Содержание

- 2. Текущее состояние The methodology of application has been fully developed. Methodological recommendations on application for medical

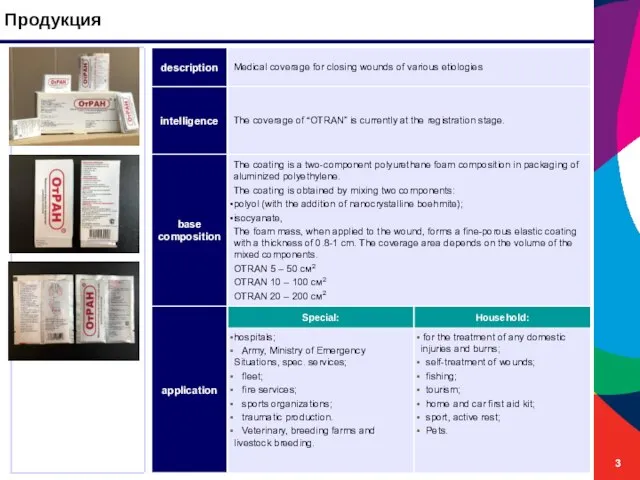

- 3. Продукция

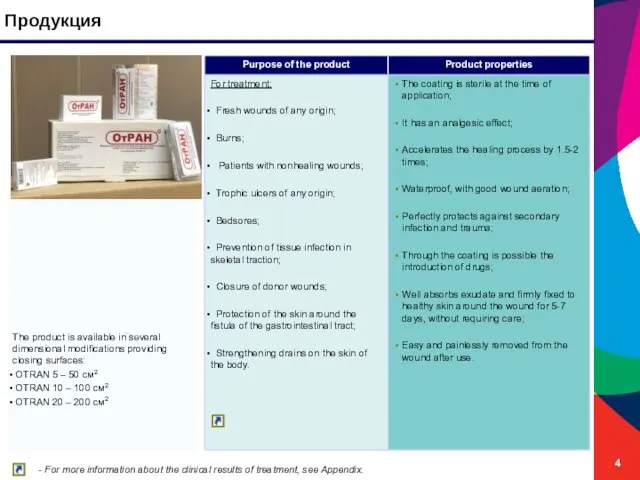

- 4. Продукция 10 см 15 см - For more information about the clinical results of treatment, see

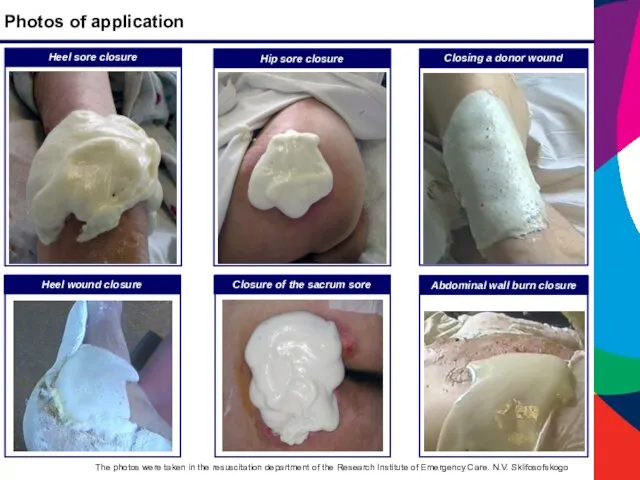

- 5. Photos of application Hip sore closure Heel wound closure Closing a donor wound Closure of the

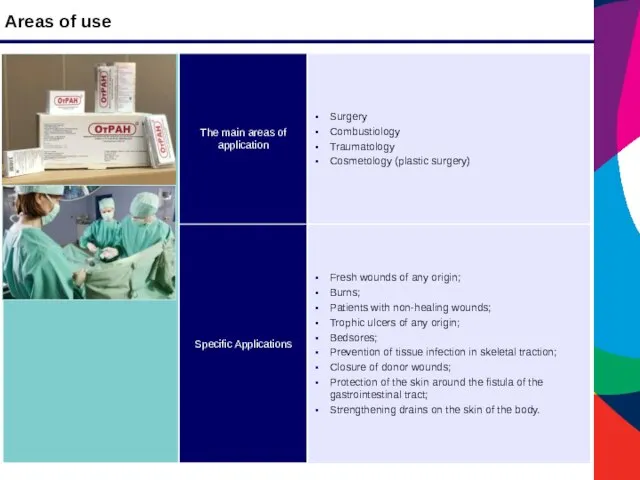

- 6. Areas of use стр.

