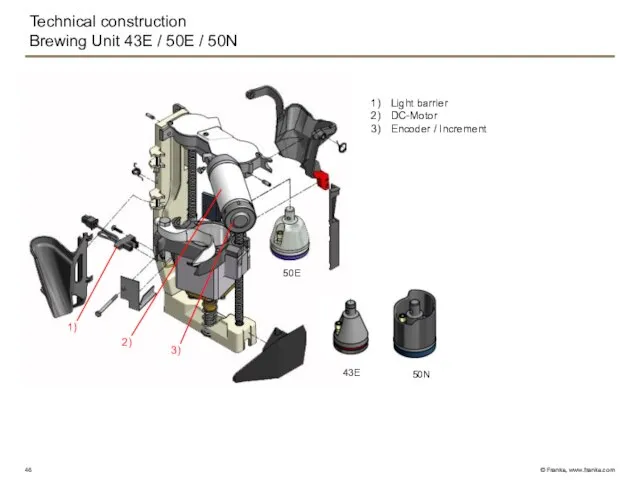

- 46. Technical construction Brewing Unit 43E / 50E / 50N 43E 50E 50N 1) 3) 2) Light

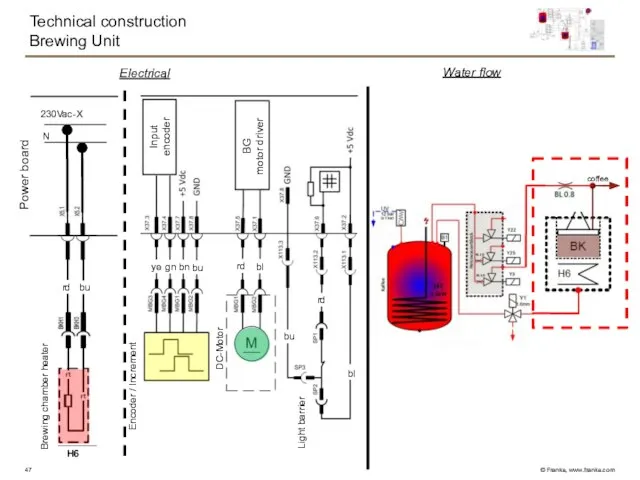

- 47. Technical construction Brewing Unit Water flow Electrical Power board N 230Vac-X Brewing chamber heater Encoder /

- 48. Technical construction Fixed increment positions 100 Increments E 042 E 043 E 041 E 044 Lower

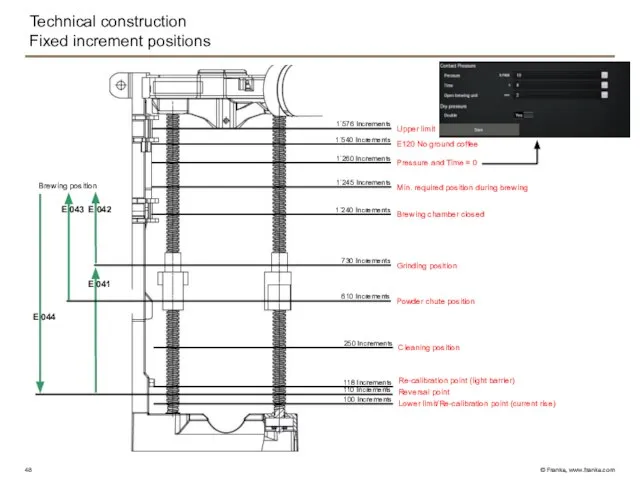

- 49. Technical construction Coffee outlet Distributor FM: Cold or hot milk Coffee 1) 2) 3) 4) Coffee

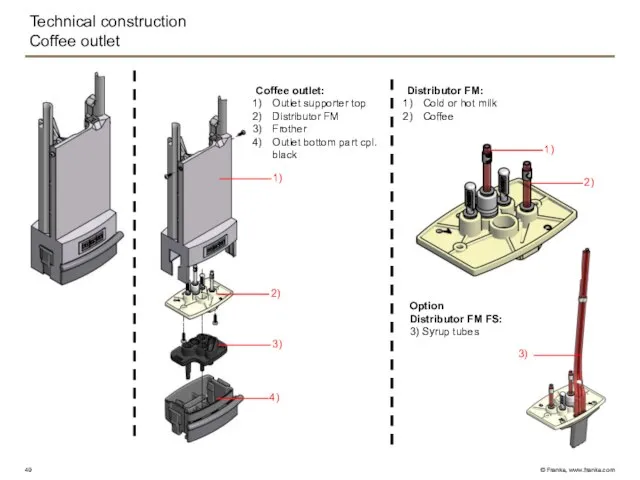

- 50. Technical construction Front door Outlet DC-Motor 24VDC Reed switch Gear wheel to the outlet Electrical Outlet

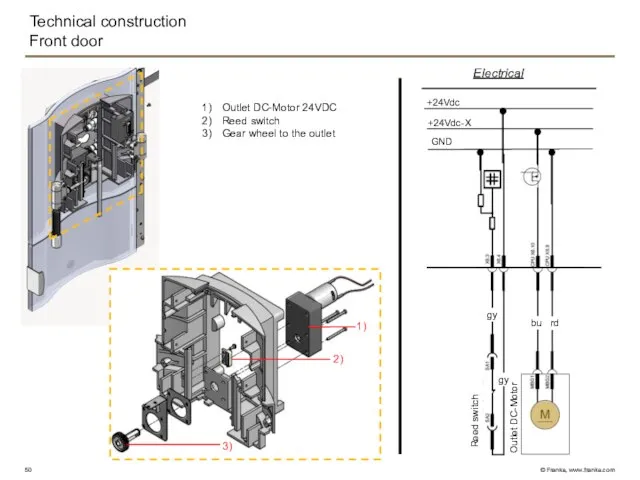

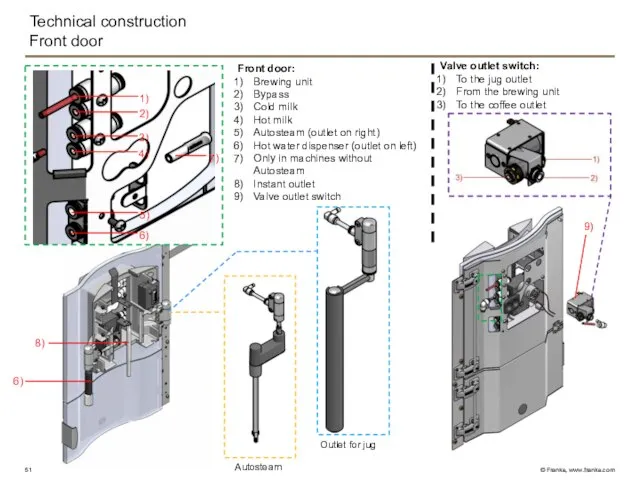

- 51. Technical construction Front door Front door: Brewing unit Bypass Cold milk Hot milk Autosteam (outlet on

