Содержание

- 2. Multivariable Process Control System (Flow, Level, Temperature, Pressure) Volume 1/2 Made by: Sharafatdin Yessirkepov Checked by:

- 3. Plan Part 1. Introduction to FLTP Part 2. Main Units of the trainer Part 3. Control

- 4. Introduction How do we control the tank in the field without the manual control? Do we

- 5. Introduction It is difficult to control the liquid vessel manually because it is time consuming and

- 6. Introduction (Cont’d) Therefore, the Process Control System is helpful by controlling the unit parameters even at

- 7. Introduction Cont’d Multivariable Process Control System can control the flow rate, level, Pressure and Temperature of

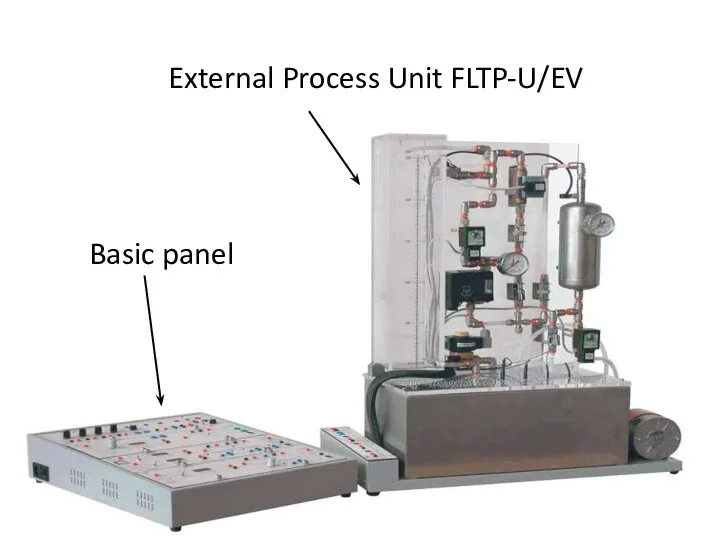

- 8. External Process Unit FLTP-U/EV Basic panel

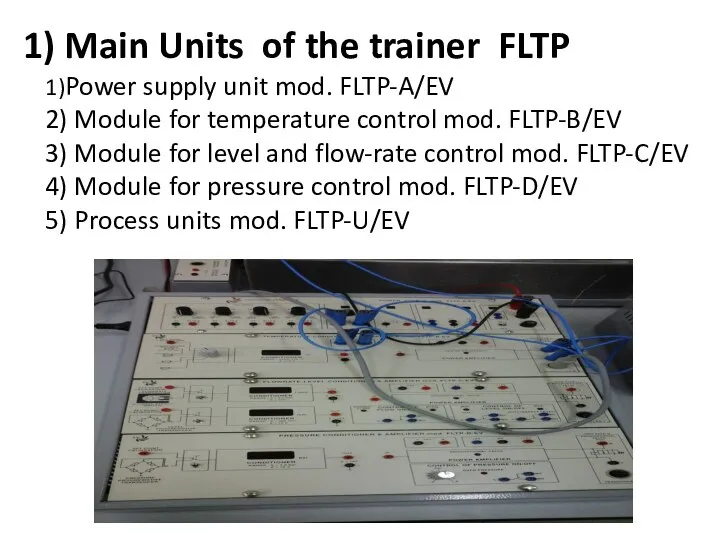

- 9. 1) Main Units of the trainer FLTP 1)Power supply unit mod. FLTP-A/EV 2) Module for temperature

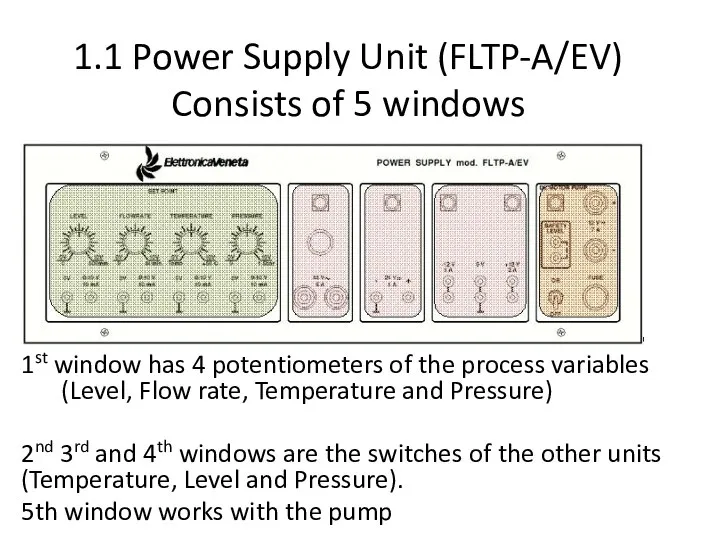

- 10. 1.1 Power Supply Unit (FLTP-A/EV) Consists of 5 windows 1st window has 4 potentiometers of the

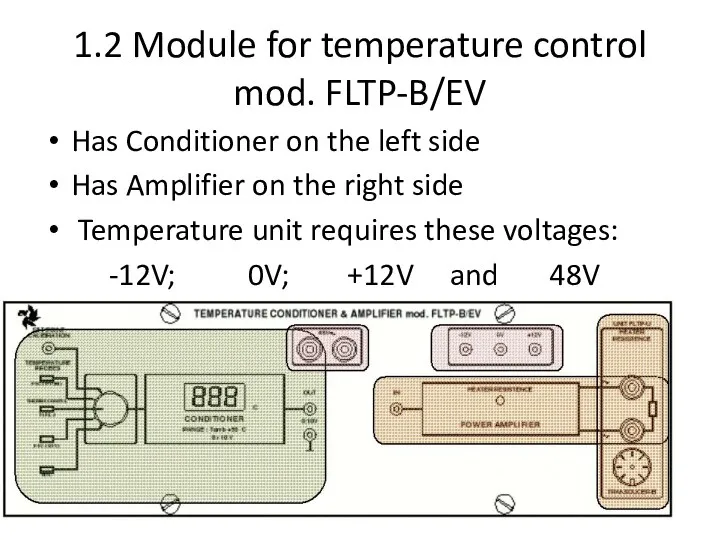

- 11. 1.2 Module for temperature control mod. FLTP-B/EV Has Conditioner on the left side Has Amplifier on

- 12. Question Which kind of thermocouples do you know?

