Содержание

- 2. OBJECTIVE By the end of this course you will have completed the following Modules to an

- 3. Basic Xerography

- 4. Course Objective The Xerographic Process Charging Photoreceptors Charging Devices Exposing Development Transfer Fusing Cleaning Questions &

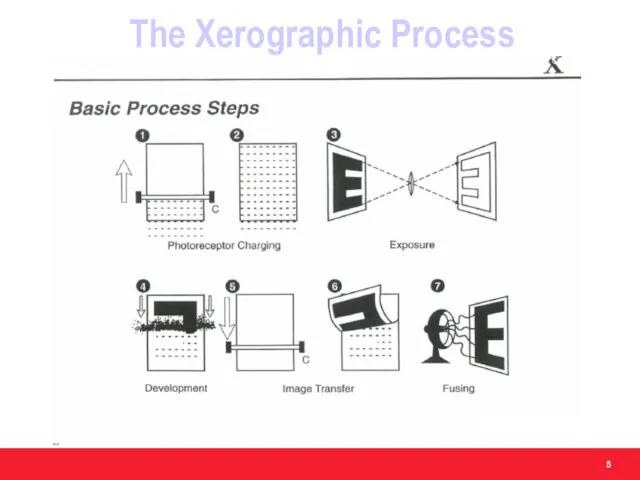

- 5. The Xerographic Process

- 6. Charging Preparing the photoreceptor for accepting the image

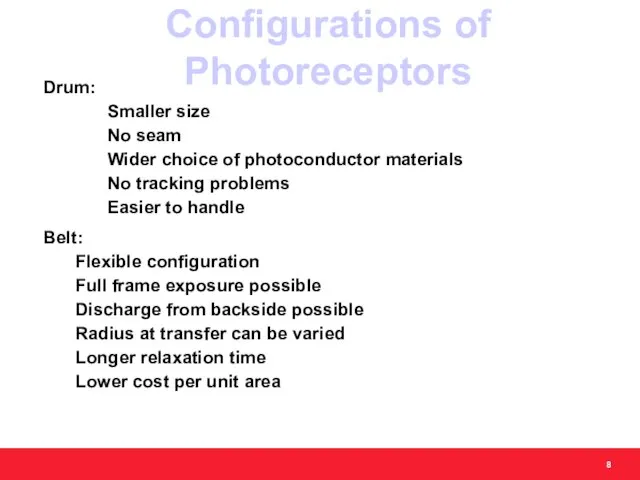

- 8. Configurations of Photoreceptors Drum: Smaller size No seam Wider choice of photoconductor materials No tracking problems

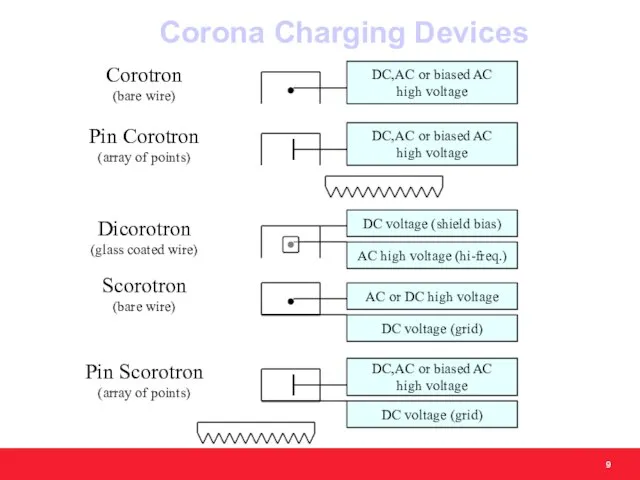

- 9. Corona Charging Devices

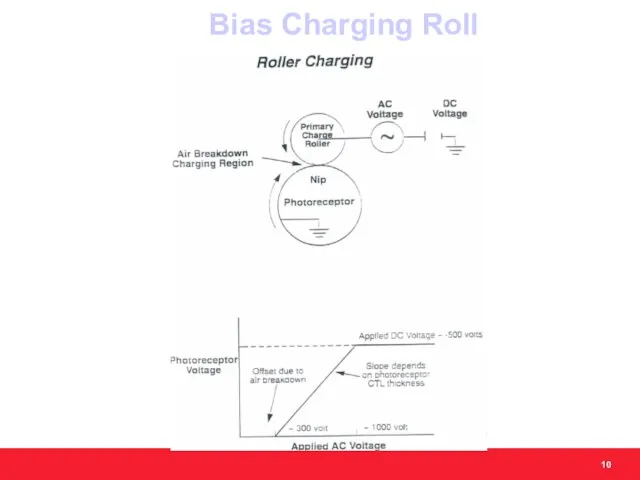

- 10. Bias Charging Roll

- 11. Bias Charging Roll – Pros & cons Advantages: Size Low Ozone emissions Lower power requirements Disadvantages:

- 12. Exposing Capturing the latent image on the photoreceptor

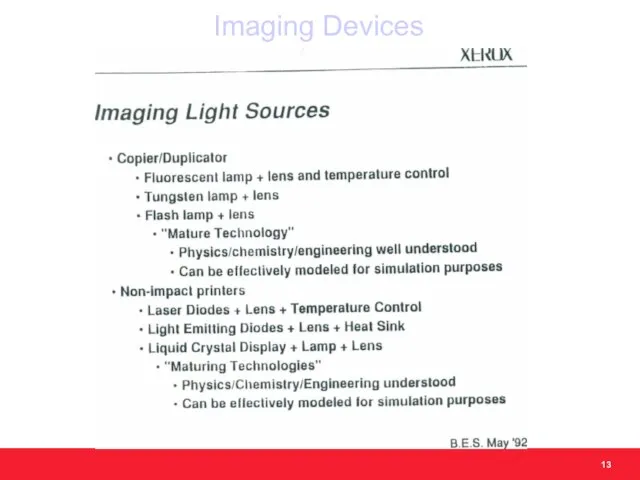

- 13. Imaging Devices

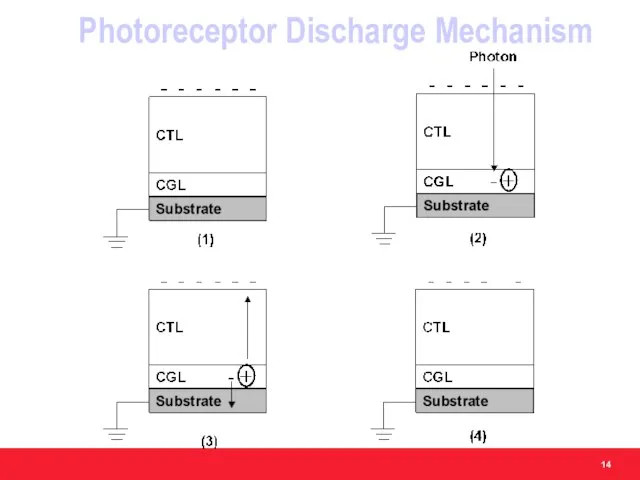

- 14. Photoreceptor Discharge Mechanism

- 15. Development Toning the latent image

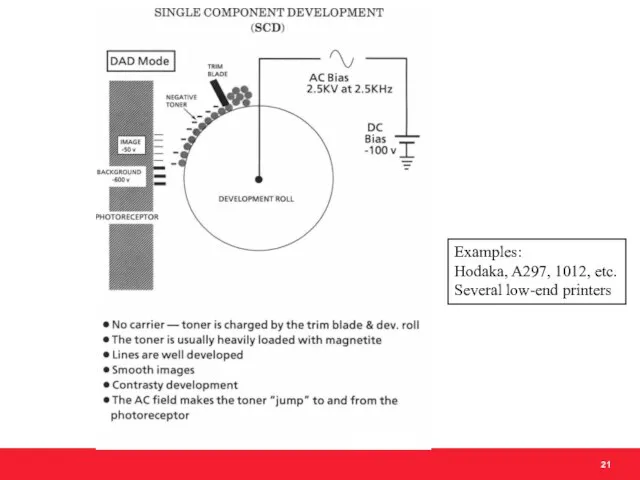

- 16. Development Two Main Schemes: Single Component Development (SCD) Toner only Two Component Development (TCD) Developer (Toner

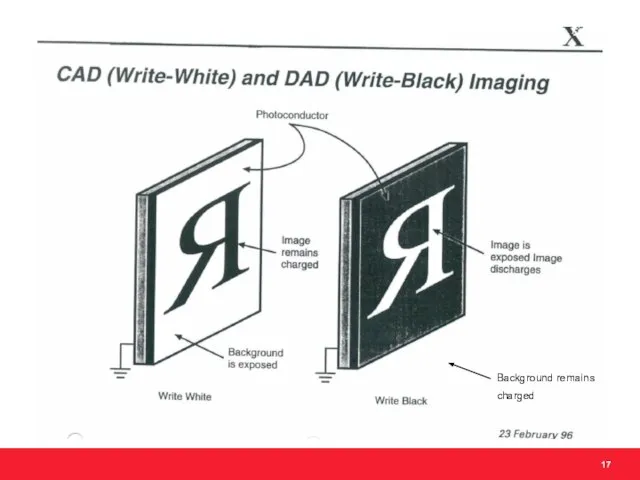

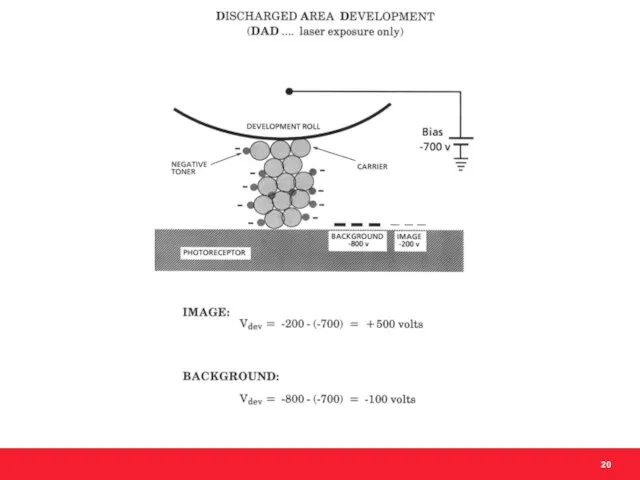

- 17. Background remains charged

- 19. Why DAD? Only the area that needs to be developed is exposed and discharged Lower exposure