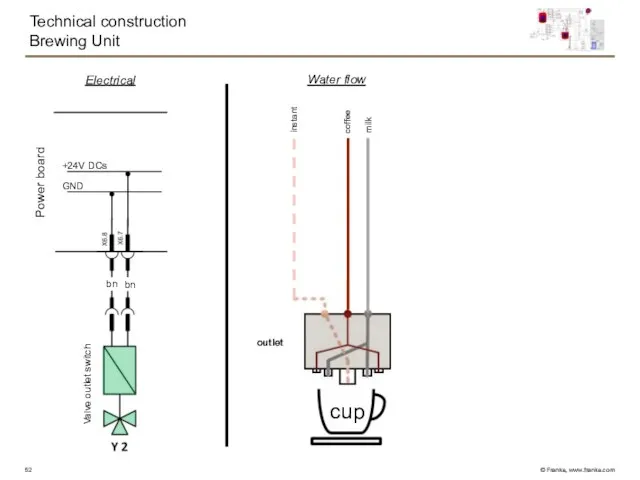

- 52. Technical construction Brewing Unit Power board Water flow Electrical outlet coffee cup milk GND +24V DCs

- 53. Technical construction Coverplate 1) 2) 3) 4) Coverplate Blind lid Support grinder outside Support grinder center

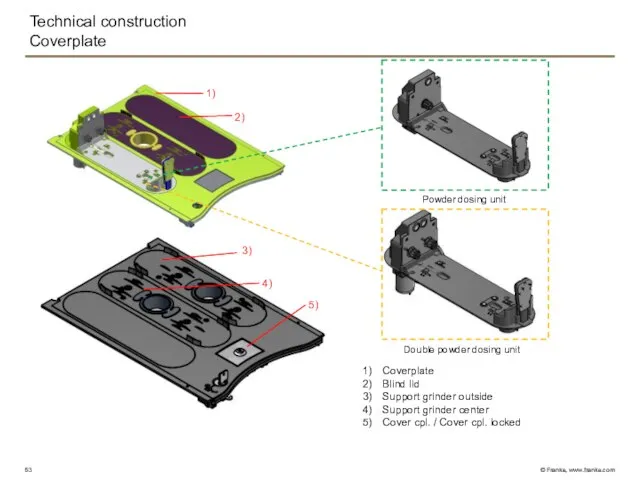

- 54. Technical construction Instant Y25 Hot water 1) 2) 3) 4) 5) 7) 8) 6) Mixing chamber

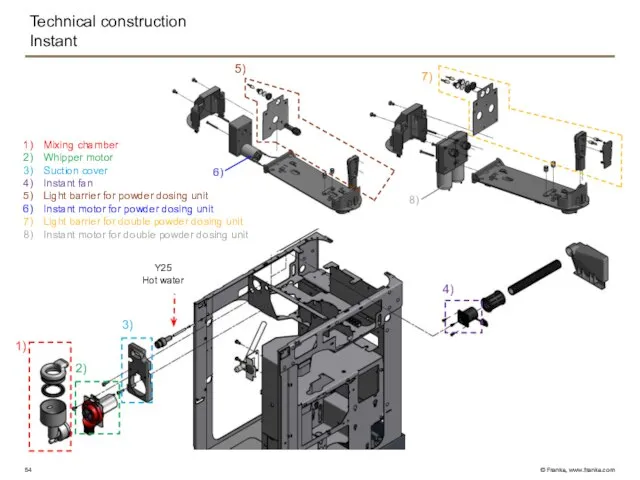

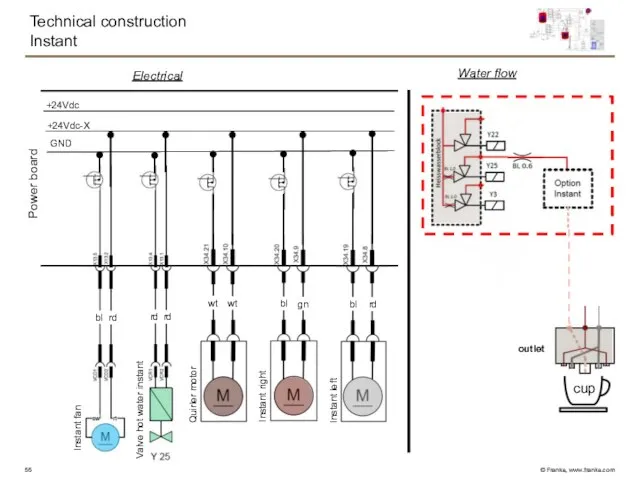

- 55. Technical construction Instant Electrical GND +24Vdc-X +24Vdc Instant fan Valve hot water instant Quirler motor Instant

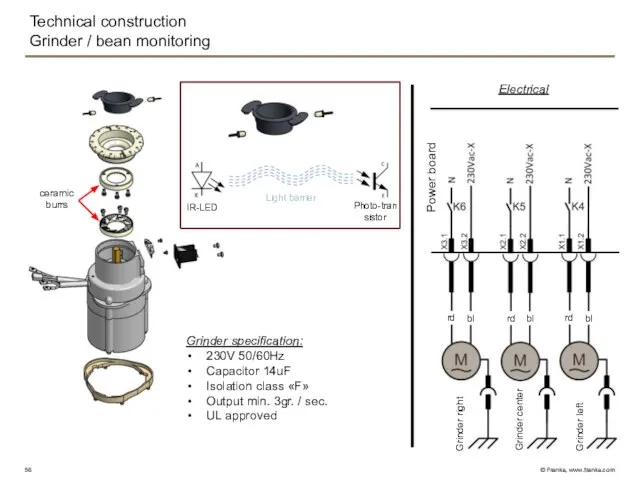

- 56. Technical construction Grinder / bean monitoring ceramic burrs Grinder specification: 230V 50/60Hz Capacitor 14uF Isolation class

