Содержание

- 2. © BARRY ORR Pre-Contract Introduction Trends in the Transference of Risk Principal causes of loss Essential

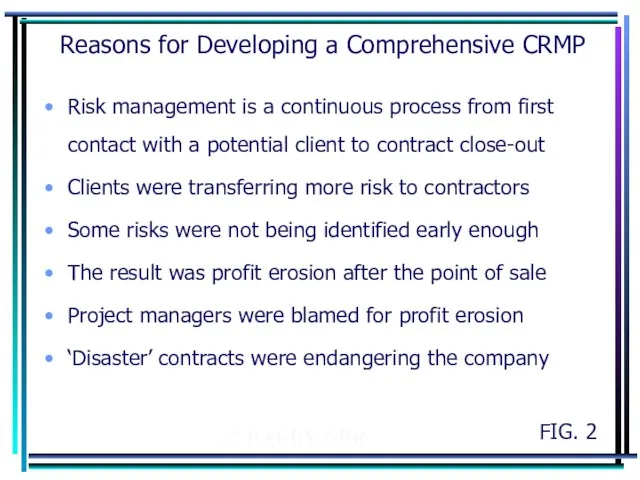

- 3. © BARRY ORR Reasons for Developing a Comprehensive CRMP Risk management is a continuous process from

- 4. © BARRY ORR Trends in the Transference of Risk Tighter prices for the contractors Lump sum

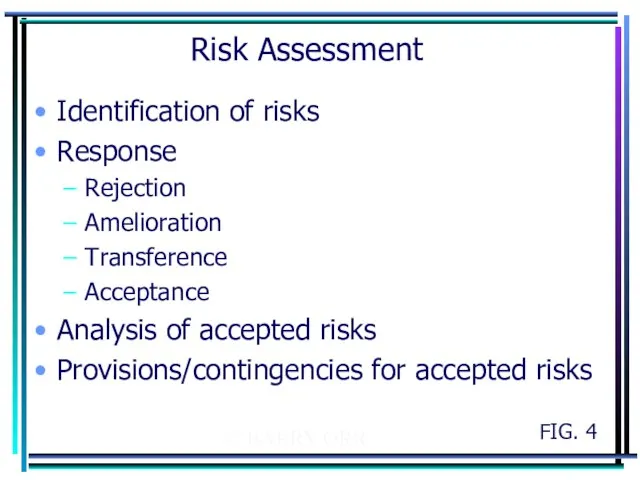

- 5. © BARRY ORR Risk Assessment Identification of risks Response Rejection Amelioration Transference Acceptance Analysis of accepted

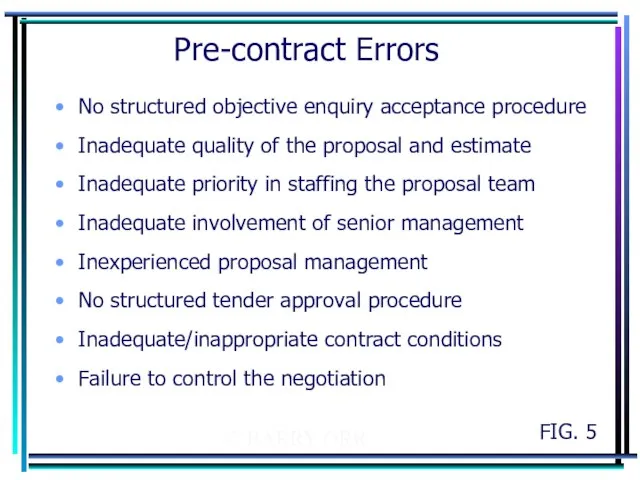

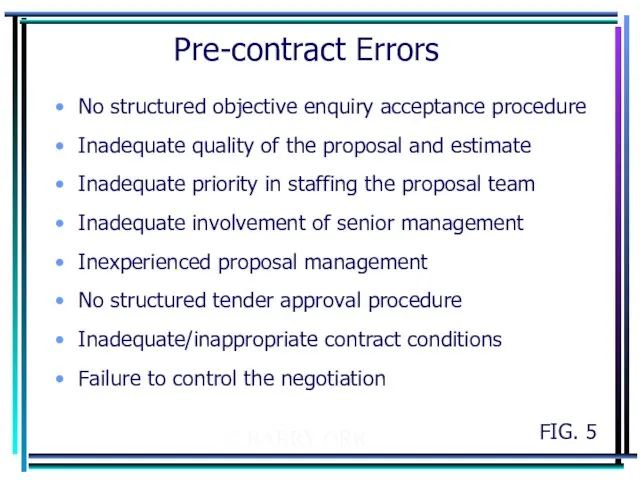

- 6. © BARRY ORR Pre-contract Errors No structured objective enquiry acceptance procedure Inadequate quality of the proposal