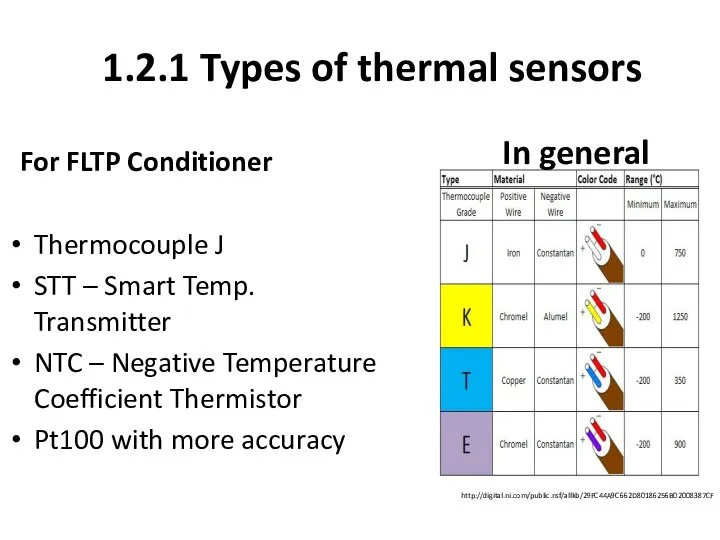

- 13. http://digital.ni.com/public.nsf/allkb/29FC44A9C662D80186256B02008387CF For FLTP Conditioner Thermocouple J STT – Smart Temp. Transmitter NTC – Negative Temperature Coefficient

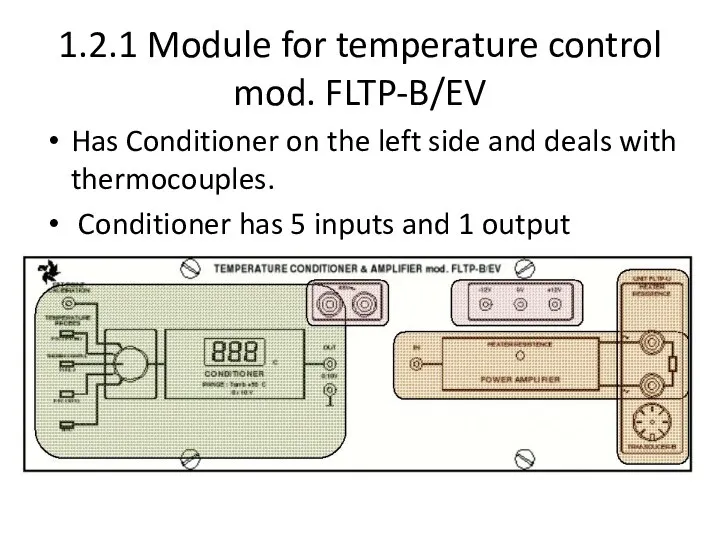

- 14. 1.2.1 Module for temperature control mod. FLTP-B/EV Has Conditioner on the left side and deals with

- 15. Question. What is amplifier?

- 16. 1.2.2 Amplifier (Brief explanation) Amplifier – modulates the output stronger than input signal For example: Input

- 17. 1.3. Flow Rate- Level Control (FLTP-C/EV) Has 2 conditioners, 1 amplifier and 2 controllers Flow rates

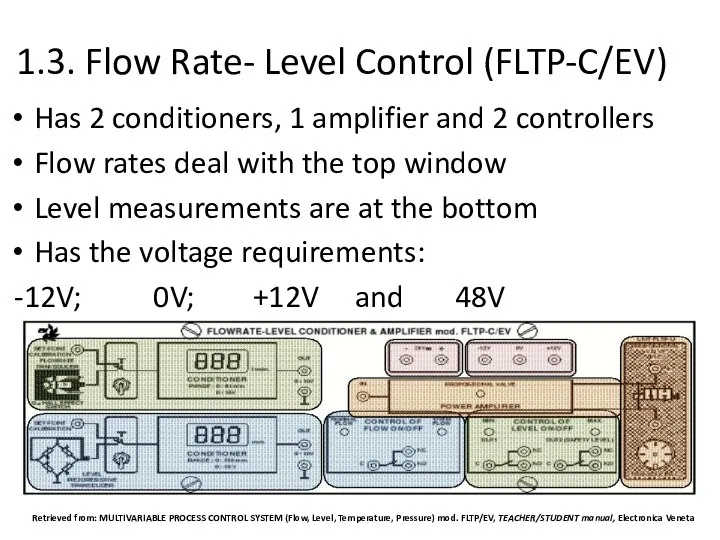

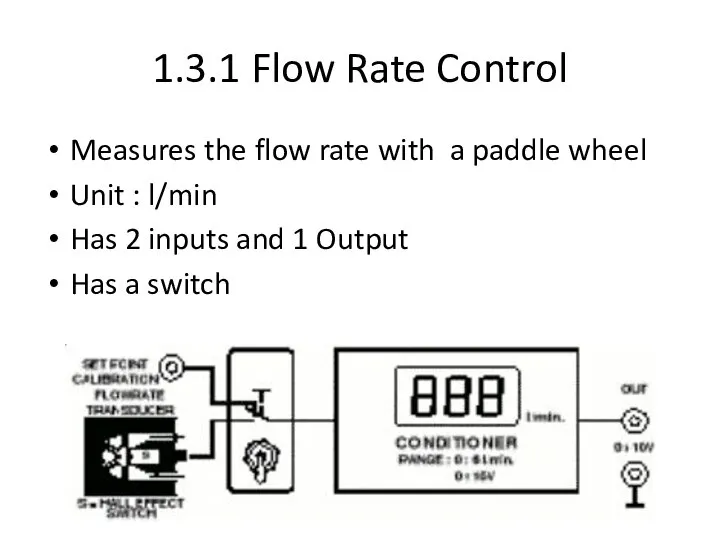

- 18. 1.3.1 Flow Rate Control Measures the flow rate with a paddle wheel Unit : l/min Has

- 19. 1.3.2 Level Control Shows the level of the tank Measured with piezometric sensor

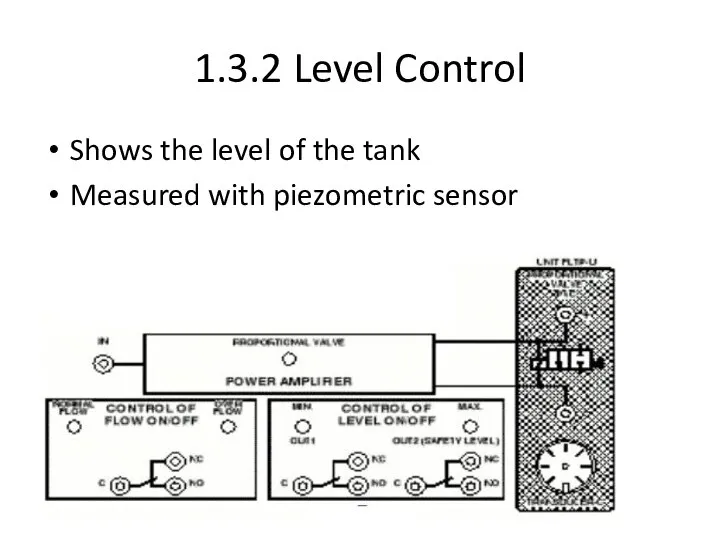

- 20. 1.4 Pressure Unit (FLTP-D/EV) Has signal conditioner and amplifier Pressure is measured in bars. Has 1