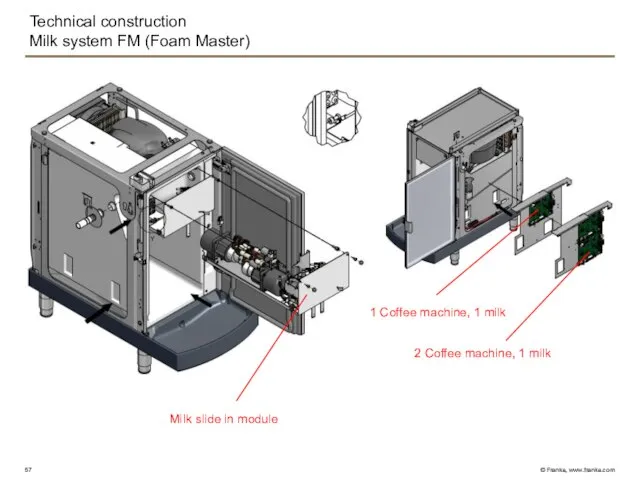

- 57. Technical construction Milk system FM (Foam Master) 1 Coffee machine, 1 milk 2 Coffee machine, 1

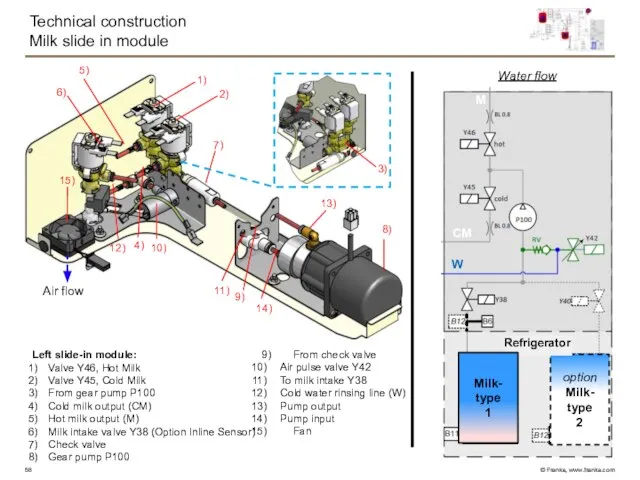

- 58. Technical construction Milk slide in module 9) From check valve Air pulse valve Y42 To milk

- 59. Technical construction Foam Master PCB USB CAN NTC Level 1 Level 2 Fuse 24 VDC Fan

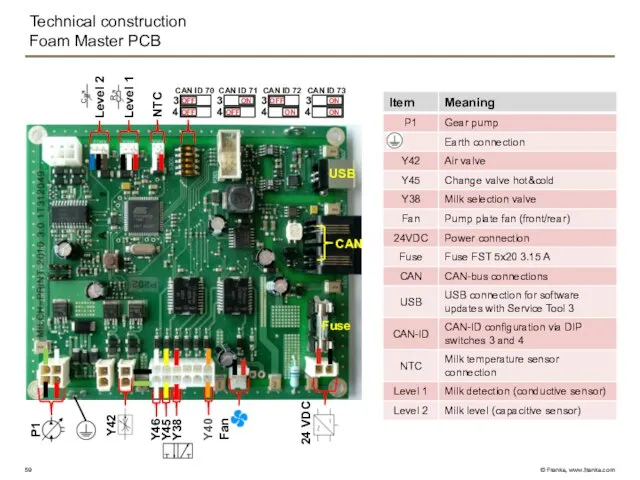

- 60. Technical construction Gear pump Construction and functionality The gear pump is a rotary pump consisting of

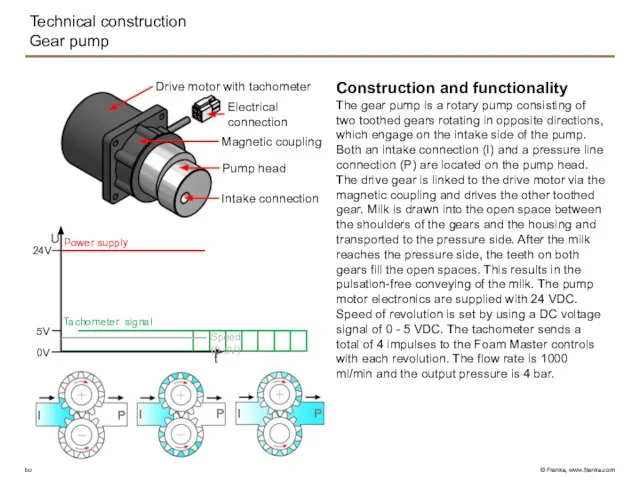

- 61. Technical construction Air valve Construction and functionality The valve plate (sealing element) is directly linked to

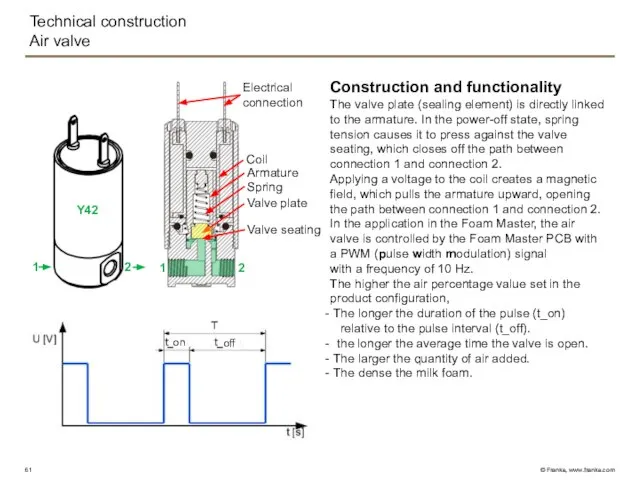

- 62. Technical construction Overview electronic Switch-mode power supply Power board (PCB) 3.1 Line Filter Transformer (USA, Version)

