Productive system and Process Approach. Operations Management in Corporate Profitability and Competitiveness

Содержание

- 2. JAP LEARNING GOALS after these lessons you will be able to describe operations in terms of

- 3. JAP LEARNING GOALS after these lessons you will be able to 7. discuss trends in operations

- 4. JAP JAP What is a Productive system (Buffa), what is a Process (Krajewski& Ritzman)? Examples of

- 5. JAP EXAMPLES OF PRODUCTIVE SYSTEMS: Electronics assembly Airplane manufacturing Steel production Automobile assembly Oil refining Fast

- 6. JAP Why must a system has to be productive?

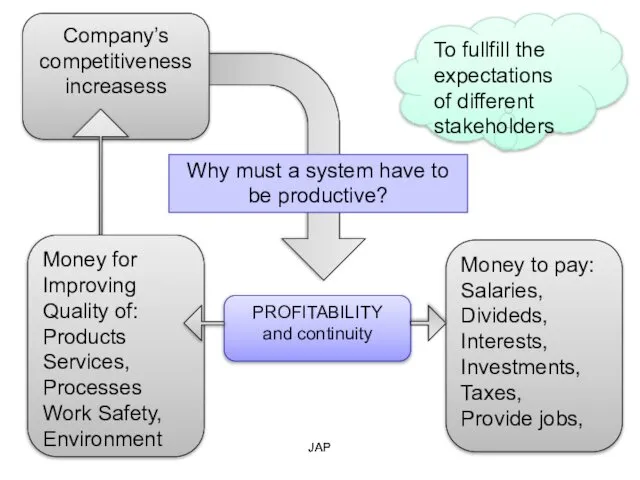

- 7. Company’s competitiveness increasess JAP JAP Why must a system have to be productive? PROFITABILITY and continuity

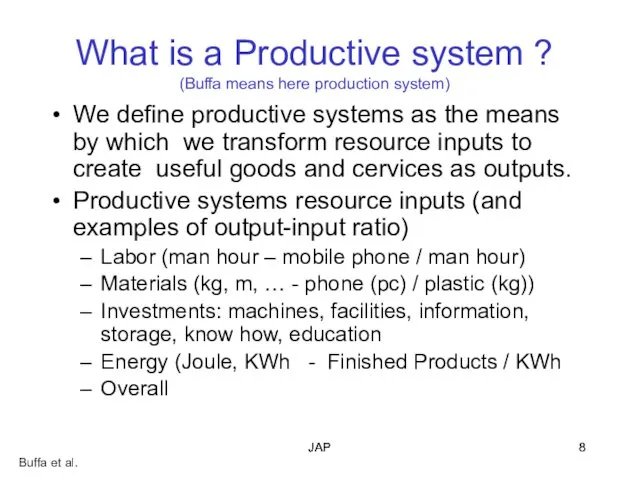

- 8. JAP JAP What is a Productive system ? (Buffa means here production system) We define productive

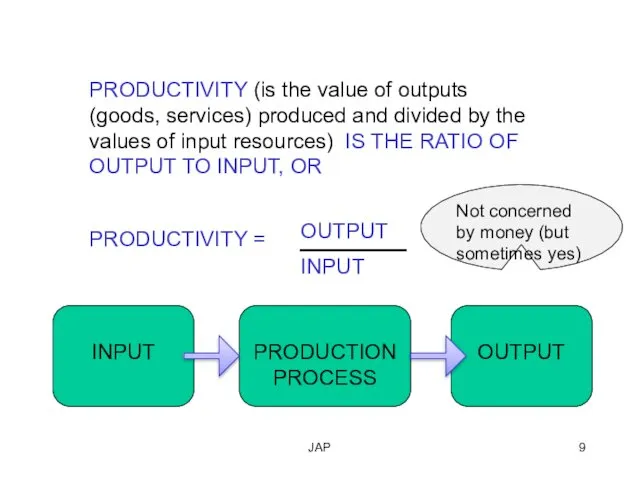

- 9. JAP PRODUCTIVITY (is the value of outputs (goods, services) produced and divided by the values of

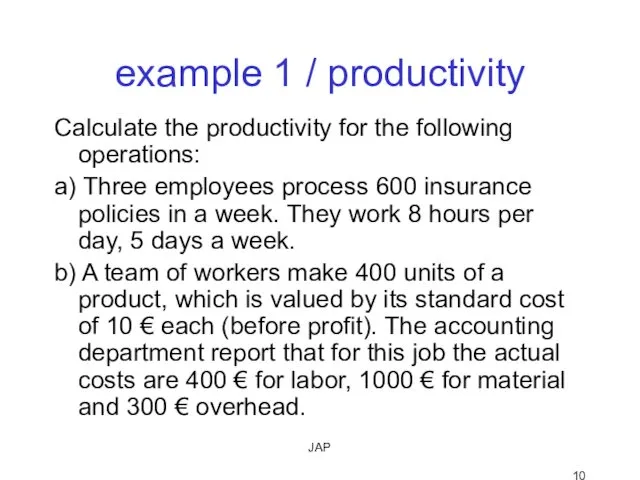

- 10. JAP example 1 / productivity Calculate the productivity for the following operations: a) Three employees process