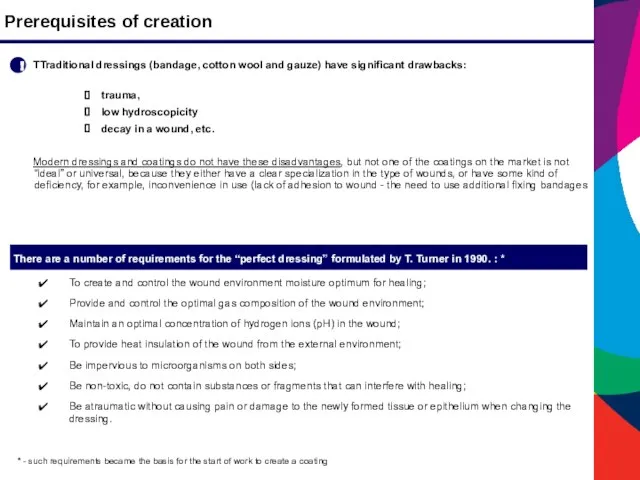

- 7. Prerequisites of creation ТTraditional dressings (bandage, cotton wool and gauze) have significant drawbacks: trauma, low hydroscopicity

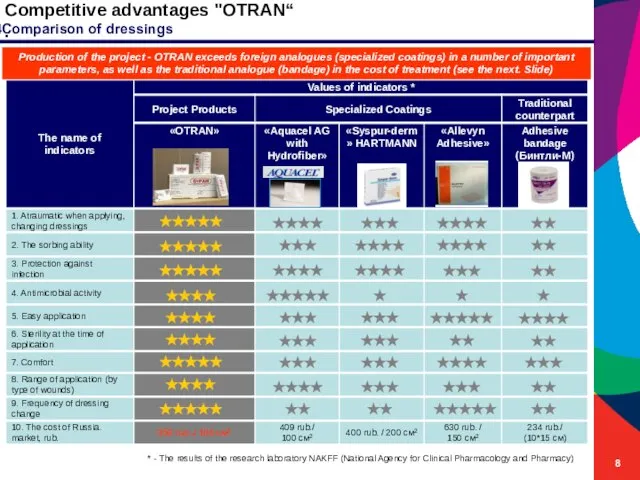

- 8. Competitive advantages "OTRAN“ . Production of the project - OTRAN exceeds foreign analogues (specialized coatings) in

- 9. Competitive advantages The high costs of OTRAN coverage are compensated by lower costs for the salaries

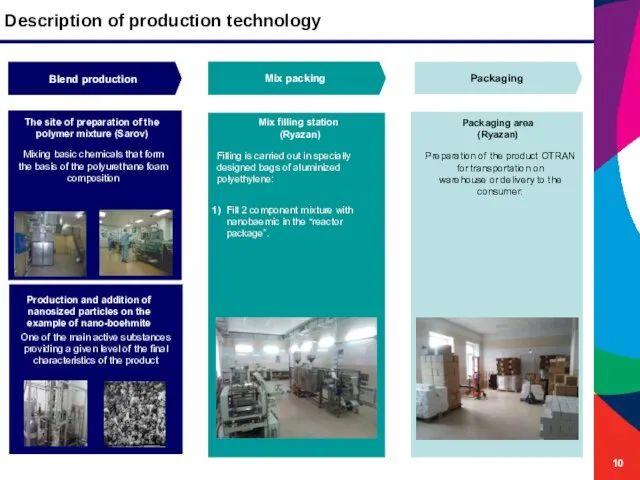

- 10. Description of production technology Packaging Mix packing Blend production The site of preparation of the polymer

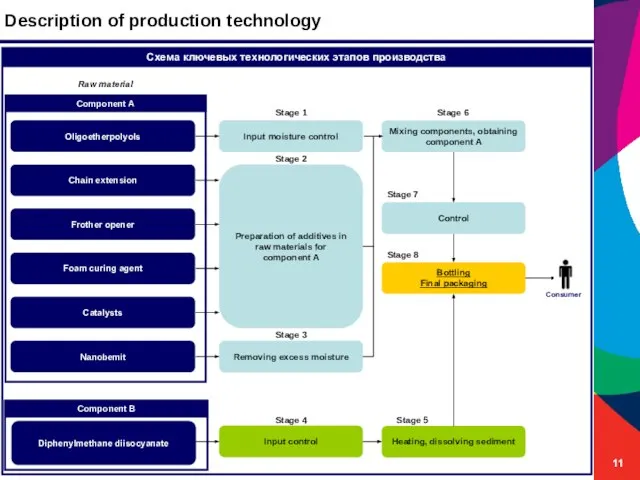

- 11. Description of production technology Oligoetherpolyols Component A Component B Diphenylmethane diisocyanate Chain extension Frother opener Foam