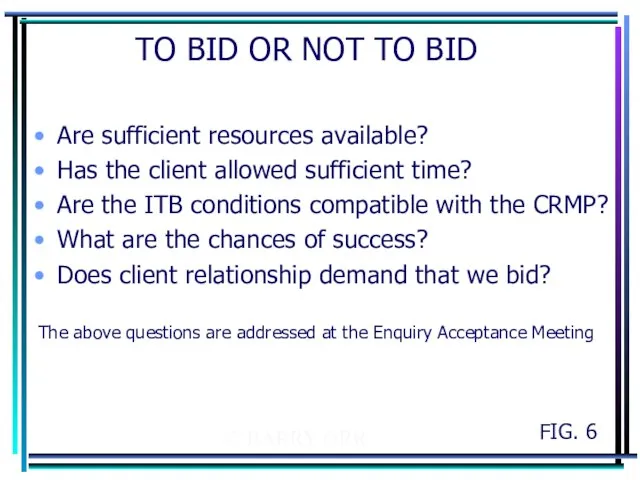

- 7. © BARRY ORR TO BID OR NOT TO BID Are sufficient resources available? Has the client

- 8. © BARRY ORR Sales Strategy Reasons for bidding The winning features of the bid Importance of

- 9. © BARRY ORR Sales Strategy (Cont.) Agents Counter trade Competition Contractor’s weaknesses and strengths Proposal documentation

- 10. © BARRY ORR Pre-contract Errors No structured objective enquiry acceptance procedure Inadequate quality of the proposal

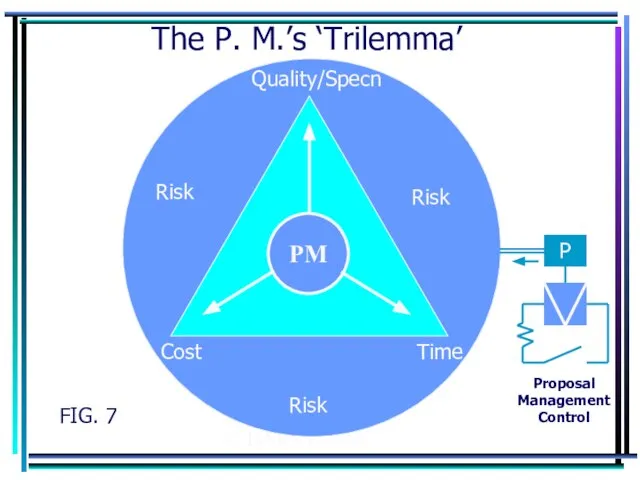

- 11. © BARRY ORR The P. M.’s ‘Trilemma’ FIG. 7

- 12. © BARRY ORR Pre-contract Errors No structured objective enquiry acceptance procedure Inadequate quality of the proposal

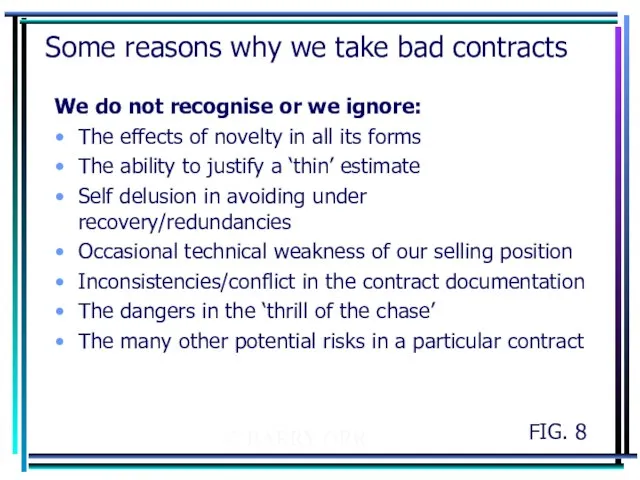

- 13. © BARRY ORR Some reasons why we take bad contracts We do not recognise or we

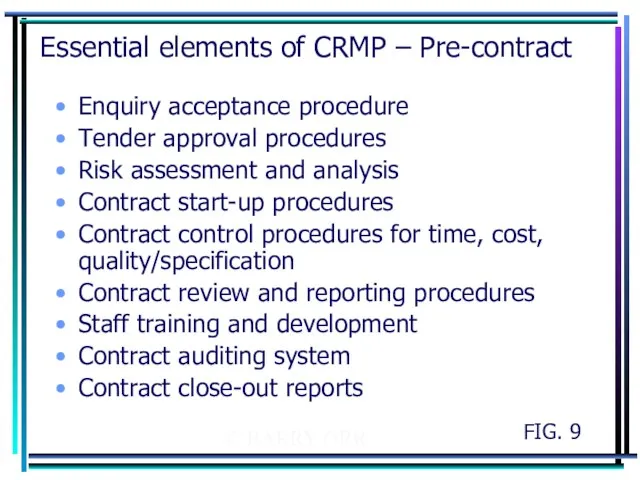

- 14. © BARRY ORR Essential elements of CRMP – Pre-contract Enquiry acceptance procedure Tender approval procedures Risk