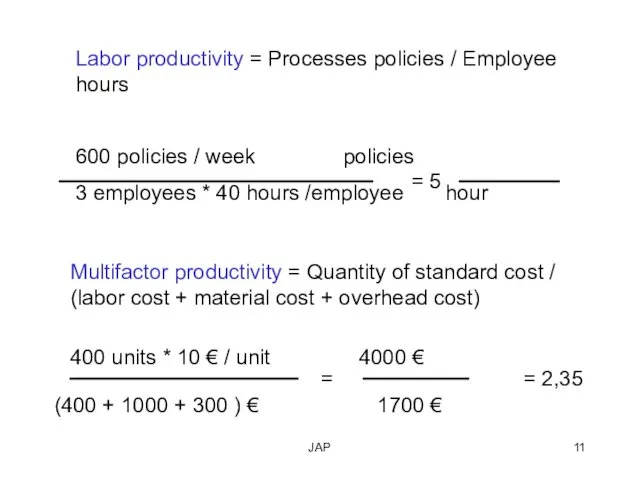

- 11. JAP Labor productivity = Processes policies / Employee hours 600 policies / week policies 3 employees

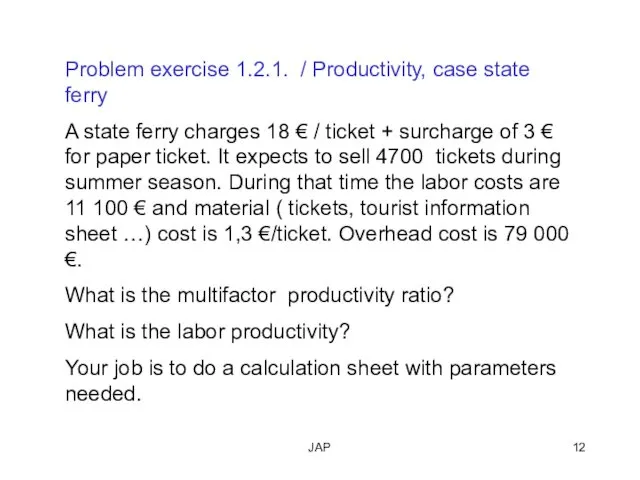

- 12. JAP Problem exercise 1.2.1. / Productivity, case state ferry A state ferry charges 18 € /

- 13. JAP Problem exercise 1.2.2 / Productivity, how to measure it? You have a workshop that manufactures

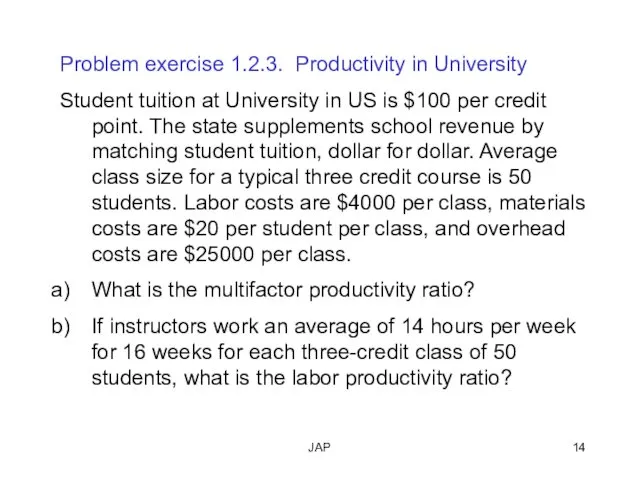

- 14. JAP Problem exercise 1.2.3. Productivity in University Student tuition at University in US is $100 per

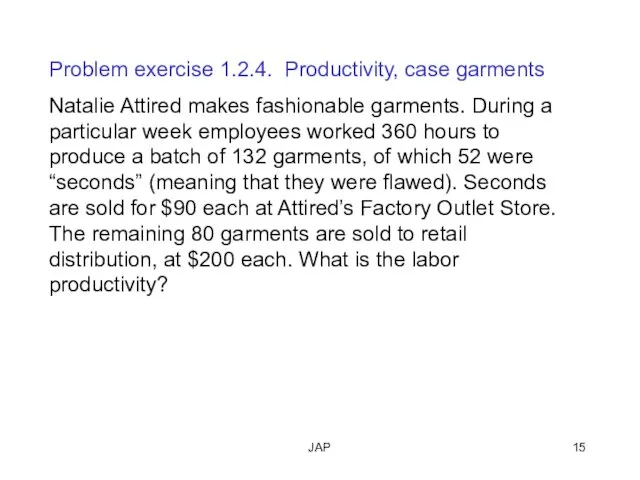

- 15. JAP Problem exercise 1.2.4. Productivity, case garments Natalie Attired makes fashionable garments. During a particular week