- 21. Examples: Hodaka, A297, 1012, etc. Several low-end printers

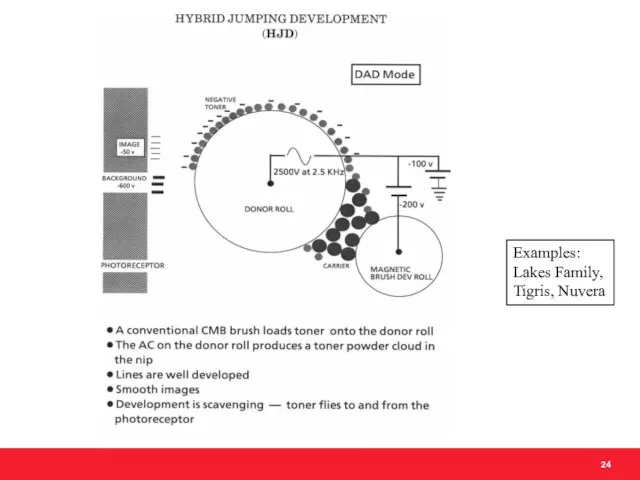

- 22. Common Two Component Development Techniques

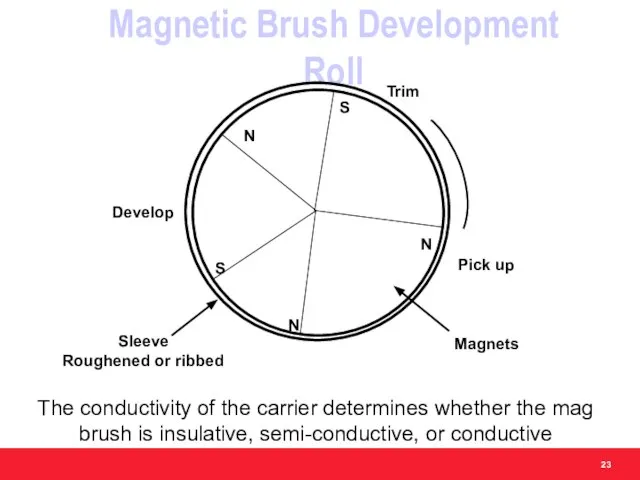

- 23. Magnetic Brush Development Roll The conductivity of the carrier determines whether the mag brush is insulative,

- 24. Examples: Lakes Family, Tigris, Nuvera

- 25. Transfer Moving the toned image to paper

- 26. Major Transfer Drivers Toner properties: Toner shape Toner size distribution Tribo Paper properties: Electrical properties (surface

- 27. Corona Biased Transfer Roll Transfer Belt Charged Transfer Roll (CTR) Intermediate Transfer Belt Acoustic Transfer Assist

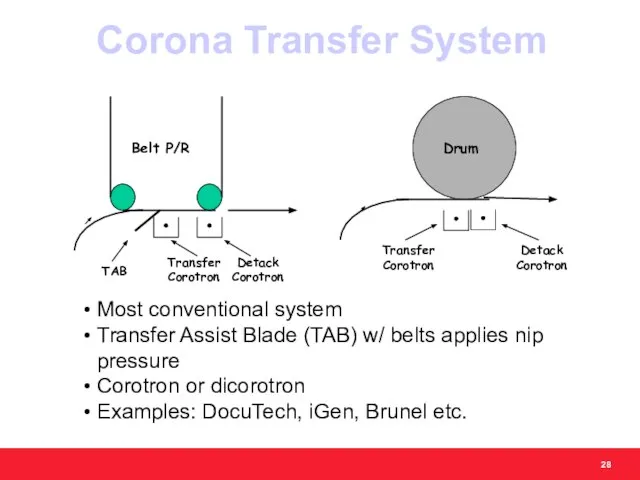

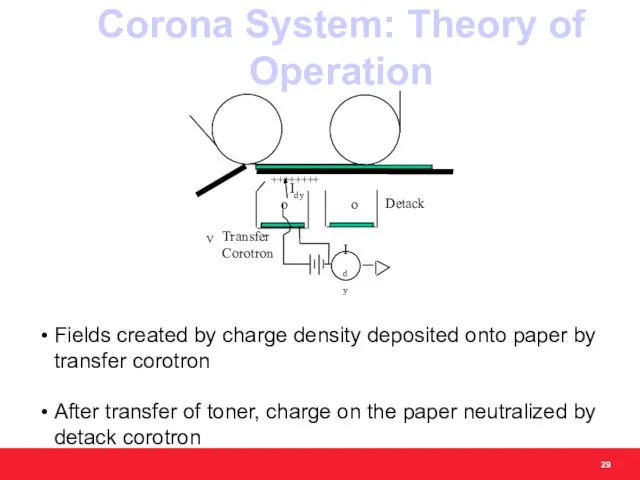

- 28. Most conventional system Transfer Assist Blade (TAB) w/ belts applies nip pressure Corotron or dicorotron Examples:

- 29. Fields created by charge density deposited onto paper by transfer corotron After transfer of toner, charge

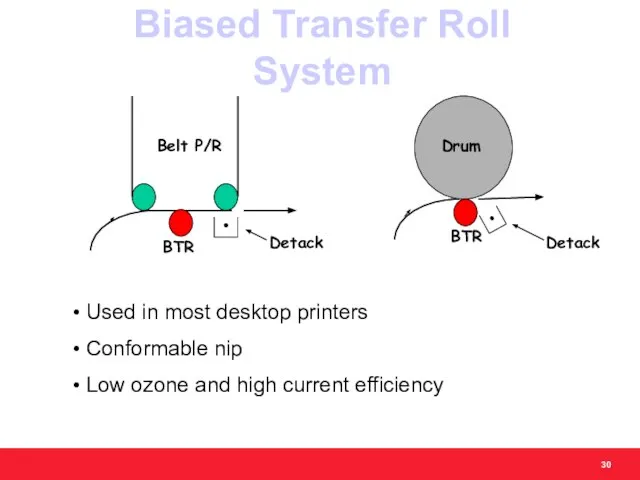

- 30. Biased Transfer Roll System Used in most desktop printers Conformable nip Low ozone and high current

