Содержание

- 2. Product part

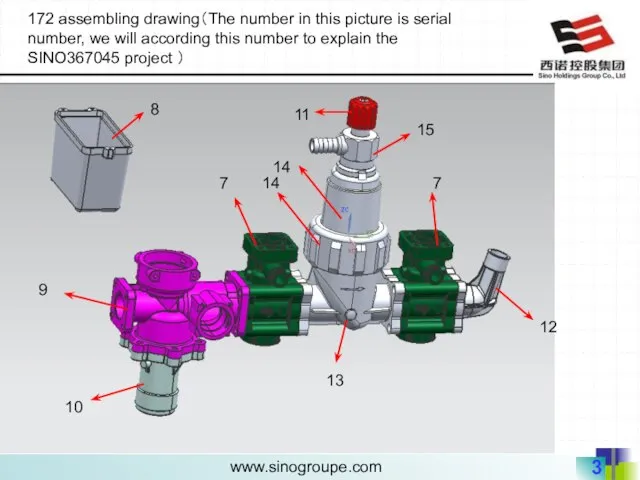

- 3. 10 9 7 13 14 14 15 11 12 8 172 assembling drawing(The number in this

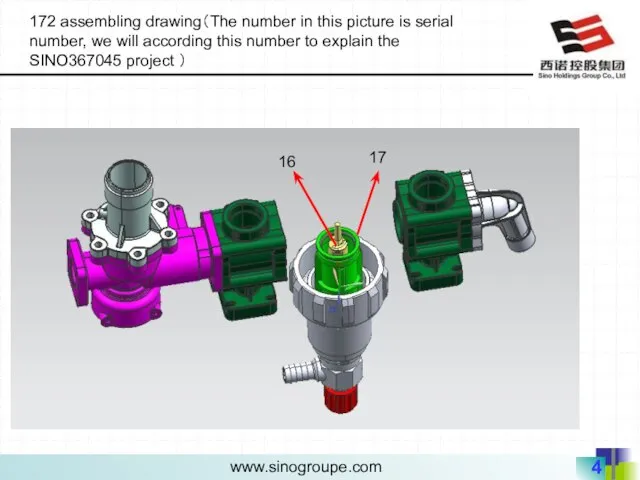

- 4. 16 17 172 assembling drawing(The number in this picture is serial number, we will according this

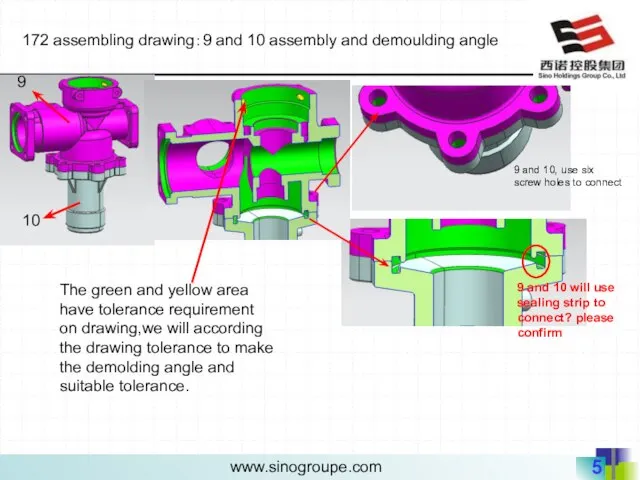

- 5. 172 assembling drawing:9 and 10 assembly and demoulding angle 9 and 10, use six screw holes