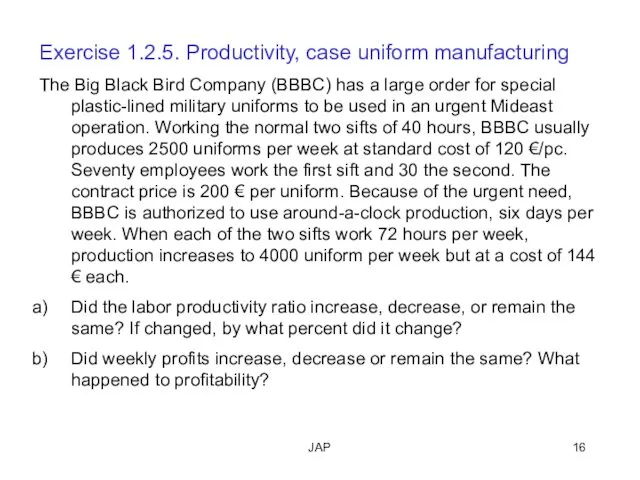

- 16. JAP Exercise 1.2.5. Productivity, case uniform manufacturing The Big Black Bird Company (BBBC) has a large

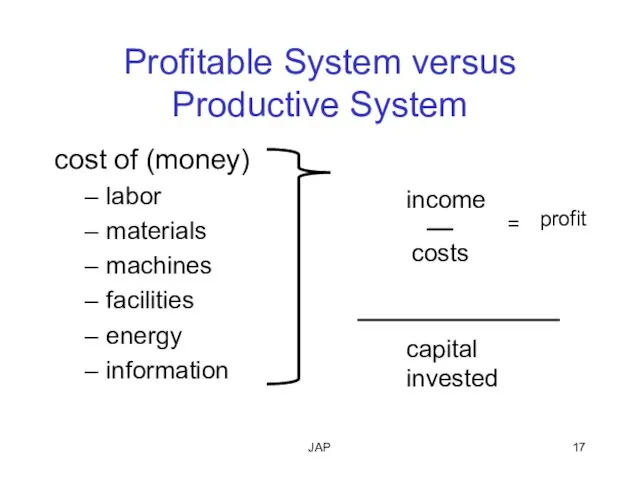

- 17. JAP Profitable System versus Productive System cost of (money) labor materials machines facilities energy information capital

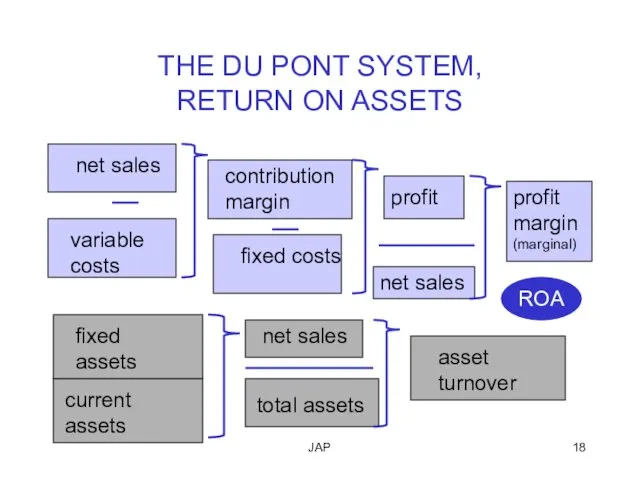

- 18. JAP THE DU PONT SYSTEM, RETURN ON ASSETS net sales variable costs contribution margin fixed costs

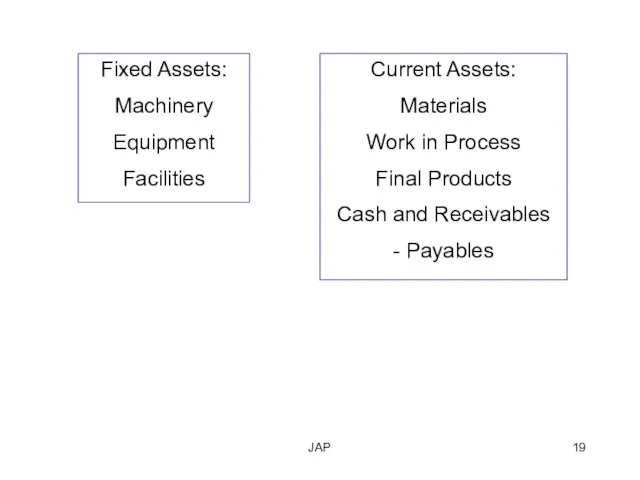

- 19. JAP Fixed Assets: Machinery Equipment Facilities Current Assets: Materials Work in Process Final Products Cash and