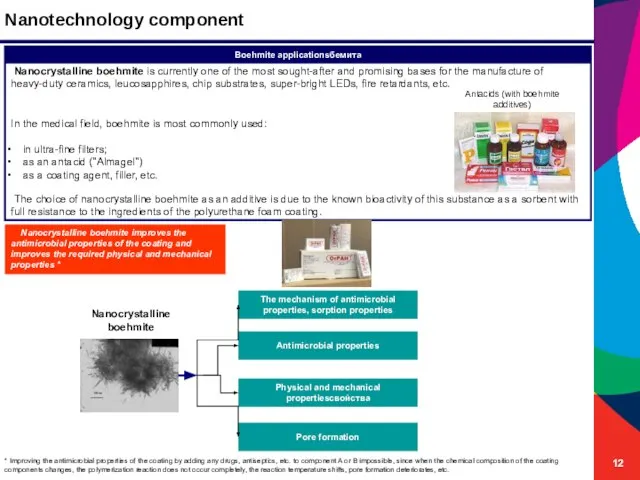

- 12. Nanotechnology component Boehmite applicationsбемита Nanocrystalline boehmite In the medical field, boehmite is most commonly used: in

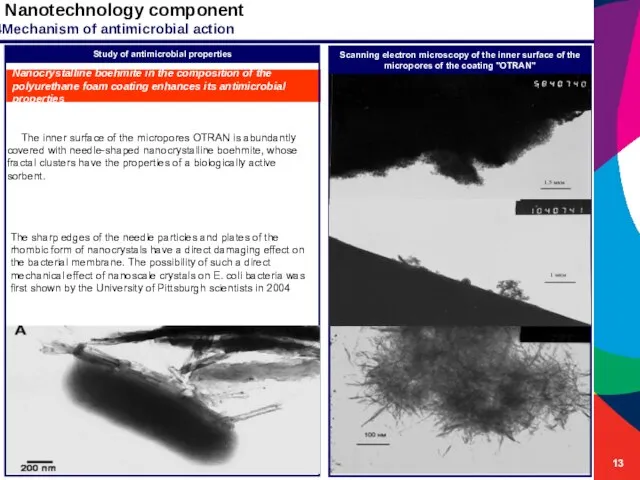

- 13. Nanotechnology component Scanning electron microscopy of the inner surface of the micropores of the coating "OTRAN"

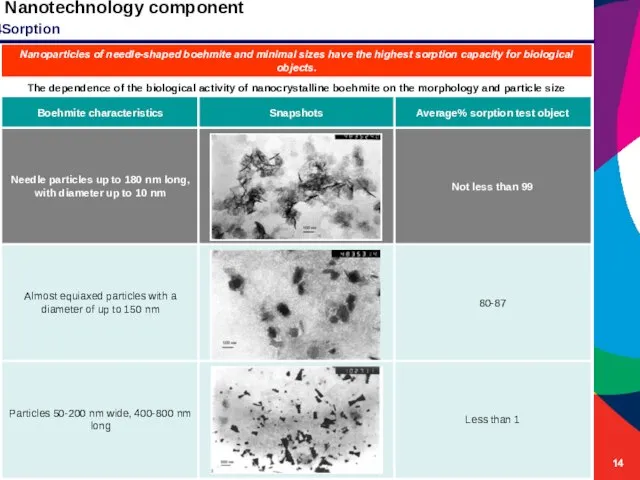

- 14. Nanotechnology component Nanoparticles of needle-shaped boehmite and minimal sizes have the highest sorption capacity for biological

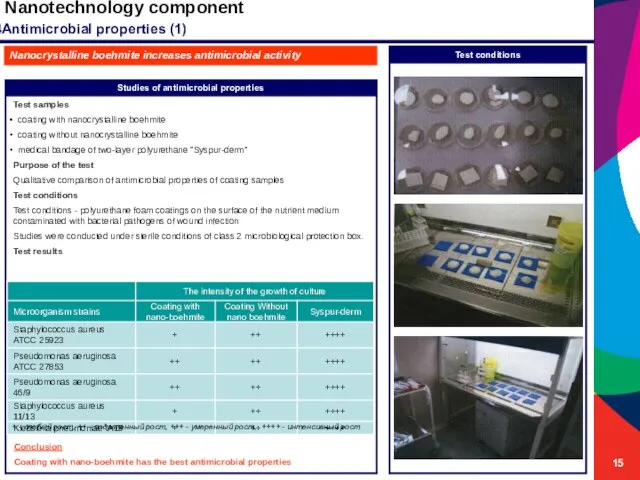

- 15. Nanotechnology component Studies of antimicrobial properties Nanocrystalline boehmite increases antimicrobial activity Test conditions Test samples coating

