- Главная

- Образование

- Chain reaction 2016

Содержание

- 2. DRIVERS OF ATTRACTIVENESS Have a practical outcome from the project (certificate, a prize, recommendation for employment

- 3. CHAIN REACTION Project description: Chain Reaction – is a 4 month competition among students with technical/engineering/logistics

- 4. NEW IN 2016 New schools strong in technical field: HSE (logistics) UNECON (engineering) Wider promo reach:

- 5. 1st Team: Stock optimization & Stock monitor -Stock analysis within month (week by week) via templates

- 6. 1st Team: Professional Maintenance data bases & 3D library creation -To create electronic version of Machine

- 8. Скачать презентацию

Слайд 2

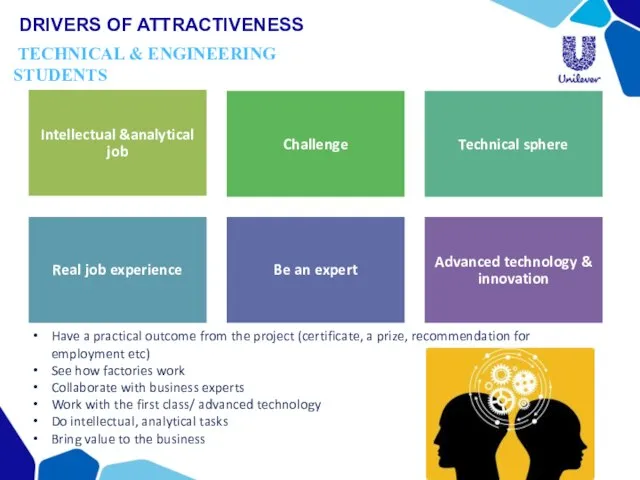

DRIVERS OF ATTRACTIVENESS

Have a practical outcome from the project (certificate, a

DRIVERS OF ATTRACTIVENESS

Have a practical outcome from the project (certificate, a

prize, recommendation for employment etc)

See how factories work

Collaborate with business experts

Work with the first class/ advanced technology

Do intellectual, analytical tasks

Bring value to the business

See how factories work

Collaborate with business experts

Work with the first class/ advanced technology

Do intellectual, analytical tasks

Bring value to the business

TECHNICAL & ENGINEERING STUDENTS

Слайд 3

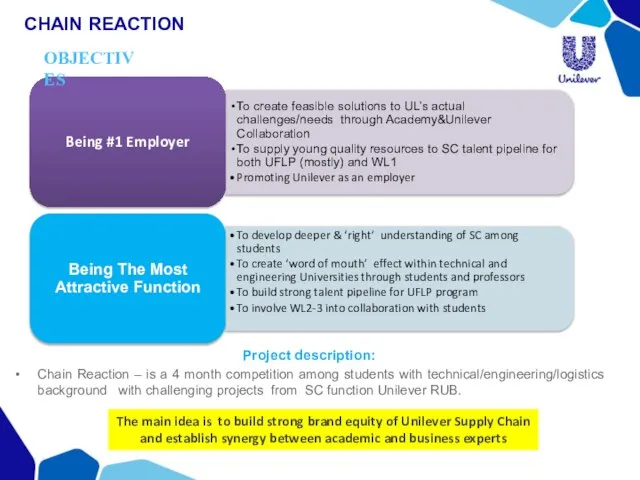

CHAIN REACTION

Project description:

Chain Reaction – is a 4 month competition among

CHAIN REACTION

Project description:

Chain Reaction – is a 4 month competition among

students with technical/engineering/logistics background with challenging projects from SC function Unilever RUB.

The main idea is to build strong brand equity of Unilever Supply Chain and establish synergy between academic and business experts

OBJECTIVES

Слайд 4

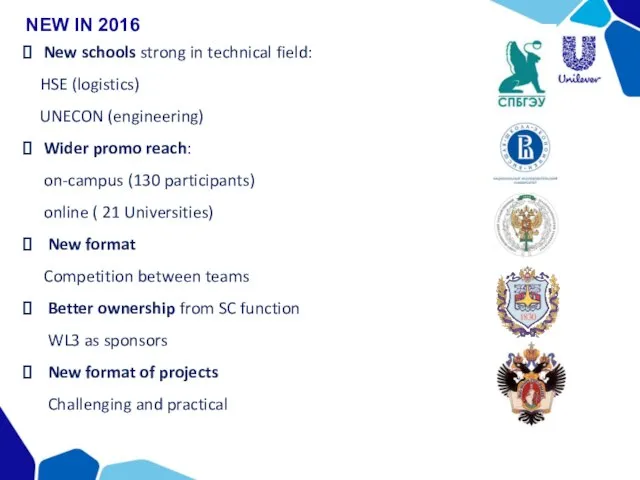

NEW IN 2016

New schools strong in technical field:

HSE (logistics)

UNECON

NEW IN 2016

New schools strong in technical field:

HSE (logistics)

UNECON

(engineering)

Wider promo reach:

on-campus (130 participants)

online ( 21 Universities)

New format

Competition between teams

Better ownership from SC function

WL3 as sponsors

New format of projects

Challenging and practical

Wider promo reach:

on-campus (130 participants)

online ( 21 Universities)

New format

Competition between teams

Better ownership from SC function

WL3 as sponsors

New format of projects

Challenging and practical

Слайд 5

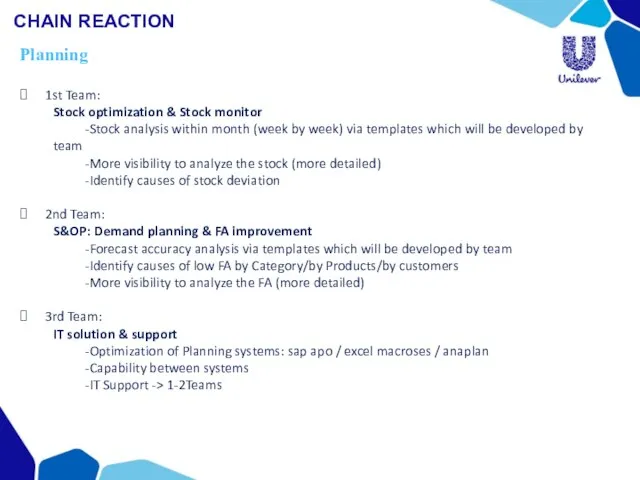

1st Team:

Stock optimization & Stock monitor

-Stock analysis within month (week by

1st Team:

Stock optimization & Stock monitor

-Stock analysis within month (week by

week) via templates which will be developed by team

-More visibility to analyze the stock (more detailed)

-Identify causes of stock deviation

2nd Team:

S&OP: Demand planning & FA improvement

-Forecast accuracy analysis via templates which will be developed by team

-Identify causes of low FA by Category/by Products/by customers

-More visibility to analyze the FA (more detailed)

3rd Team:

IT solution & support

-Optimization of Planning systems: sap apo / excel macroses / anaplan

-Capability between systems

-IT Support -> 1-2Teams

-More visibility to analyze the stock (more detailed)

-Identify causes of stock deviation

2nd Team:

S&OP: Demand planning & FA improvement

-Forecast accuracy analysis via templates which will be developed by team

-Identify causes of low FA by Category/by Products/by customers

-More visibility to analyze the FA (more detailed)

3rd Team:

IT solution & support

-Optimization of Planning systems: sap apo / excel macroses / anaplan

-Capability between systems

-IT Support -> 1-2Teams

CHAIN REACTION

Planning

Слайд 6

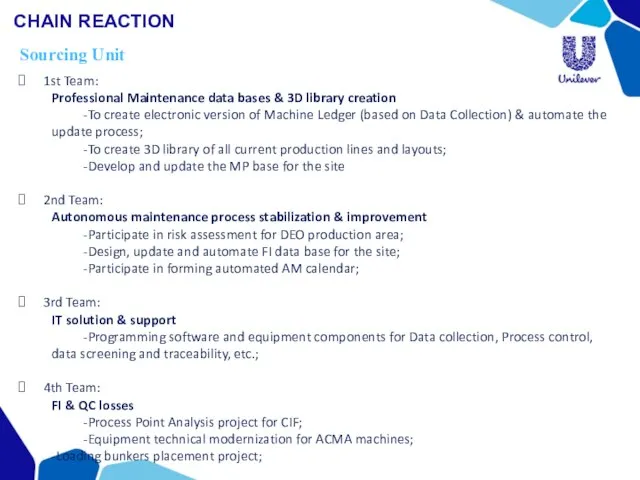

1st Team:

Professional Maintenance data bases & 3D library creation

-To create electronic

1st Team:

Professional Maintenance data bases & 3D library creation

-To create electronic

version of Machine Ledger (based on Data Collection) & automate the update process;

-To create 3D library of all current production lines and layouts;

-Develop and update the MP base for the site

2nd Team:

Autonomous maintenance process stabilization & improvement

-Participate in risk assessment for DEO production area;

-Design, update and automate FI data base for the site;

-Participate in forming automated AM calendar;

3rd Team:

IT solution & support

-Programming software and equipment components for Data collection, Process control, data screening and traceability, etc.;

4th Team:

FI & QC losses

-Process Point Analysis project for CIF;

-Equipment technical modernization for ACMA machines;

-Loading bunkers placement project;

-To create 3D library of all current production lines and layouts;

-Develop and update the MP base for the site

2nd Team:

Autonomous maintenance process stabilization & improvement

-Participate in risk assessment for DEO production area;

