Содержание

- 2. Introduction Object Recognition via Classical Moments Control of a Robot Arm System Conclusion Contents:

- 3. In this project, an application of computer image processing to recognize various objects and the vision-based

- 4. Introduction Image Processing (Object Recognition via feature extraction, Edge Detection to define the place of the

- 5. After Hu presented moment invarients in 1962, they are widely used in many applications. Subsequently, Resis

- 6. Image Processing via Classical Moments Central Moment of an Area: Whereas; and If we calculate the

- 7. Image Processing via Classical Moments Hu moments can be found. (2) (3) (4)

- 8. Image Processing via Classical Moments (5) (6) (7) Six of these invariants are invariable if the

- 9. Image Processing via Classical Moments Zernike Moments: Zernike polynomials, form a complete orthogonal set over the

- 10. Image Processing via Classical Moments Zernike moments of order p with repitation q for a digital

- 11. Image Processing via Classical Moments Orthogonal Fourier-Mellin Moments: r is the length of the vector from

- 12. Image Processing via Classical Moments The magnitude of Hu moments, OFMMs and ZMs are rotation, translation

- 13. Image Processing via Classical Moments Light Shields (on both sides) CCD Camera (connected to the grabber

- 14. Image Processing via Classical Moments Trigerring Line Boundary Lines Object Direction Object Conveyor Band CCD Camera

- 15. Image Processing via Classical Moments In this project, four types of image processing techniques are used:

- 16. Image Processing via Classical Moments Image Data Reduction a. Digital Conversion: It reduces the number of

- 17. Image Processing via Classical Moments 2. Segmentation a. Edge Detection In Edge Detection it is considered

- 18. Image Processing via Classical Moments Some examples of Canny Edge Detection Algorithym can be seen below

- 19. Image Processing via Classical Moments 2. Segmentation a. Edge Detection b. Tresholding Tresholding is a binary

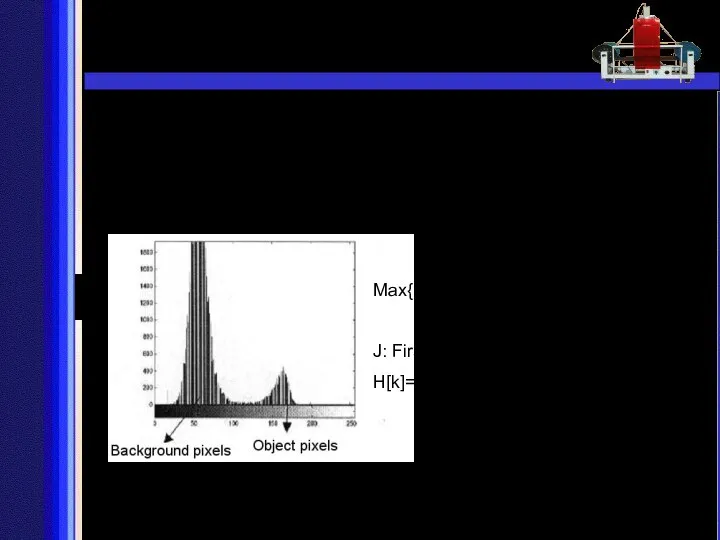

- 20. Image Processing via Classical Moments 2. Segmentation a. Edge Detection b. Tresholding Max{[((k-j)2*h[k])] | (0 J:

- 21. Image Processing via Classical Moments Images of some of the objects, tresholded images and histograms of

- 22. Image Processing via Classical Moments 3. Feature Extraction Hu moments, Legendre moments, ortogonal moments, geometrical moments,

- 23. Image Processing via Classical Moments 4. Object Recognition Object Recognition process can be defined as labeling

- 24. Robot Arm System and Control Motor # 5 Motor # 4 Motor # 3 Motor #

- 25. Robot Arm System and Control First, kinematic analysis and “link table “ of the revolute jointed

- 26. Robot Arm System and Control Second step in forward kinematics is to construct a table to

- 27. Robot Arm System and Control Transformation matrices according to table are,

