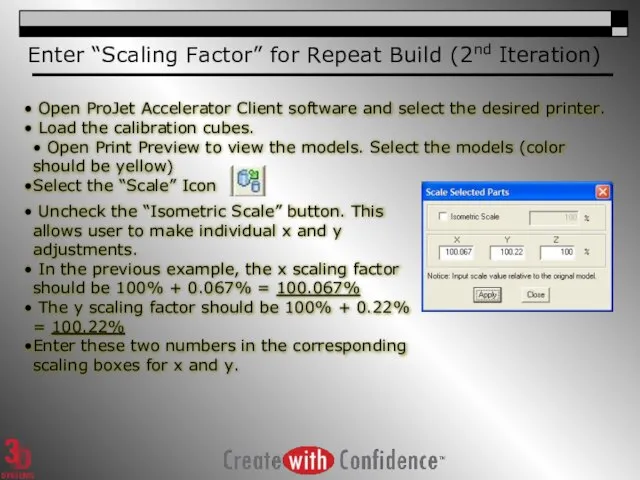

Enter “Scaling Factor” for Repeat Build (2nd Iteration)

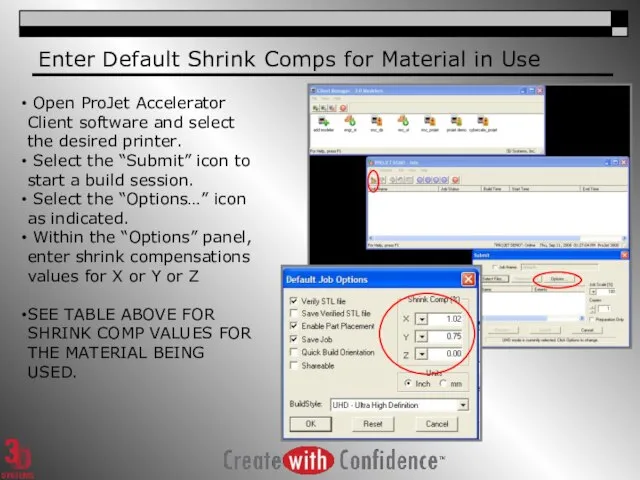

Open ProJet Accelerator

Client software and select the desired printer.

Load the calibration cubes.

• Open Print Preview to view the models. Select the models (color should be yellow)

Select the “Scale” Icon

Uncheck the “Isometric Scale” button. This allows user to make individual x and y adjustments.

In the previous example, the x scaling factor should be 100% + 0.067% = 100.067%

The y scaling factor should be 100% + 0.22% = 100.22%

Enter these two numbers in the corresponding scaling boxes for x and y.