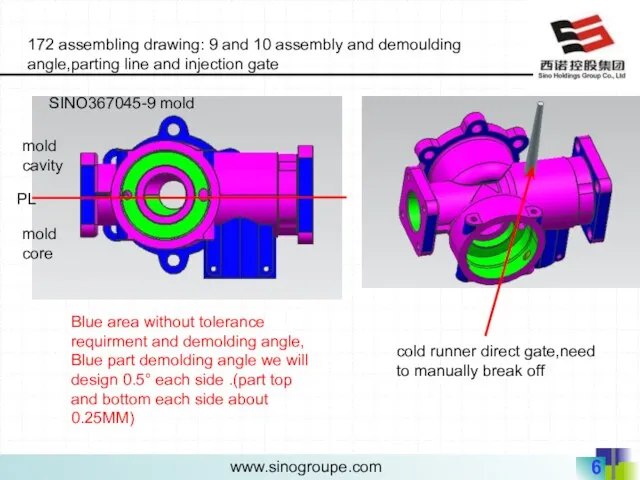

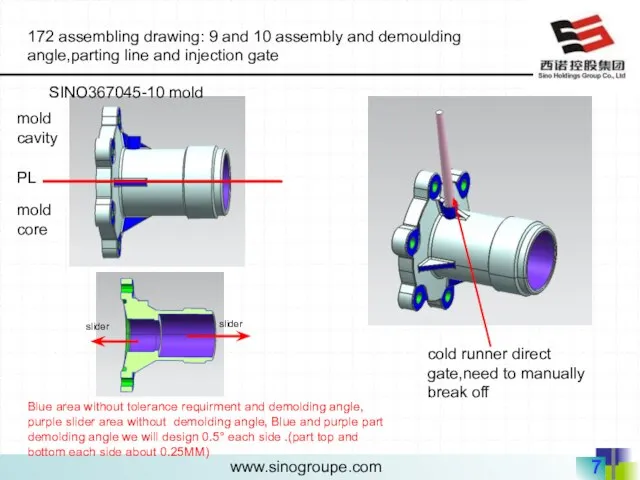

- 6. PL mold cavity mold core 172 assembling drawing: 9 and 10 assembly and demoulding angle,parting line

- 7. PL mold cavity mold core 172 assembling drawing: 9 and 10 assembly and demoulding angle,parting line

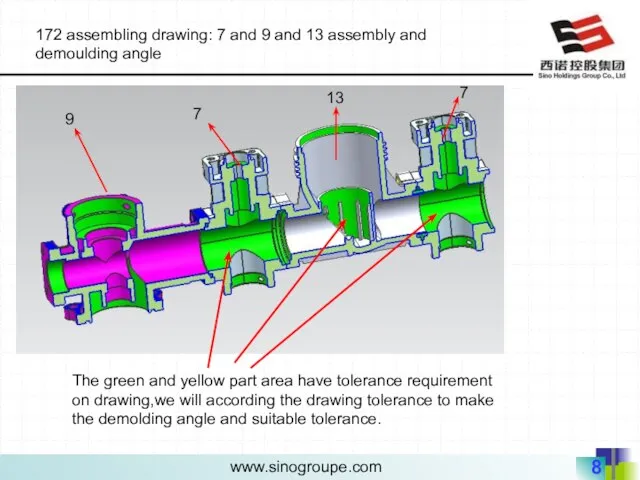

- 8. 172 assembling drawing: 7 and 9 and 13 assembly and demoulding angle 9 7 7 13

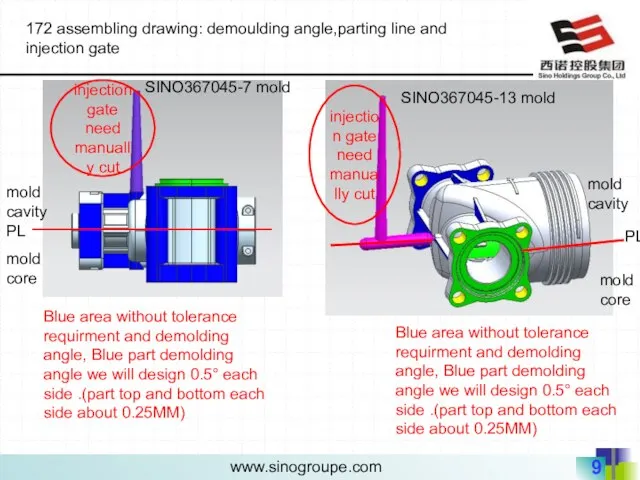

- 9. 172 assembling drawing: demoulding angle,parting line and injection gate PL mold cavity mold core injection gate