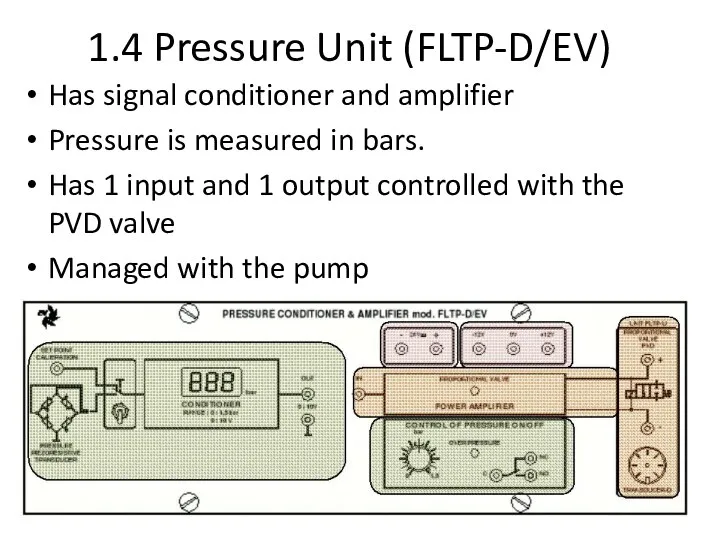

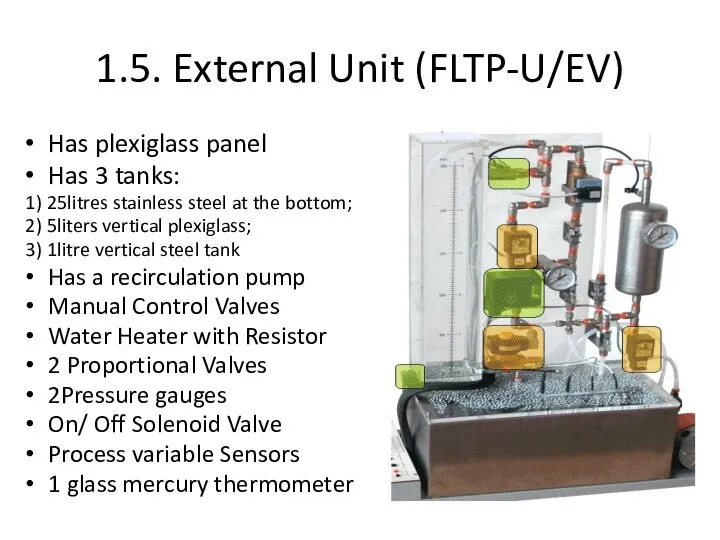

- 21. 1.5. External Unit (FLTP-U/EV) Has plexiglass panel Has 3 tanks: 1) 25litres stainless steel at the