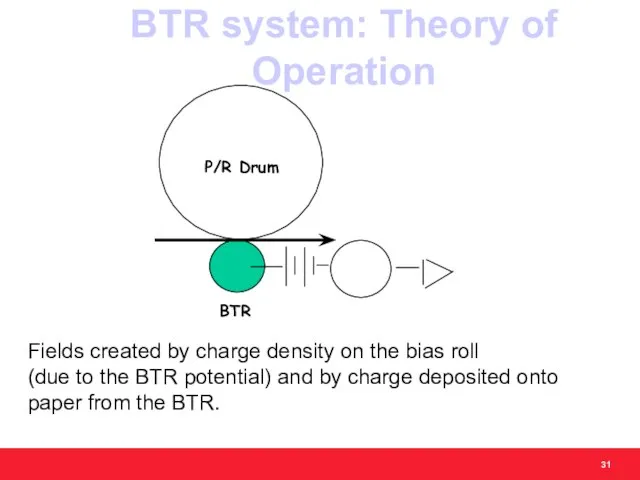

- 31. Fields created by charge density on the bias roll (due to the BTR potential) and by

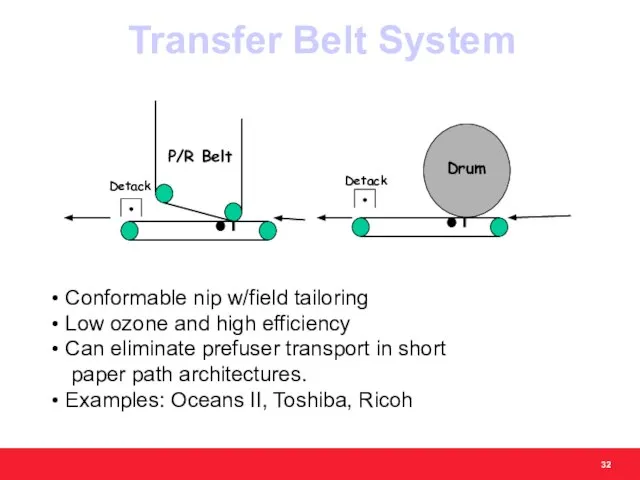

- 32. Transfer Belt System Conformable nip w/field tailoring Low ozone and high efficiency Can eliminate prefuser transport

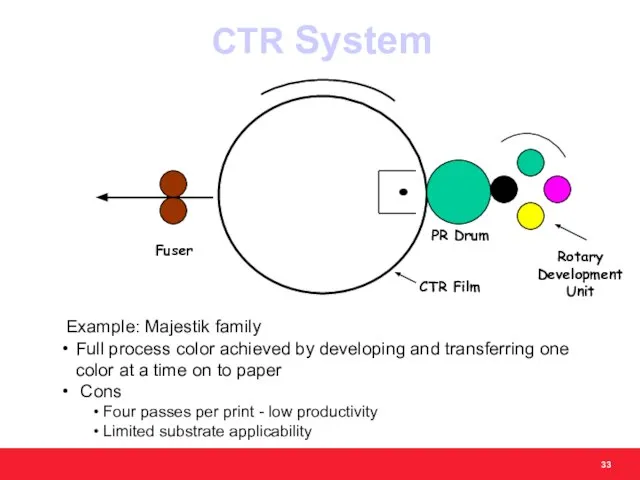

- 33. CTR System Example: Majestik family Full process color achieved by developing and transferring one color at

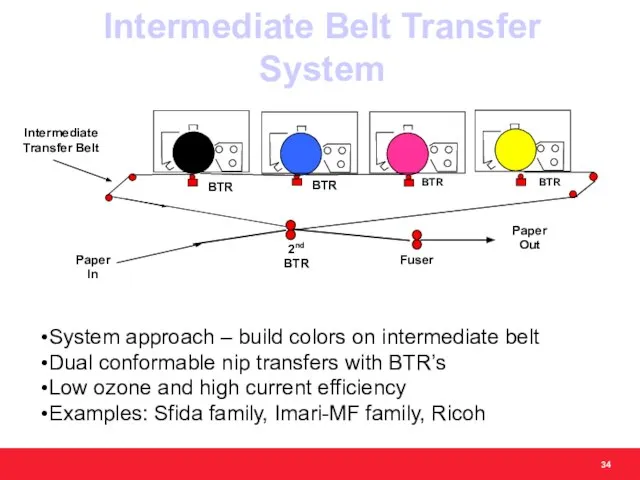

- 34. Intermediate Belt Transfer System System approach – build colors on intermediate belt Dual conformable nip transfers

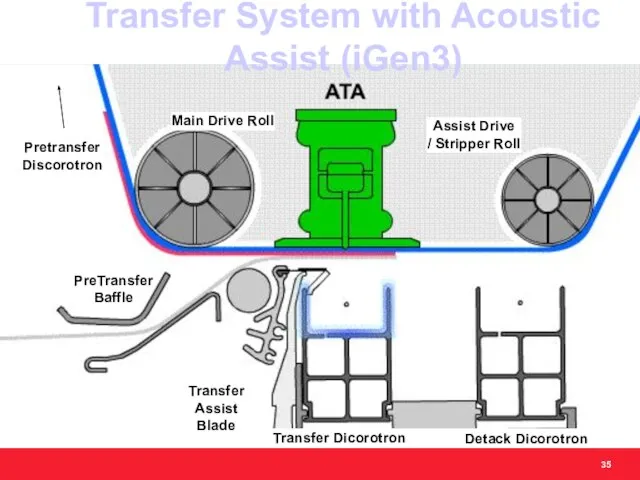

- 35. Transfer Assist Blade PreTransfer Baffle Detack Dicorotron Transfer Dicorotron Main Drive Roll Assist Drive / Stripper