- 10. 172 assembling drawing:7and 9 and 13 part question( customer original assembly) ☆:Blue circle assembly is raised(higher),

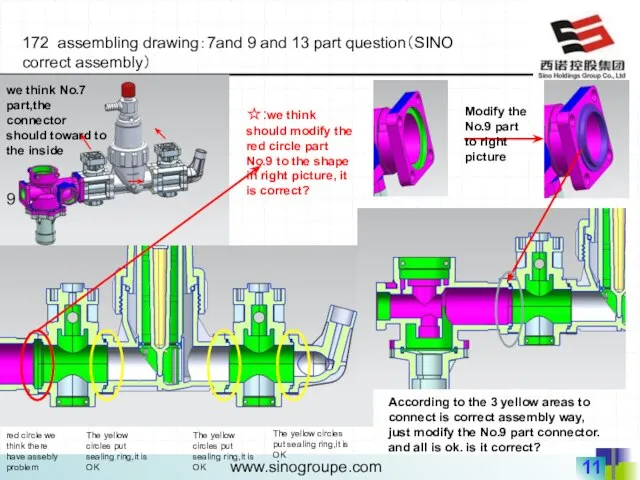

- 11. 172 assembling drawing:7and 9 and 13 part question(SINO correct assembly) ☆:we think should modify the red

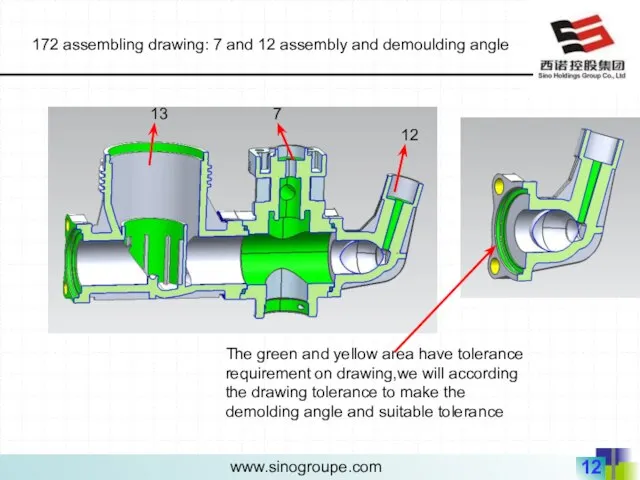

- 12. 172 assembling drawing: 7 and 12 assembly and demoulding angle The green and yellow area have

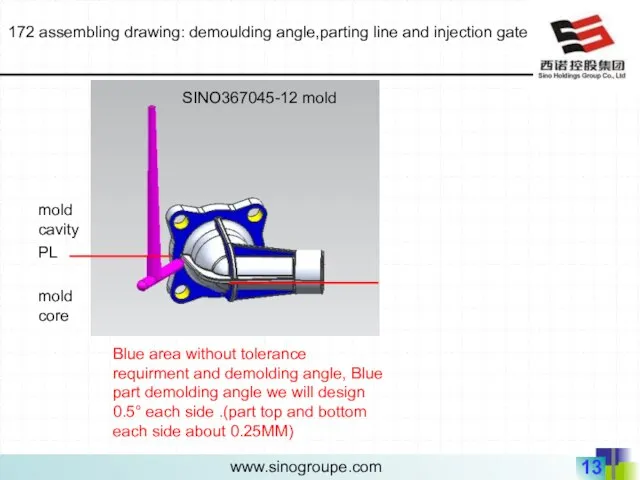

- 13. 172 assembling drawing: demoulding angle,parting line and injection gate PL mold cavity mold core Blue area

