- Главная

- Менеджмент

- Risk management process training

Содержание

- 2. CONTENT Overview Why do we need to manage risk Definitions Risk Roles & Responsibilities Risk Management

- 3. OVERVIEW Risk management is one of the key processes in the Care Strategy which supports well

- 4. RISK MANAGEMENT DEFINITIONS

- 5. RISK MANAGEMENT DEFINITIONS

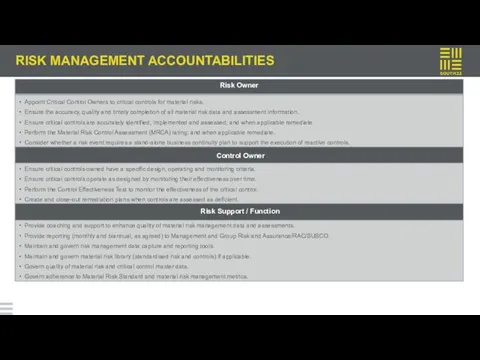

- 6. RISK MANAGEMENT ACCOUNTABILITIES

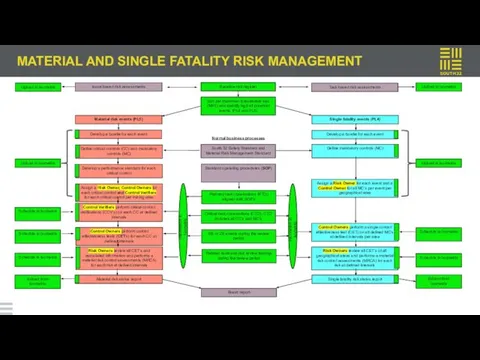

- 7. MATERIAL AND SINGLE FATALITY RISK MANAGEMENT

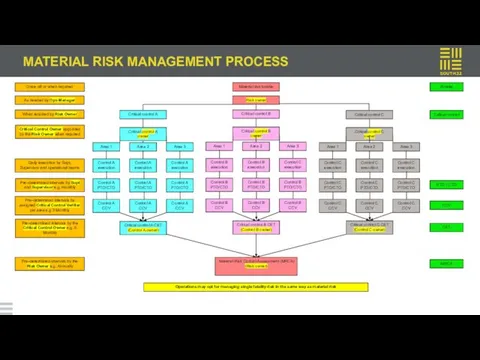

- 8. MATERIAL RISK MANAGEMENT PROCESS

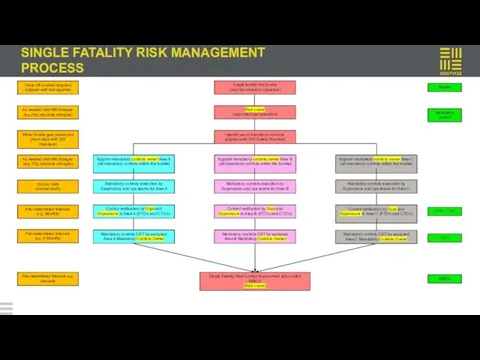

- 9. SINGLE FATALITY RISK MANAGEMENT PROCESS

- 10. BASELINE RISK ASSESSMENT The baseline risk register documents all risks identified within the organisation When new

- 11. BOWTIE RISK ASSESSMENT METHODOLOGY Clearly define the scope Detailed description of the risk event Clear boundaries

- 12. SELECTING CRITICAL CONTROLS AND CONTROL OWNERS SLIDE When selecting critical controls, the risk owner would: List

- 13. SELECTING CRITICAL CONTROLS AND OWNERS An object, action or system that is independent and that actively

- 14. RISK IDENTIFICATION AND VERIFICATION PROCESS Risk Identification From the baseline risk register, identify material and single

- 15. CONTROL EFFECTIVENESS TESTS Control Effectiveness Test A control effectiveness test is conducted to provide assurance that