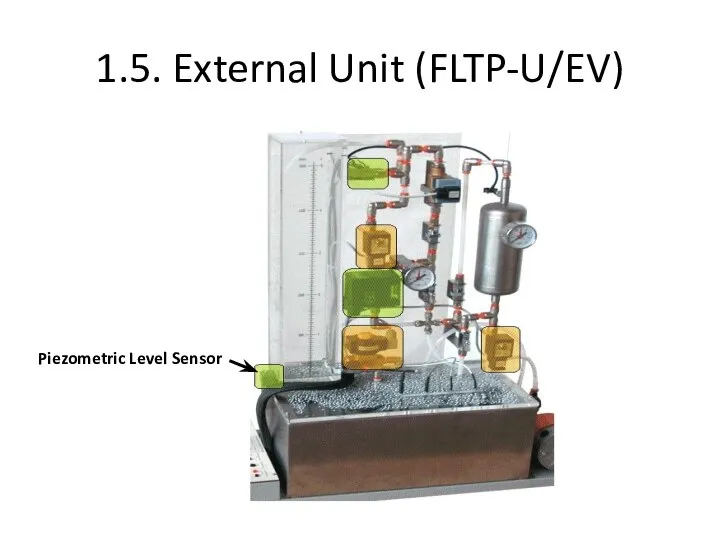

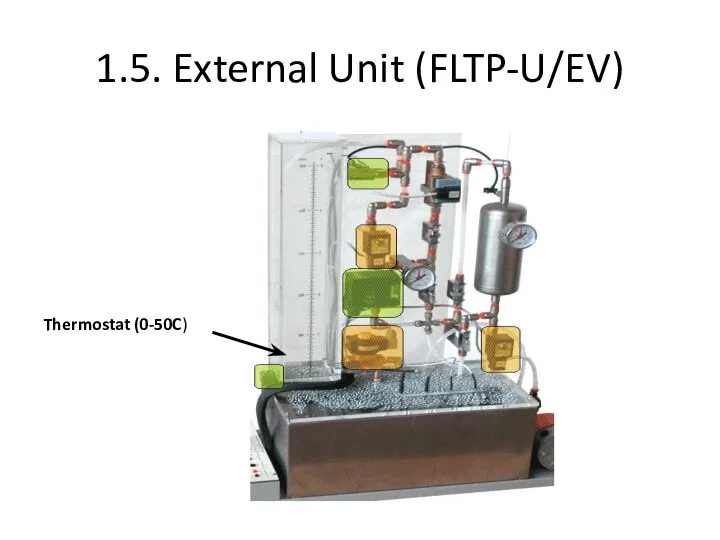

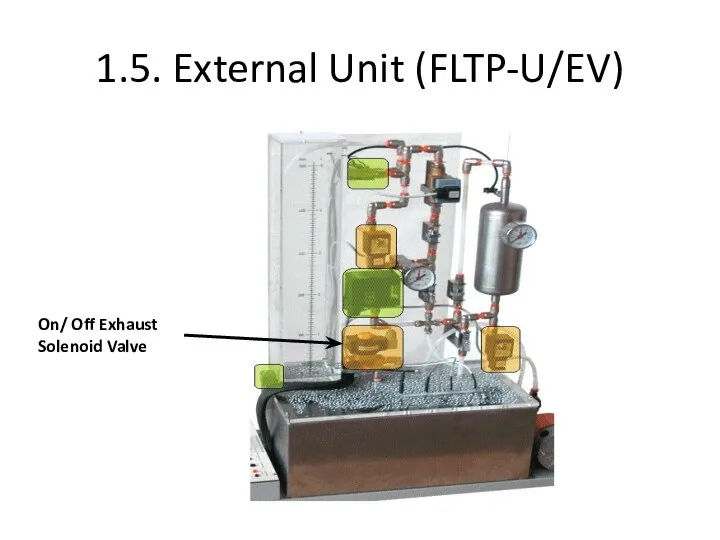

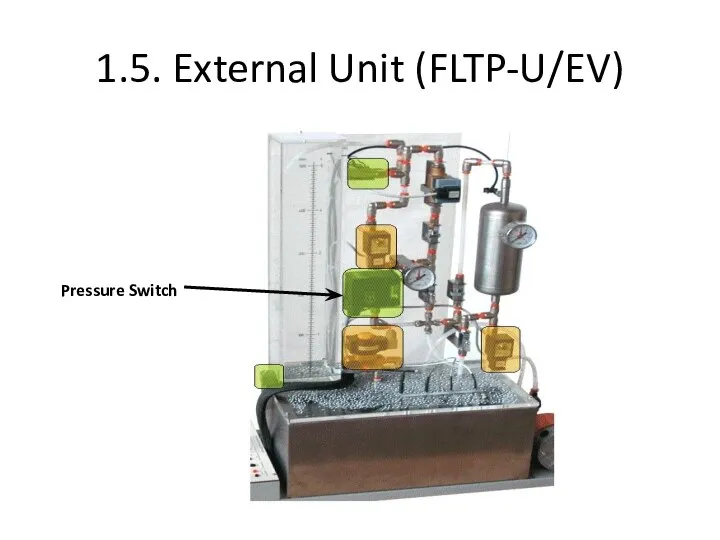

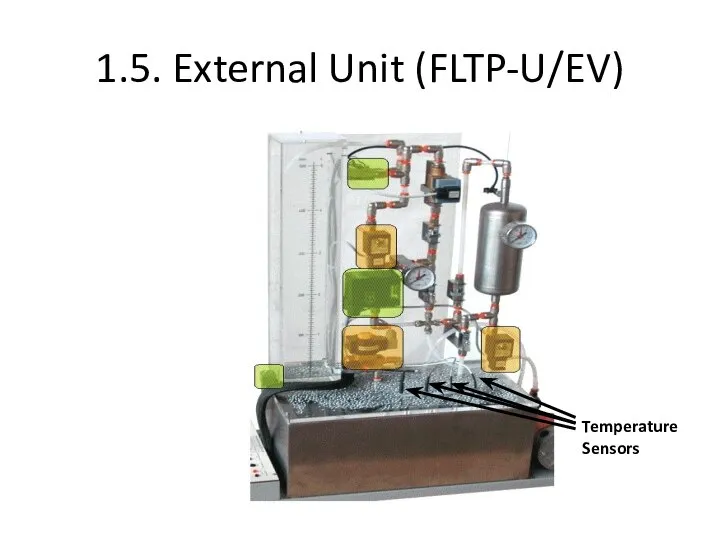

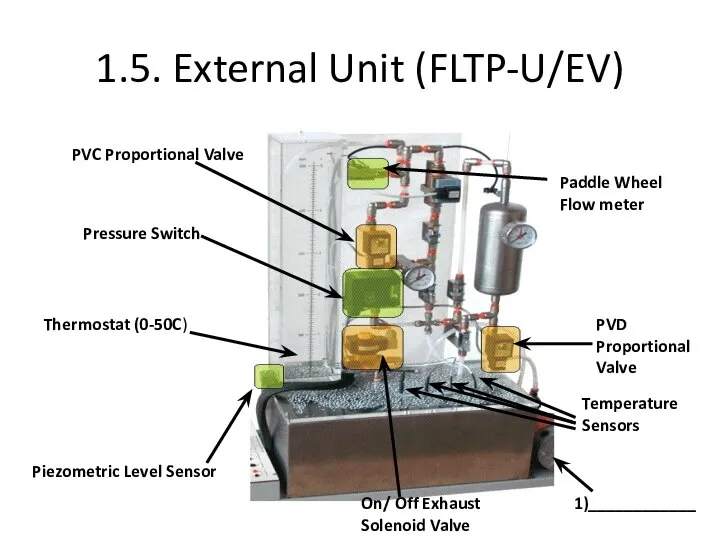

- 22. 1.5. External Unit (FLTP-U/EV) Piezometric Level Sensor

- 23. 1.5. External Unit (FLTP-U/EV) Thermostat (0-50C)