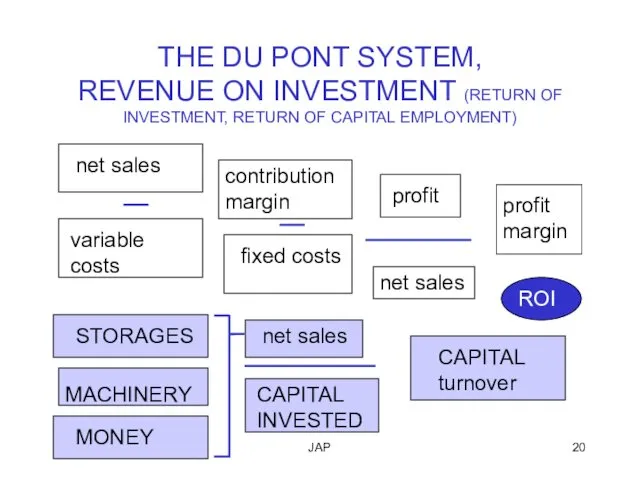

- 20. JAP THE DU PONT SYSTEM, REVENUE ON INVESTMENT (RETURN OF INVESTMENT, RETURN OF CAPITAL EMPLOYMENT) net

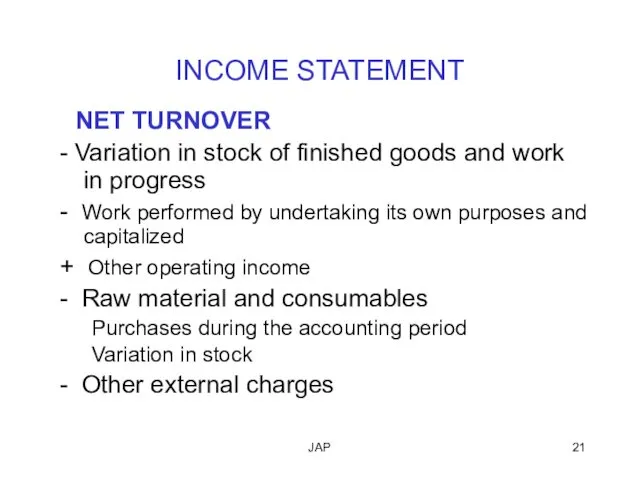

- 21. JAP INCOME STATEMENT NET TURNOVER - Variation in stock of finished goods and work in progress

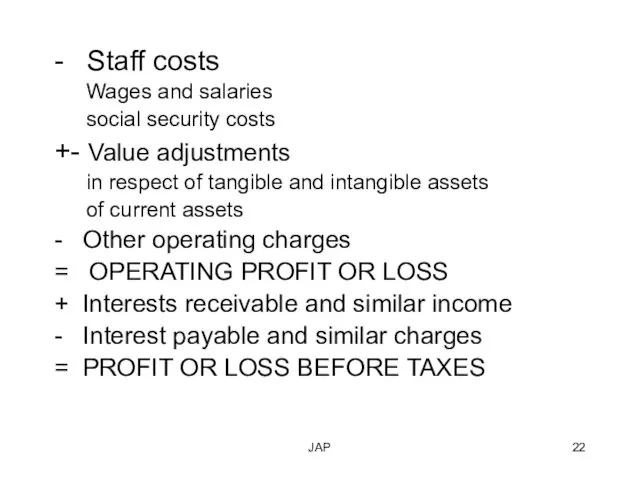

- 22. JAP - Staff costs Wages and salaries social security costs +- Value adjustments in respect of

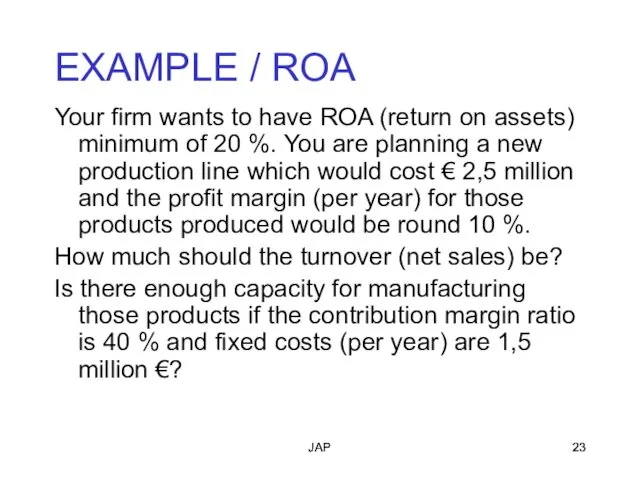

- 23. JAP JAP EXAMPLE / ROA Your firm wants to have ROA (return on assets) minimum of

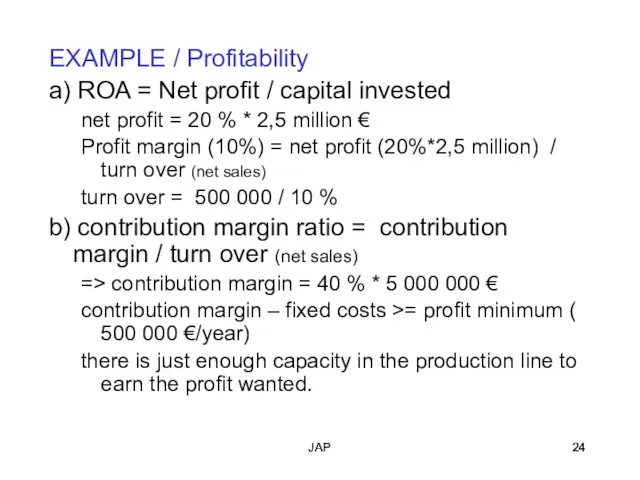

- 24. JAP JAP EXAMPLE / Profitability a) ROA = Net profit / capital invested net profit =