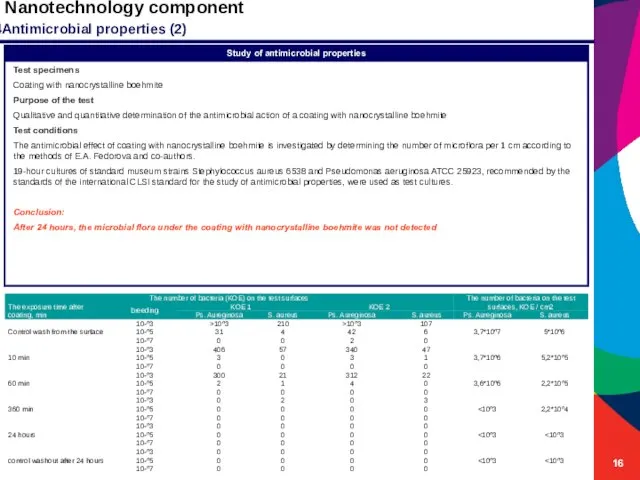

- 16. Nanotechnology component Study of antimicrobial properties Test specimens Coating with nanocrystalline boehmite Purpose of the test

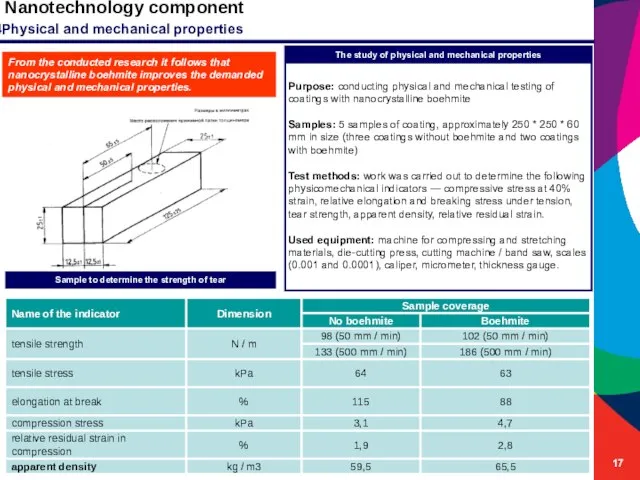

- 17. Nanotechnology component From the conducted research it follows that nanocrystalline boehmite improves the demanded physical and

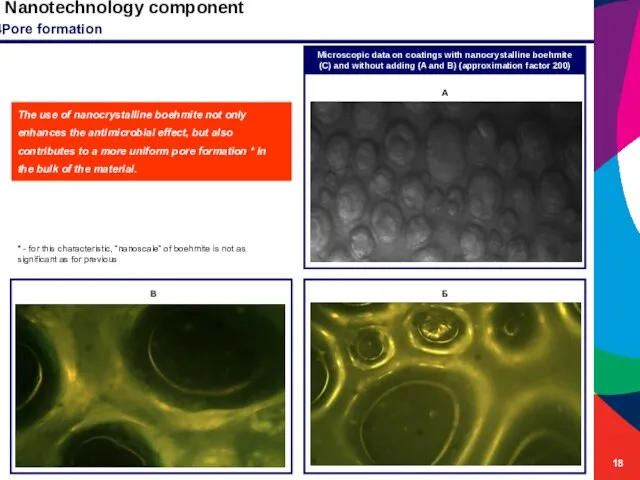

- 18. Nanotechnology component The use of nanocrystalline boehmite not only enhances the antimicrobial effect, but also contributes