- 36. Fusing Fixing the image to paper

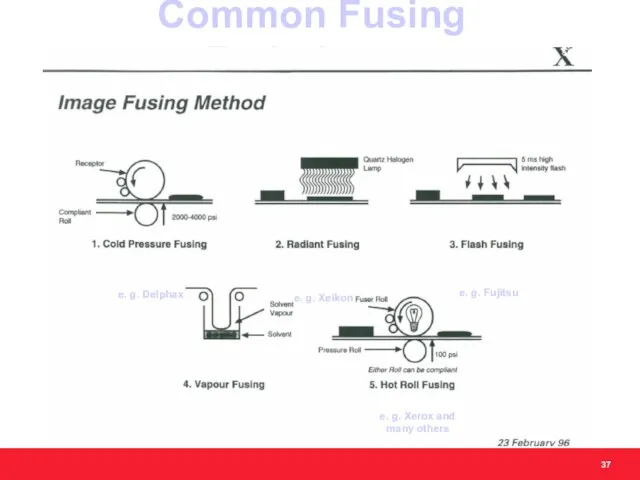

- 37. Common Fusing Techniques e. g. Delphax e. g. Xeikon e. g. Fujitsu e. g. Xerox and

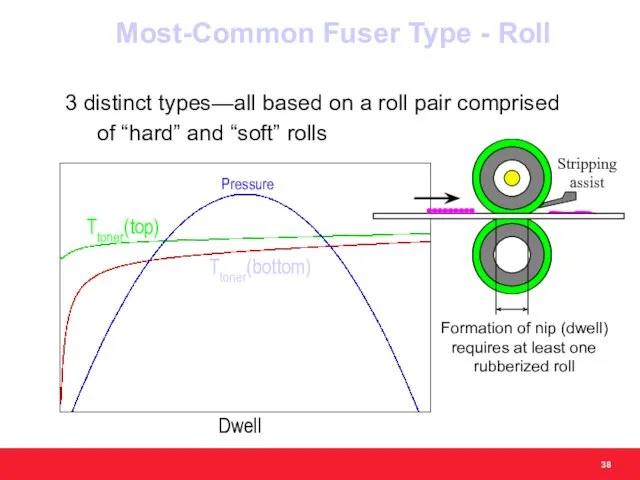

- 38. 3 distinct types—all based on a roll pair comprised of “hard” and “soft” rolls Dwell Pressure

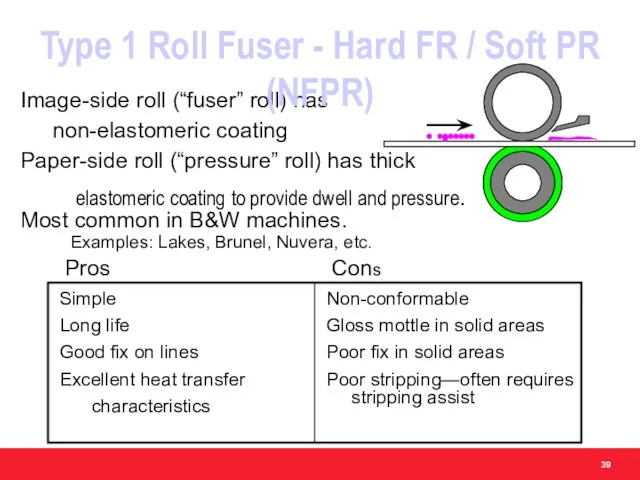

- 39. Image-side roll (“fuser” roll) has non-elastomeric coating Paper-side roll (“pressure” roll) has thick elastomeric coating to

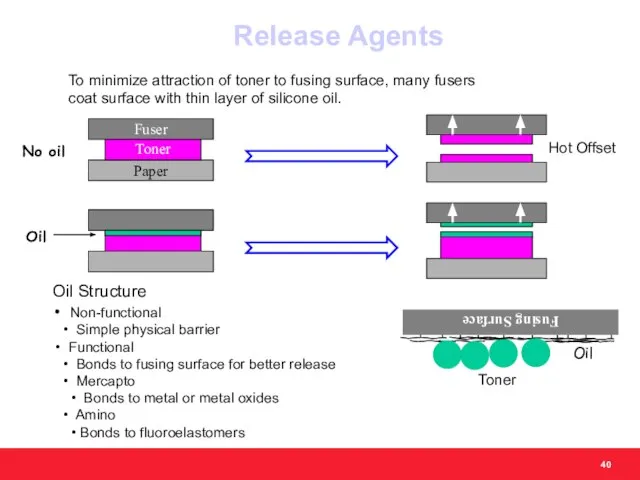

- 40. Oil Structure Non-functional Simple physical barrier Functional Bonds to fusing surface for better release Mercapto Bonds