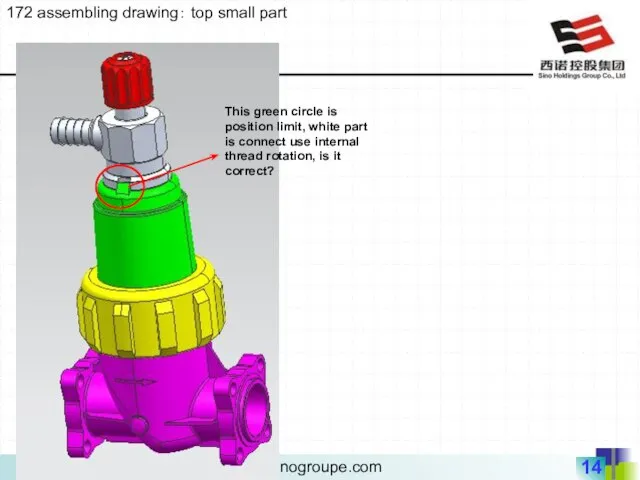

- 14. 172 assembling drawing: top small part This green circle is position limit, white part is connect

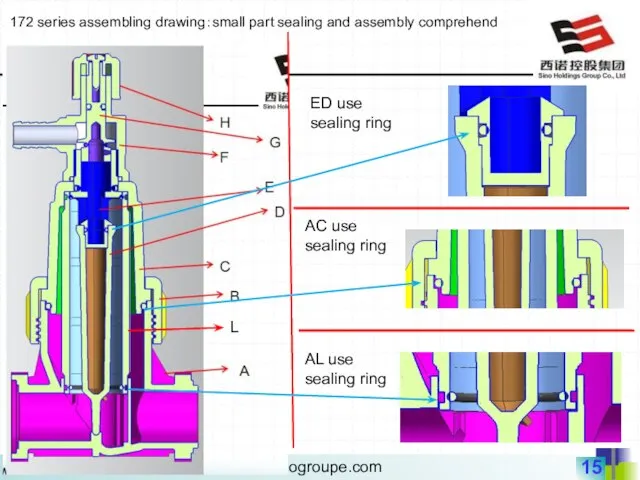

- 15. 172 series assembling drawing:small part sealing and assembly comprehend L AL use sealing ring AC use

- 16. 172 series assembling drawing:small part sealing and assembly comprehend L CL use sealing ring EC use

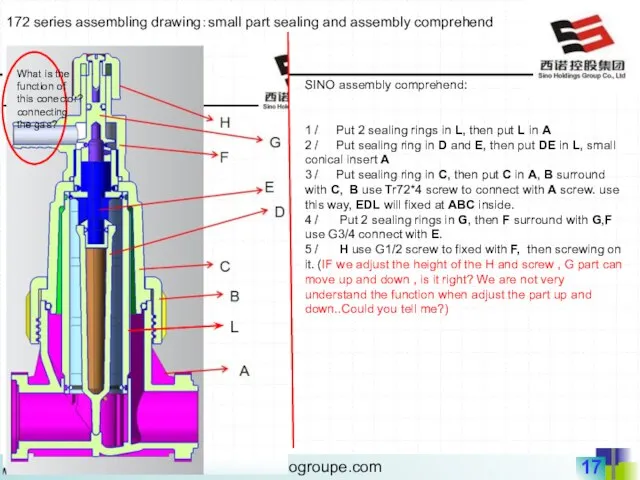

- 17. 172 series assembling drawing:small part sealing and assembly comprehend L SINO assembly comprehend: 1 / Put

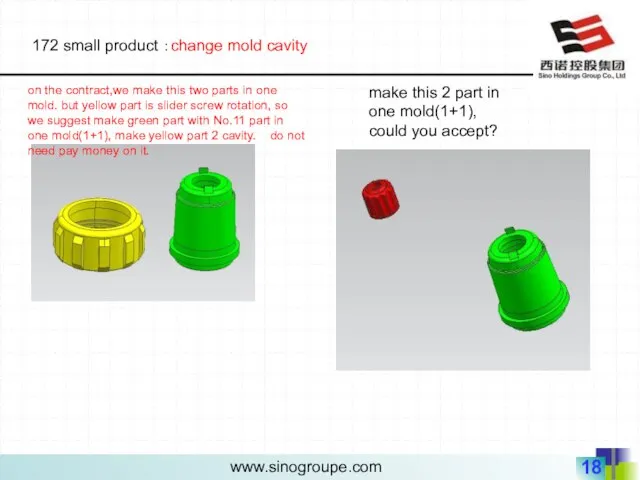

- 18. 172 small product :change mold cavity on the contract,we make this two parts in one mold.