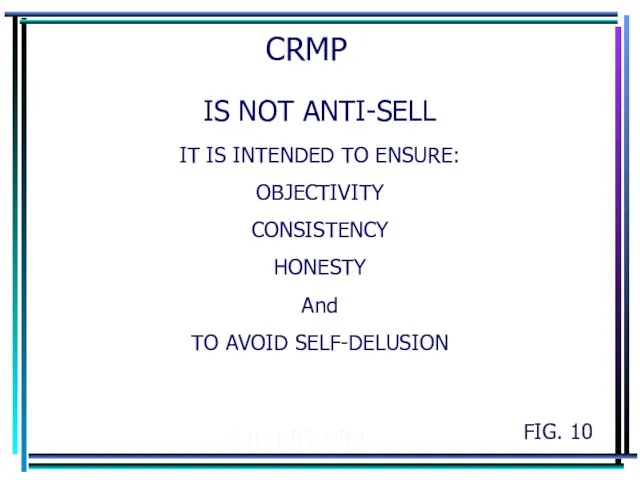

- 15. © BARRY ORR CRMP IS NOT ANTI-SELL IT IS INTENDED TO ENSURE: OBJECTIVITY CONSISTENCY HONESTY And

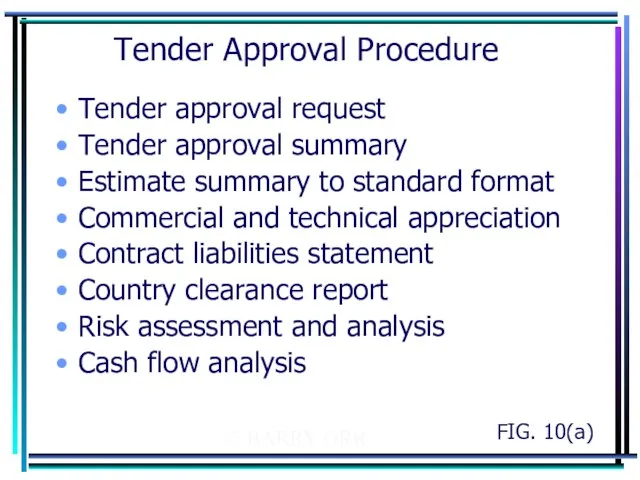

- 16. © BARRY ORR Tender Approval Procedure Tender approval request Tender approval summary Estimate summary to standard

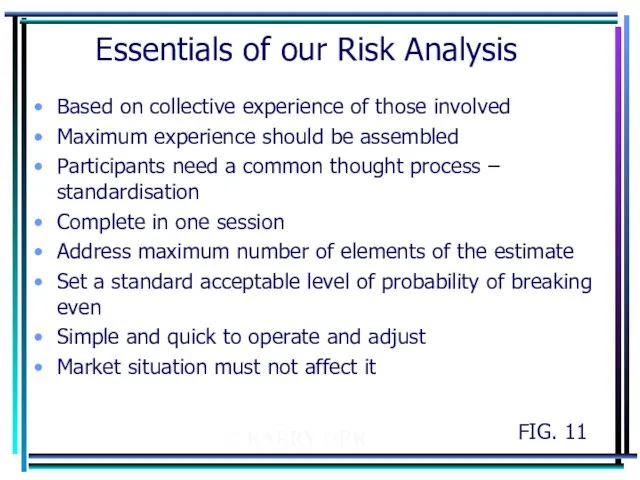

- 17. © BARRY ORR Essentials of our Risk Analysis Based on collective experience of those involved Maximum

- 18. © BARRY ORR What is a fair price? PRICE = COST + PROFIT COST = BASE

- 19. © BARRY ORR Areas Addressed in our Risk Analysis Estimating accuracy – all elements Degree of