- 24. 1.5. External Unit (FLTP-U/EV) On/ Off Exhaust Solenoid Valve

- 25. 1.5. External Unit (FLTP-U/EV) Pressure Switch

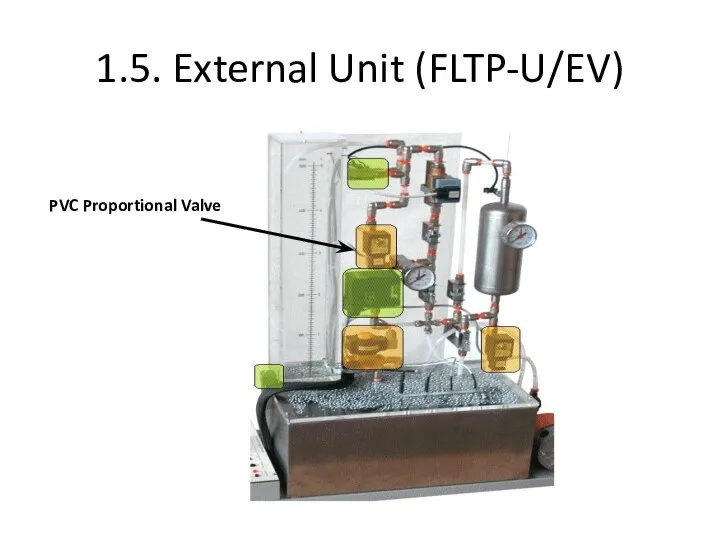

- 26. 1.5. External Unit (FLTP-U/EV) PVC Proportional Valve

- 27. 1.5. External Unit (FLTP-U/EV) Paddle Wheel Flow meter

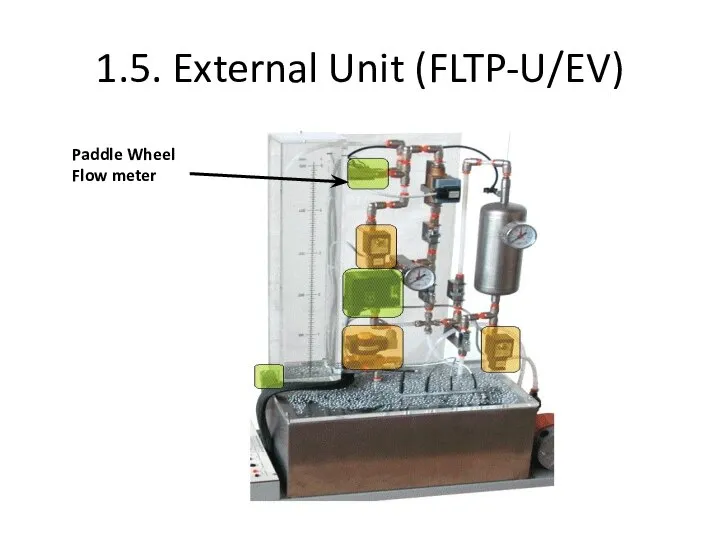

- 28. Paddle wheel flow measurement Has a magnet in one of the paddles Hall effect is represented

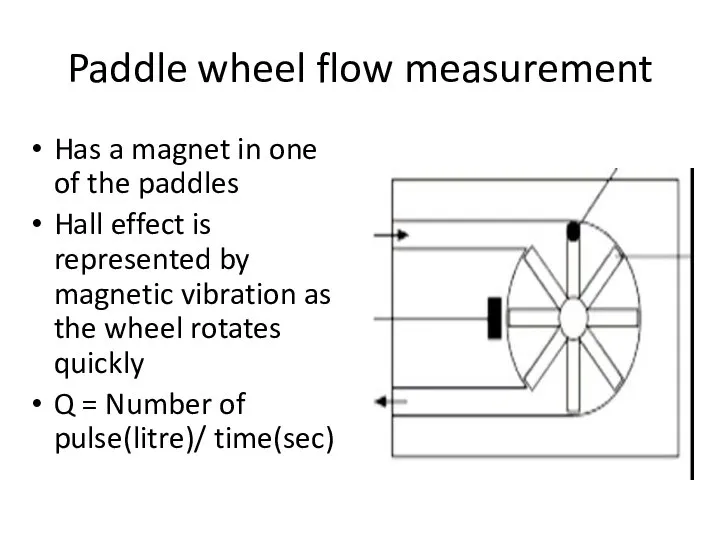

- 29. 1.5. External Unit (FLTP-U/EV) PVD Proportional Valve

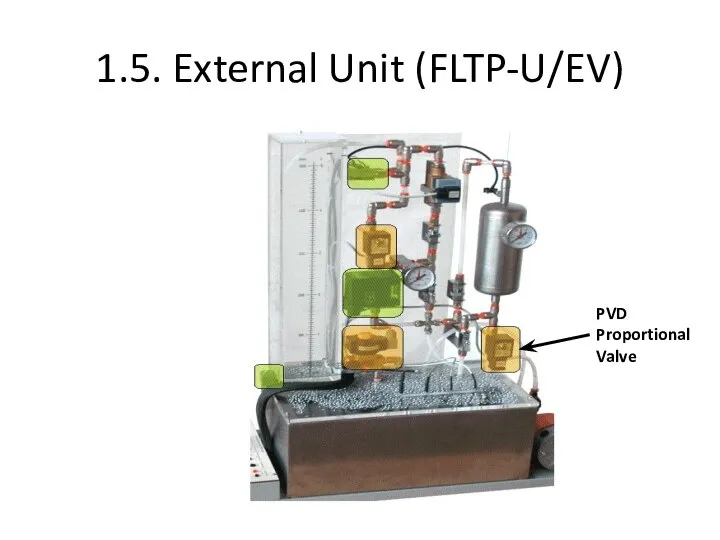

- 30. 1.5. External Unit (FLTP-U/EV) Temperature Sensors

- 31. 1.5. External Unit (FLTP-U/EV) PVC Proportional Valve PVD Proportional Valve Pressure Switch Thermostat (0-50C) Piezometric Level

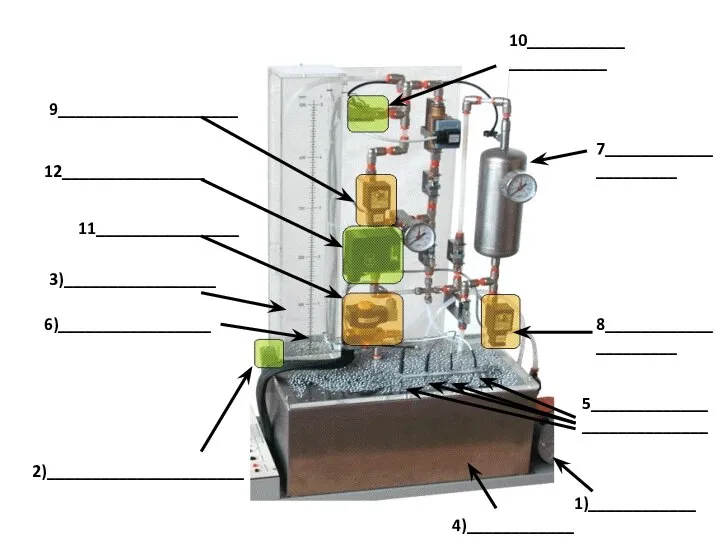

- 32. 9____________________ 8_____________________ 11________________ 6)_________________ 2)______________________ 5___________________________ 10______________________ 1)____________ 3)_________________ 4)____________ 7_____________________ 12________________

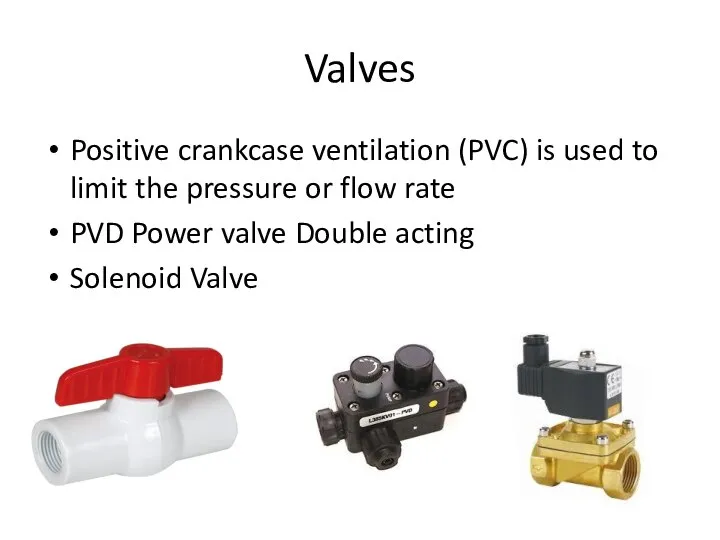

- 33. Valves Positive crankcase ventilation (PVC) is used to limit the pressure or flow rate PVD Power