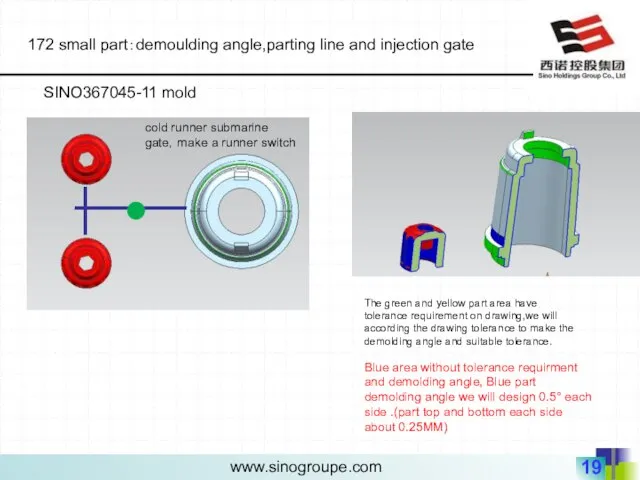

- 19. 172 small part:demoulding angle,parting line and injection gate SINO367045-11 mold cold runner submarine gate,make a runner

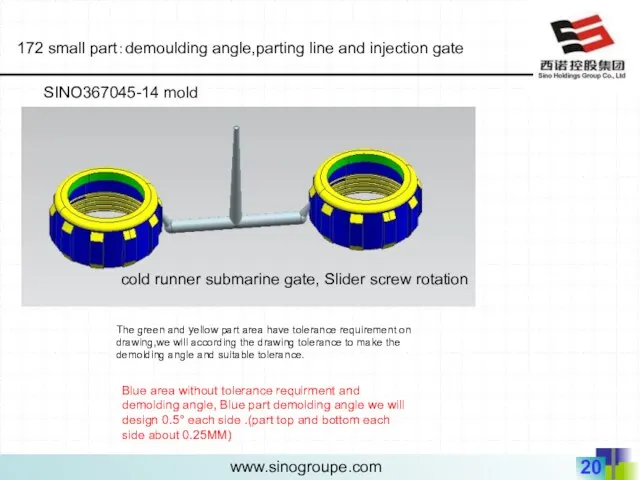

- 20. 172 small part:demoulding angle,parting line and injection gate SINO367045-14 mold Blue area without tolerance requirment and

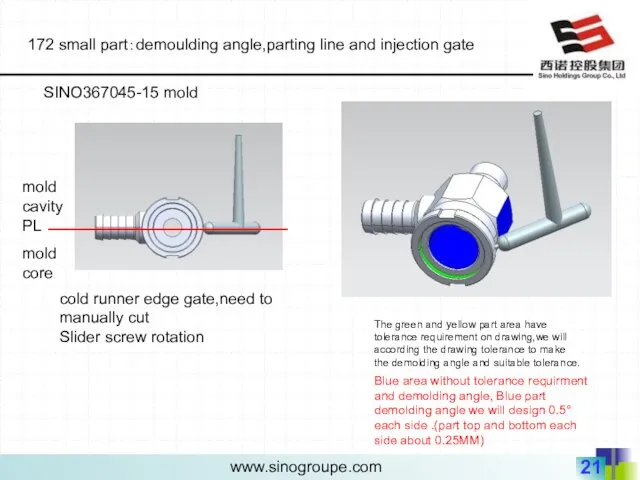

- 21. 172 small part:demoulding angle,parting line and injection gate SINO367045-15 mold Blue area without tolerance requirment and