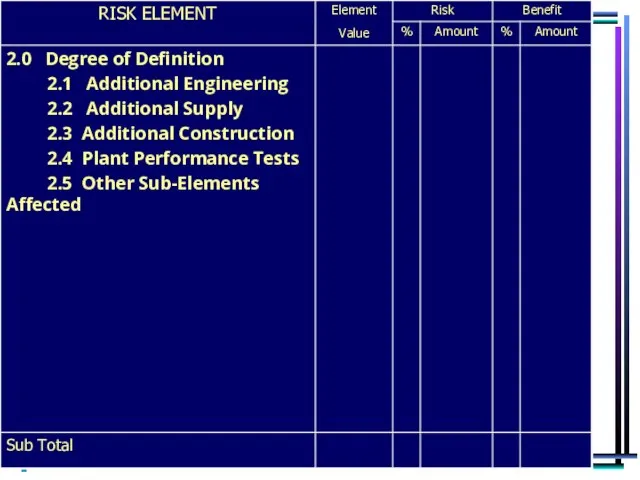

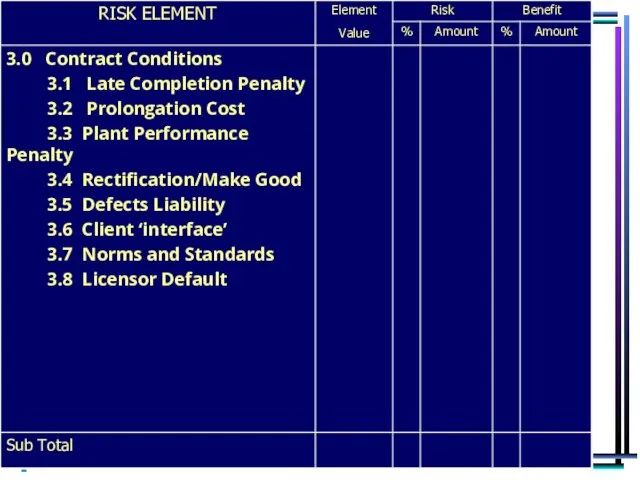

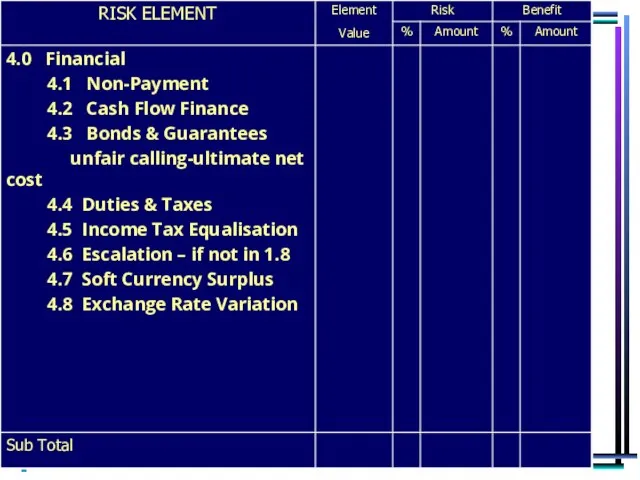

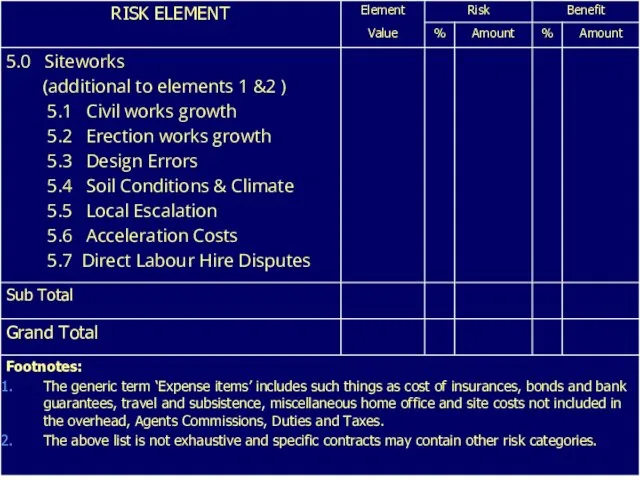

- 20. © BARRY ORR

- 21. © BARRY ORR

- 22. © BARRY ORR

- 23. © BARRY ORR

- 24. © BARRY ORR

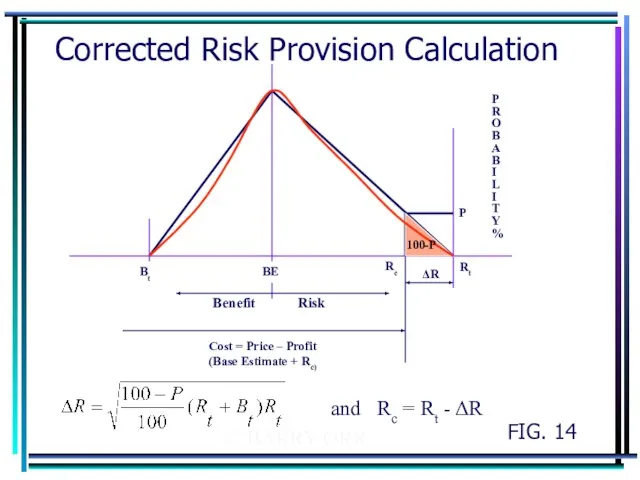

- 25. © BARRY ORR Corrected Risk Provision Calculation FIG. 14 and Rc = Rt - ΔR

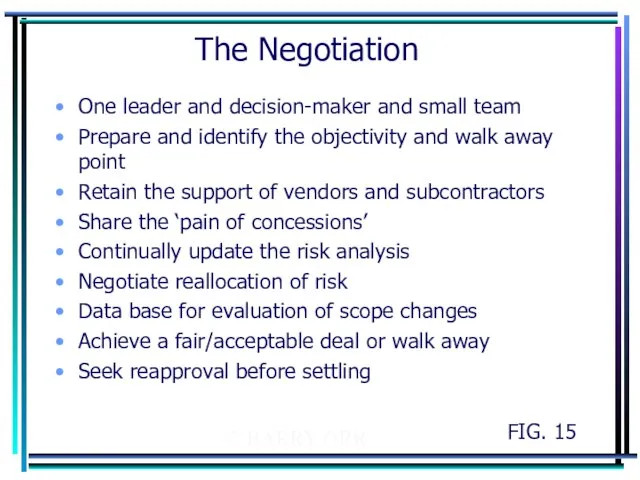

- 26. © BARRY ORR The Negotiation One leader and decision-maker and small team Prepare and identify the