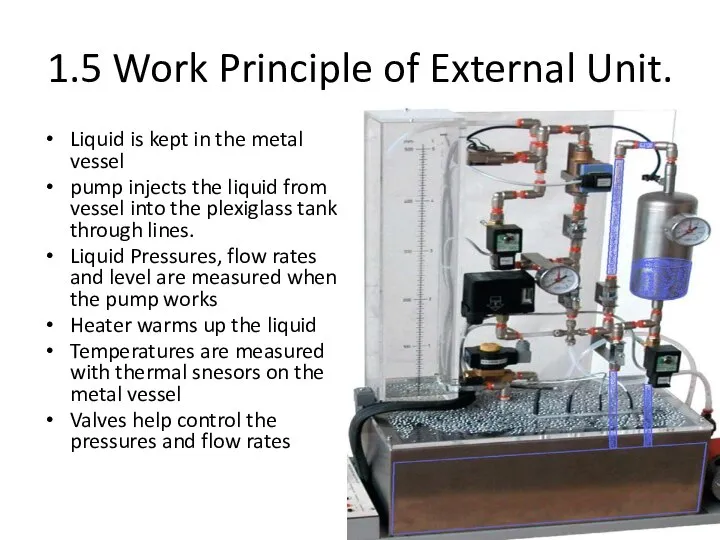

- 34. 1.5 Work Principle of External Unit. Liquid is kept in the metal vessel pump injects the

- 35. 2. Control Units PLC Trainer Industrial PID Control Card

- 36. 2.1 PLC Trainer (PLC-5A/EV) Учебная панель Has 16 digital inputs 14 digital outputs 4 Analog Inputs

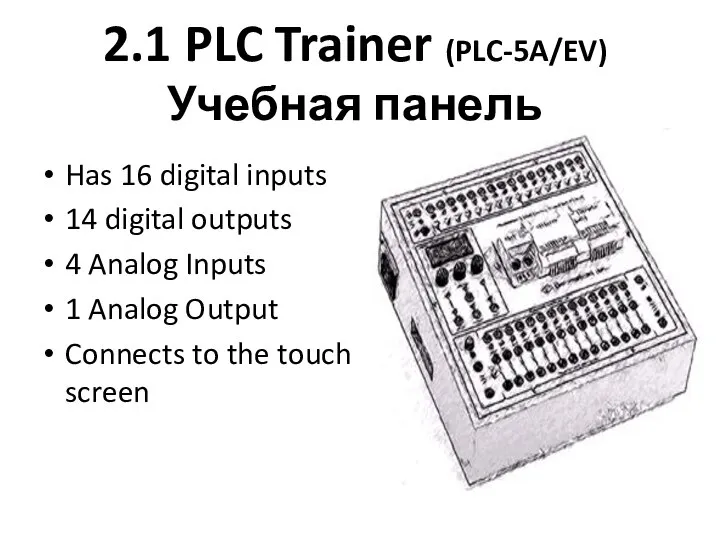

- 37. 2.2 PID Controller Has inputs Outputs

- 38. Control Card (MFI-U/EV) Has 8Digital Inputs; 8Digital Outputs 16 Analog inputs 2 Analog Outputs

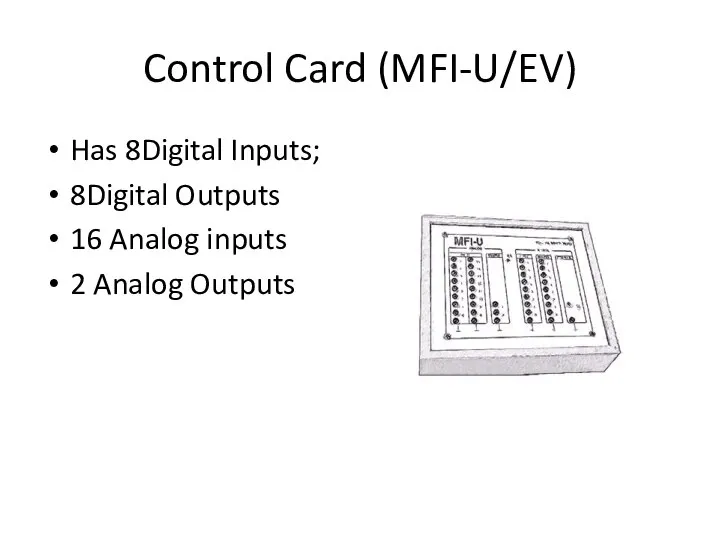

- 39. 3 Control Techniques PID Control Amplifier Heater Transducer Signal Conditioner Set-Point

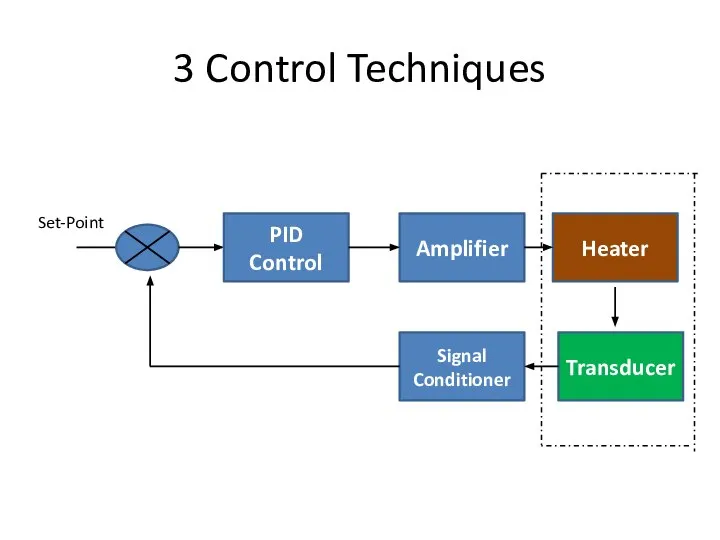

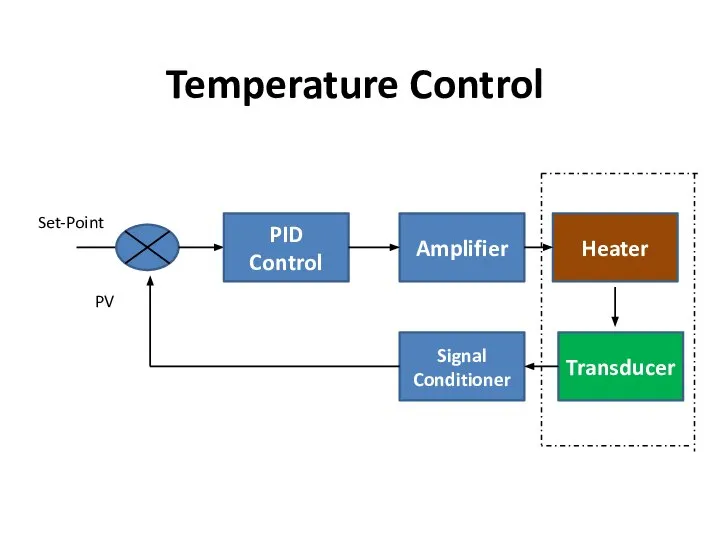

- 40. Question. Is it open loop or closed loop control? PID Control Amplifier Heater Transducer Signal Conditioner