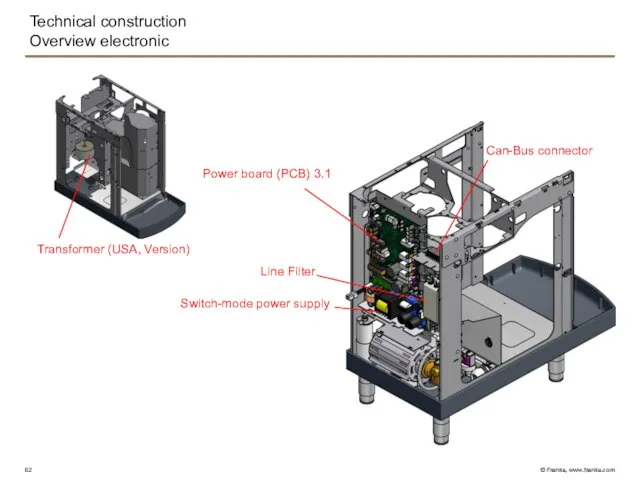

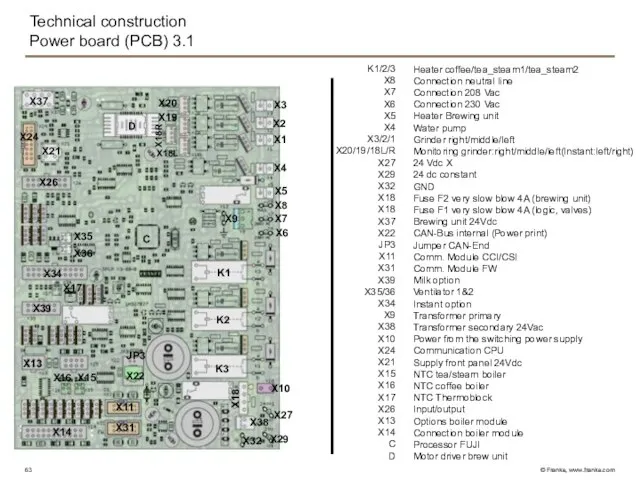

- 63. Technical construction Power board (PCB) 3.1 Heater coffee/tea_steam1/tea_steam2 Connection neutral line Connection 208 Vac Connection 230

- 64. Technical construction Switch-mode power supply Power Milk Print 24VDC Powerboard 3.1 / 24VDC Power 176-265VAC Fuse

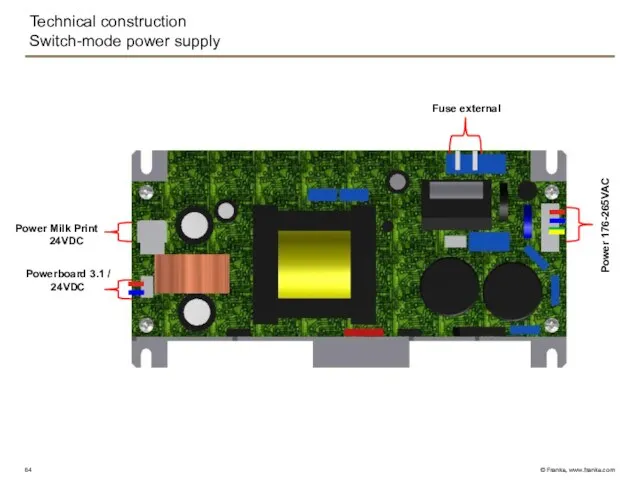

- 65. Technical construction Operator panel / Vetro Touch 1) 3) 2) Panel holder guide Panel connection Panel

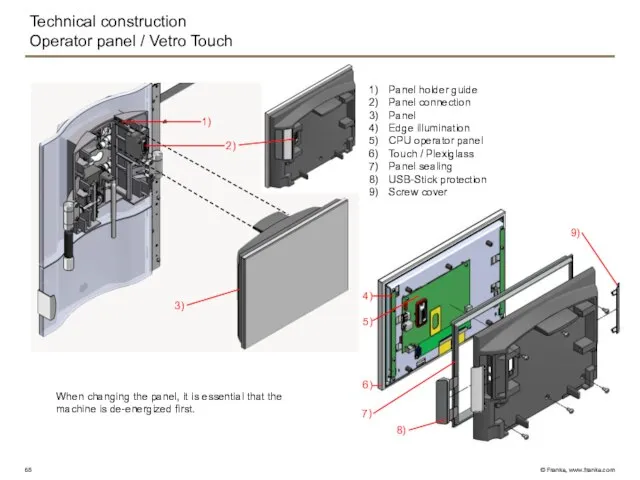

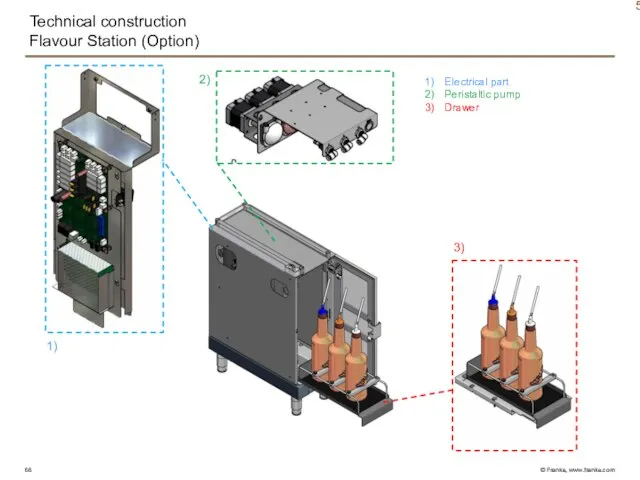

- 66. Technical construction Flavour Station (Option) 5) Electrical part Peristaltic pump Drawer 2) 1) 3)

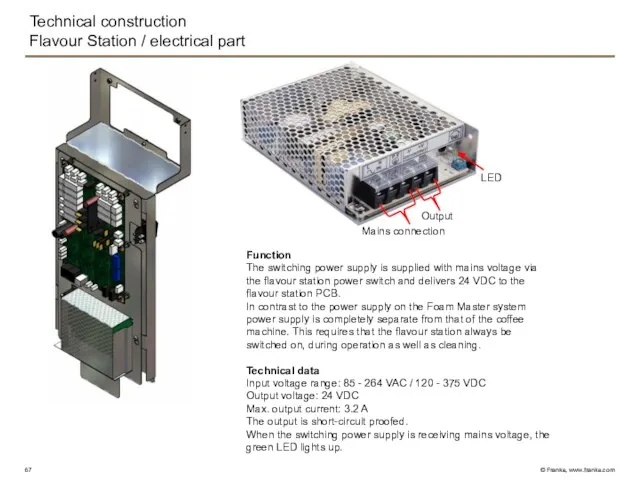

- 67. Technical construction Flavour Station / electrical part Function The switching power supply is supplied with mains