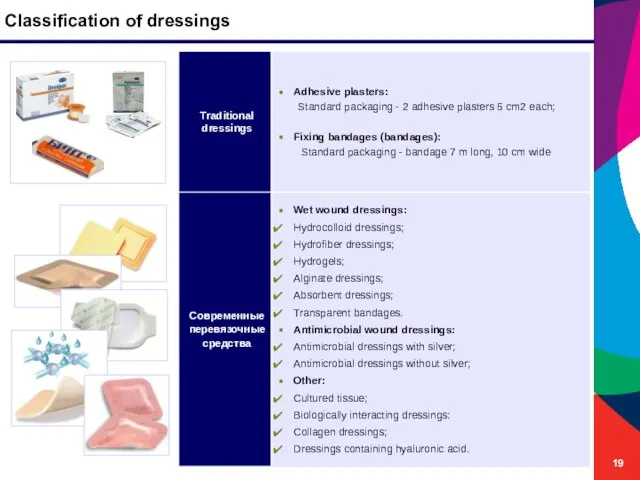

- 19. Classification of dressings

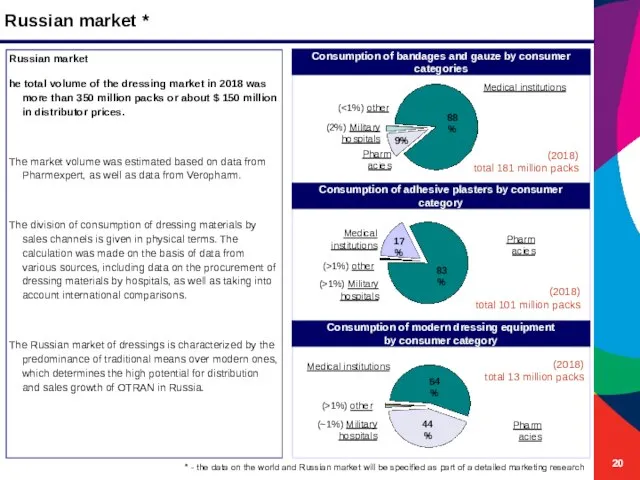

- 20. Russian market * Russian market he total volume of the dressing market in 2018 was more

- 21. Certification

- 22. Patents

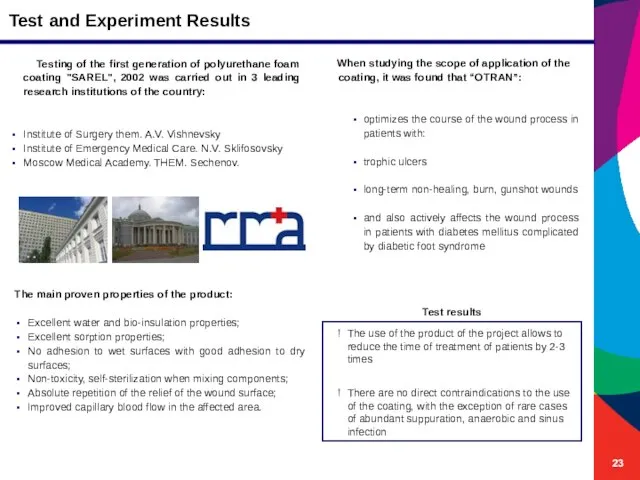

- 23. Test and Experiment Results Testing of the first generation of polyurethane foam coating "SAREL", 2002 was

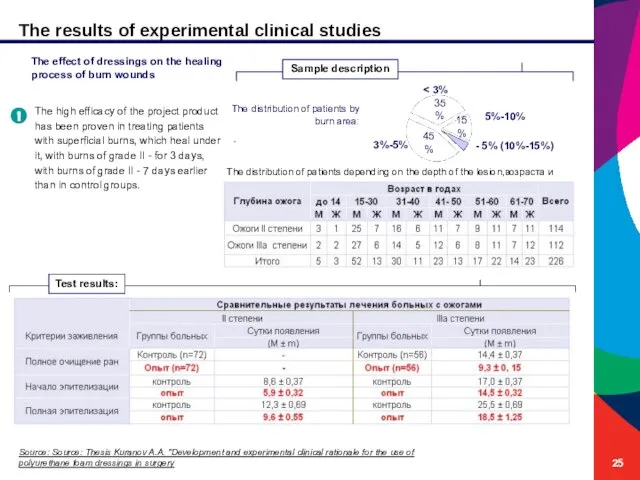

- 24. The results of experimental clinical studies 1 The main findings of the research: The influence of

- 25. The distribution of patients depending on the depth of the lesion,возраста и пола: The distribution of

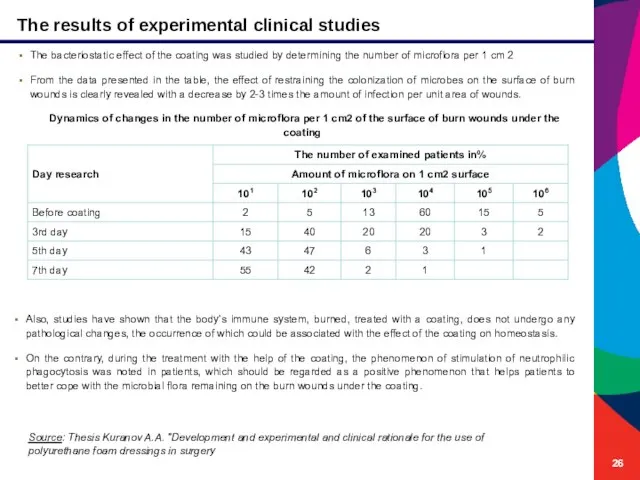

- 26. The bacteriostatic effect of the coating was studied by determining the number of microflora per 1