-Design, update and automate FI data base for the site;

-Participate in forming automated AM calendar;

3rd Team:

IT solution & support

-Programming software and equipment components for Data collection, Process control, data screening and traceability, etc.;

4th Team:

FI & QC losses

-Process Point Analysis project for CIF;

-Equipment technical modernization for ACMA machines;

-Loading bunkers placement project;

CHAIN REACTION

Sourcing Unit

- Предыдущая

Клетка как биологическая система

Требования к выполнению контрольной работы

Требования к выполнению контрольной работы Создание безопасной среды для обучающихся в МБОУ СОШ п. Агириш

Создание безопасной среды для обучающихся в МБОУ СОШ п. Агириш Профессиональная деятельность человека

Профессиональная деятельность человека Федеральный закон Об образовании в Российской Федерации

Федеральный закон Об образовании в Российской Федерации Структура исторического образования (с 1959 по 1964 г.)

Структура исторического образования (с 1959 по 1964 г.) Аттестационная работа. Методическая разработка Организация исследовательской деятельности по истории

Аттестационная работа. Методическая разработка Организация исследовательской деятельности по истории Правила приёма в 1 класс

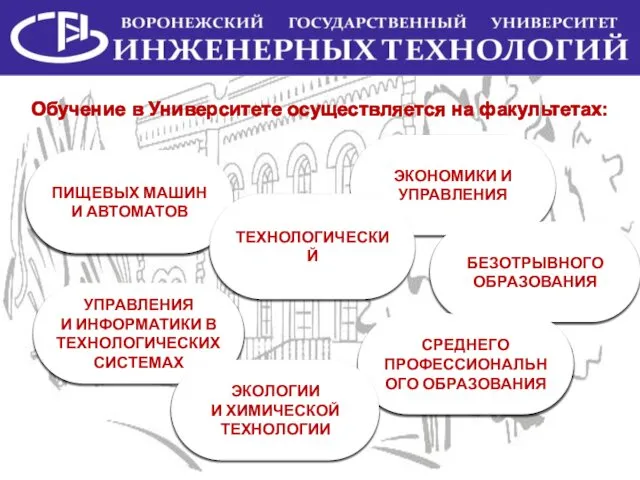

Правила приёма в 1 класс Абитуриенту. Воронежский государственный университет инженерных технологий

Абитуриенту. Воронежский государственный университет инженерных технологий Аттестационная работа. Методическая разработка по выполнению и оформлению индивидуальной исследовательской работы по предмету

Аттестационная работа. Методическая разработка по выполнению и оформлению индивидуальной исследовательской работы по предмету Добро пожаловать в лагерь Звёздный. Открытие смены

Добро пожаловать в лагерь Звёздный. Открытие смены День магистратуры. Магистерская программа Организационная психология

День магистратуры. Магистерская программа Организационная психология Ораторская речь как разновидность выступления

Ораторская речь как разновидность выступления Оформление реферата, курсовой работы, выпускной квалификационной работы. Требования к оформлению

Оформление реферата, курсовой работы, выпускной квалификационной работы. Требования к оформлению Языковой портфель, как инструмент оценивания и развития ученика

Языковой портфель, как инструмент оценивания и развития ученика Теоретическая часть научно-исследовательской работы

Теоретическая часть научно-исследовательской работы Аттестационная работа. Методическая разработка программы дополнительного образования Мои первые проекты

Аттестационная работа. Методическая разработка программы дополнительного образования Мои первые проекты Львівська комерційна академія. Факультет міжнародних економічних відносин

Львівська комерційна академія. Факультет міжнародних економічних відносин Условно-графическая наглядность

Условно-графическая наглядность Ученическое самоуправление Lider МБОУ СОШ №2

Ученическое самоуправление Lider МБОУ СОШ №2 Основы сетевого взаимодействия образовательных организаций в формировании ресурсов безопасной образовательной среды

Основы сетевого взаимодействия образовательных организаций в формировании ресурсов безопасной образовательной среды Индивидуальные образовательные маршруты на этапе дошкольного и начального образования

Индивидуальные образовательные маршруты на этапе дошкольного и начального образования Критерии и нормы оценок по предметам в начальной школе в со́отвествии с ФГОС

Критерии и нормы оценок по предметам в начальной школе в со́отвествии с ФГОС Что такое проект,

Что такое проект, Целевое обучение: ординатура

Целевое обучение: ординатура БелГУ. Кафедра социальных технологий

БелГУ. Кафедра социальных технологий Федеральные государственные образовательные стандарты для обучающихся с ограниченными возможностями здоровья

Федеральные государственные образовательные стандарты для обучающихся с ограниченными возможностями здоровья Аттестационная работа. Требования к оформлению

Аттестационная работа. Требования к оформлению Атомный урок

Атомный урок