- 16. MATERIAL RISK CONTROL ASSESSMENTS The material risk control assessment is completed once the Risk Owner has

- 18. Скачать презентацию

CONTENT

Overview

Why do we need to manage risk

Definitions

Risk Roles & Responsibilities

Risk

CONTENT

Overview

Why do we need to manage risk

Definitions

Risk Roles & Responsibilities

Risk

Baseline risk assessment

Bowtie methodology

Material risk control assessment (MRCA)

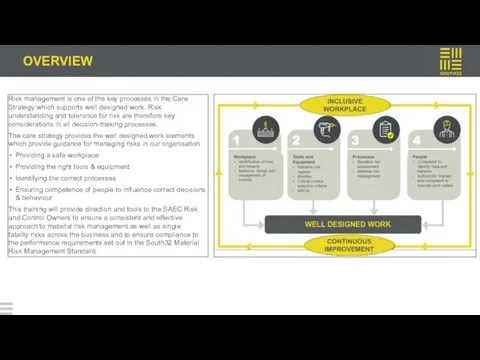

OVERVIEW

Risk management is one of the key processes in the Care

OVERVIEW

Risk management is one of the key processes in the Care

The care strategy provides the well designed work elements which provide guidance for managing risks in our organisation

Providing a safe workplace

Providing the right tools & equipment

Identifying the correct processes

Ensuring competence of people to influence correct decisions & behaviour

This training will provide direction and tools to the SAEC Risk and Control Owners to ensure a consistent and effective approach to material risk management as well as single fatality risks across the business and to ensure compliance to the performance requirements set out in the South32 Material Risk Management Standard.

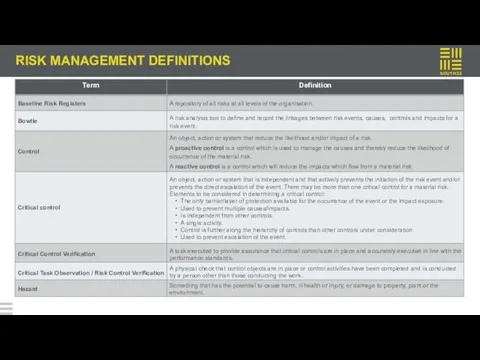

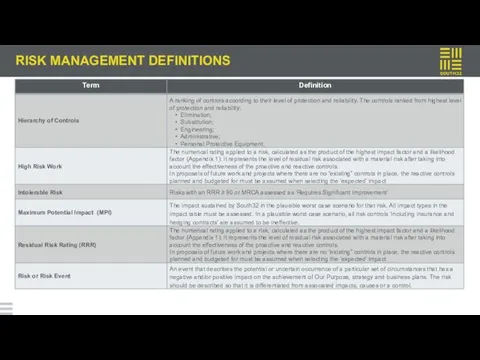

RISK MANAGEMENT DEFINITIONS

RISK MANAGEMENT DEFINITIONS

RISK MANAGEMENT DEFINITIONS

RISK MANAGEMENT DEFINITIONS

RISK MANAGEMENT ACCOUNTABILITIES

RISK MANAGEMENT ACCOUNTABILITIES

MATERIAL AND SINGLE FATALITY RISK MANAGEMENT

MATERIAL AND SINGLE FATALITY RISK MANAGEMENT

MATERIAL RISK MANAGEMENT PROCESS

MATERIAL RISK MANAGEMENT PROCESS

SINGLE FATALITY RISK MANAGEMENT PROCESS

SINGLE FATALITY RISK MANAGEMENT PROCESS

BASELINE RISK ASSESSMENT

The baseline risk register documents all risks identified within

BASELINE RISK ASSESSMENT

The baseline risk register documents all risks identified within

When new risks are captured on the baseline risk register, the Risk Owner performs an initial assessment to determine the MPI.