- 27. Hydrocolloid dressings

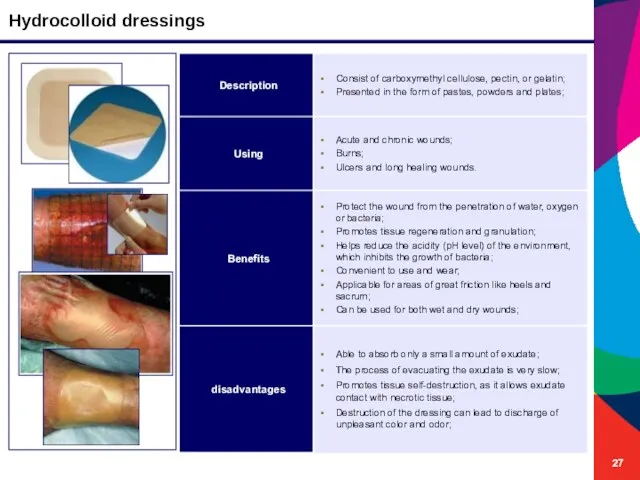

- 28. Hydrofibre Handwraps

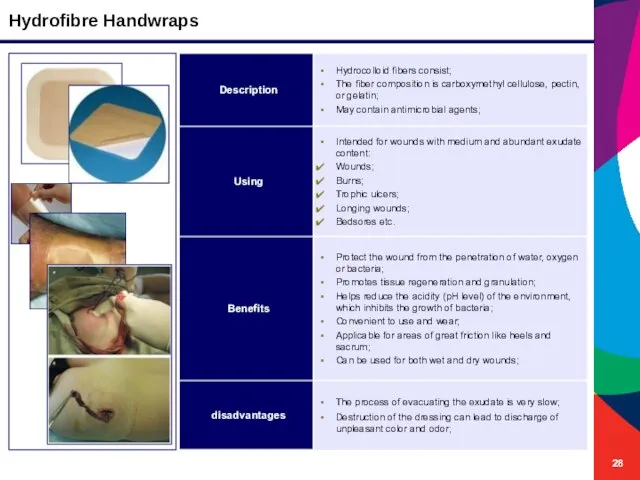

- 29. Hydrogel dressings

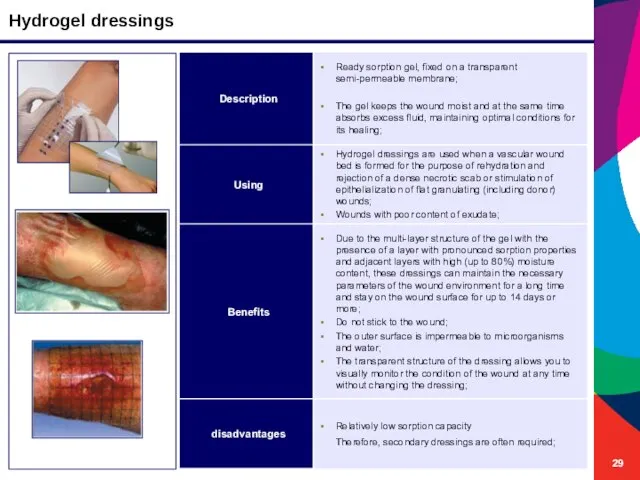

- 30. Alginate dressings

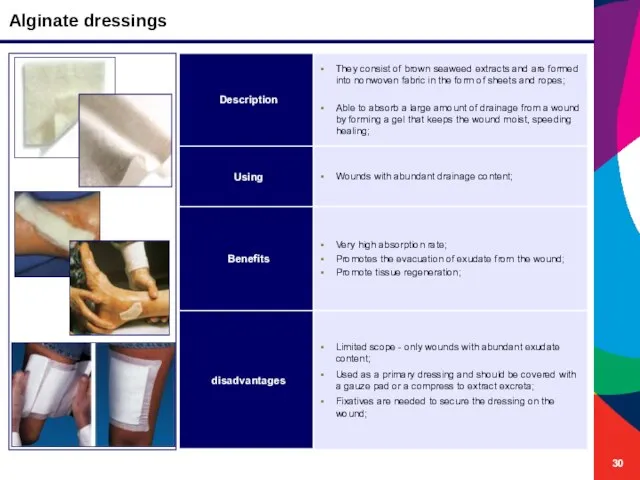

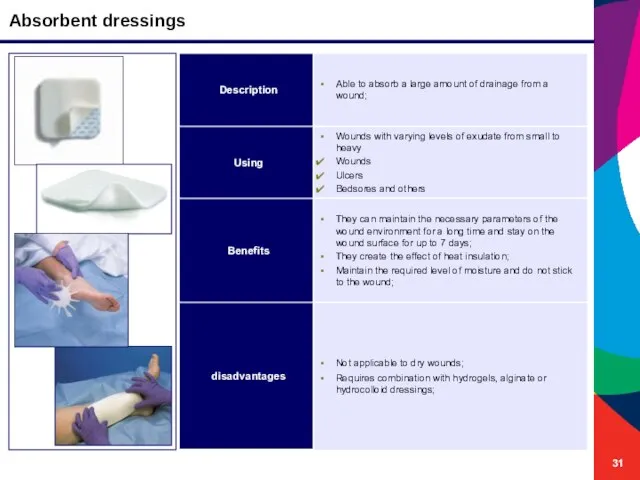

- 31. Absorbent dressings