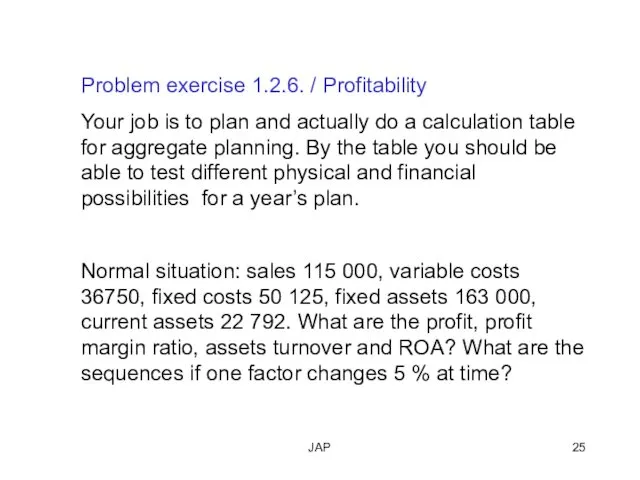

- 25. JAP Problem exercise 1.2.6. / Profitability Your job is to plan and actually do a calculation

- 26. JAP Exercise 7 / Profitability As a president of Mölkky Oy you find that one of

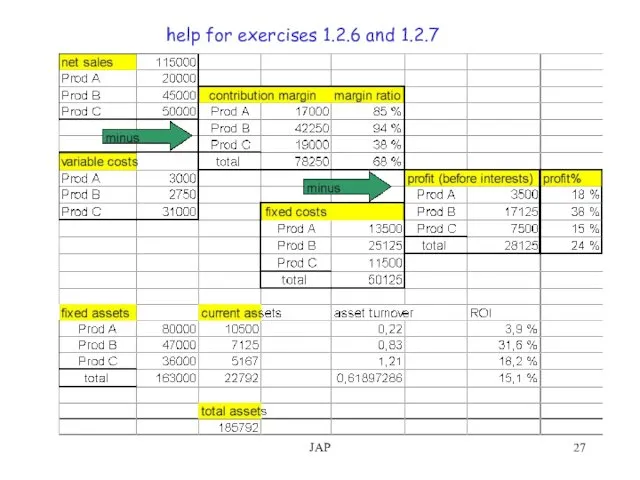

- 27. JAP help for exercises 1.2.6 and 1.2.7

- 28. JAP Problem exercise 1.2.8. /Profitability How can You reach a 100% increase in profit when the

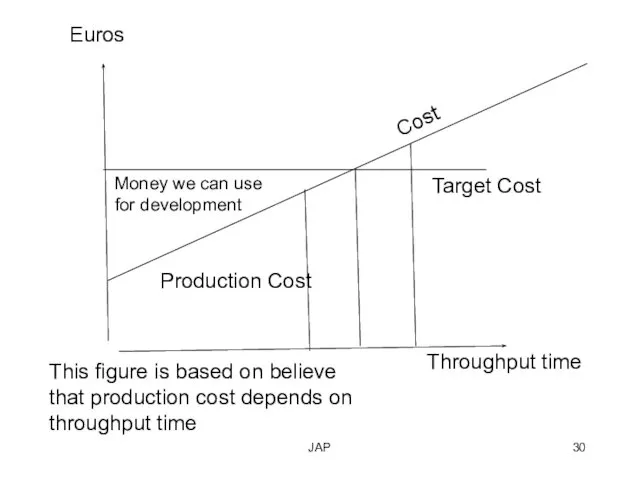

- 29. JAP Target Costing Market Price (an estimate or real price of a product a company is

- 30. JAP Euros Target Cost Production Cost Money we can use for development Throughput time Cost This

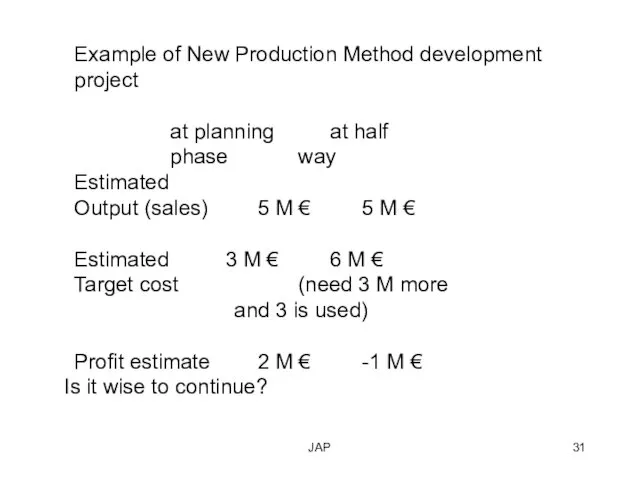

- 31. JAP Example of New Production Method development project at planning at half phase way Estimated Output