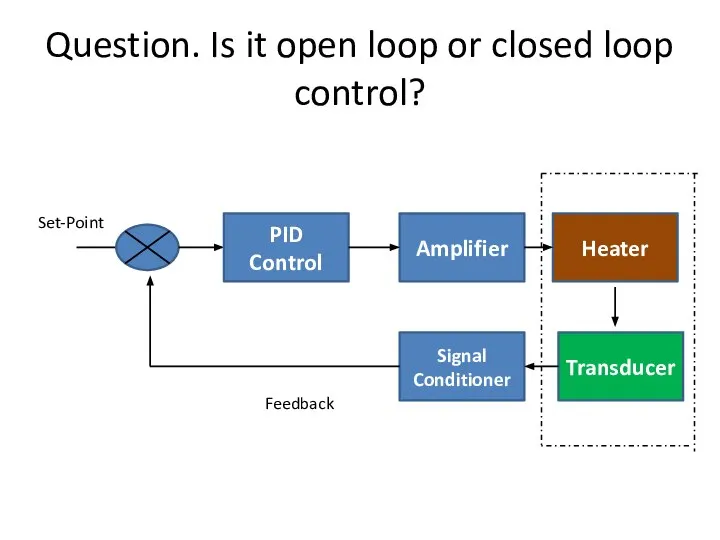

- 41. Answer: It is closed loop control because of PID Control and feedback PID Control Amplifier Heater

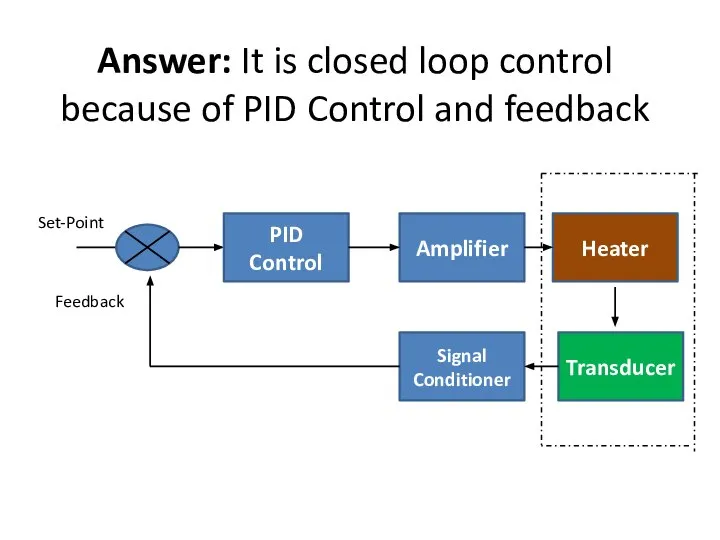

- 42. Open Loop Control Signal Conditioner

- 43. Question What are the transducers?

- 44. 3 Transducers Converter from physical variable to the electrical variable. Example: Pressure at 4 bars is

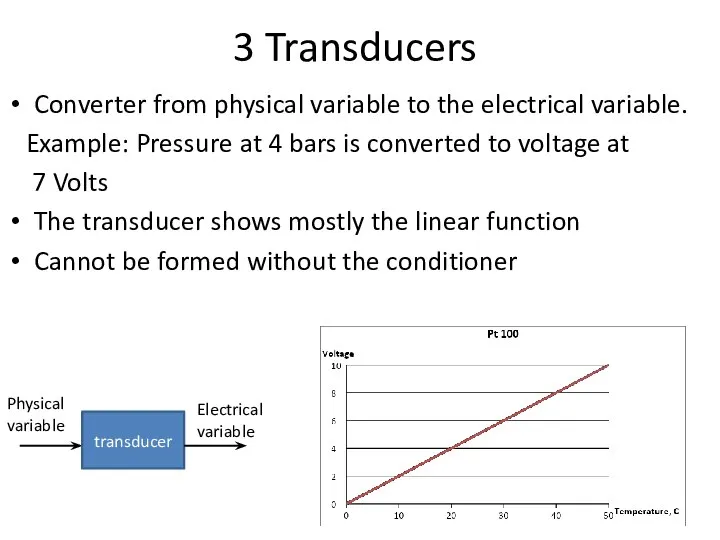

- 45. Question What is the Conditioner?

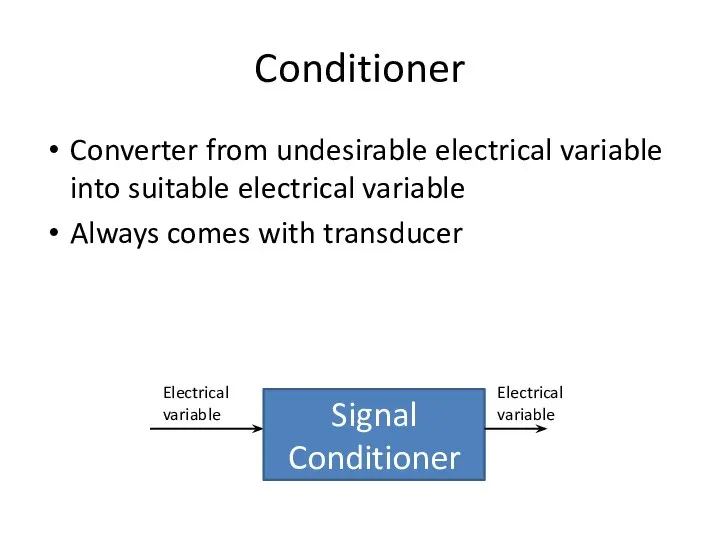

- 46. Conditioner Converter from undesirable electrical variable into suitable electrical variable Always comes with transducer Signal Conditioner

- 47. Temperature Control PID Control Amplifier Heater Transducer Signal Conditioner Set-Point PV

- 48. Pressure Control PID Control Amplifier Pump Transducer Signal Conditioner Set-Point PV