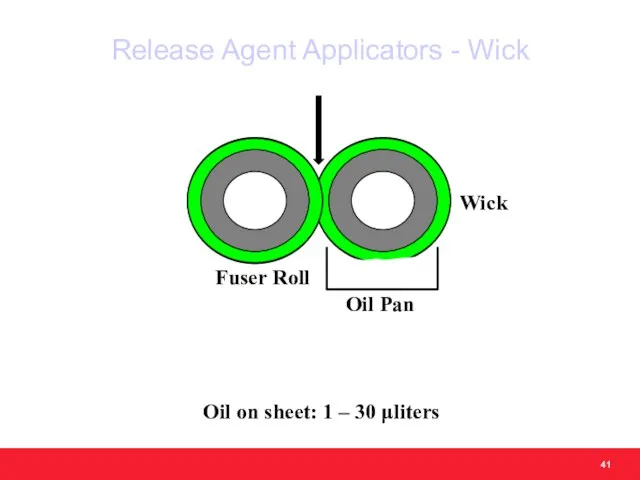

- 41. Oil on sheet: 1 – 30 μliters Release Agent Applicators - Wick Wick

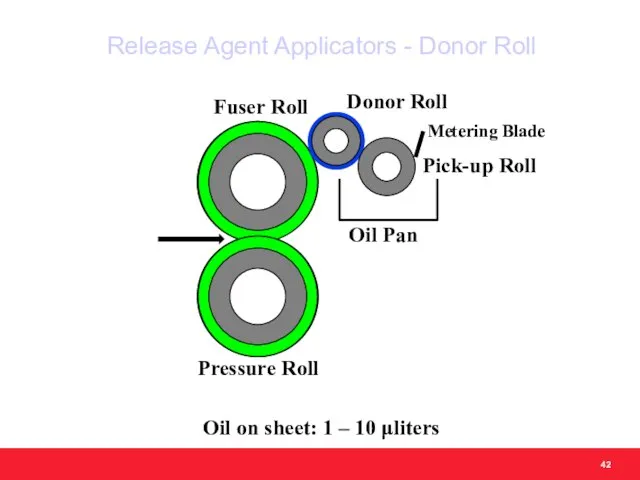

- 42. Release Agent Applicators - Donor Roll Metering Blade Oil on sheet: 1 – 10 μliters

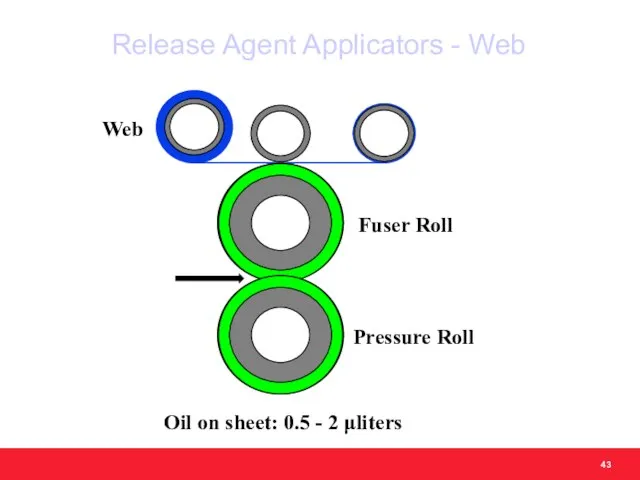

- 43. Release Agent Applicators - Web Oil on sheet: 0.5 - 2 μliters Pressure Roll Fuser Roll

- 44. Release Agent Issues Undesirable feel Inability to write on the print or to stick “Post-it” notes

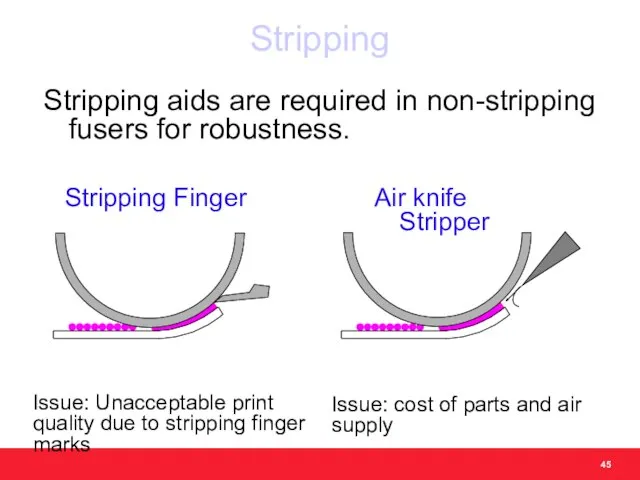

- 45. Stripping aids are required in non-stripping fusers for robustness. Stripping Issue: Unacceptable print quality due to

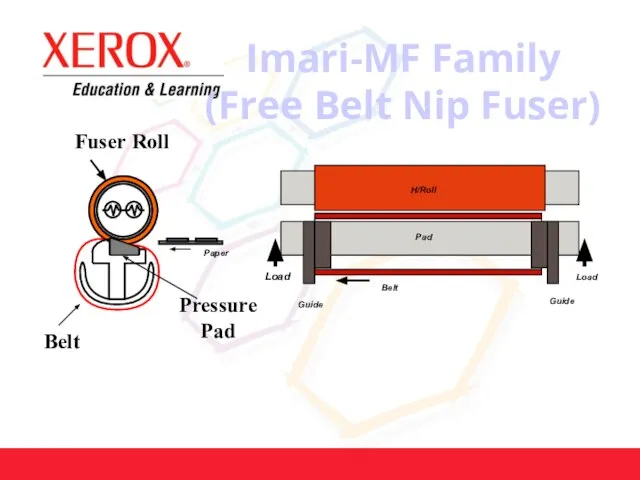

- 46. Imari-MF Family (Free Belt Nip Fuser) Fuser Roll Belt Pressure Pad

- 47. Erase Removing the charge from the photoreceptor

- 48. Erase Erase is the process of eliminating any electric memory of the previous image from the

- 49. Cleaning Removing the residues from the photoreceptor

- 50. Types of Residual Materials Toner Paper Debris Fibers Fillers: Talc, Kaolin (clays), etc. Adhesives (e.g. ream

- 51. Methods of Cleaning Toner Mechanical Forces Blade Multi – Blades Mechanical Brush Foam Roll Web Electrostatic

- 52. Methods of Cleaning Other Residuals Disturber Brushes Paper fibers and debris Films from toner additives Comets

- 53. Common Cleaning Systems

- 54. Blade Cleaner Photoreceptor Blade Critical Parameters: Blade Angle Force Pros: Simple Design Low Cost Cons: P/R