A risk assessment must be prepared by a team with experience and understanding of the proposed risk

The risk owner defines the purpose, scope, causes, impact rating of the highest impact type, MPI & RRR of the risk, assigns controls to the risk and improvement actions are registered and workflows to the relevant action owners

If the risk meets MPI materiality criteria it will workflow to the Bowtie risk analysis module. Material for South32 is MPI ≥ level 5; and 9 common fatality risks (ref: Safety Standard v6).

Lower level risks that are managed by operational and functional risk management processes must be excluded from the Bowtie risk assessment process.

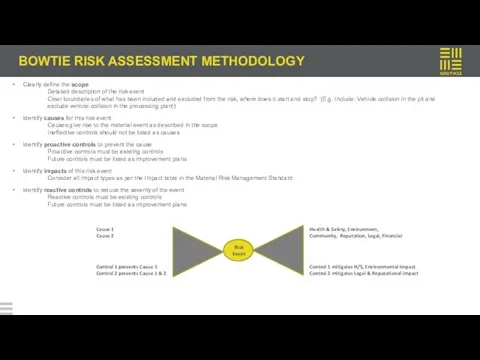

BOWTIE RISK ASSESSMENT METHODOLOGY

Clearly define the scope

Detailed description of the

BOWTIE RISK ASSESSMENT METHODOLOGY

Clearly define the scope

Detailed description of the

Clear boundaries of what has been included and excluded from the risk, where does it start and stop? (E.g. Include: Vehicle collision in the pit and exclude vehicle collision in the processing plant)

Identify causes for this risk event

Causes give rise to the material event as described in the scope

Ineffective controls should not be listed as causes

Identify proactive controls to prevent the cause

Proactive controls must be existing controls

Future controls must be listed as improvement plans

Identify impacts of this risk event

Consider all impact types as per the Impact table in the Material Risk Management Standard

Identify reactive controls to reduce the severity of the event

Reactive controls must be existing controls

Future controls must be listed as improvement plans

SELECTING CRITICAL CONTROLS AND CONTROL OWNERS

SLIDE

When selecting critical controls, the

SELECTING CRITICAL CONTROLS AND CONTROL OWNERS

SLIDE

When selecting critical controls, the

List all existing proactive & reactive controls

Apply the Critical Control Selection Criteria to each of the controls to determine which would meet the materiality criteria

Once the Risk Owner has selected the possible critical controls, it is his/her responsibility to make

a decision on the final critical controls (typically not more than 3 or 4)

In making this selection, the Risk Owner may consult the Control Owners, Subject Matter Experts or benchmark similar risks and associated controls/critical controls

The Risk Owner appoints a Control Owner based on expertise/area of responsibility

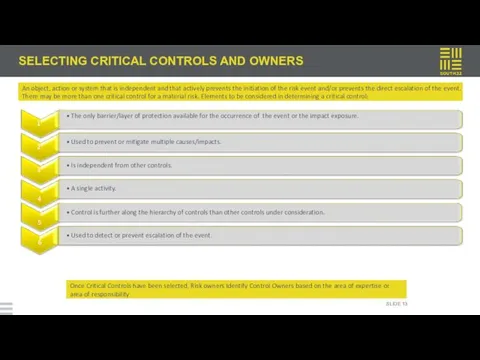

SELECTING CRITICAL CONTROLS AND OWNERS

An object, action or system that is

SELECTING CRITICAL CONTROLS AND OWNERS

An object, action or system that is

SLIDE

Once Critical Controls have been selected, Risk owners Identify Control Owners based on the area of expertise or area of responsibility