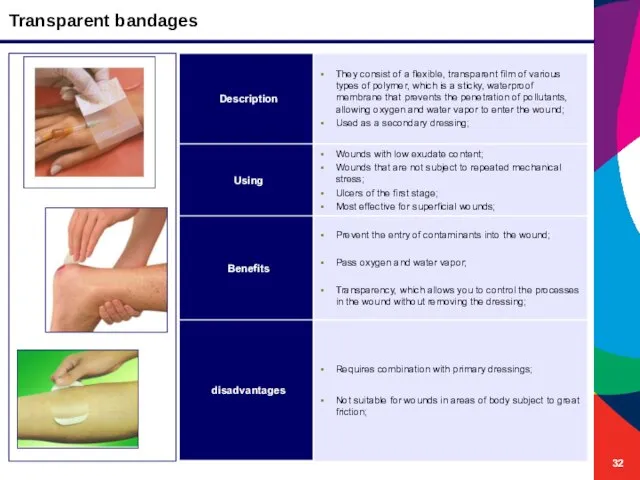

- 32. Transparent bandages

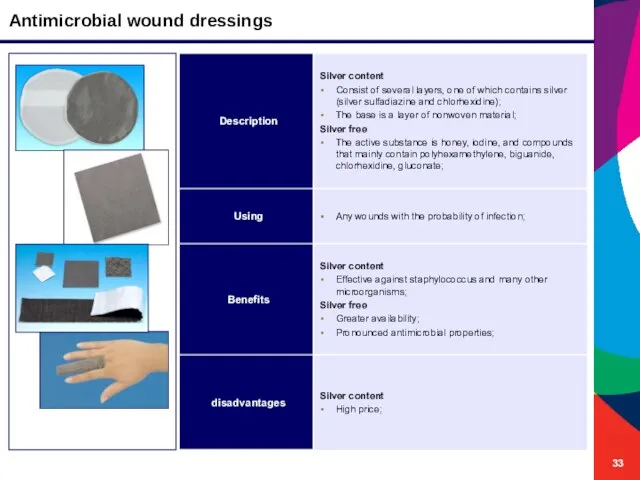

- 33. Antimicrobial wound dressings

- 34. Other dressings

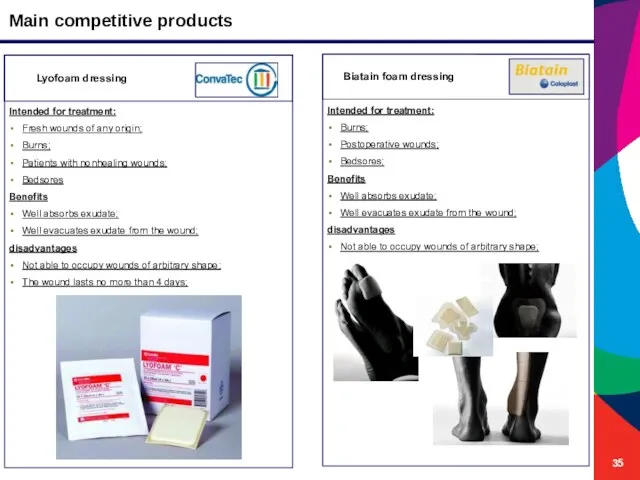

- 35. Main competitive products Intended for treatment: Fresh wounds of any origin; Burns; Patients with nonhealing wounds;