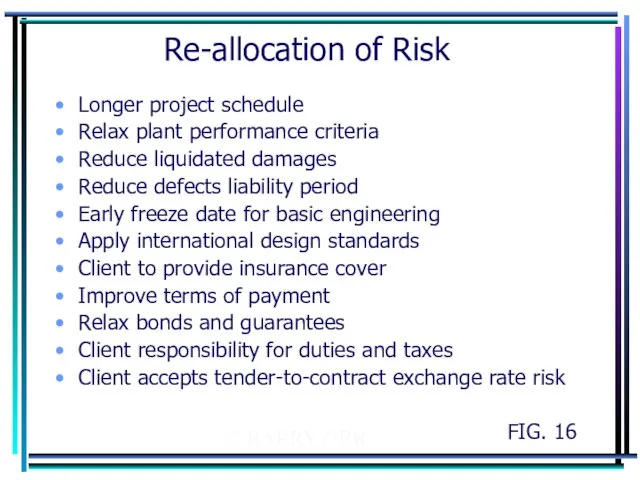

- 27. © BARRY ORR Re-allocation of Risk Longer project schedule Relax plant performance criteria Reduce liquidated damages

- 28. Contract Risk Management for Engineering Contractors Part 2: Post-contract

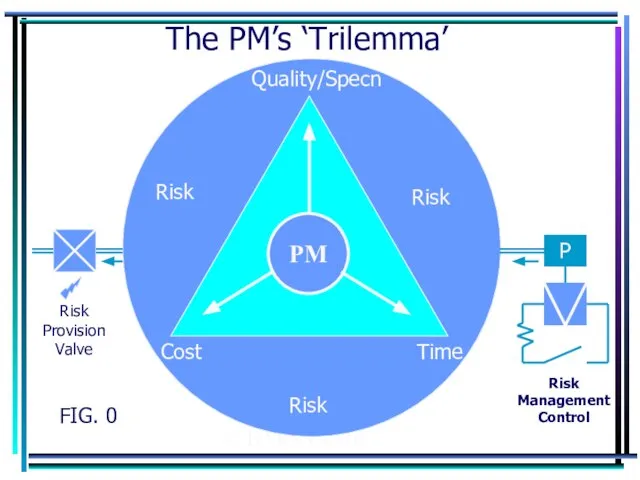

- 29. © BARRY ORR The PM’s ‘Trilemma’ FIG. 0

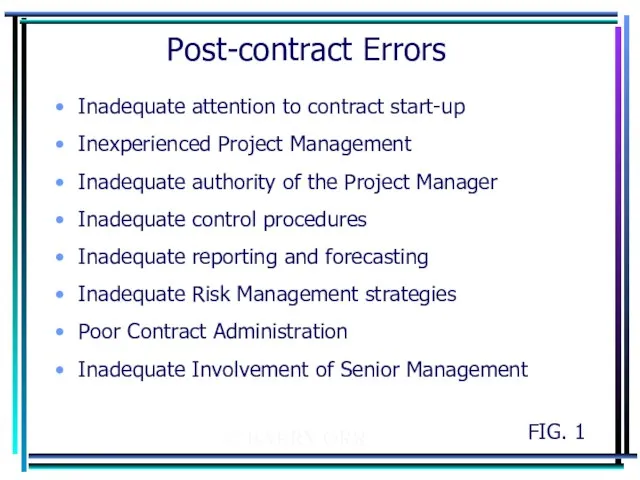

- 30. © BARRY ORR Post-contract Errors Inadequate attention to contract start-up Inexperienced Project Management Inadequate authority of