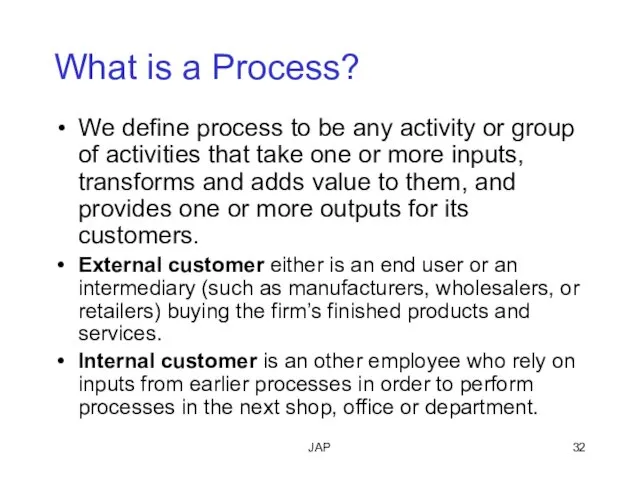

- 32. JAP What is a Process? We define process to be any activity or group of activities

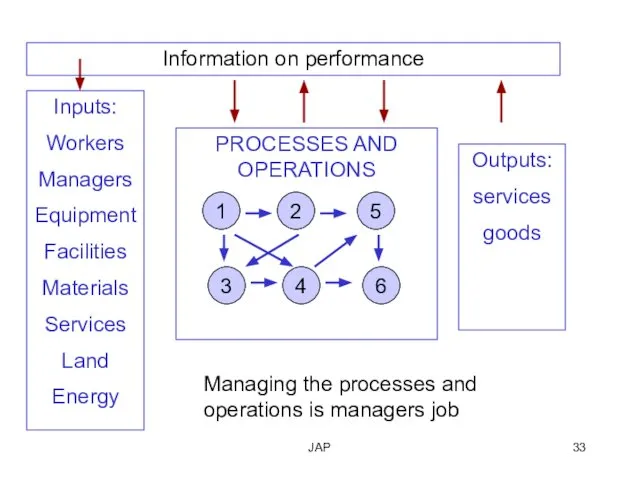

- 33. JAP PROCESSES AND OPERATIONS Inputs: Workers Managers Equipment Facilities Materials Services Land Energy Outputs: services goods

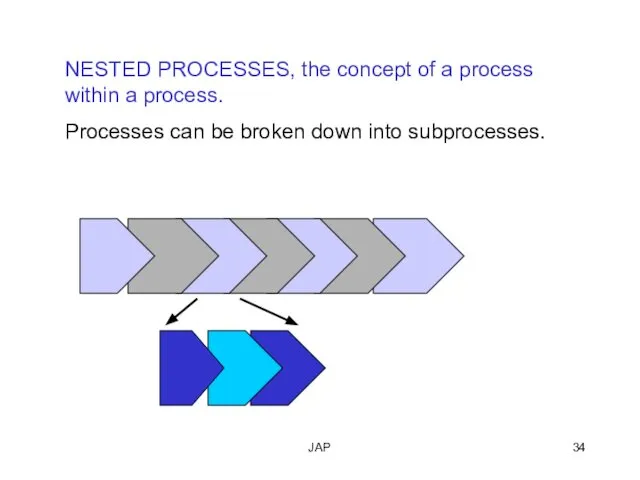

- 34. JAP NESTED PROCESSES, the concept of a process within a process. Processes can be broken down

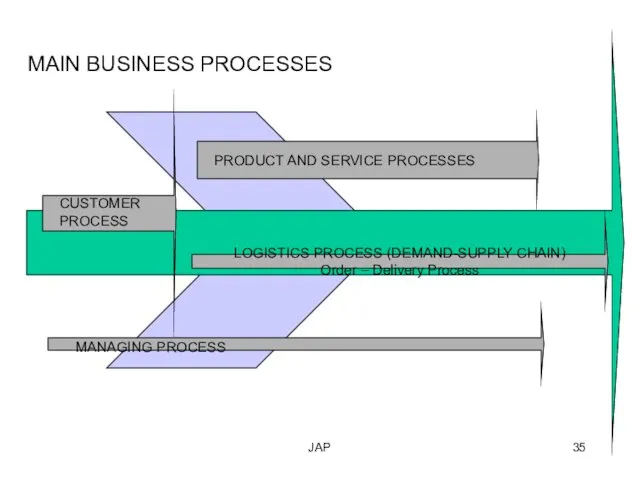

- 35. JAP LOGISTICS PROCESS (DEMAND-SUPPLY CHAIN) Order – Delivery Process PRODUCT AND SERVICE PROCESSES CUSTOMER PROCESS MAIN

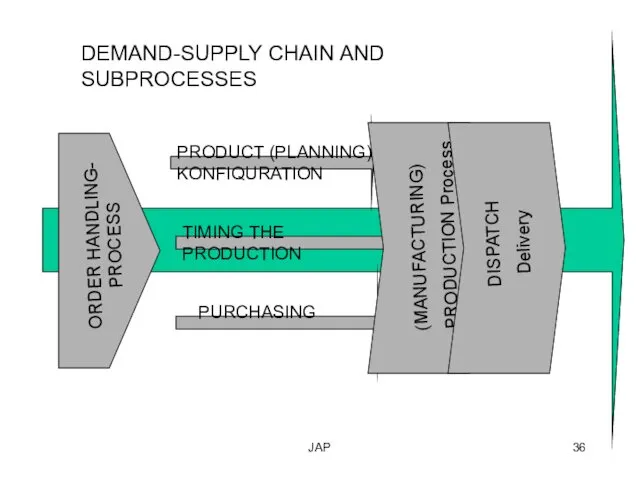

- 36. JAP DEMAND-SUPPLY CHAIN AND SUBPROCESSES PRODUCT (PLANNING) KONFIQURATION PURCHASING TIMING THE PRODUCTION (MANUFACTURING) PRODUCTION Process DISPATCH

- 37. JAP CASE NOKIA: CUSTOMER SATISFACTION PROCESS is a process for systematic customer satisfaction and competition/competitor evaluations.

