Содержание

- 2. The importance of non-destructive testing methods in ensuring the safety of railway transport The most important

- 3. Classification of defects in metal structures of railway transport Defect - each non-compliance of the controlled

- 4. Main features of ultrasonic testing These ultrasonic testing methods allow you to carry out one hundred

- 5. Defects of metal structures detected by ultrasonic inspection methods Casting defects: shrinkage shells (cavities formed during

- 6. Classification of types of non-destructive testing of metal structures A type of NC is a group

- 7. Areas of application of the magnetic type of control in railway transport Of the methods of

- 8. Brief description of the eddy current type of non-destructive testing Eddy-current testing is based on the

- 9. Areas of application of eddy current type of non-destructive testing in railway transport On railway transport,

- 11. Скачать презентацию

The importance of non-destructive testing methods in ensuring the safety of

The importance of non-destructive testing methods in ensuring the safety of

The most important problem of Railways is ensuring transport safety and environmental safety Features of the operation of Railways in Latvia and other Baltic countries : excessive terms of use of track structures, rolling stock, electric traction complex; insufficiently high technical level of operation of track structures, rolling stock, electric traction complex; difficult climatic conditions for diagnostics of technical devices during their operation; growth in transit traffic volumes on the international transport corridor East-West; increasing the weight of trains and the speed of movement. Prevention of accidents and man-made disasters in real conditions is associated with the need for monitoring, as well as diagnostics of the technical condition of railway transport devices by non-destructive testing methods

Classification of defects in metal structures of railway transport

Defect - each

Classification of defects in metal structures of railway transport

Defect - each

Main features of ultrasonic testing

These ultrasonic testing methods allow you to

Main features of ultrasonic testing

These ultrasonic testing methods allow you to

Defects of metal structures detected by ultrasonic inspection methods

Casting defects: shrinkage

Defects of metal structures detected by ultrasonic inspection methods

Casting defects: shrinkage

Classification of types of non-destructive testing of metal structures

A type of

Classification of types of non-destructive testing of metal structures

A type of

Areas of application of the magnetic type of control in railway

Areas of application of the magnetic type of control in railway

Of the methods of magnetic type of control in railway transport, the most widespread are the following: magnetic Powder (used everywhere); magnetic powder control is subjected to the following objects of rolling stock: parts of shock-traction and braking equipment, bogie frames of various models both assembled and by elements, axles of wheel pairs of all types both assembled and in a free state, disks, comb and spokes of locomotive wheels, etc. Fluxgate method of control – used in railcar and locomotive sector for the control of parts and components of locomotives and wagons. Induction method is used in the road economy is to control the rails.

Brief description of the eddy current type of non-destructive testing

Eddy-current testing

Brief description of the eddy current type of non-destructive testing

Eddy-current testing

Areas of application of eddy current type of non-destructive testing in

Areas of application of eddy current type of non-destructive testing in

On railway transport, the following components are checked by eddy current control : - all-rolled wheels of the wheel pair; - elements of the axle box unit; - elements of bogies of various models and axle bearings; - brake transmission devices, automatic coupling device. Eddy current monitoring is widely used to detect hidden metal and metal-containing objects. The method detects all types of metals and even objects with a very low metal content eddy Current methods have two main limitations –- they are used only for the control of electrically conductive products – they have a small depth of control associated with the peculiarities of penetration of electromagnetic waves into the object of control.

Разработка программного обеспечения для заведующего складом предприятия

Разработка программного обеспечения для заведующего складом предприятия Электромеханические системы (электропривод)

Электромеханические системы (электропривод) Презентация Microsoft PowerPoint

Презентация Microsoft PowerPoint Школьный курс Основы религиозных культур и светской этики

Школьный курс Основы религиозных культур и светской этики Сегодня выпускной

Сегодня выпускной pitanie_studenta-konvertirovan

pitanie_studenta-konvertirovan Hindu Law

Hindu Law Лядская Л.Г. Портфолио Алеси Пономаренко

Лядская Л.Г. Портфолио Алеси Пономаренко Реставрация кресла

Реставрация кресла родительный и дательный падеж имен прилагательных

родительный и дательный падеж имен прилагательных Игра Внутри, снаружи

Игра Внутри, снаружи Медный всадник

Медный всадник 20140818_prezentatsiya_triik_1_-_kopiya

20140818_prezentatsiya_triik_1_-_kopiya Vozmozhnosti_Studentov_TU

Vozmozhnosti_Studentov_TU Казка про те, чому папуга не навчився розмовляти

Казка про те, чому папуга не навчився розмовляти Проектирование локально-вычислительной сети на предприятии

Проектирование локально-вычислительной сети на предприятии Строим экологический город

Строим экологический город презентация

презентация Ярмарка Скидок -презентация

Ярмарка Скидок -презентация Интегральные микросхемы

Интегральные микросхемы Основы стандартизации сертификации и метрологии

Основы стандартизации сертификации и метрологии Проектирование карьеры предпринимателя в системе пассажирских автоперевозок

Проектирование карьеры предпринимателя в системе пассажирских автоперевозок Правила отыскания первообразных

Правила отыскания первообразных О региональном конкурсе лучший проект года - 2020

О региональном конкурсе лучший проект года - 2020 Цветник и его виды

Цветник и его виды 20141222_pravovoe_gosudarstvo_8k

20141222_pravovoe_gosudarstvo_8k Технологическое оборудование автосервиса. Потребительские свойства

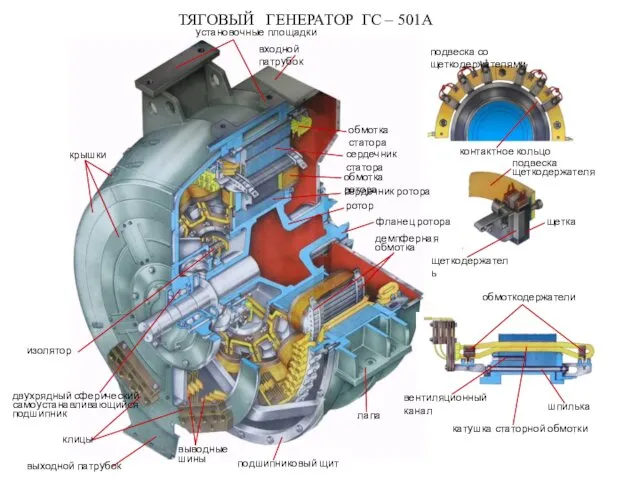

Технологическое оборудование автосервиса. Потребительские свойства Электрическое оборудование тепловозов

Электрическое оборудование тепловозов