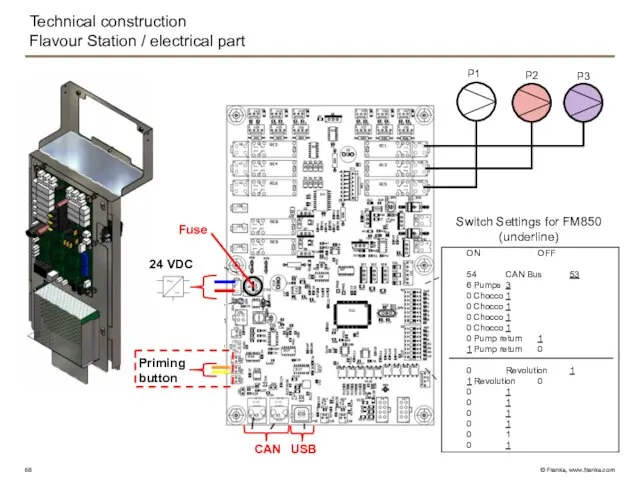

- 68. Technical construction Flavour Station / electrical part P1 P3 P2 24 VDC USB CAN Priming button

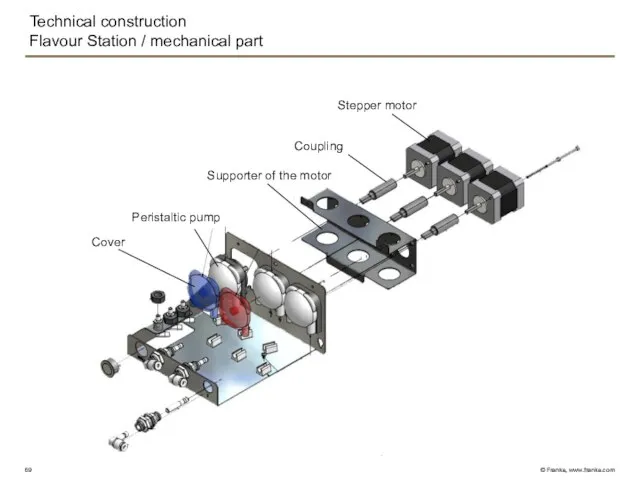

- 69. Technical construction Flavour Station / mechanical part Stepper motor Coupling Supporter of the motor Peristaltic pump

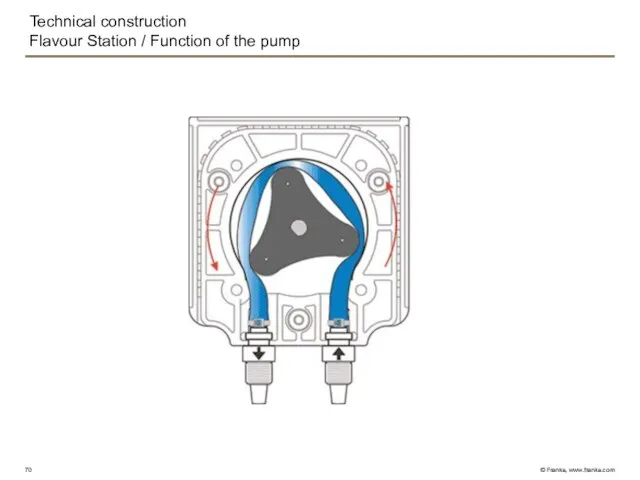

- 70. Technical construction Flavour Station / Function of the pump

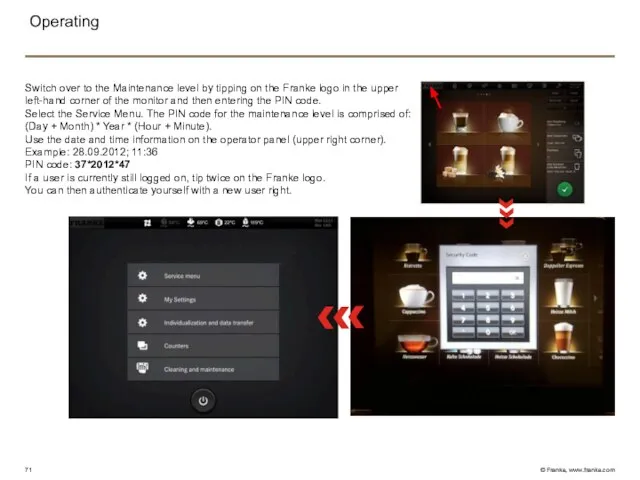

- 71. Operating Switch over to the Maintenance level by tipping on the Franke logo in the upper