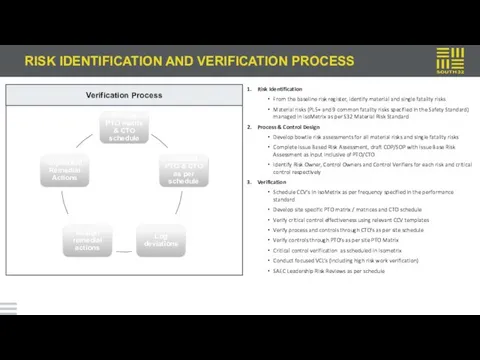

RISK IDENTIFICATION AND VERIFICATION PROCESS

Risk Identification

From the baseline risk

RISK IDENTIFICATION AND VERIFICATION PROCESS

Risk Identification

From the baseline risk

Material risks (PL5+ and 9 common fatality risks specified in the Safety Standard) managed in IsoMetrix as per S32 Material Risk Standard

Process & Control Design

Develop bowtie risk assessments for all material risks and single fatality risks

Complete Issue Based Risk Assessment, draft COP/SOP with Issue Base Risk Assessment as input inclusive of PTO/CTO

Identify Risk Owner, Control Owners and Control Verifiers for each risk and critical control respectively

Verification

Schedule CCV’s in IsoMetrix as per frequency specified in the performance standard

Develop site specific PTO matrix / matrices and CTO schedule

Verify critical control effectiveness using relevant CCV templates

Verify process and controls through CTO’s as per site schedule

Verify controls through PTO’s as per site PTO Matrix

Critical control verification as scheduled in Isometrix

Conduct focused VCL’s (including high risk work verification)

SAEC Leadership Risk Reviews as per schedule

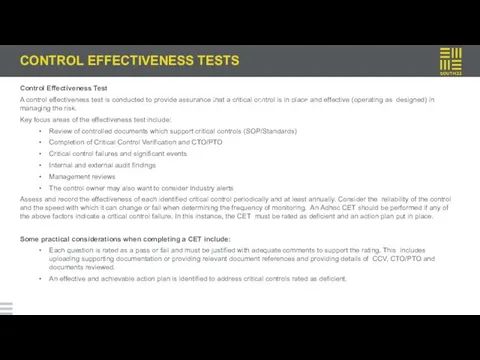

CONTROL EFFECTIVENESS TESTS

Control Effectiveness Test

A control effectiveness test is conducted to

CONTROL EFFECTIVENESS TESTS

Control Effectiveness Test

A control effectiveness test is conducted to

Key focus areas of the effectiveness test include:

Review of controlled documents which support critical controls (SOP/Standards)

Completion of Critical Control Verification and CTO/PTO

Critical control failures and significant events

Internal and external audit findings

Management reviews

The control owner may also want to consider Industry alerts

Assess and record the effectiveness of each identified critical control periodically and at least annually. Consider the reliability of the control and the speed with which it can change or fail when determining the frequency of monitoring. An Adhoc CET should be performed if any of the above factors indicate a critical control failure. In this instance, the CET must be rated as deficient and an action plan put in place.

Some practical considerations when completing a CET include:

Each question is rated as a pass or fail and must be justified with adequate comments to support the rating. This includes uploading supporting documentation or providing relevant document references and providing details of CCV, CTO/PTO and documents reviewed.

An effective and achievable action plan is identified to address critical controls rated as deficient.

MATERIAL RISK CONTROL ASSESSMENTS

The material risk control assessment is completed once

MATERIAL RISK CONTROL ASSESSMENTS

The material risk control assessment is completed once

The MRCA must be completed at least annually. However the following events will also trigger completion:

When a critical control has failed and

Change to the risk

When an action plan has been identified or actioned

Some practical considerations when completing an MRCA

When completing a review of the effectiveness tests, the Risk Owner should consider the following:

Are they adequate and relevant to support ratings?

For any issues raised and critical control failures, have appropriate action plans been raised and actioned?

Is there clear document references or supporting documentation

Each material risk must be assessed and a rating given (Well controlled, Requires some improvement or requires significant improvement). The material risk control assessment must consider the critical control operating assessment results, actual control failure or a control failure that resulted in a similar material risk, internal audit findings, external audit findings and management reviews. Assessments must have sufficient detail to be executed reliably over time. Its purpose is to assess the level of control and tolerability of a material risk. All ratings must be justified.