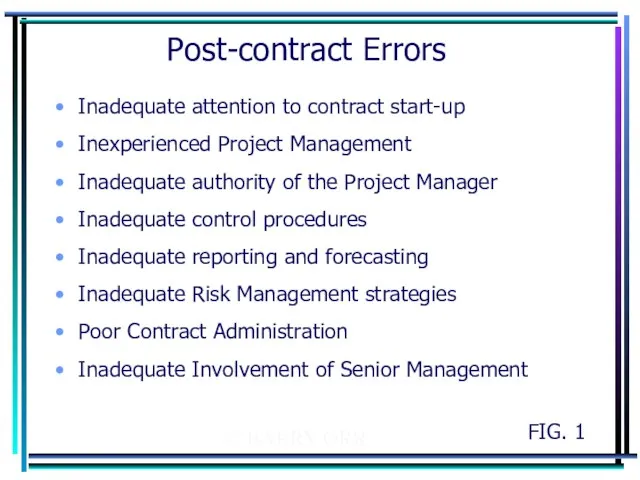

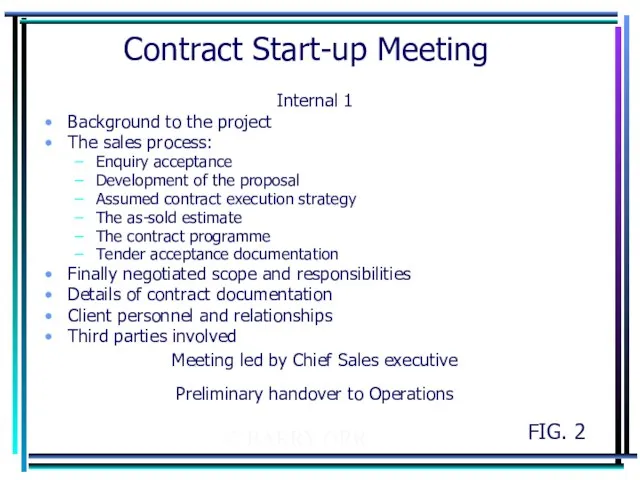

- 31. © BARRY ORR Contract Start-up Meeting Internal 1 Background to the project The sales process: Enquiry

- 32. © BARRY ORR Contract Start-up Meeting Internal 2 Introduction of key members of team Confirmation of

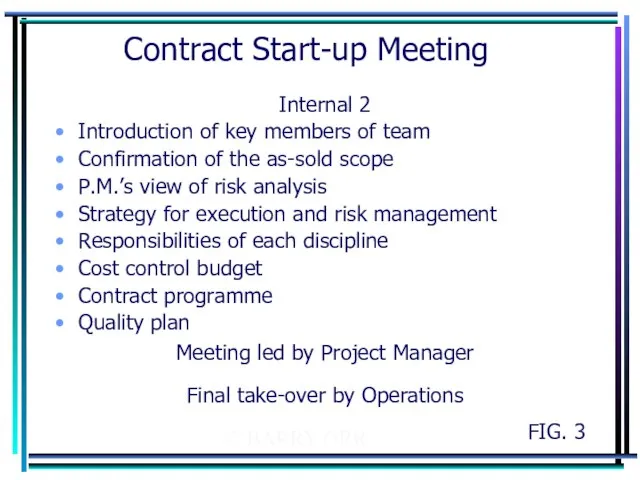

- 33. © BARRY ORR Contract Start-up Meeting With Client As-sold scope Project administration procedures Contract variation procedure

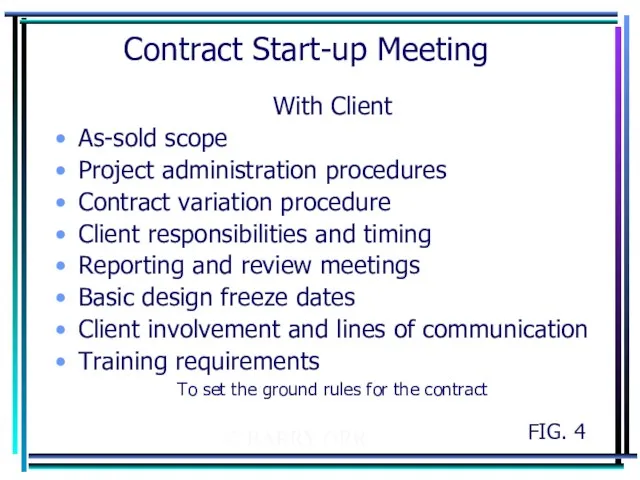

- 34. © BARRY ORR Post-contract Errors Inadequate attention to contract start-up Inexperienced Project Management Inadequate authority of

- 35. © BARRY ORR Risk management – Key Requirements PM to review risk provision at contract start-up

- 36. © BARRY ORR Essential Elements of a CRMP Enquiry acceptance procedure Tender approval procedures Risk assessment

- 37. © BARRY ORR Contract Administration Full time contract administrator Detailed records and computerised retrieval system Credit

- 38. © BARRY ORR Control of Quality Quality plan should be part of contract controls Apply quality

- 39. © BARRY ORR Safety and Operability Reviews HAZOP studies Qualitative and systematic Based on PFDs and