Программное обеспечение компьютера

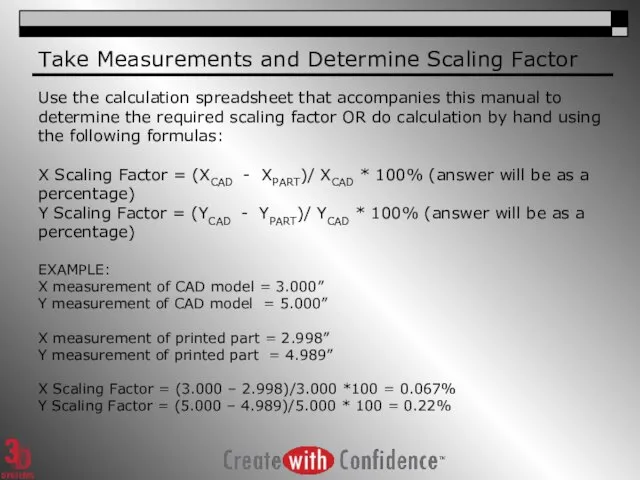

Программное обеспечение компьютера Композиция. Правила и приемы

Композиция. Правила и приемы Желілік операциялық жүйелер

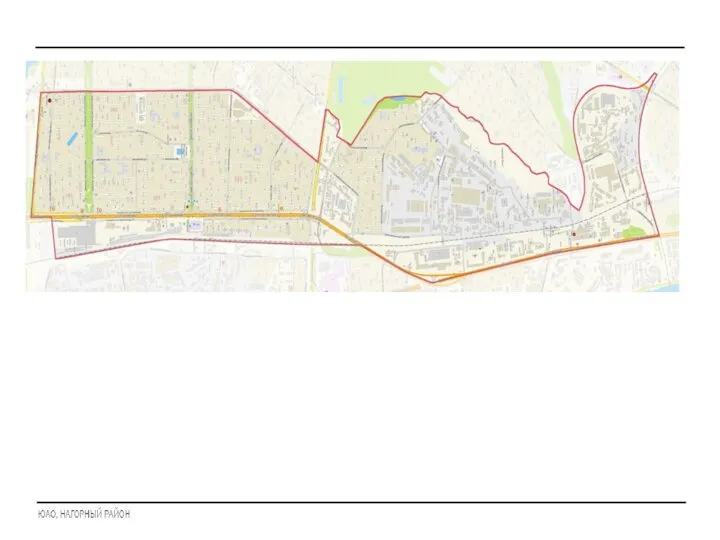

Желілік операциялық жүйелер Схема маршрута метро

Схема маршрута метро Сервис онлайн голосования собственников МКД №С1-53417

Сервис онлайн голосования собственников МКД №С1-53417 Проектирование и реализация сети, настройка на маршрутизаторе службы DHCP в программе Cisco Packet Tracer

Проектирование и реализация сети, настройка на маршрутизаторе службы DHCP в программе Cisco Packet Tracer Средства информационных и коммуникационных технологий. Логические функции и схемы – основа элементной базы компьютера

Средства информационных и коммуникационных технологий. Логические функции и схемы – основа элементной базы компьютера ЭВМ и периферийные устройства. Память вычислительных машин. (Лекция 4)

ЭВМ и периферийные устройства. Память вычислительных машин. (Лекция 4) Виды и характеристики памяти. Дисциплина Структура компьютерных средств. Тема №4. Занятие №1/1

Виды и характеристики памяти. Дисциплина Структура компьютерных средств. Тема №4. Занятие №1/1 3 класс

3 класс  Нормальные формы баз данных

Нормальные формы баз данных Алгоритмы и способы их описания

Алгоритмы и способы их описания Основні поняття комп'ютерної графіки

Основні поняття комп'ютерної графіки Подсистема оптических приводов

Подсистема оптических приводов Анализ бизнес информации – основные принципы

Анализ бизнес информации – основные принципы Характеристика электронных картографических систем

Характеристика электронных картографических систем Приветствую Вас на курсе Java!

Приветствую Вас на курсе Java! Разбор заданий первой части. Информатика. ОГЭ-2016

Разбор заданий первой части. Информатика. ОГЭ-2016 Дни валидации. Практика квалификации оборудования компьютеризированной системы

Дни валидации. Практика квалификации оборудования компьютеризированной системы מהי לוגיקה

מהי לוגיקה Презентация "Руководство пользователя программы "Microsoft Word"" - скачать презентации по Информатике

Презентация "Руководство пользователя программы "Microsoft Word"" - скачать презентации по Информатике Презентация "Информационный калейдоскоп" - скачать презентации по Информатике

Презентация "Информационный калейдоскоп" - скачать презентации по Информатике Файлдық жүйелер мен ДҚБЖ арасындағы негізгі айырмашылық

Файлдық жүйелер мен ДҚБЖ арасындағы негізгі айырмашылық Модернизация ИТ-инфраструктуры с помощью Windows Server 2016 (совместно с Veeam Software)

Модернизация ИТ-инфраструктуры с помощью Windows Server 2016 (совместно с Veeam Software) Программирование сервера баз данных

Программирование сервера баз данных Что такое языки программирования и как их можно применить

Что такое языки программирования и как их можно применить Алгоритмы, структуры алгоритмов, структурное программирование

Алгоритмы, структуры алгоритмов, структурное программирование Киберпреступность и кибертерроризм определение понятия «киберпреступность»; определение понятия «кибертерроризм»; способы, с

Киберпреступность и кибертерроризм определение понятия «киберпреступность»; определение понятия «кибертерроризм»; способы, с