- 38. JAP What is Operations Management / Process Management (Krajewski & Ritzman)? Operations Management term refers to

- 39. JAP Major Process for manufacturing/production process decisions: Process choice: A process decision that determines whether resources

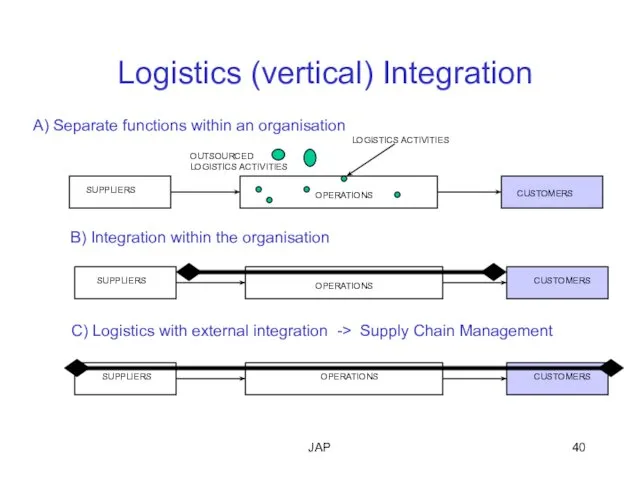

- 40. JAP Logistics (vertical) Integration SUPPLIERS SUPPLIERS SUPPLIERS CUSTOMERS CUSTOMERS CUSTOMERS OPERATIONS OPERATIONS OPERATIONS LOGISTICS ACTIVITIES A)

- 41. JAP Enterprise Competitiveness and Operations Function There are four (five) dimensions of competitiveness that measure the

- 42. JAP cost reduction by organizational learning improved production methods and tools improved product design -> manufacturability

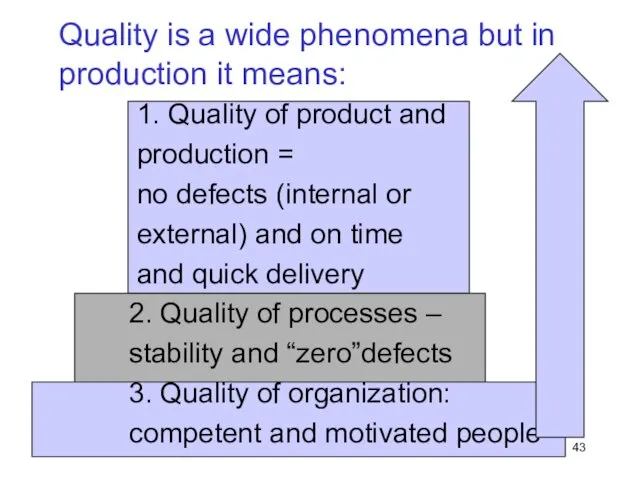

- 43. JAP Quality is a wide phenomena but in production it means: 1. Quality of product and

- 44. JAP High-performance design: Determination of the level of operations performance required in making a product or

- 45. JAP “Time is money”: Short delivery time: The elapsed time between receiving a customer’s order and

- 46. JAP Time based competition: The process by which managers define the steps and time needed to

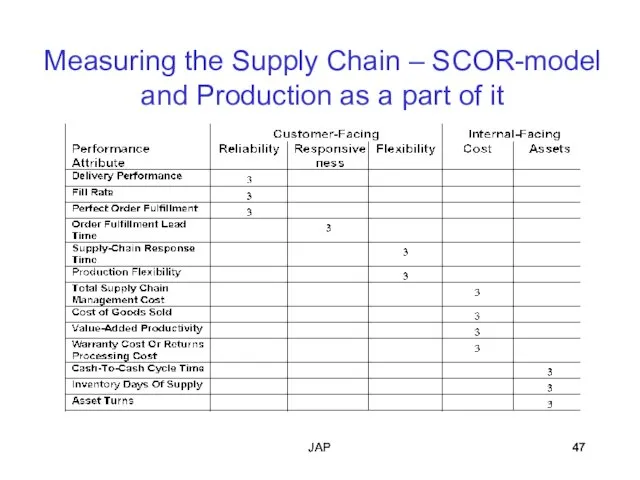

- 47. JAP JAP Measuring the Supply Chain – SCOR-model and Production as a part of it

- 48. JAP Flexibility of Production means: Capability to produce several different products with the machinery (customization). Capability

- 49. JAP Problem 1.2.9 Productivity A health –check clinic has five employees and “processes” 200 patients per