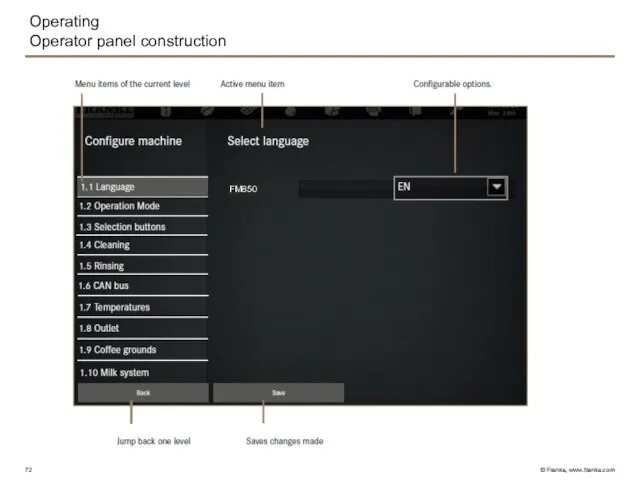

- 72. Operating Operator panel construction FM850

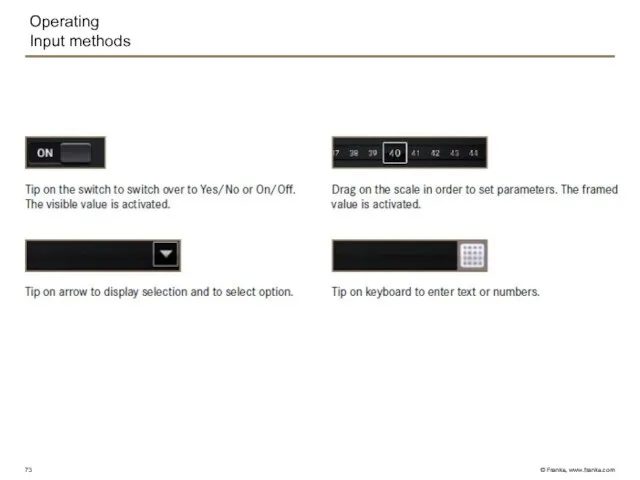

- 73. Operating Input methods

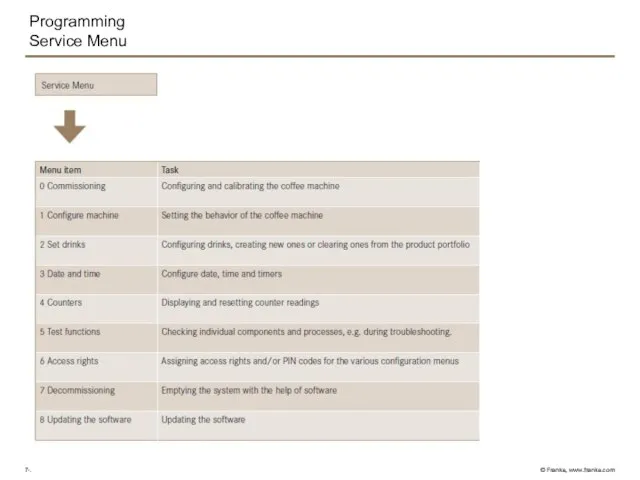

- 74. Programming Service Menu

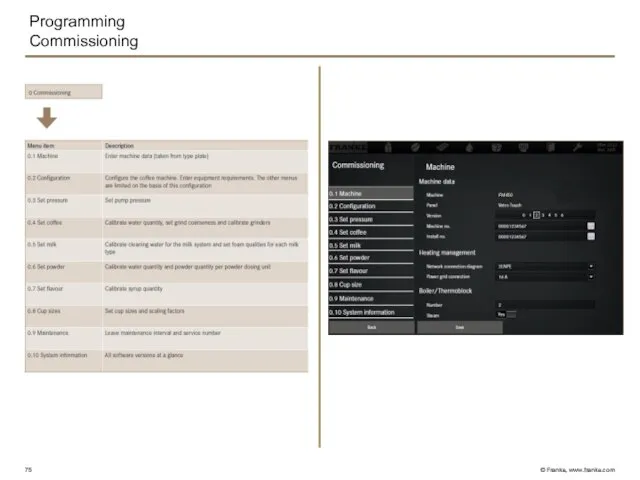

- 75. Programming Commissioning FM850

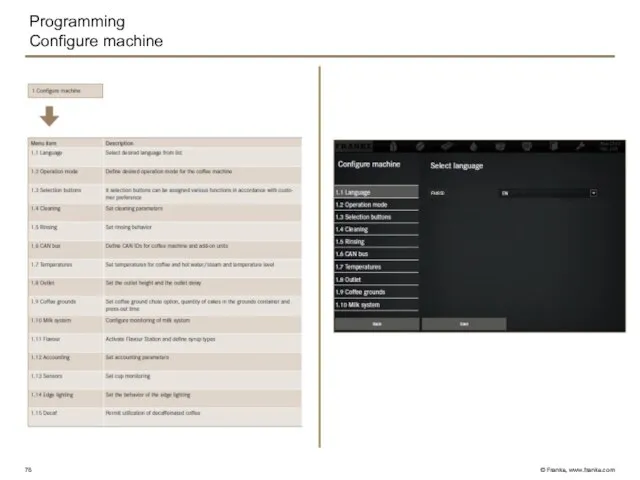

- 76. Programming Configure machine FM850

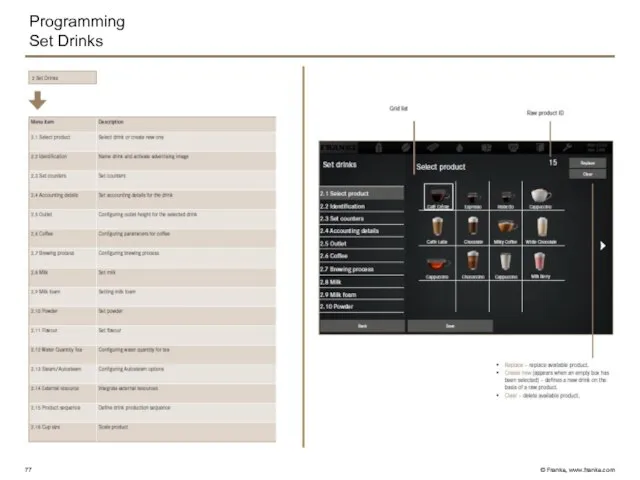

- 77. Programming Set Drinks

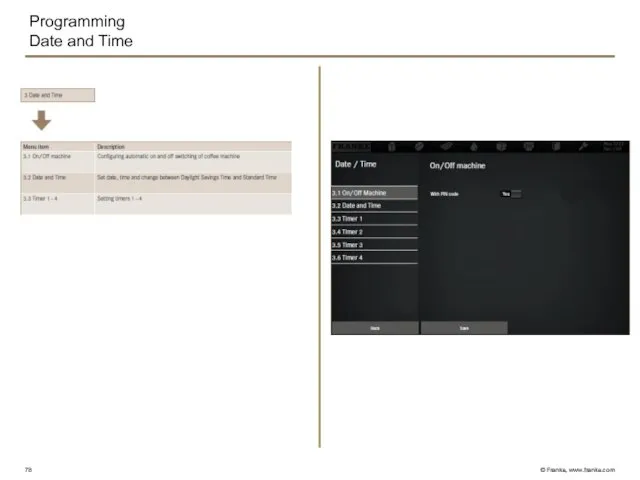

- 78. Programming Date and Time

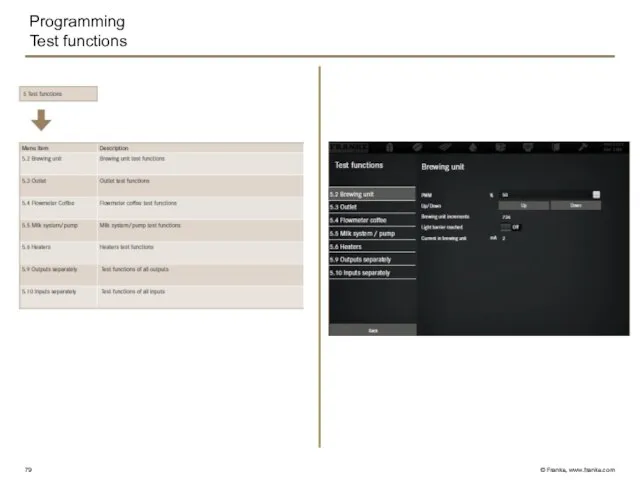