- 28. Robot Arm System and Control In deriving the kinematical equations, we formed the product of link

- 29. Robot Arm System and Control Px , Py, Pz, can be found with respect to the

- 30. Robot Arm System and Control Before the path control applications, the position following capability of the

- 31. Robot Arm System and Control While planning a trajectory, first two or more points should be

- 32. Robot Arm System and Control After defining these angles, the trajectory of a joint can be

- 33. Robot Arm System and Control As an example the trajectory and parameters of the manipulator are

- 34. Robot Arm System and Control By this table, we can easily determine the needed time of

- 35. After theoretical study, to test the performance of the presented algorithym, an application mechanism is prepared

- 37. Скачать презентацию

Кинетические свойства радиоматериалов

Кинетические свойства радиоматериалов  Module 8. Regular Expressions

Module 8. Regular Expressions Ирина Петровна Токмакова. Жизнь и творчество

Ирина Петровна Токмакова. Жизнь и творчество Дизайн и вёрстка (05)

Дизайн и вёрстка (05) Ацтеки

Ацтеки  ПЯВУ. Основы программирования. Лекция 8. Алгоритм Евклида. “Решето” Эратосфена

ПЯВУ. Основы программирования. Лекция 8. Алгоритм Евклида. “Решето” Эратосфена Управление персоналом

Управление персоналом Площадь прямоугольника Презентация к уроку математики во 2 классе учителя МОУ «СОШ п. Бурасы Новобурасского района Саратовской о

Площадь прямоугольника Презентация к уроку математики во 2 классе учителя МОУ «СОШ п. Бурасы Новобурасского района Саратовской о Увеличение числа в 10,100,1000 раз. Путешествие по городу.

Увеличение числа в 10,100,1000 раз. Путешествие по городу. Международная интеграция

Международная интеграция МИНИМИЗАЦИЯ ПЕРЕКЛЮЧАТЕЛЬНЫХ ФУНКЦИЙ ПО КАРТАМ КАРНО

МИНИМИЗАЦИЯ ПЕРЕКЛЮЧАТЕЛЬНЫХ ФУНКЦИЙ ПО КАРТАМ КАРНО Адвокатура. Задача каждого адвоката и адвокатуры в целом

Адвокатура. Задача каждого адвоката и адвокатуры в целом 01.12 Номинация

01.12 Номинация Канада

Канада от почтового ящика до дополненной реальности

от почтового ящика до дополненной реальности  Презентация Налоговые вычеты

Презентация Налоговые вычеты Презентация "Художественное описание картины Н.П. Крымова «Зимний вечер»" - скачать презентации по МХК

Презентация "Художественное описание картины Н.П. Крымова «Зимний вечер»" - скачать презентации по МХК Некоузская средняя общеобразовательная школа, 2006 год

Некоузская средняя общеобразовательная школа, 2006 год Мысли, несущие силу и исцеление

Мысли, несущие силу и исцеление Проектирование административно-бытовых корпусов промышленного здания

Проектирование административно-бытовых корпусов промышленного здания Пожарная техника

Пожарная техника Учитель МХК – Рогудеева Лилия Анатольевна Symbols of the USA Символы США

Учитель МХК – Рогудеева Лилия Анатольевна Symbols of the USA Символы США Развитие системы социальной защиты населения в Республике Казахстан

Развитие системы социальной защиты населения в Республике Казахстан Азаматтық іс жүргізу мерзімдері

Азаматтық іс жүргізу мерзімдері Мандала - тибетский символ божественного мира

Мандала - тибетский символ божественного мира Обеспечение уплаты таможенных платежей (поручительство) Подготовили: Шунайлова Жанна, Епифанова Евгения

Обеспечение уплаты таможенных платежей (поручительство) Подготовили: Шунайлова Жанна, Епифанова Евгения Сущность и принципы территориального общественного самоуправления (ТОС)

Сущность и принципы территориального общественного самоуправления (ТОС) Презентация Внешнеэкономические операции и сделки

Презентация Внешнеэкономические операции и сделки