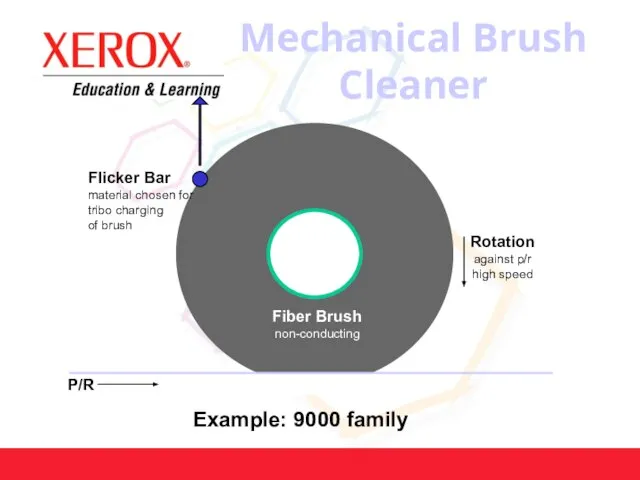

- 55. Mechanical Brush Cleaner Example: 9000 family

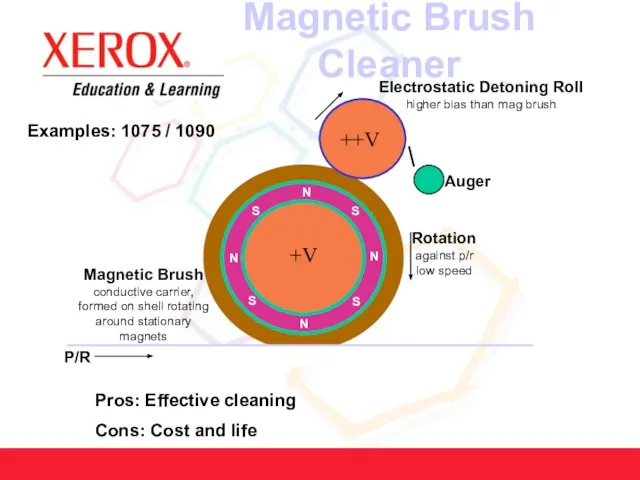

- 56. Magnetic Brush Cleaner Examples: 1075 / 1090 Pros: Effective cleaning Cons: Cost and life

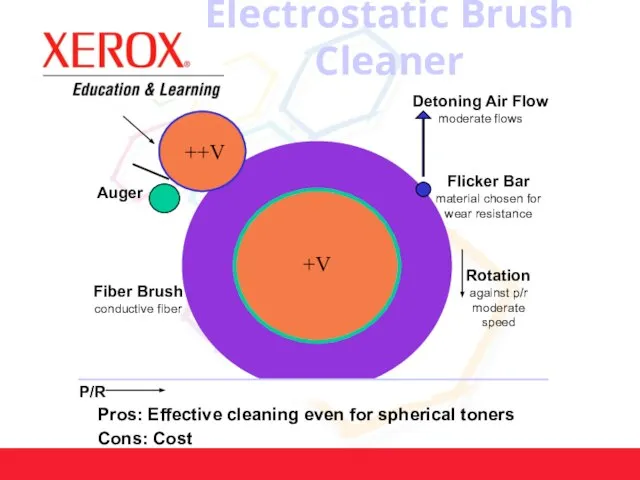

- 57. Electrostatic Brush Cleaner Pros: Effective cleaning even for spherical toners Cons: Cost

- 58. TONER

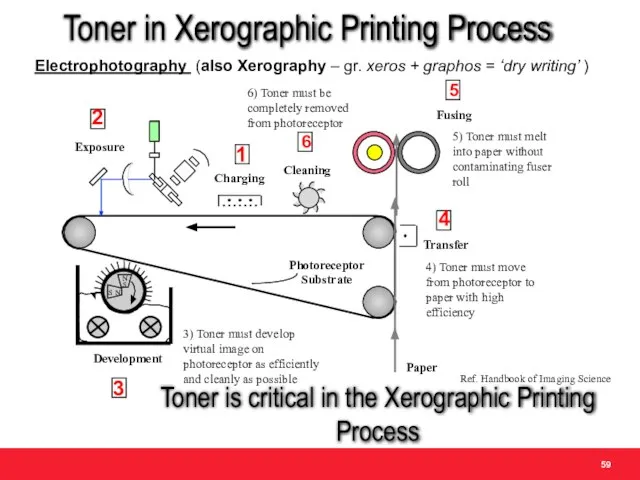

- 59. Toner in Xerographic Printing Process Electrophotography (also Xerography – gr. xeros + graphos = ‘dry writing’

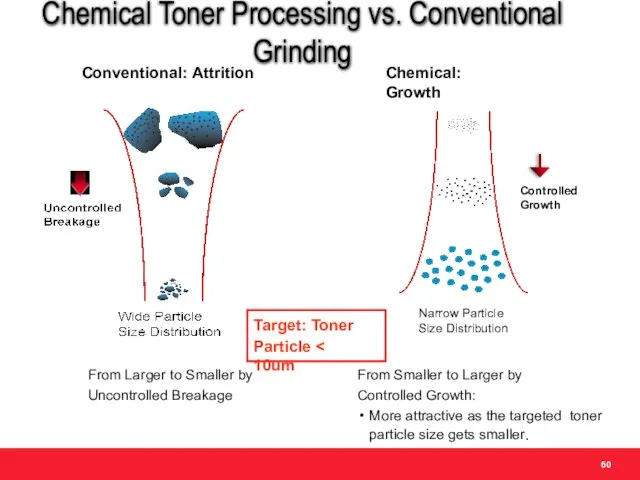

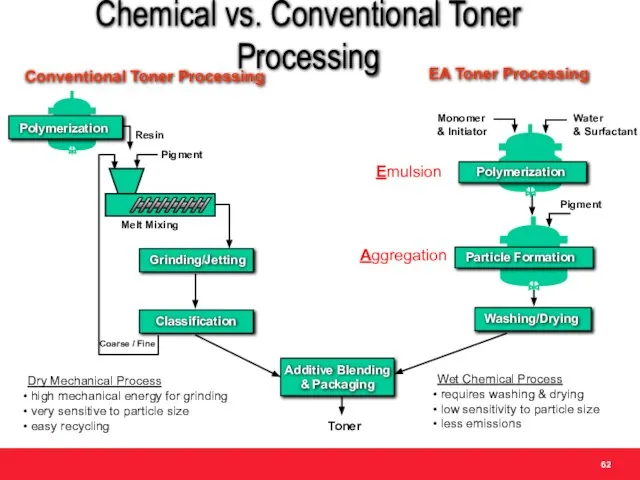

- 60. From Larger to Smaller by Uncontrolled Breakage Conventional: Attrition Narrow Particle Size Distribution From Smaller to