- 79. Programming Test functions

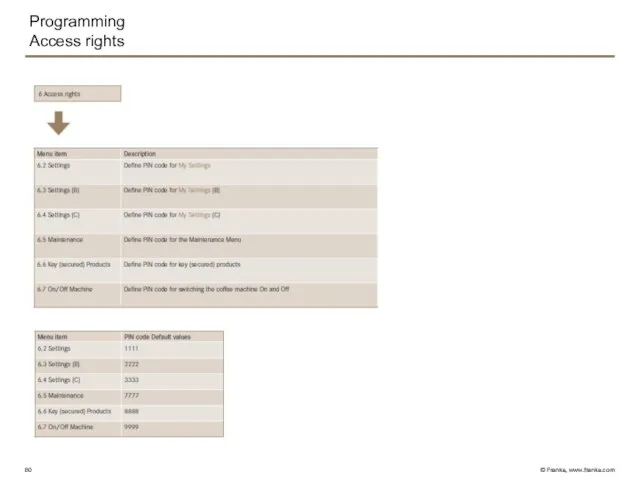

- 80. Programming Access rights

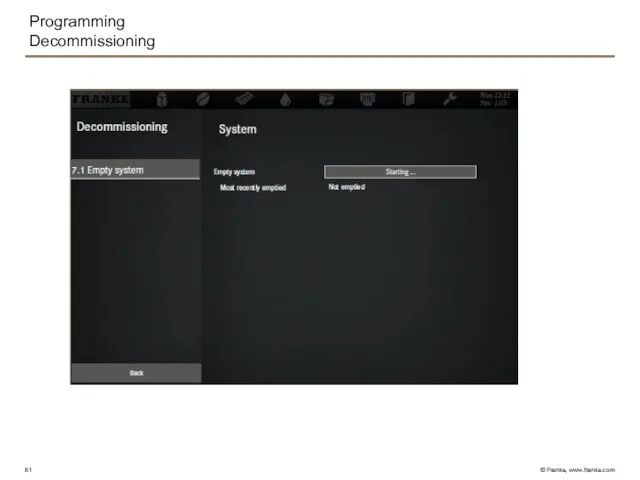

- 81. Programming Decommissioning

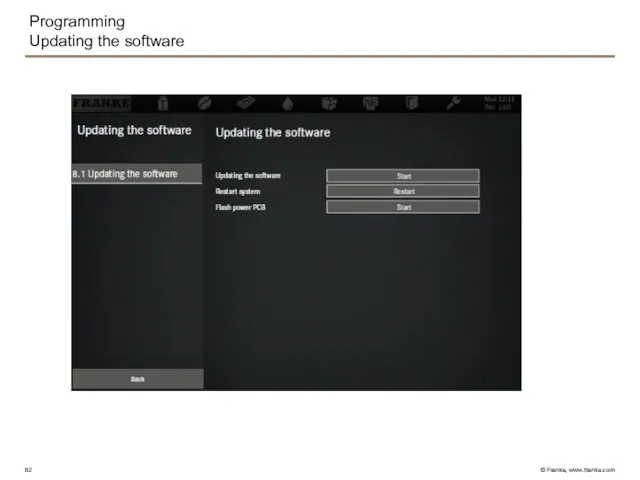

- 82. Programming Updating the software

- 83. Programming Individualization and data transfer

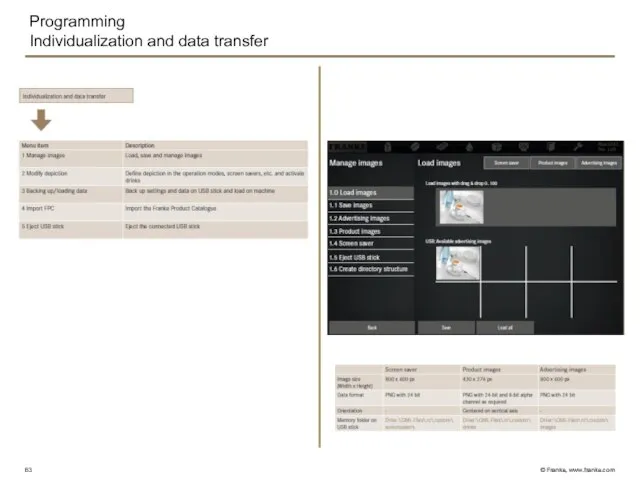

- 84. Programming Modify depiction

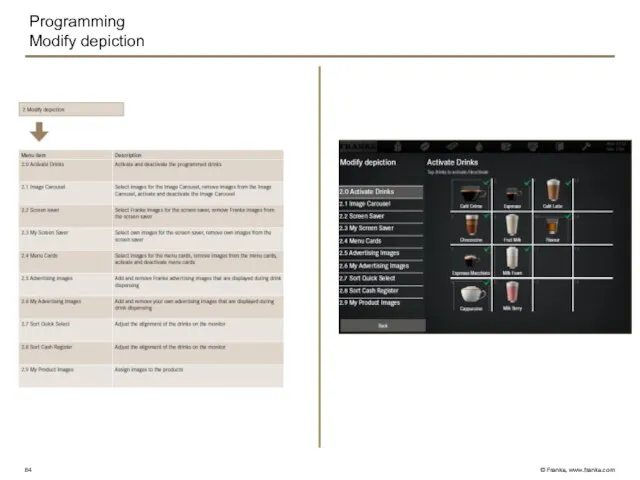

- 85. Programming Backing up/loading All setting in the menu «0 Commmissioning» is NOT included in the confugration