Модель согласования Д. Надлера и М. Тушмена : политическая система, организм

Модель согласования Д. Надлера и М. Тушмена : политическая система, организм Основы социального управления

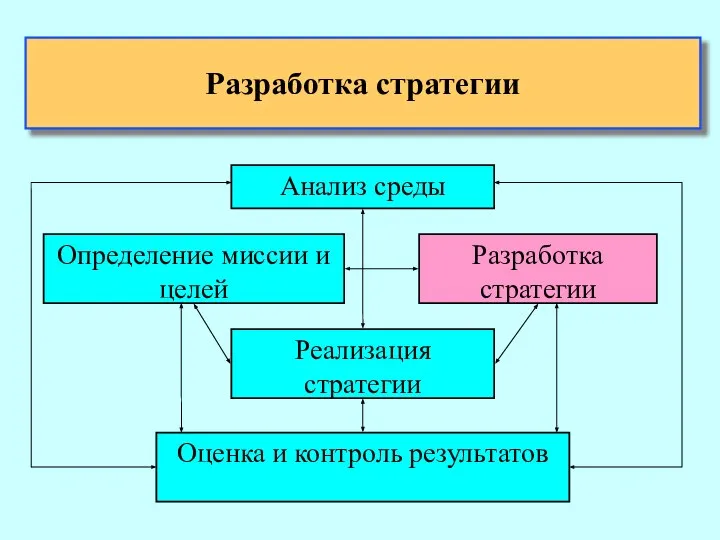

Основы социального управления Разработка стратегии

Разработка стратегии Классификация информации. Управленческая информация

Классификация информации. Управленческая информация Гостиничный продукт. Тема 12

Гостиничный продукт. Тема 12 Система управления персоналом образовательной организации

Система управления персоналом образовательной организации Адаптация персонала

Адаптация персонала Мотивация труда сотрудников и экономических партнеров страховой компании

Мотивация труда сотрудников и экономических партнеров страховой компании Слагаемые профессионального успеха современного руководителя

Слагаемые профессионального успеха современного руководителя Консалтинг. (Лекция 2)

Консалтинг. (Лекция 2) Product Placement: Клипы

Product Placement: Клипы Ресепшионист

Ресепшионист Инновационные процессы в информационных системах

Инновационные процессы в информационных системах Анализ выполнения тактических заданий по программе Кадровый резерв

Анализ выполнения тактических заданий по программе Кадровый резерв Операционный менеджмент и управление проектами

Операционный менеджмент и управление проектами Сутність, функції та завдання логістики. Логістика, як фактор підвищення конкурентоспроможності фірми

Сутність, функції та завдання логістики. Логістика, як фактор підвищення конкурентоспроможності фірми Управление качеством организации предметноразвивающей среды в ДОУ

Управление качеством организации предметноразвивающей среды в ДОУ Организационная структура управления

Организационная структура управления Test execution. Version control systems

Test execution. Version control systems Деловые переговоры

Деловые переговоры Системность, как общее свойство. Основные понятия теории систем

Системность, как общее свойство. Основные понятия теории систем Тайм-менеджмент

Тайм-менеджмент Мотивация Ресечера. Схема оплаты за оформленного кандидата

Мотивация Ресечера. Схема оплаты за оформленного кандидата Функции управления. Целеполагание, програмирование, проектирование

Функции управления. Целеполагание, програмирование, проектирование Руководитель в системе управления персоналом. (Лекция 4.1)

Руководитель в системе управления персоналом. (Лекция 4.1) Управленческое консультирование

Управленческое консультирование Планирование личного времени с использованием технологий стратегического планирования и Time Management

Планирование личного времени с использованием технологий стратегического планирования и Time Management Как отправлять письмо заказчику

Как отправлять письмо заказчику