- 51. Скачать презентацию

Организационная культура

Организационная культура Повышение эффективности оптовых продаж с помощью автоматизации отдела сбыта

Повышение эффективности оптовых продаж с помощью автоматизации отдела сбыта Транспортная логистика

Транспортная логистика Модель управления в Индии

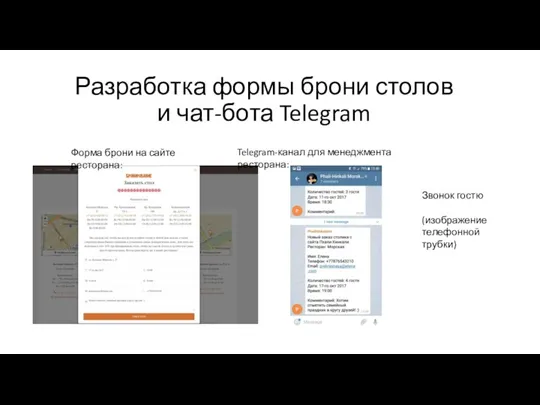

Модель управления в Индии Разработка формы брони столов и чат-бота Telegram

Разработка формы брони столов и чат-бота Telegram Управление инновационными проектами

Управление инновационными проектами Корпоративная культура

Корпоративная культура Организация и управление

Организация и управление Научные основы управления

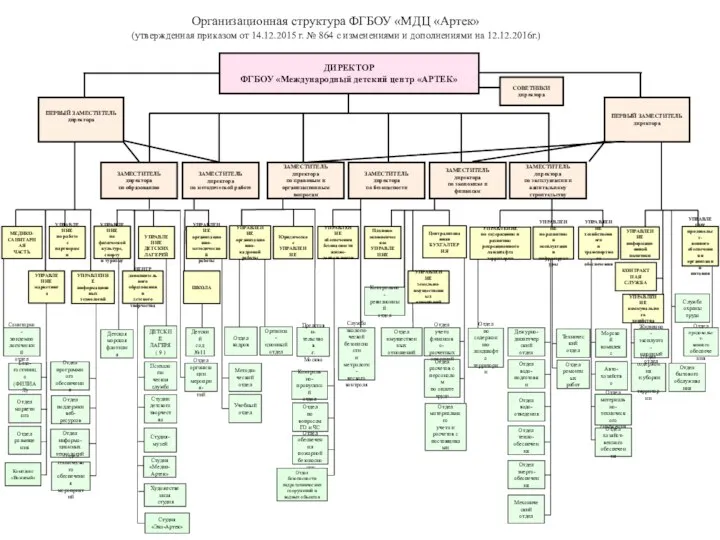

Научные основы управления Организационная структура ФГБОУ МДЦ Артек

Организационная структура ФГБОУ МДЦ Артек Коммуникационный менеджмент

Коммуникационный менеджмент Кто такой лидер

Кто такой лидер Трудовая адаптация персонала на предприятии

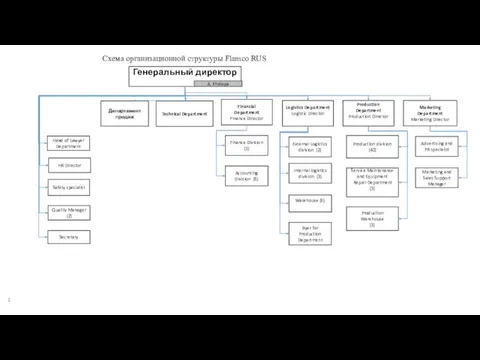

Трудовая адаптация персонала на предприятии Схема организационной структуры Flamco RUS

Схема организационной структуры Flamco RUS Определение деловых коммуникаций

Определение деловых коммуникаций Совершенствование системы логистики снабжения. ОАО Нижнекамский хлебокомбинат

Совершенствование системы логистики снабжения. ОАО Нижнекамский хлебокомбинат Планирование, контроль, учет в управленческом цикле

Планирование, контроль, учет в управленческом цикле Проектирование эффективных региональных моделей управления образовательными организациями

Проектирование эффективных региональных моделей управления образовательными организациями Дисфункциональность и несостоятельность государственного и муниципального управления. Лекция 7

Дисфункциональность и несостоятельность государственного и муниципального управления. Лекция 7 Стэйкхолдерская модель корпорации

Стэйкхолдерская модель корпорации Матрица MCC: Mission and Core Competencies (МКК: Миссия и Ключевые компетенции)

Матрица MCC: Mission and Core Competencies (МКК: Миссия и Ключевые компетенции) Построение системы управления персоналом

Построение системы управления персоналом Организационное развитие. Общий взгляд на проблему

Организационное развитие. Общий взгляд на проблему Разработка рекламного модуля для сувенирной продукции для кафе-бара Корейской кухни Kannam Chicken

Разработка рекламного модуля для сувенирной продукции для кафе-бара Корейской кухни Kannam Chicken Системы менеджмента качества

Системы менеджмента качества Классификация информации. Управленческая информация

Классификация информации. Управленческая информация Планирование – как функция менеджмента

Планирование – как функция менеджмента Советник, которому доверяют

Советник, которому доверяют