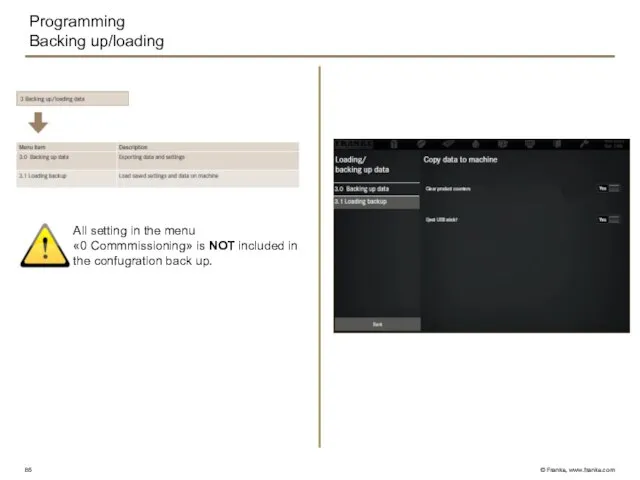

- 86. Programming Counters

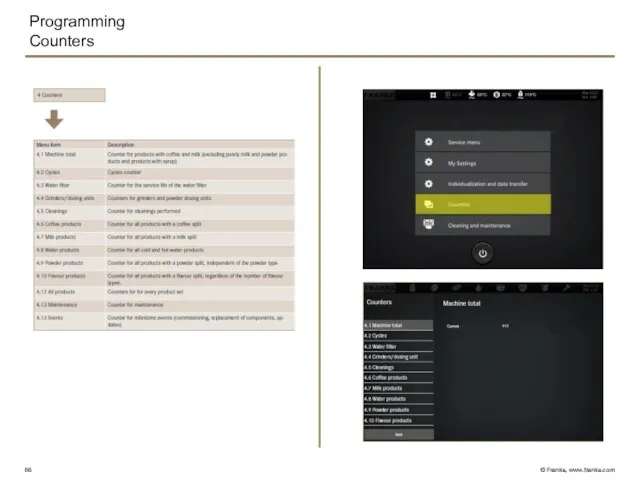

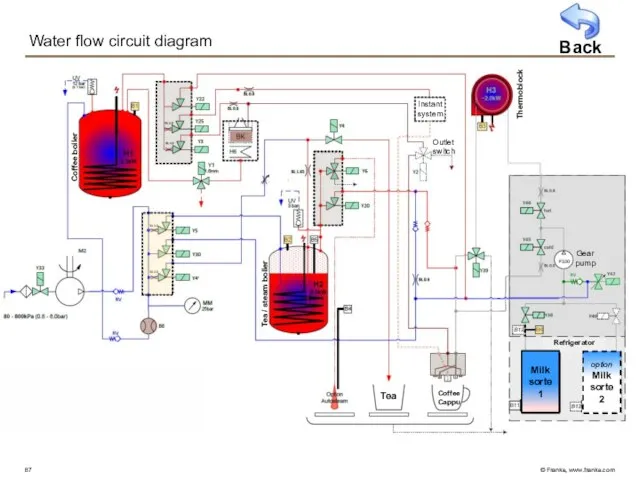

- 87. Water flow circuit diagram Coffee boiler Outlet switch Instant system Coffee Cappu Tea Tea / steam

- 88. FM850 Commissioning Product adjustment Troubleshooting Cleaning

- 90. Скачать презентацию

Пешеход на дороге

Пешеход на дороге 20140201_muzykalnaya_azbuka

20140201_muzykalnaya_azbuka Устройство стены, колонны и перекрытия в здании из монолитного железобетона

Устройство стены, колонны и перекрытия в здании из монолитного железобетона Сказочная птица

Сказочная птица Определение в ткани нитей основы и утка

Определение в ткани нитей основы и утка Виртуальная выставка по страницам периодических изданий посвященная Дню науки и техники Библиотека КМРК

Виртуальная выставка по страницам периодических изданий посвященная Дню науки и техники Библиотека КМРК Восстановление грузовых шин методом холодной варки

Восстановление грузовых шин методом холодной варки Понятие и элементы социально-психологического климата

Понятие и элементы социально-психологического климата Методика игровой деятельности

Методика игровой деятельности Байкальское общество архитекторов и инженеров

Байкальское общество архитекторов и инженеров Электричество

Электричество КФ Интонация

КФ Интонация Заголовок слайда

Заголовок слайда Технологія виробництва молока корів

Технологія виробництва молока корів Поздравление на день рождения

Поздравление на день рождения Религия и мораль. Нравственные заповеди в религиях ислама и буддизма. Урок 26

Религия и мораль. Нравственные заповеди в религиях ислама и буддизма. Урок 26 Предмет и методы изучения Истории государства и права зарубежных стран

Предмет и методы изучения Истории государства и права зарубежных стран 6. Ребусы 270722

6. Ребусы 270722 Технологические процессы заготовительных производств

Технологические процессы заготовительных производств Аппаратура защиты и управления напряжением до 1000 В. Лекция №4

Аппаратура защиты и управления напряжением до 1000 В. Лекция №4 Памятник, детская площадка, музей

Памятник, детская площадка, музей 20180113_dm_7_dlina_okruzhnosti_i_ploshchad_kruga

20180113_dm_7_dlina_okruzhnosti_i_ploshchad_kruga Расчет эффективности поисков заблудившихся и пропавших без вести в лесной (и не только лесной) местности

Расчет эффективности поисков заблудившихся и пропавших без вести в лесной (и не только лесной) местности Обзор ограждающих конструкций

Обзор ограждающих конструкций Мир уцелел, потому что смеялся

Мир уцелел, потому что смеялся Game of Thrones

Game of Thrones Малышам о космосе

Малышам о космосе Триггеры в презентации. Применение. Создание слайдов с триггерами

Триггеры в презентации. Применение. Создание слайдов с триггерами