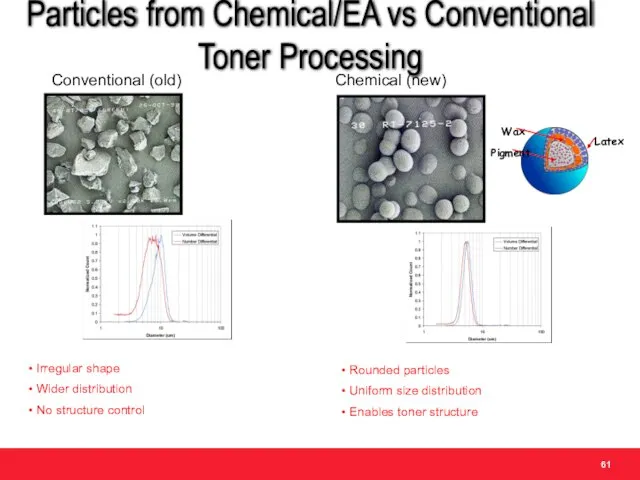

- 61. Irregular shape Wider distribution No structure control Particles from Chemical/EA vs Conventional Toner Processing Conventional (old)

- 62. Toner Additive Blending & Packaging Melt Mixing Coarse / Fine Resin Pigment Grinding/Jetting Classification Polymerization Conventional

- 64. Скачать презентацию

GameCore. Monogame

GameCore. Monogame Оnline системы управления библиографической информацией в помощь научному и учебному процессу

Оnline системы управления библиографической информацией в помощь научному и учебному процессу Основные этапы разработки и исследования моделей на компьютере Урок-презентация 9 класс

Основные этапы разработки и исследования моделей на компьютере Урок-презентация 9 класс Кейс по созданию сайта математических статей

Кейс по созданию сайта математических статей Протоколы сети Internet

Протоколы сети Internet Логика - наука о формах и способах мышления

Логика - наука о формах и способах мышления Базис и Мкм. 10 первых задач

Базис и Мкм. 10 первых задач Современные алгоритмы шифрования

Современные алгоритмы шифрования Модуль 1. Практическое занятие 3. Метод. Передача параметров. Переключатель

Модуль 1. Практическое занятие 3. Метод. Передача параметров. Переключатель Загальні засади медіапедагогіки

Загальні засади медіапедагогіки Система автономной навигации антропоморфного робота

Система автономной навигации антропоморфного робота Информационные процессы

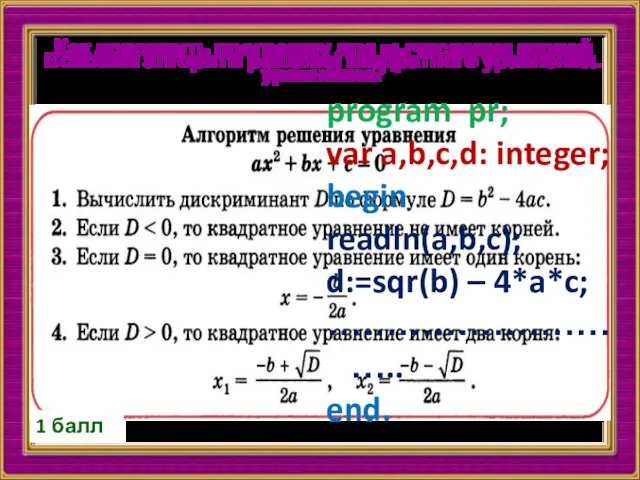

Информационные процессы Ур. 25

Ур. 25 Кодирование информации с помощью знаковых систем

Кодирование информации с помощью знаковых систем Презентация "Устройство компьютера 3 класс" - скачать презентации по Информатике

Презентация "Устройство компьютера 3 класс" - скачать презентации по Информатике Компьютерная графика

Компьютерная графика Способы представления криволинейных поверхностей

Способы представления криволинейных поверхностей Сетевые службы. Кластеры

Сетевые службы. Кластеры Презентация "Кодирование текстовой информации 6 класс" - скачать презентации по Информатике

Презентация "Кодирование текстовой информации 6 класс" - скачать презентации по Информатике Управление задачами

Управление задачами Язык запросов к реляционным базам данных

Язык запросов к реляционным базам данных Интерактивные возможности PowerPoint

Интерактивные возможности PowerPoint Антивирусные программы

Антивирусные программы Двоичное кодирование графической и звуковой информации

Двоичное кодирование графической и звуковой информации  Jira Advanced - Module 1

Jira Advanced - Module 1 Презентация "Экспертные системы. Технология разработки. Этап формализации" - скачать презентации по Информатике

Презентация "Экспертные системы. Технология разработки. Этап формализации" - скачать презентации по Информатике Проектирование и разработка программно-информационной обучающей системы

Проектирование и разработка программно-информационной обучающей системы How to apply NLA-5&15S Preset

How to apply NLA-5&15S Preset