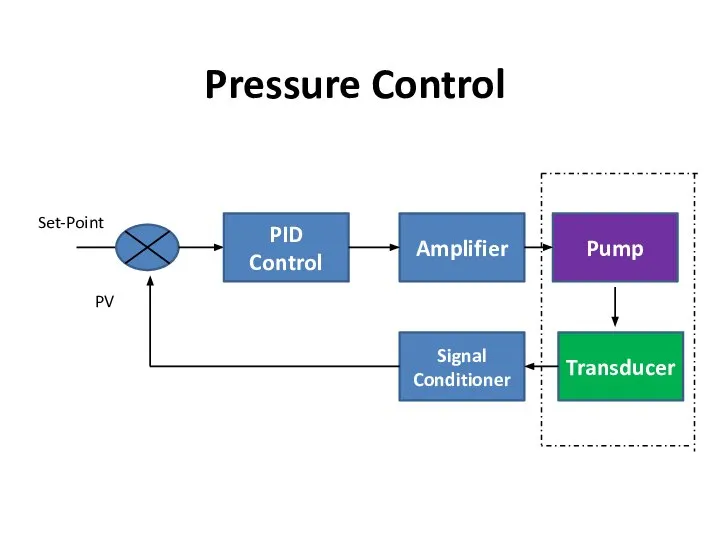

- 50. Скачать презентацию

день мира

день мира Sara Sewastianik- instalacja wodociągowa- poprawiona

Sara Sewastianik- instalacja wodociągowa- poprawiona Система управления регионами. (Тема 4)

Система управления регионами. (Тема 4) Пиелонефрит укр

Пиелонефрит укр Орындаған: Құмарбекова Н.Е Қабылдаған: Қожекенова Ж.А. Топ: 10-011-02қ Факультет: жалпы медицина

Орындаған: Құмарбекова Н.Е Қабылдаған: Қожекенова Ж.А. Топ: 10-011-02қ Факультет: жалпы медицина Уголовно-правовые аспекты противодействия незаконному перемещению через границу объектов дикой флоры и фауны Курамшина Ольга

Уголовно-правовые аспекты противодействия незаконному перемещению через границу объектов дикой флоры и фауны Курамшина Ольга  Формулировка диагноза при черепно-мозговой травме Состоит из двух частей

Формулировка диагноза при черепно-мозговой травме Состоит из двух частей  Презентация "Французский классицизм XVII века" - скачать презентации по МХК

Презентация "Французский классицизм XVII века" - скачать презентации по МХК My idol - Pavel Datsyuk

My idol - Pavel Datsyuk Соединения с натягом

Соединения с натягом Фразеологизмы из Библии

Фразеологизмы из Библии УЧЕНИЧЕСКОЕ САМОУПРАВЛЕНИЕ МОУ НИЖНЕПОДКУМСКОЙ СОШ №24 ГОРОДА ПЯТИГОРСКА Совет старост

УЧЕНИЧЕСКОЕ САМОУПРАВЛЕНИЕ МОУ НИЖНЕПОДКУМСКОЙ СОШ №24 ГОРОДА ПЯТИГОРСКА Совет старост HTML құжатында кестелерді қалыптастыру. Кесте параметрлерін тағайындау тегтері

HTML құжатында кестелерді қалыптастыру. Кесте параметрлерін тағайындау тегтері Технические средства радиосвязи. Для различных должностных категорий обучающихся

Технические средства радиосвязи. Для различных должностных категорий обучающихся Быт XIV-XV веков

Быт XIV-XV веков Оценка эффективности ажиотажного маркетинга в социальных медиа Агентство веб-коммуникаций ErstMedia. - презентация

Оценка эффективности ажиотажного маркетинга в социальных медиа Агентство веб-коммуникаций ErstMedia. - презентация В третий месяц по выходу из Египта израильтяне подошли к горе Синай, где Моисей получил от Бога Скрижали Завета с десятью заповедям

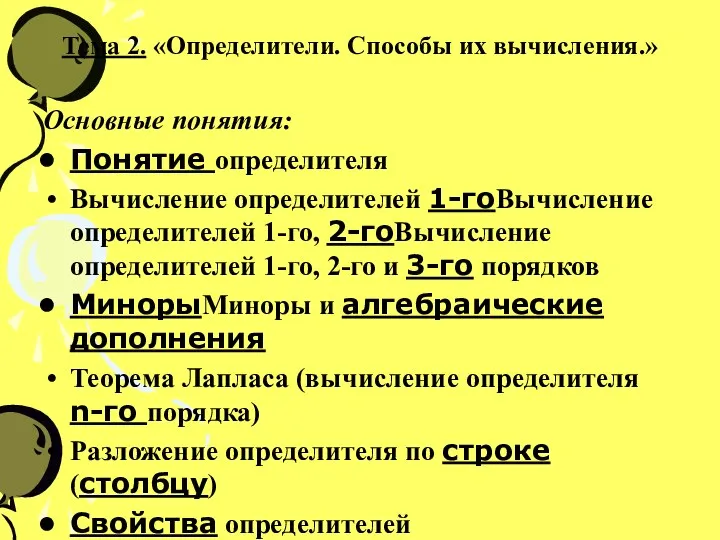

В третий месяц по выходу из Египта израильтяне подошли к горе Синай, где Моисей получил от Бога Скрижали Завета с десятью заповедям Определители и способы их вычисления

Определители и способы их вычисления  Сущность менеджмента продаж, понятие и функции. Ершова Ирина, Грабер Оля

Сущность менеджмента продаж, понятие и функции. Ершова Ирина, Грабер Оля Remotely Controlling Devices

Remotely Controlling Devices Использование ИКТ на уроках истории и обществознания при подготовке к ЕГЭ Подготовила: учитель истории и обществознания МОУСОШ 34

Использование ИКТ на уроках истории и обществознания при подготовке к ЕГЭ Подготовила: учитель истории и обществознания МОУСОШ 34 Презентация Краткий конспект лекции по микроэкономике с использованием статистических баз официальных сайтов

Презентация Краткий конспект лекции по микроэкономике с использованием статистических баз официальных сайтов  Архитектура барокко

Архитектура барокко  Методы решения систем уравнений МОУ - СОШ №6 Учитель математики Миссюра Ирина Николаевна

Методы решения систем уравнений МОУ - СОШ №6 Учитель математики Миссюра Ирина Николаевна Горнолыжные курорты Южной Кореи

Горнолыжные курорты Южной Кореи . Многогранный угол

. Многогранный угол Парки и социальные проблемы начала XXI века

Парки и социальные проблемы начала XXI века Інтернет: розуміти більше, досягати більшого

Інтернет: розуміти більше, досягати більшого