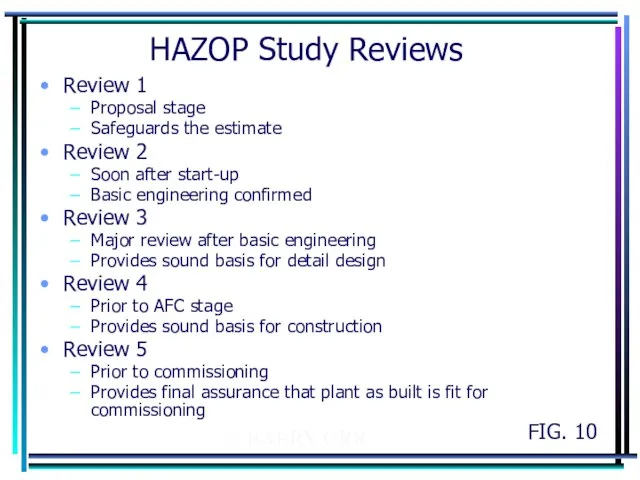

- 40. © BARRY ORR HAZOP Study Reviews Review 1 Proposal stage Safeguards the estimate Review 2 Soon

- 41. © BARRY ORR Contract Reporting (Part 1) Internal PM’s Monthly Report Executive Summary Contract Financial Status

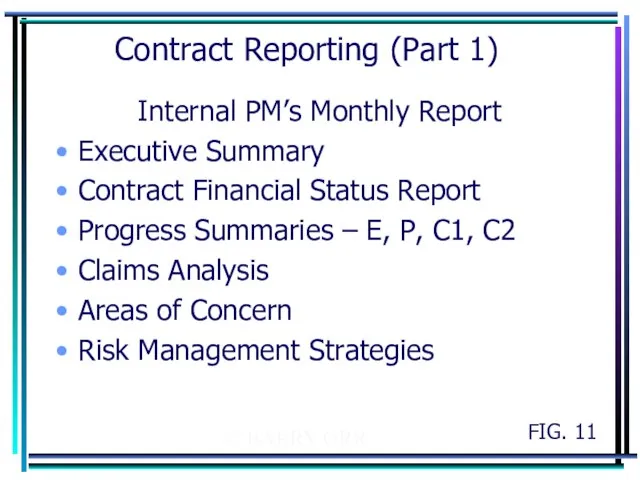

- 42. © BARRY ORR Contract Reporting (Part 2) Report to client – lump sum contracts General description

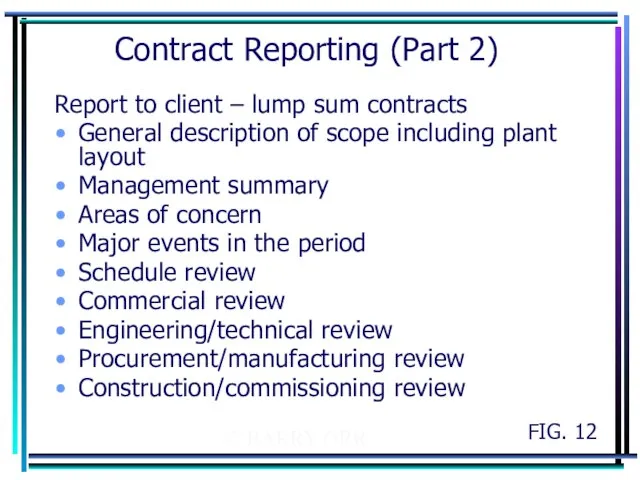

- 43. © BARRY ORR Contract Reporting (Part 3) Report to client – Management reimbursable contracts Project Director’s

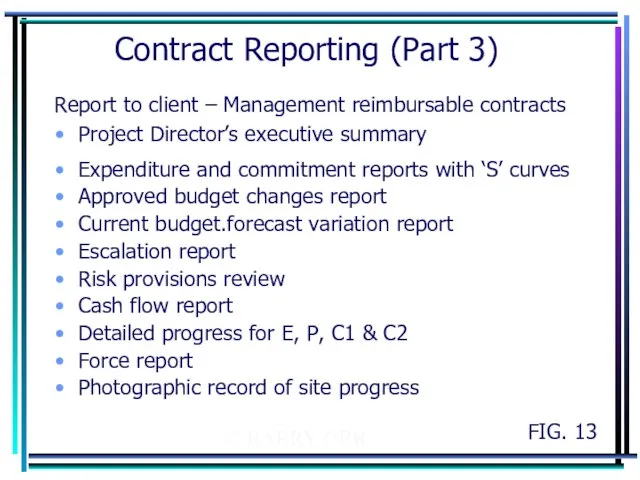

- 44. © BARRY ORR Principal objectives of a contract audit Compliance with the CRMP Adequacy of contract

- 45. © BARRY ORR Contract Audit Principles Impartial and objective Competent audit team Authority from Main Board

- 46. © BARRY ORR Preparations for Audit Develop standard interrogation procedure Set up standard format for recording

- 47. © BARRY ORR Audit Execution - Presale Full overview briefing by project manager Interrogation of sales

- 48. © BARRY ORR Audit Execution – Start-up Check handover procedure from proposals to operations and start-up

- 49. © BARRY ORR Audit Execution – Contract Management Controls for: Time Cost Quality/specification Cash management Site