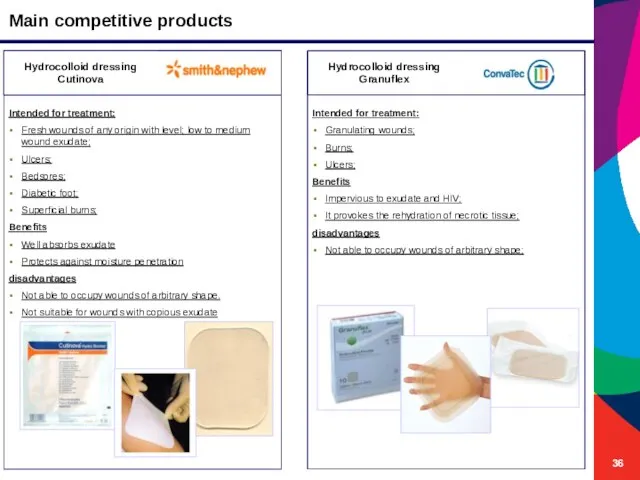

- 36. Main competitive products Intended for treatment: Fresh wounds of any origin with level; low to medium

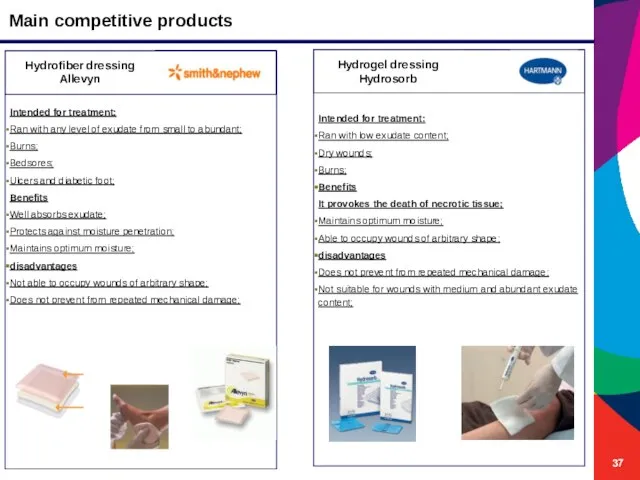

- 37. Main competitive products Intended for treatment: Ran with any level of exudate from small to abundant;

- 38. Intended for treatment: Wounds with any exudate content; II degree burns; Skin lesions; Benefits Protects against

- 40. Скачать презентацию

תזונה נכונה

תזונה נכונה Антибактериальные химиотерапевтические средства. Введение

Антибактериальные химиотерапевтические средства. Введение Человек-гаджет

Человек-гаджет Физиология почек и основные нефрологические синдромы

Физиология почек и основные нефрологические синдромы Группы здоровья детей

Группы здоровья детей Парциальды құрысуы бар науқастарда құрысуды алдын алу және жиілігін төмендетуде карбамазепинге

Парциальды құрысуы бар науқастарда құрысуды алдын алу және жиілігін төмендетуде карбамазепинге Приобретенные коагулопатии

Приобретенные коагулопатии Вскармливание недоношенных детей

Вскармливание недоношенных детей Электрокардиографические методы диагностики поражения сердца при тиреоидной патологии

Электрокардиографические методы диагностики поражения сердца при тиреоидной патологии Тіл аурулары мен аномалиялары. Глоссалгия

Тіл аурулары мен аномалиялары. Глоссалгия Внимание и внимательность детей

Внимание и внимательность детей Типы эпидемиологических исследований

Типы эпидемиологических исследований Нейроонтогенез и дизонтогенез

Нейроонтогенез и дизонтогенез Иридоиды. Классификация

Иридоиды. Классификация Фізіологічні аспекти рухової активності людини

Фізіологічні аспекти рухової активності людини Менструальді цикл

Менструальді цикл Морфогенез рака кишки

Морфогенез рака кишки СПИД и его профилактика

СПИД и его профилактика Особенности структуры и метаболизма тканей зуба

Особенности структуры и метаболизма тканей зуба Рандомизированное исследование 6 и 12 часового введения мизопростола для прерывания беременности во втором триместре

Рандомизированное исследование 6 и 12 часового введения мизопростола для прерывания беременности во втором триместре 7 признаков эмоциональной зрелости по Фрейду

7 признаков эмоциональной зрелости по Фрейду Наследственные заболевания человека

Наследственные заболевания человека Трофобластическая болезнь

Трофобластическая болезнь Конструктивное решение конфликтов в молодежной среде

Конструктивное решение конфликтов в молодежной среде Грудное вскармливание

Грудное вскармливание Правовое обеспечение профессиональной деятельности

Правовое обеспечение профессиональной деятельности Хроническая болезнь почек (ХБП)

Хроническая болезнь почек (ХБП) Какие питательные вещества всасываются в разных отделах ЖКТ при кормлении через стому

Какие питательные вещества всасываются в разных отделах ЖКТ при кормлении через стому