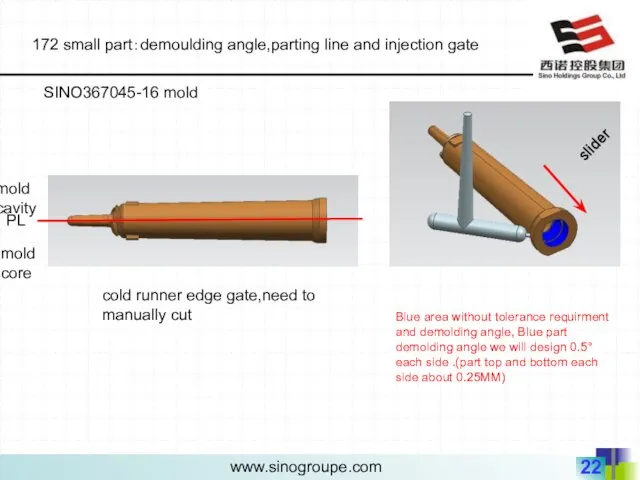

- 22. 172 small part:demoulding angle,parting line and injection gate SINO367045-16 mold Blue area without tolerance requirment and

- 24. Скачать презентацию

Электромагниттік толқындар

Электромагниттік толқындар Построение изображений, даваемых линзами

Построение изображений, даваемых линзами Автомобили. Рулевое управление автомобилем и управляемый занос

Автомобили. Рулевое управление автомобилем и управляемый занос Принцип минимума и смена факторов, лимитирующих рост популяции

Принцип минимума и смена факторов, лимитирующих рост популяции Определение прочных размеров деталей рулевого устройства

Определение прочных размеров деталей рулевого устройства Электростатическое поле в вакууме и его характеристики

Электростатическое поле в вакууме и его характеристики Создание платформы для изучения формул по физике

Создание платформы для изучения формул по физике ИСПОЛЬЗОВАНИЕ ЭЛЕКТРОЭНЕРГИИ В РАЗЛИЧНЫХ ОБЛАСТЯХ НАУКИ И ВЛИЯНИЕ НАУКИ НА ИСПОЛЬЗОВАНИЕ ЭЛЕКТРОЭНЕРГИИ В ЖИЗНИ

ИСПОЛЬЗОВАНИЕ ЭЛЕКТРОЭНЕРГИИ В РАЗЛИЧНЫХ ОБЛАСТЯХ НАУКИ И ВЛИЯНИЕ НАУКИ НА ИСПОЛЬЗОВАНИЕ ЭЛЕКТРОЭНЕРГИИ В ЖИЗНИ  Надпровідність

Надпровідність Колебания. Общие понятия

Колебания. Общие понятия Применение ионизирующего излучения в науке, технике и медицине

Применение ионизирующего излучения в науке, технике и медицине Методы наблюдения и регистрации элементарных частиц

Методы наблюдения и регистрации элементарных частиц Технология разборки, ремонта, сборки и регулировки коробки скоростей фрезерного станка

Технология разборки, ремонта, сборки и регулировки коробки скоростей фрезерного станка Основные законы динамики. Принцип Даламбера. Техническая механика

Основные законы динамики. Принцип Даламбера. Техническая механика Теория судна. Статика. Лекция № 1. Геометрия корпуса судна

Теория судна. Статика. Лекция № 1. Геометрия корпуса судна Магнитные материалы

Магнитные материалы Единицы измерения энергии

Единицы измерения энергии МОУ СОШ №13 Педагог: Васильева М.В. 7 класс 2006 год

МОУ СОШ №13 Педагог: Васильева М.В. 7 класс 2006 год Поверхностное натяжение. Термодинамика жидкостей

Поверхностное натяжение. Термодинамика жидкостей Плоская система сил

Плоская система сил Профессия - ТОРАТ (техническое обслуживание и ремонт автомобильного транспорта)

Профессия - ТОРАТ (техническое обслуживание и ремонт автомобильного транспорта) Качество электрической энергии

Качество электрической энергии Размер и форма Земли

Размер и форма Земли Отражение звука. Эхо. Звуковой резонанс

Отражение звука. Эхо. Звуковой резонанс Система кондиционирования воздуха

Система кондиционирования воздуха Баллистическое движение

Баллистическое движение Магнитное поле

Магнитное поле Презентация по физике "Физика и методы научного познания" - скачать

Презентация по физике "Физика и методы научного познания" - скачать