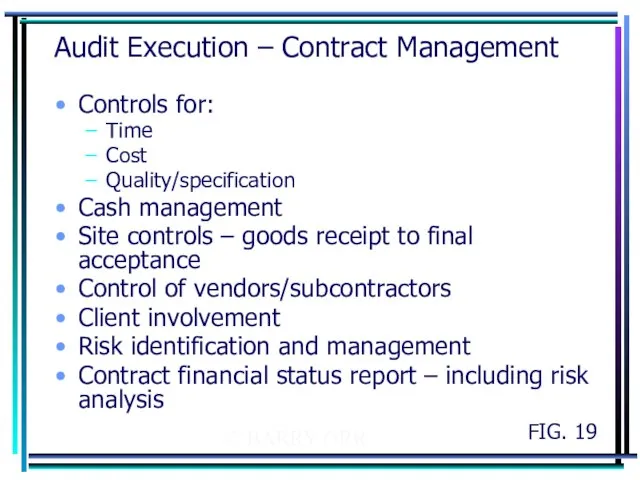

- 50. © BARRY ORR Contract Close-out and final actions Progressive dismantling of task force Staff appraisals Re-entry

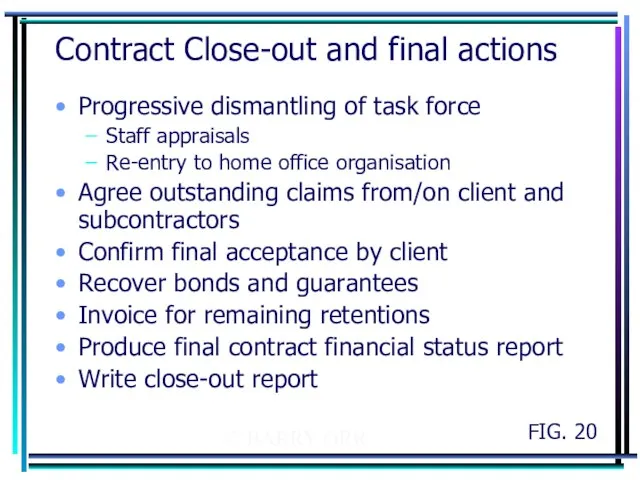

- 52. Скачать презентацию

Современные качества на рынке труда. Качества необходимые для устойчивого развития (Занятие 1)

Современные качества на рынке труда. Качества необходимые для устойчивого развития (Занятие 1) Процесс принятия управленческих решений. (Тема 8)

Процесс принятия управленческих решений. (Тема 8) Управление трудовыми ресурсами

Управление трудовыми ресурсами Искусство делегирования

Искусство делегирования Модель управления и оценка системы территориальной логистической системы пассажирских перевозок в онлайн режиме

Модель управления и оценка системы территориальной логистической системы пассажирских перевозок в онлайн режиме Хэдхандинг на рынке труда

Хэдхандинг на рынке труда Классическая школа управления

Классическая школа управления Понятие и сущность проектов

Понятие и сущность проектов Модели управления проектами

Модели управления проектами Теоретические основы управления персоналом

Теоретические основы управления персоналом Основные и дополнительные услуги в отеле Ливадийский

Основные и дополнительные услуги в отеле Ливадийский Совершенствование стратегии управления организацией на основе маркетинговой стратегии

Совершенствование стратегии управления организацией на основе маркетинговой стратегии Теоретические аспекты командообразования: понятия, признаки, отличие от группы

Теоретические аспекты командообразования: понятия, признаки, отличие от группы Processes, Technology, and Capacity

Processes, Technology, and Capacity Методологические основы научного исследования

Методологические основы научного исследования Организационное поведение, как наука. (Тема 1)

Организационное поведение, как наука. (Тема 1) Менеджер в организации

Менеджер в организации Стейкхолдеры

Стейкхолдеры Исследование структуры HR в компании L'Oréal

Исследование структуры HR в компании L'Oréal Анализ факторов влияющих на эффективность деятельности персонала овд в стрессовых ситуациях

Анализ факторов влияющих на эффективность деятельности персонала овд в стрессовых ситуациях Введение в профессию Менеджер по персоналу, Специалист по управлению персоналом

Введение в профессию Менеджер по персоналу, Специалист по управлению персоналом Нумерация событий сетевой модели: правило вычёркивания дуг (работ)

Нумерация событий сетевой модели: правило вычёркивания дуг (работ) Комплектация тележки горничной

Комплектация тележки горничной Средства управления проектами

Средства управления проектами Профессия менеджер

Профессия менеджер Модель конкурентных сил. Конкурентное силы на рынке сервисного сопровождения оргтехники

Модель конкурентных сил. Конкурентное силы на рынке сервисного сопровождения оргтехники Работа с возражениями при приглашении. Oriflame Cosmetics

Работа с возражениями при приглашении. Oriflame Cosmetics Набор персонала в организации: понятие, источники, методы

Набор персонала в организации: понятие, источники, методы